Abstract

This paper presents an extensive set of measurements from complementary surface analysis techniques performed for characterizing deuterium retention in carbon fiber composite Sepcarb®NB31 subsequently to a deuterium beam exposition: adsorption isotherm measurements and Hg porosimetry to characterize the porous network, coupled deuterium beam exposure and in situ µ-NRA analysis to follow the dynamics of the penetration of the retained deuterium in the material, TEM and Raman microscopy to investigate the change in the material structure induced by ion irradiation, and finally TPD to estimate the respective proportion of deuterium retained in the surface layer and in the bulk material. The parameters extracted from this set of characterizations are introduced in a 2D Monte Carlo model which couples the propagation of deuterium and eroded carbon atoms in a network of rectilinear pores and plasma–surface interaction parameters from the SRIM code. The simulations reproduce satisfactorily the main features of the measured deuterium concentration profile and behavior of the retained deuterium amount with incident fluence, validating the physical picture of deuterium retention in CFC as due to the simultaneous implantation of the incident ions in the few 10-nm-depth layer the closest to the surface and penetration of atoms deeper in the material (several tens of microns) through the pore network.

Similar content being viewed by others

Introduction

Plasma–wall interactions play a key role in the stable, efficient, and long-term discharge quest within fusion reactors. For decades, carbon fiber composites (CFC) were considered as an excellent candidate, as its main qualities are to be a low-Z material, whose eroded particles radiate at the edge of the discharge—thus preventing from huge radiative losses in the core of the discharge, and to have excellent power handling capability and thermo-mechanical properties due to its particular structure (a 3D fiber structure orienting the material properties densified by a graphitic matrix). Initially envisaged as the main plasma-facing material (PFM) for the targets (the most loaded parts of the machine in terms of heat and particle fluxes) in the first design of the ITER divertor, it was given up for tungsten because hydrogen isotope-rich deposits resulting from CFC erosion would lead to a high deuterium and tritium retention, preventing the tritium inventory from being maintained under the required safety limit [1]. The advantages of CFC as a PFM are however still high for being used in new coming devices, namely the JT60-SA tokamak [2] and the W7-X stellarator [3], and as long as devices are not supposed to use a mixture of deuterium and tritium as a working gas.

Nowadays, and based on decades of experimental campaigns and strong modeling efforts, it is admitted that the largest reservoir of unwanted trapped fuel is trapped in the deposits resulting from the erosion and redeposition of the high-flux components [4]. Retention capabilities of the CFC itself are however non-negligible and still suffer from poor characterization and understanding, in particular in operando context. Numerous post-mortem studies have been carried out for estimating the hydrogen isotope retention in various CFCs after deuterium plasma exposure [5], ion implantation [6], or tokamak operation [7, 8], but understanding the mechanisms behind this process is complicated by the limitation of in situ analyses. For this reason, a bench intended for simultaneous low-energy ion implantation and high-energy micro-ion beam analysis was set up at the Light Element Analysis Laboratory (LEEL) in CEA Saclay (France) in order to provide an insight into the phenomenon dynamics. The studies presented in this paper concentrate on CFC Sepcarb®NB31, which will be used as a PFM in JT60-SA [2] and W7-X [3]. A number of surface analysis techniques are used for investigating the dynamics of deuterium retention: adsorption isotherm measurements and Hg porosimetry to characterize the porous network, coupled deuterium beam exposure and in situ micro-nuclear reaction analysis (μ-NRA) to follow the dynamics of the penetration of the retained deuterium in the material, transmission electron microscopy (TEM) and Raman microscopy to investigate the change in the material structure induced by ion irradiation, and finally temperature-programed desorption (TPD) to estimate the respective proportion of deuterium retained in the surface layer and in the bulk material. The parameters extracted from this set of measurements are introduced in a 2D Monte Carlo model which describes the propagation of deuterium and eroded carbon atoms in a network of rectilinear pores.

