Abstract

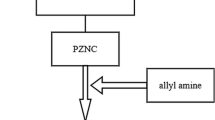

Melt-spinnable polyaluminocarbosilane (PACS) is of importance as the precursor to prepare the Si–C–Al–O ceramic fibers, which can be employed for the preparation of SiC fibers with high tensile strength and good thermal stability. In this work, low-softening-point polycarbosilane (LPCS) was synthesized by pyrolysis of polydimethylsilane and applied to prepare PACS precursors with variable aluminum content by the reaction with aluminum(III) acetylacetonate. GPC, 1H NMR, UV–Vis, FT-IR, 29Si NMR, 27Al MAS NMR, TGA, and elemental analysis were used to analyze the composition and structure of the PACS precursors. Finally, Si–C–Al–O fibers were obtained successfully by melt-spinning, curing, and final pyrolysis of the precursors. The method demonstrated in this work can be further extended to synthesize other melt-spinnable metal-containing polycarbosilane (PMCS, M: Zr, Ti, Fe, Co, et.) of high ceramic yield and adjustable M content by reacting LPCS with other corresponding metal-containing compounds.

Similar content being viewed by others

References

Yajima S, Hasegawa Y, Okamura K, Matsuzawa T (1978) Development of high tensile strength silicon carbide fiber using an organosilicon polymer precursor. Nature 273:525–527

Ishikawa T (2005) Advances in inorganic fibers. Chapter 2 in polymeric and inorganic fibers. Springer, Berlin

Korb LJ (1981) The shuttle orbiter thermal protection system. Am Ceram Soc Bull 60:1188–1193

Katoh Y, Kohyama A, Hinoki T (2003) Progress in SiC-based ceramic composites for fusion applications. Fusion Sci Technol 44:155–162

Wang Y, Wang B, Lei Y, Wu N, Han C, Gou Y, Fang D (2015) Scalable in situ growth of SnO2 nanoparticle chains on SiC ultrathin fibers via a facile sol–gel-flame method. Appl Surf Sci 335:208–212

Wang B, Wang Y, Lei Y, Wu N, Gou Y, Han C, Fang D (2014) Hierarchically porous SiC ultrathin fibers mat with enhanced mass transport, amphipathic property and high-temperature erosion resistance. J Mater Chem A 2:20873–20881

Colombo P, Mera G, Riedel R, Sorarù GD (2010) Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics. J Am Ceram Soc 93:1805–1837

Gou Y, Tong X, Zhang Q, Wang H, Wang B, Xie S, Wang Y (2015) Synthesis of hyperbranched polyferrocenylsilanes as preceramic polymers for Fe/Si/C ceramic microspheres with porous structures. J Mater Sci 50:7975–7984. doi:10.1007/s10853-015-9362-9

Wang H, Gao B, Chen X, Wang J, Chen S, Gou Y (2013) Synthesis and pyrolysis of a novel preceramic polymer PZMS from PMS to fabricate high-temperature-resistant Z rC/SiC ceramic composite. Appl Organometal Chem 27:166–173

Borchardt L, Kockrick E, Wollmann P, Kaskel S, Guron MM, Sneddon LG, Geiger D (2010) Ordered mesoporous boron carbide based materials via precursor nanocasting. Chem Mater 22:4660–4668

Xie Z, Deng X, Suo X, Zhou T, Gou Y (2015) Synthesis and characterization of zirconium diboride precursor based on polycentric bridge bonds. Mater Chem Phys 159:178–184

Bunsell AR, Piant A (2006) A review of the development of three generations of small diameter silicon carbide fibres. J Mater Sci 41:823–839. doi:10.1007/s10853-006-6566-z

Schawaller D, Clauß B, Buchmeiser MR (2012) Ceramic filament fibers: a review. Macromol Mater Eng 297:502–522

Ishikawa T, Kohtoku Y, Kumagawa K, Yamamura T, Nagasawa T (1998) High-strength alkali-resistant sintered SiC fibre stable to 2200 °C. Nature 391:773–775

Ishikawa T, Kajii S, Matsunaga K, Hogami T, Kohtoku Y, Nagasawa T (1998) A tough, thermally conductive silicon carbide composite with high strength up to 1600 °C in air. Science 282:1295–1297

