Abstract

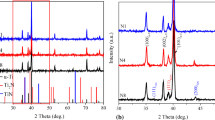

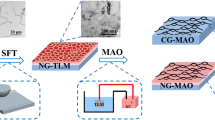

To enhance the corrosion resistance of Ti–6Al–4V and extend its lifetime in medical applications, Ti–O–N/Ti composite coating was synthesized on the surface via plasma immersion ion implantation and deposition (PIIID). Surface morphology and cross sectional morphology of the composite coating were characterized using atomic force microscopy and scanning electron microscopy, respectively. Although X-ray photoelectron spectroscopic analysis revealed that the Ti–O–N/Ti composite coating was composed of non-stoichiometric titanium oxide, titanium nitride and titanium oxynitride, no obvious characteristic peak corresponding to the crystalline phases of them was detected in the X-ray diffraction pattern. In accordance with Owens–Wendt equation, surface free energy of the uncoated and coated samples was calculated and compared. Moreover, the corrosion behavior of uncoated and coated samples was evaluated by means of electrochemical impedance spectroscopy measurement, and an equivalent circuit deriving from Randles model was used to fit Bode plots and describe the electrochemical processes occurring at the sample/electrolyte interface. On the basis of the equivalent circuit model, the resistance of the composite coating was 4.7 times higher than that of the passive layer on uncoated samples, indicating the enhanced corrosion resistance after PIIID treatment. Compared to uncoated Ti–6Al–V, Ti–O–N/Ti-coated samples facilitated ostoblast proliferation within 7 days of cell culture, while there was no statistically significant difference in alkaline phosphate activity between uncoated and coated samples during 21 days of cell culture.

Similar content being viewed by others

References

Long M, Rack HJ. Titanium alloys in total joint replacement—a materials science perspective. Biomaterials. 1998;19:1621–39.

Park YG, Wey MY, Hong SI. Enhanced wear and fatigue properties of Ti–6Al–4V alloy modified by plasma carburizing/CrN coating. J Mater Sci. 2007;18:925–31.

Gil FJ, Delgado L, Espinar E, Llamas JM. Corrosion and corrosion-fatigue behavior of cp-Ti and Ti–6Al–4V laser-marked biomaterials. J Mater Sci. 2012;23:885–90.

Rodriguez D, Manero JM, Gil FJ, Planell JA. Low cycle fatigue behavior of Ti6Al4V thermochemically nitrided for its use in hip prostheses. J Mater Sci. 2001;12:935–7.

Boyce BF, Byars J, McWilliams S, Mocan MZ, Elder HY, Boyle IT, Junor BJR. Histological and electron-microprobe studies of mineralization in aluminum-related osteomalacia. J Clin Pathol. 1992;45:502–8.

Zaffe D, Bertoldi C, Consolo U. Accumulation of aluminium in lamellar bone after implantation of titanium plates, Ti–6Al–4V screws, hydroxyapatite granules. Biomaterials. 2004;25:3837–44.

Eisenbarth E, Velten D, Müller M, Thull R, Breme J. Biocompatibility of β-stabilizing elements of titanium alloys. Biomaterials. 2004;25:5705–13.

Rack HJ, Qazi JI. Titanium alloys for biomedical applications. Mater Sci Eng C. 2006;26:1269–77.

Popa AC, Stan GE, Husanu MA, Pasuk I, Popescu ID, Popescu AC, Mihailescu IN. Multi-layer haemocompatible diamond-like carbon coatings obtained by combined radio frequency plasma enhanced chemical vapor deposition and magnetron sputtering. J Mater Sci. 2013;24:2695–707.

Sun T, Wang M. Low-temperature biomimetic formation of apatite/TiO2 composite coatings on Ti and NiTi shape memory alloy and their characterization. Appl Surf Sci. 2008;255:396–400.

Diangang W, Chuanzhong C, Ting H, Tingquan L. Hydroxyapatite coating on Ti6Al4V alloy by a sol-gel method. J Mater Sci. 2008;19:2281–6.