Experimental set-up and analysis techniques

Sepcarb®NB31 CFC, provided by the Fusion For Energy organization, was used for the experiments. This CFC contains a 3D fibrous reinforcement architecture based on stacking woven plies of carbon fiber fabric, interlocked by a needling procedure that partly transfers the fibers in the stacking direction [9]. The matrix is obtained by gas-phase infiltration and pitch impregnation and pyrolysis, followed by a graphitization cycle. It is therefore not fully dense, some residual porosity appearing upon cooling after the last heat treatment. Observed surfaces can therefore include bundles of planar fibers, bundles of orthogonal fibers (called sectioned fibers), matrix areas, and various size and shape of porosities. The face of the CFC samples corresponding to that used as a plasma-facing surface in tokamaks was polished before to be exposed to the implantation beam and analyzed.

Sample porosity was analyzed by adsorption isotherm measurements and Hg intrusion–extrusion experiments. Both techniques are suitable for studying porosity in a multistage range and allow the characterization of the volume and structure of the porous network. Adsorption isotherms were measured step by step on a home-made set-up developed for porosity analyses of carbon of interest for fusion applications [10, 11]. The adsorbed molecule was methane (Air Liquide, 99.95 %), and before each adsorption isotherm the cubic samples of volume 1 mm3 and 1 cm3 were outgassed up to 400 °C under vacuum (10−7 mbar). We used the BET method [12, 13] as a standard procedure to determine the equivalent specific surface area, aBET. The Hg intrusion–extrusion experiments were carried out with an Autopore 9220 apparatus from Micromeritics at Madirel Laboratory. The usual intrusion pressure range 0–400 MPa was used to screen the pore volume and size from ~0.003 to 300 µm, as derived from the intrusion curve applying the Laplace–Washburn equation.

Simultaneous deuterium (D) irradiation and in-depth profile measurement were performed in a bench intended for low-energy ion implantation coupled to the nuclear microprobe of the LEEL laboratory (Saclay, France) [14]. A compact electron cyclotron resonance (ECR) ion source [15] produces a D beam of high flux and low energy on a square-centimeter scale surface. The sample holder is self-biased, thus blocking the secondary electron leakage, and can rotate to present the sample perpendicularly to the D beam during the implantation phase and to the 3He beam during the analysis. Deuterium is implanted at 200–350 eV, with total incident fluences ranging from 1022 to 2 × 1024 D/m2. During a cycle, the sample (2 × 30 × 2 mm3) is alternatively implanted in D (from 3 to 70 h) and analyzed (3–4 h); in situ campaigns consist in 3–5 cycles. Implantation occurs at room temperature. The D profile is obtained using the D(3He,p)4He nuclear reaction. A 3 MeV 3He+ beam, of 3 × 3 µm2 size and 2 nA current, is used in order to non-destructively probe the sample up to 11 µm depth. Damages caused by the analyzing beam to the material structure are of negligible influence on the D content, as shown in Ref. [14]. Data processing is performed using the SIMNRA software [16]. The analytical depth resolution—i.e., the minimal thickness of each layer of the modeled target—is estimated to be ~0.7 µm at the surface.

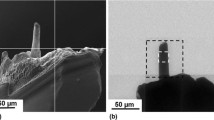

TEM measurements were carried out using a JEOL 2010F field emission microscope (of 0.18 nm structural resolution and 0.2 nm spot size) on one thin specimen (0.1 × 10.5 × 5 µm3) processed from an implanted sample using the focused ion beam (FIB) technique, using a Philips FIB 200 TEM.

Raman microscopy is a common method for characterizing the structure and D content of carbon materials with a space resolution of ~1 μm2 [17–19]. Raman spectra were obtained at room temperature with a Horiba–Jobin–Yvon HR LabRAM apparatus (laser wavelength: λ L = 514.532 and 633 nm, ×100 objective, spectral resolution ~1 cm−1, probed surface ~1 μm2 spot). The laser power was chosen to be ~0.2 mW/m2 to prevent from material damaging.

The total D content of samples of volume 2 × 7.5 × 2 mm3 was measured by TPD, using a 300 °C/h temperature ramp from room temperature up to 1000 °C. The rate of deuterium desorption was measured as a function of temperature using a mass spectrometer Inficon H100 M.

Experimental results

Characterization of the open pore distribution

As a material of complex 3D structure, it seems important beforehand to characterize the material morphology in order to understand further material analyses and more specifically NRA 3D profiles.