Zheng CM, Li XD, Wang H, Zhao DF, Hu TJ (2008) Evolution of crystallization and its effects on properties during pyrolysis of Si–Al–C–(O) fibers. J Mater Sci 43:3314–3319. doi:10.1007/s10853-008-2542-0

Li XD, Edirisinghe MJ (2004) Evolution of the ceramic structure during thermal degradation of a Si–C–Al–O precursor. Chem Mater 16:1111–1119

Cao F, Li XD, Peng P, Feng CX, Wang J, Kim DP (2002) Structural evolution and associated properties on conversion from Si–C–O–Al ceramic fibers to Si–C–Al fibers by sintering. J Mater Chem 12:606–610

Sorarù GD, Mercadini M, Maschio RD, Taulelle F, Babonneau F (1993) Si–Al–O–N fibers from polymeric precursor: synthesis, structural, and mechanical characterization. J Am Ceram Soc 76:2595–2600

Sorarù GD, Ravagni A, Campostrini R, Babonneau F (1991) Synthesis and characterization of β-SiAlON ceramics from organosilicon polymers. J Am Ceram Soc 74:2220–2223

Babonneau F, Sorarù GD, Thorne KJ, Mackenzie JD (1991) Chemical characterization of Si–C–Al–O precursor and its pyrolysis. J Am Ceram Soc 74:1725–1728

Li X, Edirisinghe MJ (2003) A new aluminum coordination site in Si–C–Al–N–(O) ceramics. J Am Ceram Soc 86:2212–2214

Yu Y, Tang X (2009) Ceramic precursor aluminum-containing polycarbosilane: preparation and structure. J Inorg Organomet Polym 19:389–394

Yu Y, Zhang Y, Yang J, Tang M (2007) Synthesis and characterization of ceramic precursor aluminum-containing polycarbosilane and its pyrolysis. J Inorg Organomet Polym 17:569–575

Yu Y, Li X, Cao F (2005) Synthesis and characterization of polyaluminocarbosilane. J Mater Sci 40:2093–2095. doi:10.1007/s10853-005-1243-1

Cao F, Kim DP, Li X, Feng C, Song Y (2002) Synthesis of polyaluminocarbosilane and reaction mechanism study. J Appl Polym Sci 85:2787–2792

Yajima S, Hasegawa Y, Hayashi J, Iimura M (1978) Synthesis of continuous silicon carbide fibre with high tensile strength and high Young’s modulus part 1 synthesis of polycarbosilane as precursor. J Mater Sci 13:2569–2576. doi:10.1111/j.1151-2916.1976.tb10975.x

Ichikawa H, Teranishi H, Ishikawa T (1987) Effect of curing conditions on mechanical properties of SiC fibre (Nicalon). J Mater Sci 6:420–422. doi:10.1007/BF01756783

Hasegawa Y, Okamura K (1983) Synthesis of continuous silicon carbide fibre. Part 3 pyrolysis process of polycarbosilane and structure of the products. J Mater Sci 18:3633–3648. doi:10.1007/BF00540736

Fritz G, Grobe J, Kummer D (1965) Carbosilanes. Adv Inorg Chem Radiochem 7:349–418

Wang H, Li XD, Kim TS, Kim DP (2005) Inorganic polymer-derived tubular SiC arrays from sacrificial alumina templates. Appl Phys Lett 86:173104

Xie W, Möbus G, Zhang S (2011) Molten salt synthesis of silicon carbide nanorods using carbon nanotubes as templates. J Mater Chem 21:18325–18330

Acknowledgements

This research was sponsored by the National Natural Science Foundation of China (Grant No. 51302313) and the Fund of Science and Technology on Advanced Ceramic Fibers and Composites Laboratory (Grant Nos. 9140C820203140C82345, 9140C820403150C82024). The financial support from Postdoctoral Science Foundation of China (Grant No. 2014M552685) was appreciated as well. The authors are also thankful for the financial support from Aid Program for Science and Technology Innovative Research Team in Higher Educational Institutions of Hunan Province and Aid Program for Innovative Group of National University of Defense Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Gou, Y., Wang, H., Jian, K. et al. Facile synthesis of melt-spinnable polyaluminocarbosilane using low-softening-point polycarbosilane for Si–C–Al–O fibers. J Mater Sci 51, 8240–8249 (2016). https://doi.org/10.1007/s10853-016-0101-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0101-7