Abstract

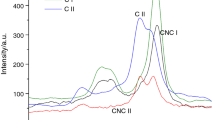

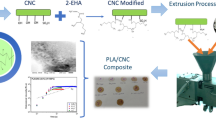

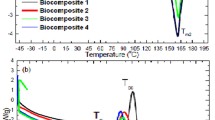

Poly(lactic acid) (PLA) is a semi-crystalline polymer with good transparency, mechanical strength, and melt processability. However, the use of PLA in applications like food packaging is limited by its low heat resistance and slow crystallization rate. The addition of cellulose nanofibers can be an efficient solution to enhance PLA crystallinity and stiffness, maintaining the transparency and biodegradability, which are mandatory for packaging applications. The combined effect of annealing and cellulose nanofibers (surface treated—SCN or untreated—CN) on the crystalline structure of PLA was thoroughly studied at both micro- and nano-scales by differential scanning calorimetry (DSC), mechanical tests, X-ray diffraction (XRD), scanning electron microscopy (SEM), and atomic force microscopy (AFM), Peak Force QNM (Quantitative Nanomechanical Mapping) mode. The ability of CN to act as nucleating agents was highlighted by DSC and XRD, both methods pointing out similar trends of crystallinity variation. Higher crystallinity was observed after annealing, 59 % instead of 40 % for PLA, 67 % instead of 48 % for PLA-CN and 57 % instead of 39 % for PLA-SCN, respectively. A mixture of α and α′ crystals was detected in all the samples after annealing but the concentration of the more disordered α′ form was higher in PLA-CN than in PLA-SCN. The transformation of the grained structure specific to amorphous PLA into a crystalline lamellar structure (average lamellar thickness of about 22 nm) after annealing was detected by Peak Force QNM. Nanoindentation tests showed an improvement of the surface modulus and hardness for the composites compared to PLA, after annealing. Thus, modulus increased from 5.9 GPa for PLA to 6.2 GPa for PLA-CN and 6.6 GPa for PLA-SCN. The understanding of PLA nanostructure modification by annealing and CN addition may contribute to adjust post-processing treatments, thus making PLA more suitable for packaging and other applications.

Similar content being viewed by others

References

Arrieta MP, Fortunati E, Dominici F, Rayón E, López J, Kenny JM (2014) Multifunctional PLA–PHB/cellulose nanocrystal films: processing, structural and thermal properties. Carbohyd Polym 107:16–24

Bulota M, Budtova T (2015) PLA/algae composites: morphology and mechanical properties. Compos A 73:109–115

Arjmandi R, Hassan A, Eichhorn SJ, Haafiz MKM, Zakaria Z, Tanjung FA (2015) Enhanced ductility and tensile properties of hybrid montmorillonite/cellulose nanowhiskers reinforced polylactic acid nanocomposites. J Mater Sci 50:3118–3130. doi:10.1007/s10853-015-8873-8

Fortunati E, Luzi F, Puglia D, Petrucci R, Kenny JM, Torre L (2015) Processing of PLA nanocomposites with cellulose nanocrystals extracted from Posidonia oceanica waste: innovative reuse of coastal plant. Ind Crop Prod 67:439–447

Murariu M, Dechief A-L, Ramy-Ratiarison R, Paint Y, Raquez J-M, Dubois P (2015) Recent advances in production of poly(lactic acid) (PLA) nanocomposites: a versatile method to tune crystallization properties of PLA. Nanocomposites 1:71–82

Henton DE, Gruber P, Lunt J, Randall J (2005) Polylactic acid technology. Taylor & Francis, London

Gámez-Pérez J, Velazquez-Infante JC, Franco-Urquiza E, Pages P, Carrasco F, Santana OO, Maspoch ML (2011) Fracture behavior of quenched poly(lactic acid). Express Polym Lett 5:82–91

Pan P, Zhu B, Inoue Y (2007) Enthalpy relaxation and embrittlement of poly(l-lactide) during physical aging. Macromolecules 40:9664–9671

Yang X, Kang S, Yang Y, Aou K, Hsu SL (2004) Raman spectroscopic study of conformational changes in the amorphous phase of poly(lactic acid) during deformation. Polymer 45:4241–4248