The specific surface area measured for NB31 is a BET = 0.13 ± 0.01 and 0.23 ± 0.01 m2/g for the centimeter- and millimeter-size samples, respectively. This low value for CFC compared to porous carbons is in agreement with the literature and indicates that NB31 is not microporous (i.e., that there are no pores of size lower than 2 nm). For a millimeter-size sample, this specific surface area is due to the so-called external surface corresponding to both the rough surface of the sample and to the surface of the large pores, whereas, for a centimeter-size sample, the specific surface area is only due to the surface of the large pores. The total volume of these large pores, as measured by Hg porosimetry, is 0.07 cm3/g and the pore size distribution derived from the intrusion of Hg is displayed in Fig. 1, allowing the determination of the contributions of the pores to total porosity as a function of their size, and then to the specific surface area. The differential volume is calculated by dV/d(log(r)), V being the volume of intruded Hg and r the equivalent radius of the pore. The pore size distribution shows that three types of pores contribute to the total hollow volume. The strongest contribution peaks at 10 µm in radius, corresponding mainly to the inter-bundle porosity of the preform, the contribution at 4 µm is probably due to matrix porosity, and finally the distribution at 0.03 µm of narrow pores is identified as the porosity located at the interface between the fiber and the matrix. (The effective surface of these narrow pores cannot be directly deduced from V p: it is estimated by subtracting the effective surfaces S eff of the 10- and 4-μm-radius pores to the a BET of the centimeter-size sample.) These three contributions (see Table 1) represent more than 90 % of the total porosity and about 60 % of the total specific area measured by adsorption isotherm for a millimeter-size sample. These results are in good agreement with the characterization of CFC NB31 by X-ray μ-tomography [20], evidencing the strong interconnectivity of the pore network.

In-depth D distribution by μ-NRA

The in situ µ-NRA study highlighted the instantaneous and permanent character of the long-range deuterium profile. As soon as implantation begins (i.e., at low fluence with our experimental procedure), two distinct parts emerge in the D profiles (see Figs. 2 and 2 of Ref. [14]): in the near-surface layer (<0.7 µm, the space resolution imposed by the experimental conditions), a relatively high deuterium concentration (D/(C + D) = 0.01–0.02) is observed, while in the bulk (0.7–11 µm) the deuterium content is much lower.

Although implantation conditions (Fig. 2a) and surface morphology of the irradiated zone (pore size and density, Fig. 2b) varied depending on the sample, it is worth noting that the deuterium content at the surface remains nearly constant for all the analyzed areas, which seems to indicate that the surface is saturated from the very beginning of implantation. The 0.7 µm layer resolution at the surface imposed by the experimental conditions being typically two orders of magnitude larger than the estimated penetration of the 350 eV D ions (~20 nm from SRIM [21] calculations), the energy of the 3He beam was lowered down to 1 MeV for one sample (i.e., improving the first-layer depth resolution from ~0.7 to 0.1 µm), showing a higher D content for the first surface layer. The result is shown in Fig. 3: whatever the surface location measured and for a fluence range between 2 × 1021 and 2 × 1022 D m−2, the D content in the first 0.7 µm the closest to the surface is 1.6 ± 0.9 × 1021 D m−2. This value corresponds to the quantity of D which can be stored in a saturated C layer (D/C = 0.47, i.e., D/(D + C) = 0.32) of thickness ~20 nm, this value being comparable to the penetration depth of the 350 eV D ions cited above.

The dependence of the in-depth deuterium concentration with surface characteristics is exemplified in Fig. 2b, which shows the profiles measured at two different locations of the same sample. One of the areas exhibits large pores when the second is more compact, as shown in the corresponding scanning electron microscopy (SEM) images (500 × 500 μm2) of the measured locations. It is clear that the larger the pores, the higher the deuterium content at large depth (the D concentrations at the surface differ by less than a factor of 2 when those in the bulk of the material display a ratio of ~20).

The mechanisms at the origin of these different behaviors were investigated by mapping the D content at two different ranges. A SEM image of the analyzed surface is displayed in Fig. 4a, the surface D concentration in Fig. 4b, and the bulk D concentration (integrated from 0.7 to 11 µm deep) in Fig. 4c. It is clear that if the deuterium in the surface layer is rather homogeneously distributed, the bulk material deuterium is concentrated in specific sites. As shown by the comparison of Fig. 4a and c, these preferential trapping sites correspond to porosities. Additional measurements were carried out on samples cut perpendicularly to the exposed surface, polished, and then analyzed by µ-NRA; deuterium could be found up to 500 µm deep in the CFC. All these results are in full agreement with X-ray µ-tomography measurements, which allows a non-destructive access to the complex multi-scale network of the in-depth porosities. It was shown by this method that open porosities constitute preferential paths for deuterium migration and trapping [14].