Sun T, Lee W-C, Wang M. A comparative study of apatite coating and apatite/collagen composite coating fabricated on NiTi shape memory alloy through electrochemical deposition. Mater Lett. 2011;65:2575–7.

Sun T, Wang L, Yu Y, Wang Y, Wang X, Tang B. TiN/ZrO2 multilayers synthesized on GCr15 bearing steel using plasma immersion ion implantation and deposition. Surf Coat Technol. 2007;201:6615–8.

da Silva LLG, Ueda M, Silva MM, Codaro EN. Corrosion behavior of Ti–6Al–4V alloy treated by plasma immersion ion implantation process. Surf Coat Technol. 2007;201:8136–9.

Zheng YF, Liu D, Liu XL, Li L. Enhanced corrosion resistance of Zr coating on biomedical TiNi alloy prepared by plasma immersion ion implantation and deposition. Appl Surf Sci. 2008;255:512–4.

Sun T, Wang L-P, Wang M, Tong H-W, Lu WW. PIIID-formed (Ti, O)/Ti, (Ti, N)/Ti and (Ti, O, N)/Ti coatings on NiTi shape memory alloy for medical applications. Mater Sci Eng C. 2012;32:1469–79.

Michiardi A, Aparicio C, Ratner BD, Planell JA, Gil J. The influence of surface energy on competitive protein adsorption on oxidized NiTi surfaces. Biomaterials. 2007;28:586–94.

Sun T, Wang L-P, Wang M, Tong H-W, Lu WW. Characteristics and in vitro biological assessment of (Ti, O, N)/Ti composite coating formed on NiTi shape memory alloy. Thin Solid Films. 2011;519:4623–8.

da Silva SLR, Kerber LO, Amaral L, dos Santos CA. X-ray diffraction measurements of plasma-nitrided Ti–6Al–4V. Surf Coat Technol. 1999;116–119:342–6.

Leng YX, Chen JY, Yang P, Wang J, Zhao AS, Wan GJ, Sun H, Huang N. The microstructure and mechanical properties of TiN and TiO2/TiN duplex films synthesized by plasma immersion ion implantation and deposition on artificial heart valve. Surf Coat Technol. 2006;201:1012–6.

Jung YS, Choi YW, Lee HC, Lee DW. Effects of thermal treatment on the electrical and optical properties of silver-based indium tin oxide/metal/indium tin oxide structures. Thin Solid Films. 2003;440:278–84.

Yang Y, Zhang C, Peng Y, Yu Y, Liu L. Effects of crystallization on the corrosion resistance of Fe-based amorphous coatings. Corros Sci. 2012;59:10–9.

Shibata Y, Suzuki D, Omori S, Tanaka R, Murakami A, Kataoka Y, Baba K, Kamijo R, Miyazaki T. The characteristics of in vitro biological activity of titanium surfaces anodically oxidized in chloride solutions. Biomaterials. 2010;31:8546–55.

Cheng Y, Zheng YF. Surface characterization and mechanical property of TiN/Ti-coated NiTi alloy by PIIID. Surf Coat Technol. 2007;201:6869–73.

Chan M-H, Lu F-H. X-ray photoelectron spectroscopy analyses of titanium oxynitride films prepared by magnetron sputtering using air/Ar mixtures. Thin Solid Films. 2009;517:5006–9.

Guillot J, Chappé J-M, Heintz O, Martin N, Imhoff L, Takadoum J. Phase mixture in MOCVD and reactive sputtering TiOxNy thin films revealed and quantified by XPS factorial analysis. Acta Mater. 2006;54:3067–74.

Hao L, Lawrence J, Li L. Manipulation of the osteoblast response to a Ti–6Al–4V titanium alloy using a high power diode laser. Appl Surf Sci. 2005;247:602–6.

