Abstract

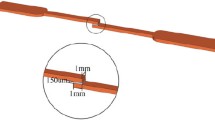

Solder joints in electronic packaging systems are becoming smaller and smaller to meet the miniaturization requirements of electronic products and high density interconnect technology. Furthermore, many properties of the real solder joints at the microscale level are obviously different from that of bulk solder materials. Creep, as one of the key mechanical properties at elevated temperatures, can impair the reliability of miniature solder joints in electronic devices. However, there is a lack of knowledge about the comparative creep properties of microscale solder joints of different sizes. Most previous studies have focused on the creep properties of bulk solder materials or solder joints of the same size. In this research, to determine whether a size effect exists for creep properties of solder joints or not, we characterized the creep behaviors of Sn–3.0Ag–0.5Cu lead-free solder joints under tensile loading modes using microscale butt-joint specimens with a copper-wire/solder/copper-wire sandwich structure with two different sizes. Also, the creep failure mechanisms were investigated. Experimental results show that the creep activation energy and creep stress exponent are very similar for both sizes of solder joint. However, under the same testing conditions, the joints with a larger size exhibit a much higher steady-state creep rate and a shorter creep lifetime than the smaller joints.

Similar content being viewed by others

References

D. Witkin, J Electron Mater 41, 190 (2012)

J. Villain, O.S. Brueller, T. Qasim, Sensor ActuatorA Phys 99, 194 (2002)

M. Kerr, N. Chawla, Acta Mater 52, 4527 (2004)

T.S. Park, S.B. Lee, J Electron Packag 127, 237 (2005)

G. Cuddalorepatta, M. Williams, A. Dasgupta, J Electron Mater 29, 2292 (2010)

X.P. Zhang, C.B. Yu, S. Shrestha, L. Dorn, J Mater Sci Mater Electron 18, 665 (2007)

X.P. Zhang, L.M. Yin, C.B. Yu, J Mater Sci Mater Electron 19, 393 (2008)

L.M. Yin, X.P. Zhang, C. Lu, J Electron Mater 38, 2179 (2009)

P. Zimprich, A. Betzwar-Kotas, G. Khatibi, B. Weiss, H. Ipser, J Mater Sci Mater Electron 19, 383 (2008)

H. Mavoori, J. Chin, S. Vaynman, B. Moran, L. Keer, M. Fine, J Electron Mater 26, 783 (1997)

S.H. Suh, J.B. Cohen, J. Weertman, Metall Mater Trans A 14, 117 (1983)

R.S. Sidhu, N. Chawla, Metall Mater Trans A 39, 340 (2008)

J. Cadek, Creep in metallic materials, 1st edn. (Elsevier, Amsterdam, 1988), pp. 46–47

M. He, S.N. Ekpenuma, V.L. Acoff, J Electron Mater 37, 300 (2008)

H.G. Song, J.W. Morris, F. Hua, J Miner Met Mater Soc 56, 30 (2002)

Weertman J (1984) Wilshire B, Owen DRJ (eds) Proceedings of the 2nd international conference on creep and fracture in engineering materials and structures. Pineridge Press, Swansea, p 1

Acknowledgments

This research is funded by Chongqing Natural Science Foundation (No. cstc2011 jjA40016) and the Research Foundation of Chongqing University of Science and Technology (No. CK2010B23). L. M. Yin is grateful to Prof. X. P. Zhang at South China University of Technology, China and Prof. M. Pecht at the Center for Advanced Life Cycle Engineering (CALCE), University of Maryland, for their valuable advice.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yin, L., Wei, S., Xu, Z. et al. The effect of joint size on the creep properties of microscale lead-free solder joints at elevated temperatures. J Mater Sci: Mater Electron 24, 1369–1374 (2013). https://doi.org/10.1007/s10854-012-0936-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-012-0936-x