D surface concentration and material structure with TEM and Raman

Optical observations of ante and post implanted samples reveal that the surface becomes darker subsequently to ion bombardment. In order to distinguish surface and bulk D interactions with CFC, a thin foil was cut using FIB from an implanted sample (1.3 × 1024 D m−2 at 350 eV), in an area composed of fibers (oriented perpendicularly to the surface) and matrix, in order to perform TEM analysis. The obtained in-depth cross-section images (Fig. 5) clearly reveal an amorphous carbon layer at the surface (a-C layer), whose thickness is 35 ± 15 nm, similar for both the fiber and matrix. The relative accuracy of this measurement is mainly due to the indistinctness of the interface between the platinum coating and the a-C layer. It is noticeable that an a-C layer of similar thickness was observed at the surface of the CFC N11 exposed to a D+ flux of temperature ~200 eV in the Tore–Supra tokamak [22]. SRIM [21] calculations performed on a carbon of same density as that of CFC show that the 350 eV deuterium beam of the set-up should damage the material on a thickness of the order of 20 nm, a value comparable to that measured, even if smaller by ~40 %.

In order to refine the characterization of the near-surface behavior for explaining the quasi-constant deuterium content at the surface of implanted CFC, out of the apparent porosities and overstep the µ-NRA lateral resolution (~3 µm), we performed Raman microscopy measurements on several samples ante and post deuterium irradiation.

Figure 6 displays Raman mappings of typical areas with different fiber structures, before and after implantation (planar and sectioned fibers, Fig. 6a, b, and c, d, respectively). The areas spotted before and after implantation are not exactly the same but—for each pair—the comparison is meaningful. The G band wavenumber (σ G) is shown for the ante irradiation samples, because it is an efficient spectroscopic parameter for distinguishing between fiber and matrix. It is however not pertinent for the post implanted samples because the structure has changed subsequently to ion implantation (this is discussed deeper in Fig. 7); we preferred therefore to display the ratio between the slope of the underlying continuum and the height of the G band (m/HG), because this parameter is sensitive to the implanted deuterium content. As visible on the σ G plots (Fig. 6a, c), Raman microscopy distinguishes very well the fiber and the matrix structure as well as the orientation of fibers with respect to the surface. Hence, it is possible to look closely at the fiber–matrix interface. The plots of (m/HG) for two fiber orientations (Fig. 6b and 6d) denote that there are large variations at the surface (ranging from ~2 to 18 μm), which correspond to a D concentration varying from 27 to 43 % according to [23] (25–40 % according to [24]). Bright spots of a few microns and bright lines are visible in Fig. 6b. Only bright spots are found in Fig. 6d. The bright lines are likely located at the interface between fibers and matrix. This localized high D concentration on surfaces without major porosity was not visible in the deuterium images obtained with µ-NRA, most likely due to the lower resolution of the technique (emphasis was put on the major contribution of large porosities). Raman mapping allows distinguishing more precise and smaller zones of preferential D trapping, giving access to multi-scale D trapping characterization.

The Raman spectra of pristine and implanted NB31 samples are displayed in Fig. 7, which shows the Raman spectra recorded using two exciting wavelengths, λ L = 514.532 and 632.8 nm (the latter wavelength penetrating deeper in carbon materials and then probing carbon vibrations deeper). In both cases, the D and G bands’ broadening after irradiation confirms that the structure of the graphite is partially lost in the probed volume. This is consistent with TEM observations, a first (thin) layer fully amorphized, hence rich in sp3 C sites, followed by a preserved, graphitized substrate with higher sp2 C. The m/HG ratio is 7.8 μm, corresponding to D/C = 0.47 (D/(D + C) = 0.32) according to Casiraghi et al. [23] and to D/C = 0.49 (D/(D + C) = 0.33) according to Pardanaud et al. [19]. It follows that this amorphous carbon layer is deuterium saturated, which explains flux-independent D contents on the µ-NRA data set.