Ponsonnet L, Reybier K, Jaffrezic N, Comte V, Lagneau C, Lissac M, Martelet C. Relationship between surface properties (roughness, wettability) of titanium and titanium alloys and cell behaviour. Mater Sci Eng C. 2003;23:551–60.

Hu X, Shen H, Shuai K, Zhang E, Bai Y, Cheng Y, Xiong X, Wang S, Fang J, Wei S. Surface bioactivity modification of titanium by CO2 plasma treatment and induction of hydroxyapatite: in vitro and in vivo studies. Appl Surf Sci. 2011;257:1813–23.

Athanasiou NS. Wettability and interfacial interactions of amorphous titanium treated by ion implantation. Mod Phys Lett B. 1997;11:829–39.

Wenzel RN. Resistance of solid surfaces to wetting by water. Ind Eng Chem. 1936;28:988–94.

Fouladi M, Amadeh A. Effect of phosphating time and temperature on microstructure and corrosion behavior of magnesium phosphate coating. Electrochim Acta. 2013;106:1–12.

Simka W, Kaczmarek M, Baron-Wiecheć A, Nawrat G, Marciniak J, Żak J. Electropolishing and passivation of NiTi shape memory alloy. Electrochim Acta. 2010;55:2437–41.

Figueira N, Silva TM, Carmezim MJ, Fernandes JCS. Corrosion behaviour of NiTi alloy. Electrochim Acta. 2009;54:921–6.

Milošev I, Metikoš-Huković M, Strehblow HH. Passive film on orthopaedic TiAlV alloy formed in physiological solution investigated by X-ray photoelectron spectroscopy. Biomaterials. 2000;21:2103–13.

Baker MA, Assis SL, Higa OZ, Costa I. Nanocomposite hydroxyapatite formation on a Ti–13Nb–13Zr alloy exposed in a MEM cell culture medium and the effect of H2O2 addition. Acta Biomater. 2009;5:63–75.

Assis SL, Costa I. Electrochemical evaluation of Ti–13Nb–13Zr, Ti–6Al–4V and Ti–6Al–7Nb alloys for biomedical application by long-term immersion tests. Mater Corros. 2007;58:329–33.

Liu C, Bi Q, Matthews A. EIS comparison on corrosion performance of PVD TiN and CrN coated mild steel in 0.5 N NaCl aqueous solution. Corros Sci. 2001;43:1953–61.

Burgos-Asperilla L, García-Alonso MC, Escudero ML, Alonso C. Study of the interaction of inorganic and organic compounds of cell culture medium with a Ti surface. Acta Biomater. 2010;6:652–61.

Huang H-H, Wu C-P, Sun Y-S, Yang W-E, Lin M-C, Lee T-H. Surface nanoporosity of β-type Ti–25Nb–25Zr alloy for the enhancement of protein adsorption and cell response. Surf Coat Technol. 2014;. doi:10.1016/j.surfcoat.2014.02.037.

Sunny MC, Sharma CP. Fibrinogen–aluminium interaction: changes with oxide layer thickness onto metal surface. J Biomed Mater Res. 1990;24:455–62.

Sharma CP, Paul W. Protein interaction with tantalum: changes with oxide layer and hydroxyapatite at the interface. J Biomed Mater Res. 1992;26:1179–84.

Silva-Bermudez P, Rodil SE. An overview of protein adsorption on metal oxide coatings for biomedical implants. Surf Coat Technol. 2013;233:147–58.

Lubarsky GV, Browne MM, Mitchell SA, Davidson MR, Bradley RH. The influence of electrostatic forces on protein adsorption. Colloids Surf B. 2005;44:56–63.

Huang R, Lu S, Han Y. Role of grain size in the regulation of osteoblast response to Ti–25Nb–3Mo–3Zr–2Sn alloy. Colloids Surf B. 2013;111:232–41.

Misra RDK, Nune C, Pesacreta TC, Somani MC, Karjalainen LP. Interplay between grain structure and protein adsorption on functional response of osteoblasts: ultrafine-grained versus coarse-grained substrates. J Biomed Mater Res A. 2013;101A:1–12.