Ferri JM, Samper MD, Garcıa-Sanoguera D, Reig MJ, Fenollar O, Balart R (2016) Plasticizing effect of biobased epoxidized fatty acid esters on mechanical and thermal properties of poly(lactic acid). J Mater Sci 51:5356–5366. doi:10.1007/s10853-016-9838-2

Chen L, Pang X, Yu G, Cui J, Cheng J, Qi J (2013) Poly(L-lactide acid) composites containing needlelike fibers assembled by C60 with improved crystallization and thermal properties. Compos Sci Technol 74:160–165

Hossain KMZ, Ahmed I, Parsons AJ, Scotchford CA, Walker GS, Thielemans W, Rudd CD (2012) Physico-chemical and mechanical properties of nanocomposites prepared using cellulose nanowhiskers and poly(lactic acid). J Mater Sci 47:2675–2686. doi:10.1007/s10853-011-6093-4

Turng L-S, Srithep Y (2014) Annealing conditions for injection-molded poly(lactic acid), Society of Plastics Engineers (SPE). Plast Res Online. doi:10.2417/spepro.005392

Ye C, Ma G, Fu W, Wu H (2015) Effect of fiber treatment on thermal properties and crystallization of sisal fiber reinforced polylactide composites. J Reinf Plastic Compos 34:718–730

Kovalakova M, Olcak D, Hronsky V, Vrabel P, Fricova O, Chodak I, Alexy P, Sucik G (2016) Morphology and molecular mobility of plasticized polylactic acid studied using solid-state 13C- and 1H-NMR spectroscopy. J Appl Polym Sci 133:43517–43528

Frone AN, Nicolae CA, Gabor RA, Panaitescu DM (2015) Thermal properties of water-resistant starch–polyvinyl alcohol films modified with cellulose nanofibers. Polym Degrad Stab 121:385–397

Panaitescu DM, Frone AN, Ghiurea M, Chiulan I (2015) Influence of storage conditions on starch/PVA films containing cellulose nanofibers. Ind Crop Prod 70:170–177

Songa Z, Xiaoa H, Zhao Y (2014) Hydrophobic-modified nano-cellulose fiber/PLA biodegradablecomposites for lowering water vapor transmission rate (WVTR) of paper. Carbohyd Polym 111:442–448

Belbekhouche S, Bras J, Siqueira G, Chappey C, Lebrun L, Khelifi B, Maraisa S, Dufresne A (2011) Water sorption behavior and gas barrier properties of cellulose whiskers and microfibrils films. Carbohyd Polym 83:1740–1748

Arjmandi R, Hassan A, Haafiz MM, Zakaria Z (2015) Partial replacement effect of montmorillonite with cellulose nanowhiskers on polylactic acid nanocomposites. Int J Biol Macromol 81:91–99

Arjmandi R, Hassan A, Haafiz MKM, Zakaria Z, Islam MS (2016) Effect of hydrolysed cellulose nanowhiskers on properties of montmorillonite/polylactic acid nanocomposites. Int J Biol Macromol 82:998–1010

Frone AN, Berlioz S, Chailan J-F, Panaitescu DM, Donescu D (2011) Cellulose fiber-reinforced polylactic acid. Polym Comp 32:976–985

Di Lorenzo ML (2006) Calorimetric analysis of the multiple melting behavior of poly(L-lactic acid). J Appl Polym Sci 100:3145–3151

Kalb B, Pennings AJ (1980) General crystallization behaviour of poly(L-lactic acid). Polymer 21:607–612

Kanchanasopa M, Manias E, Runt J (2003) Solid-state microstructure of Poly(L-lactide) and L-lactide/meso-lactide random copolymers by atomic force microscopy (AFM). Biomacromolecules 4:1203–1213

Frone AN, Berlioz S, Chailan J-F, Panaitescu DM (2013) Morphology and thermal properties of PLA–cellulose nanofibers composites. Carbohydr Polym 91:377–384

Fernandes SCM, Freire CSR, Silvestre AJD, Neto CP, Gandini A, Berglund LA, Salmén L (2010) Transparent chitosan films reinforced with a high content of nanofibrillated cellulose. Carbohyd Polym 81:394–401

Liu H, Liu D, Yao F, Wu Q (2010) Fabrication and properties of transparent polymethylmethacrylate/cellulose nanocrystals composites. Bioresource Technol 101:5685–5692