The presence of a-C due to bombardment was confirmed by Raman microscopy by obtaining a typical broadening of the G and D bands (Fig. 7a). Confirmation that this is a thin amorphous carbon layer was obtained by collecting Raman spectra using a higher laser wavelength (λ L = 633 nm), so that the underlying unmodified CFC signature now appears due to a lower laser absorption [19]. These spectra coincide well with post mortem studies on Tore–Supra samples extracted from the erosion-dominated zone of the limiter (the main PFM) [22], where additional TEM measurements evaluated the amorphous layer to ~30 nm deep. This confirms once again the results we obtained with TEM.

Total D retention in the surface layer and in the bulk

TPD was performed on two samples, both exposed to a fluence of 1.7 × 1024 D m−2 in the ion beam (350 eV) implantation set-up. The first one was analyzed as a whole after D exposure, while the other was beforehand polished at room temperature in order to eliminate the immediate surface exposed to the ion beam and consequently to remove the essential of surface retention (although it was not possible to estimate the thickness of the layer removed by the polishing, it should be larger than the amorphized layer mentioned in “D surface concentration and material structure with TEM and Raman” section). It follows that the comparison of the two TPD spectra allows to distinguish—at least qualitatively—the relative contributions of the very surface and of the bulk CFC in the deuterium retention. Mass 4 (D2) is followed, which is assumed to be the main form under which deuterium is released [25]. Both mass spectra are presented in Fig. 8a, exhibiting a D2 desorption from ~200 °C to more than 1000 °C. Two desorption peaks are observed at ~600 and ~800 °C for both spectra, indicating two C–D different binding types, attributed by Biener and collaborators to bounds with sp3- and sp2-hybridized carbons [26], respectively. When comparing the spectra of the rough and surface-eroded samples, a clear difference appears between the two peaks at ~600 °C, with 75 % less desorption for the surface-eroded sample, indicating that most of the corresponding trapping sites were located in the surface layer and disappeared during the polishing procedure. The peak at ~800 °C displays a similar shape in both cases, but is ~25 % lower for the eroded sample. This behavior is consistent with the Raman and TEM measurements that highlighted that the CFC surface was amorphized during the D implantation, showing consequently a higher sp3/sp2 ratio. Last, the total amount of deuterium desorbed by the eroded sample is ~45 % of that desorbed by the sample for which the surface layer was not removed.

a Experimental and simulated TPD spectra for the whole and surface-eroded CFC samples (the sharp dip in the spectrum of the non-eroded sample is due to a short interruption of the heating during the temperature ramp); b distribution of binding energies for ν = 1015 s−1; c relative decrease of the D content calculated from Fig. 8a and after two months of baking at constant temperature

The experimental mass spectra of D2 (assumed to be representative of the whole deuterium, \( n_{D} = 2 \times n_{{D_{2} }} ) \) were fitted as a function of temperature T using a first-order TPD law [25]:

where k is the Boltzmann constant and n(E, t) is the population of trapped deuterium at energy E. In such an analysis, it is implicitly assumed that bulk diffusion and retrapping do not affect the desorption rate. The pre-exponential factor, ν, is not accurately known for this material. Current values range from 1 × 1013 to 1 × 1016 s−1. The resulting binding energy distributions display two peaks, in the ranges 2.75–3.15 and 3.4–4.0 eV, depending on the value chosen for ν. An example for ν = 1 × 1015 s−1 is shown in Fig. 8b, this latter value being close to that determined for CFC N11 [27]. (It is noticeable that—in the frame of this analysis—choosing another value for ν would shift the peak position in the binding energy distribution, but would not change the outgassing rate of the samples calculated for any temperature waveform.) The behavior of the amount of trapped deuterium as a function of the temperature, \( N_{\text{D}} (T) = \mathop \smallint \nolimits n\left( {E,T} \right){\text{d}}E \), was estimated in two different ways: (i) directly from Fig. 8a, by calculating the ratio between the integrated outgassing above a given temperature and the total outgassing (blue and red curves in Fig. 8c), and (ii) from Eq. (1), using the binding energy distribution for the not-eroded sample of Fig. 8b, and assuming—for every temperature—a constant baking during two months. (After such a time interval, the time constant of the evolution of the deuterium content, \( N_{D} /\dot{N}_{D} \), is of several years in all the temperature domain of interest—black curve in Fig. 8c. This procedure assumes implicitly that the material structure is not modified by the long-time baking.)