Ahmed MH, Byrne JA. Effect of surface structure and wettability of DLC and N-DLC thin films on adsorption of glycine. Appl Surf Sci. 2012;258:5166–74.

McAdams ET, Lackermeier A, McLaughlin JA, Macken D, Jossinet J. The linear and non-linear electrical properties of the electrode–electrolyte interface. Biosens Bioelectron. 1995;10:67–74.

Mercanzini A, Colin P, Bensadoun J-C, Bertsch A, Renaud P. In vivo electrical impedance spectroscopy of tissue reaction to microelectrode arrays. IEEE Trans Biomed Eng. 2009;56:1909–18.

Yao Z, Jiang Z, Wang F. Study on corrosion resistance and roughness of micro-plasma oxidation ceramic coatings on Ti alloy by EIS technique. Electrochim Acta. 2007;52:4539–46.

Feng L, Zhang H, Wang Z, Liu Y. Superhydrophobic aluminum alloy surface: fabrication, structure, and corrosion resistance. Colloids Surf A. 2014;441:319–25.

Kunzler TP, Huwiler C, Drobek T, Vörös J, Spencer ND. Systematic study of osteoblast response to nanotopography by means of nanoparticle-density gradients. Biomaterials. 2007;28:5000–6.

Kang S, Hoek EMV, Choi H, Shin H. Effect of membrane surface properties during the fast evaluation of cell attachment. Sep Sci Technol. 2006;41:1475–87.

Advincula MC, Rahemtulla FG, Advincula RC, Ada ET, Lemons JE, Bellis SL. Osteoblast adhesion and matrix mineralization on sol–gel-derived titanium oxide. Biomaterials. 2006;27:2201–12.

Chien C-C, Liu K-T, Duh J-G, Chang K-W, Chung K-H. Effect of nitride film coatings on cell compatibility. Dent Mater. 2008;24:986–93.

Orimo H, Shimada T. The role of tissue-nonspecific alkaline phosphatase in the phosphate-induced activation of alkaline phosphatase and mineralization in SaOS-2 human osteoblast-like cells. Mol Cell Biochem. 2008;315:51–60.

Tsigkou O, Jones JR, Polak JM, Stevens MM. Differentiation of fetal osteoblasts and formation of mineralized bone nodules by 45S5 Bioglass® conditioned medium in the absence of osteogenic supplements. Biomaterials. 2009;30:3542–50.

Radin S, Ducheyne P. Controlled release of vancomycin from thin sol–gel films on titanium alloy fracture plate material. Biomaterials. 2007;28:1721–9.

Li D-H, Lin J, Lin D-Y, Wang X-X. Synthesized silicon-substituted hydroxyapatite coating on titanium substrate by electrochemical deposition. J Mater Sci. 2011;22:1205–11.

Aparicio C, Rodriguez D, Gil FJ. Variation of roughness and adhesion strength of deposited apatite layers on titanium dental implants. Mater Sci Eng C. 2011;31:320–4.

Barrabes M, Michiardi A, Aparicio C, Sevilla P, Planell JA, Gil FJ. Oxidized nickel–titanium foams for bone reconstructions: chemical and mechanical characterization. J Mater Sci. 2007;18:2123–9.

Acknowledgments

This work was supported by a Natural Science Foundation of China (Grant No. 51201051), an opening project (Grant No. AWPT-M10) from the State Key Lab of Advanced Welding and Joining at Harbin Institute of Technology, and a Fundamental Research Funds for the Central Universities (Grant No. HIT. NSRIF. 2012041), China.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Cao, XL., Sun, T. & Yu, Y. Ti–O–N/Ti composite coating on Ti–6Al–4V: surface characteristics, corrosion properties and cellular responses. J Mater Sci: Mater Med 26, 144 (2015). https://doi.org/10.1007/s10856-015-5413-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-015-5413-7