Abstract

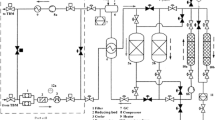

A tritium extraction system (TES) is one of important ancillary systems of the China helium cooled ceramic breeder test blanket module (CN HCCB TBM). The high reliability and availability of TES will be needed for safety operation of circulation and processing of tritium purge gas. Probabilistic Safety Assessment (PSA) and reliability, availability, maintainability, inspectability (RAMI) analysis of the TES should be performed during the design phase according to the CN HCCB TBM plan. Accurate reliability data is required to provide meaningful results for PSA and RAMI analysis. Since there is no TES pipes failure rate data available from fusion operating experiences. Therefore, it is necessary to use the existing pipe operating experiences to calculate component failure rates of the TES pipes. In this paper, the k factor method was used to adjust the failure rates of the TES pipes under the different environments and conditions by combining physics of failure models and a conservative estimation technique. The failure rates of the TES can provide references for the optimization of TES pipes design and data support for PSA and RAMI analysis of the TES.

Similar content being viewed by others

References

Z. Long, T. Luo, K. Feng, Conceptual design on interface between ITER and tritium extraction system of Chinese helium-cooled solid breeder test blanket module. Fusion Eng. Des. 85, 2213–2216 (2010)

K.M. Feng, C.H. Pan, G.S. Zhang et al., Progress on solid breeder TBM at SWIP. Fusion Eng. Des. 85, 2132–2140 (2010)

D. van Houtte, K. Okayama, F. Sagot, RAMI approach for ITER. Fusion Eng. Des. 85, 1220–1224 (2010)

Y. Wu, FDS Team, Conceptual design activities of FDS series fusion power plants in China. Fusion Eng. Des. 81(23–24), 2713–2718 (2006)

L. Qiu, Y. Wu, B. Xiao et al., A low aspect ratio tokamak transmutation system. Nucl. Fusion 40, 629–633 (2000)

Y. Wu, J. Qian, J. Yu, The fusion-driven hybrid system and its material selection. J. Nucl. Mater. 307–311, 1629–1636 (2002)

Y. Wu, J. Jiang, M. Wang et al., A fusion-driven subcritical system concept based on viable technologies. Nucl. Fusion 51(10), 103036 (2011)

Y. Wu, FDS Team, Conceptual design of the China fusion power plant FDS-II. Fusion Eng. Des. 83(10–12), 1683–1689 (2008)

Y. Wu, FDS Team, Fusion-based hydrogen production reactor and its material selection. J. Nucl. Mater. 386–388, 122–126 (2009)

L. Hu, Y. Wu, Probabilistic safety assessment of the dual-cooled waste transmutation blanket for the FDS-I. Fusion Eng. Des. 81, 1403–1407 (2006)

Y. Wu, FDS Team, Conceptual design and testing strategy of a dual functional lithium–lead test blanket module in ITER and EAST. Nucl. Fusion 47(11), 1533–1539 (2007)

Y. Wu, FDS Team, Design analysis of the China dual-functional lithium lead (DFLL) test blanket module in ITER. Fusion Eng. Des. 82, 1893–1903 (2007)

Y. Wu, FDS Team, Development of reliability and probabilistic safety assessment program riskA. Ann. Nucl. Energy. (2015). doi:10.1016/j.anucene.2015.03.020

F. Wang, Y. Chen, X. Ye, et al., System Design Description for Conceptual Design of China Helium Cooled Ceramic Breeder Test Blanked System (CN HCCB TBS). Document No. HCCB TBM-SWIP/CNDA/IOCDDD V1.0, pp. 113–117, 2014

D. Wang, J. Wang, R. Yuan et al., RAMI analysis of HCCB TBS for ITER. J. Fusion Energ. (2015). doi:10.1007/s10894-015-9913-8

R. Nyman, S. Erixon, B. Tomic et al., Reliability of Piping System Components Framework for Estimating Failure Parameters from Service Data. SKI 97:26 (Swedish Nuclear Power Inspectorate, Stockholm, 1997)

K. Simola, U. Pulkkinen, H. Talja et al., Comparison of approaches for estimating pipe rupture frequencies for risk-informed in-service inspections. Reliab. Eng. Syst. Saf. 84, 65–74 (2004)

K.N. Fleming, Markov models for evaluating risk-informed in-service inspection strategies for nuclear power plant piping systems. Reliab. Eng. Syst. Saf. 83, 27–45 (2004)

R. Tregoning, L. Abramson et al., Estimating Loss of Coolant Accident (LOCA) Frequencies Through the Elicitation Process. NUREG-1829 (US Nuclear Regulatory Commission, Washington, 2008)

F. Di Maio, D. Colli, E. Zio et al., A Multi-State Physics Modeling approach for the reliability assessment of Nuclear Power Plants piping systems. Ann. Nucl. Energy 80, 151–165 (2015)

E.L. McCabe, W.B. Pearce, G.D. Rise, Method for Developing Equipment Failure Rate K FACTORS. Report D180-17674-2 (Boeing Company, Seattle, 1975)

T.D. Marshall, L.C. Cadwallade, Recommended In-vessel Tubing Failure Rates for the International Thermonuclear Experimental Reactor. in 15th IEEE/NPSS Symposium on Fusion Engineering (1993)

B.O.Y. Lydell, Pipe failure probability-the Thomas paper revisited. Reliab. Eng. Syst. Saf. 68, 207–217 (2000)

L.C. Cadwallader, Vacuum Bellows, Vacuum Piping, Cryogenic Break, and Copper Joint Failure Rate Estimates for ITER Deisgn Use. INL/EXT-10-18973 (Idaho National Laboratory, Idaho Falls, 2010)

L.C. Cadwallader, In-Vessel Coil Material Failure Rate Estimates for ITER Design Use. INL/EXT-13-28031 (Idaho National Laboratory, Idaho Falls, 2013)

L. C. Cadwallader, Failure Rate Adjustment Factors for High Technology Components. in 25th Symposium on Fusion Engineering (2013)

W. Fa, Safety Analysis of TBM Tritium System (China Academy of Engineering Physics, Chendu, 2012). (in Chinese)

J.L. Woodward, R. Pitbaldo, LNG Risk Based Safety: Modeling and Consequence Analysis (Wiley, New Jersey, 2010), pp. 57–58

O. Haillant, D. Dumbleton, A. Zielnik, An Arrhenius approach to estimating organic photovoltaic module weathering acceleration factors. Sol. Energy Mater. Sol. Cells 95, 1889–1895 (2011)

S. Ciattaglia, G. Cambi et al., Environmental Conditions Room Book. ITER IDM 2UUZ23 (ITER IO, French, 2012)

Acknowledgments

The authors would like to show their great appreciation to other members in FDS Team for their supports and contributions to this research. Thanks for their contributed to this work. The authors would like to thank Lee Cadwallader for his helpful discussion on this work. This work was supported by National Magnetic Confinement Fusion Science Program of China (Nos. 2014GB112001, 2015GB116001), the Special Program for Informatization of the Chinese Academy of Sciences (No. XXH12504-1-09), and the Foundation of President of Hefei Institutes of Physical Science (No. YZJJ201327).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nie, M., Wang, J., Wang, J. et al. Reliability Data Analysis for Tritium Extraction System Pipes of CN HCCB TBM. J Fusion Energ 34, 1378–1384 (2015). https://doi.org/10.1007/s10894-015-9976-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10894-015-9976-6