Abstract

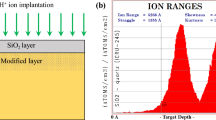

The machining damage on the certain crystal face of single crystal silicon, the manufacture of which are under diverse parameters of wire electrical discharge machining (WEDM), is tested by means of the micro-observation and X-ray diffraction rocking curve method. In the process of monocrystalline silicon machined by WEDM, when the pulse width is small, the basic methods of material removal are melting and gasification, which are also called normal removal methods. When the pulse width increases to a certain degree beyond the normal removal, thermal spalling removal also occurs, which is considered a compound removal method. The depth of machining damage is difficult to control. The structure of machining damage under two conditions is divided into normal removal and compound removal in this study. To make the depth of machining damage easy to control, compound removal should be avoided when processing the single crystal silicon by certain crystal face cutting of WEDM. Such an approach can provide the premise and guarantee for the subsequent processing of single crystal silicon with certain crystal face in the future.

Similar content being viewed by others

References

M.A. Chun, Development trend of semiconducting silicon materials of the world. Shanghai Nonferrous Met. 26(3), 145–148 (2005)

M.W. Johnson, S. Manolopoulos, N.J. Rhodes et al., Silicon APS detectors for neutron scattering. Nucl. Instrum. Methods Phys. Res. Sect. A 501, 72–79 (2003)

J. Słowik, A. Zięba, Silicon strip detector applied to X-ray diffractometer: angular resolution and counting rate. Nucl. Instrum. Methods Phys. Res. 551(1), 73–77 (2005)

Y. Wang, J. Kang, Development and challenges of lithography for ULSI. Chin. J. Semicond 3, 225–237 (2002)

Q. Zhang, H. Zhou, D. Li, Indention microcrack formation and propagation in single crystalline silicon at room temperature. J. Chin. Electron Microsc. Soc 21(1), 56–58 (2002)

U. Bismayer, E. Brinksmeier, B. Guttler et al., Measurement of subsurface damage in silicon Wafers. Precis. Eng 16(2), 139–143 (1994)

Z. Liu, W. Wang, M. Qiu, Basic research on compound EDM and ECM cutting with texturing on solar wafer. Acta Energiae Solaris Sinica 30(5), 619–623 (2009)

G. Kühn, H. F. Hadamovsky (Hrsg.). Werkstoffe der Halbleitertechnik. 2. Aufl. Deutscher Verlag für Grundstoffindustrie Leipzig 1990, 360 Seiten mit zahlreichen Abbildungen und Tabellen, Literatur-und Sachwortverzeichnis, Preis 68, — DM, ISBN 3–342–00315–4. Cryst. Res. Technol. 27(1), 58–58 (1992)

L. Zhang, I. Zarudi, Towards a deeper understanding of plastic deformation in mono-crystalline silicon. Int. J. Mech. Sci 43(9), 1985–1996 (2001)

G.G. Dongre, C. Vesivkar, R. Singh, S.S. Joshi, Modeling of silicon ingot slicing process by wire-electrical discharge machining. Proc. IMechE Part B J. Eng. Manuf 227(11), 1664–1678 (2013)

D. Chen, Chemical etching of silicon (review). Spec. Electr 3, 35–37 (1983)

Z. Zhao, Cutting Semiconductor Crystal with Specific Orientation. (Science Press, Beijing, 1979)

M Ge, Z Liu, L Shen et al., Thickness measurement of deterioration layer of monocrystalline silicon by specific crystallographic plane cutting of wire electrical discharge machining. J. Mater. Sci. Mater. Electron. 27(9), 9107–9114, (2016). doi:10.1007/s10854-016-4945-z

Z. Liu, L. Gao, M. Qiu, Z. Tian, W. Wang, Study on damage mechanism of monocrystalline silicon cut by WEDM. Acta Aeronauticaet Astronautica Sinica 1, 156–162 (2012)

Acknowledgements

This paper is supported by Funding of Jiangsu Innovation Program for Graduate Education (the Fundamental Research Funds for the Central Universities) (Grant No. KYLX15_0291) and the National Natural Science Foundation of China (Grant Nos. 51575271, 11275274, U1532106). We would like to thank all of people who contributed to this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ge, M., Liu, Z., Chen, H. et al. Machining damage of monocrystalline silicon by specific crystallographic plane cutting of wire electrical discharge machining. J Mater Sci: Mater Electron 28, 8437–8445 (2017). https://doi.org/10.1007/s10854-017-6562-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6562-x