Turner JF, Riga A, O’Connor A, Zhang J, Collis J (2004) Characterization of drawn and undrawn poly-L-lactide films by differential scanning calorimetry. J Therm Anal Calorim 75:257–268

Panaitescu DM, Ciuprina F, Iorga M, Frone A, Radovici C, Ghiurea M, Sever S, Plesa I (2011) Effects of SiO2 and Al2O3 nanofillers on polyethylene properties. J Appl Polym Sci 122:1921–1935

Cano A, Fortunati E, Chafer M, Gonzalez-Martınez C, Chiralt A, Kenny JM (2015) Effect of cellulose nanocrystals on the properties of pea starch–poly(vinyl alcohol) blend films. J Mater Sci 50:6979–6992. doi:10.1007/s10853-015-9249-9

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Ly B, Belgacem MN, Bras J, Brochier Salon MC (2010) Grafting of cellulose by fluorine-bearing silane coupling agents. Mat Sci Eng C 30:43–347

Espino-Perez E, Domenek S, Belgacem MN, Sillard C, Bras J (2014) Green process, for surface chemical functionalization of nanocrystalline cellulose with carboxylic acids. Biomacromolecules 15:4551–4560

Tingaut P, Hauert R, Zimmermann T (2011) Highly efficient and straightforward functionalization of cellulose films with thiolene. J Mater Chem 21:16066–16076

Lee SC, Han JI, Jeong YG, Kwon M (2010) Strain-induced enthalpy relaxation in poly(lactic acid). Macromolecules 43:25–28

Panaitescu DM, Gabor RA, Nicolae CA, Ghiurea M, Mihailescu M, Grigorescu RM (2014) Influence of melt processing induced orientation on the morphology and mechanical properties of polystyrene-b-ethylene/butylene-b-styrene) block copolymersand their composites with graphite. Mater Des 64:694–705

Fitz BD, Andjelic S (2003) Real-time monitoring of segmental dynamics during crystallization of poly(l(–)-lactide) by simultaneous DRS/SALS technique. Polymer 44:3031–3036

Mencze JD, Prime RB (2009) Thermal Analysis of Polymers: Fundamentals and Applications. Wiley, Upper Saddle River

Qin X, Xia W, Sinko R, Keten S (2012) Tuning glass transition in polymer nanocomposites with functionalized cellulose nanocrystals through nanoconfinement. Nano Lett 15:6738–6744

Šumigin D, Tarasova E, Krumme A, Viikna A (2012) Influence of cellulose content on thermal properties of poly(lactic) acid/cellulose and low-density polyethylene/cellulose composites. Proc Estonian Acad Sci 61:237–244

Akindoyo JO, Beg MDH, Ghazali S, Islam MR, Mamun AA (2015) Preparation and characterization of poly (lactic acid) based composites reinforced with poly dimethyl siloxane/ultrasound treated oil palm empty fruit bunch. Polym-Plast Technol 54:1321–1333

Kaczmarek H, Nowicki M, Vuković-Kwiatkowska I, Nowakowska S (2013) Crosslinked blends of poly(lactic acid) and polyacrylates: AFM, DSC and XRD studies. J Polym Res 20:91–103

Kulinski Z, Pirkowska E (2005) Crystallization, structure and properties of plasticized poly(l-lactide). Polymer 46:10290–10300

Pan P, Kai W, Zhu B, Dong T, Inoue Y (2007) Polymorphous crystallization and multiple melting behavior of poly(l-lactide): molecular weight dependence. Macromolecules 40:6898–6905

He Y, Fan Z, Wei J, Li S (2006) Morphology and melt crystallization of poly(L-lactide) obtained by ring opening polymerization of L-lactide with zinc catalyst. Polym Eng Sci 46:1583–1589

Fiore V, Botta L, Scaffaro R, Valenza A, Pirrotta A (2014) PLA based biocomposites reinforced with Arundo donax fillers. Compos Sci Technol 105:110–117

Le Marec PE, Ferry L, Quantin J-C, Benezet J-C, Bonfils F, Guilbert S, Bergeret A (2014) Influence of melt processing conditions on poly(lactic acid) degradation: molar mass distribution and crystallization. Polym Degrad Stab 110:353–363

Abe H (1998) Doi Y Solid-state structures and enzymatic degradabilities for melt-crystallized films of copolymers of (R)-3-hydroxybutyric acid with different hydroxyalkanoic acids. Macromolecules 31:1791–1797

Sullivan EM, Moon RJ, Kalaitzidou K (2015) Processing and characterization of cellulose nanocrystals/polylactic acid nanocomposite films. Materials 8:8106–8116

Tábi T, Sajó IE, Szabó F, Luyt AS, Kovács JG (2010) Crystalline structure of annealed polylactic acid and its relation to processing. Express Polym Lett 4:659–668

Pan P, Zhu B, Kai W, Dong T, Inoue Y (2008) Polymorphic transition in disordered poly(L-lactide) crystals induced by annealing at elevated temperatures. Macromolecules 41:4296–4304

El-Hadi AM (2014) Development of novel biopolymer blends based on poly(L-lactic acid), poly((R)-3-hydroxybutyrate), and plasticizer. Polym Eng Sci 54:1394–1402

Pan P, Han L, Shan G, Bao Y (2014) Heating and annealing induced structural reorganization and embrittlement of solution-crystallized poly(L-lactic acid). Macromolecules 47:8126–8130

Gil-Castell O, Badia JD, Kittikorn T, Strömberg E, Ek M, Karlsson S, Ribes-Greus A (2016) Impact of hydrothermal ageing on the thermal stability, morphology and viscoelastic performance of PLA/sisal biocomposites. Polym Degrad Stab. doi:10.1016/j.polymdegradstab.2016.03.038

Park SM, Todo M, Arakawa K (2005) Effects of isothermal crystallization on fracture toughness and crack growth behavior of poly (lactic acid). J Mater Sci 40:1055–1058. doi:10.1007/s10853-005-6534-z

Huang C, Bai H, Xiu H, Zhang Q, Fu Q (2014) Matrix crystallization induced simultaneous enhancement of electrical conductivity and mechanical performance in poly(L-lactide)/multiwalled carbon nanotubes (PLLA/MWCNTs) nanocomposites. Compos Sci Technol 102:20–27. doi: 10.1016/j.compscitech.2014.07.016

Pickering KL, Efendy MGA, Le TM (2016) A review of recent developments in natural fibre composites and their mechanical performance. Compos A 83:98–112

Pracella M, Minhaz-Ul MH, Puglia D (2014) Morphology and properties tuning of PLA/cellulose nanocrystals bionanocomposites by means of reactive functionalization and blending with PVAc. Polymer 55:3720–3728

Kowalczyk M, Piorkowska E, Kulpinski P, Pracella M (2011) Mechanical and thermal properties of PLA composites with cellulose nanofibers and standard size fibers. Compos A 42:1509–1514

Johari AP, Mohanty S, Kurmvanshi SK, Nayak SK (2016) Influence of different treated cellulose fibers on the mechanical and thermal properties of poly(lactic acid). ACS Sustain Chem Eng 4:1619–1629

Pilla S, Gong S, O’Neill E, Yang L, Rowell RM (2009) Polylactide-recycled wood fiber composites. J Appl Polym Sci 111:7–47

Tran TPT, Bénézeta J-C, Bergereta A (2014) Rice and Einkorn wheat husks reinforced poly(lactic acid) (PLA) biocomposites: effects of alkaline and silane surfacetreatments of husks. Ind Crop Prod 58:111–124

González A, Dasari A, Herrero B, Plancher E, Santarén J, Esteban A, Lim S-H (2012) Fire retardancy behavior of PLA based nanocomposites. Polym Degrad Stab 97:248–256

Acknowledgements

This research was supported by Grant PN-II-RU-TE-2014-4-1139, code 57/2015 (FULLBIOPACK) of the Romanian National Authority for Scientific Research and Innovation, CNCS – UEFISCDI and by the Projects PN-II-PCCA, code 158/2012 (POLYBAC) and INOVA-OPTIMA SMIS code 49164 (658/2014).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Frone, A.N., Panaitescu, D.M., Chiulan, I. et al. The effect of cellulose nanofibers on the crystallinity and nanostructure of poly(lactic acid) composites. J Mater Sci 51, 9771–9791 (2016). https://doi.org/10.1007/s10853-016-0212-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0212-1