Discussion and modeling

The different analyses reported in the previous section evidenced that D retention in CFC NB31 is related to the following:

-

A network of interconnected pores representing about 7 % of the sample volume and exhibiting a large effective surface (>0.1 m2/g, see Table 1) (“Characterization of the open pore distribution” section);

-

A homogeneous D concentration at the sample surface, independent on the fluence; a more localized D concentration in the bulk material, increasing with fluence, the building of this deuterium tail being simultaneous or quasi-simultaneous to irradiation (“In-depth D distribution by μ-NRA” section);

-

An amorphous carbon layer at the sample surface (35 ± 15 nm), saturated in deuterium; a more graphitic structure in the bulk material (“D surface concentration and material structure with TEM and Raman” section); and

-

Bounds of deuterium with sp3 carbons dominant close to the sample surface; bounds of deuterium with sp3 and sp2 carbons equilibrated in the bulk material (“Total D retention in the surface layer and in the bulk” section).

From these results, it can be stipulated that the retention of deuterium in CFC NB31 is due to two concomitant phenomena: implantation of impinging D ions in the very surface layer and simultaneous migration/trapping of D atoms in the porous network. (Thermally activated solid-state diffusion cannot reproduce correctly the trends and profiles observed.) Here, we infer that deep trapping is due to successive Coulomb scattering processes at the open pore internal surfaces. However, even if this picture can qualitatively explain the set of measurements listed above, validation of this hypothesis is needed and a simple model including Coulomb scattering on pore surfaces was built for verifying the picture global consistency and its ability for reproducing the behavior of D retention in CFC NB31 (this study and Refs. [6, 28]).

The model is based on 2D Monte Carlo calculations, which couple the propagation of deuterium and carbon atoms in a network of rectilinear pores and plasma–surface interaction parameters from SRIM [21, 29]. The pores—assumed to be independent from each other—are characterized by their radius 〈r〉, their average inclination with respect to the beam-facing surface 〈θ〉, their number—calculated from the volume V p—and their effective surface S eff, see Fig. 9a. Practically, 〈r〉, V p, and S eff were taken from Table 1, considering only the three dominant pore types observed in NB31. The average angle 〈θ〉 is the only parameter which is not experimentally determined, but X-ray μ-tomography characterization of NB31 [20] shows that the pores are roughly evenly distributed in the three directions of space. As a consequence, a constant value of 〈θ〉 = 45° was used in the simulations, with no attempt to optimize this value—pore per pore or by considering some distribution of angles—for fitting better the measurements. At every deuterium ion or atom impact, the reflection angle α Dr , reflection probability ρ Dr , and energy of the reflected particle E Dr are calculated from its incident angle α Di and energy and E Di , see Fig. 9b. Iterations under various incident conditions led in SRIM to gather data for all possible circumstances and fit distributions of the various parameters. The proportion of atoms recycling as molecules is estimated from particle conservation: \( \Phi^{0} = \rho_{r}^{D} \Phi^{0} + \Phi^{\text{R}} + \rho_{\text{m}}^{\text{D}} \Phi^{0}, \) where Φ 0 and ρ Dm are the incident fluence and proportion of particles recycling as molecules at the place of impact. Φ R is the retained fluence, taken from the retention measurement in pyrolytic graphite [30] (full black line in Fig. 10d). Molecules are assumed to exit the pore once formed and to be lost. The probability that a particle impinging the pore surface has to be trapped is therefore \( \rho_{\text{t}}^{\text{D}} = 1 - \rho_{\text{r}}^{\text{D}} - \rho_{\text{m}}^{\text{D}} \). The maximum retained fluence at a given location is estimated—as a function of E D i and temperature T—from the maximum admissible deuterium concentration in graphite (D/C = 0.47), the penetration depth of the incident particle Δ(α Di , E Di ), and the evolution of retention with temperature shown in Fig. 8c. At each impact, the sputtering coefficient of carbon Y C, angle α Di , and energy E Ci of the ejected atom are calculated, as a function of α Di and E Di (practically, due to the fast decrease of energy with successive impacts, only the first deuterium impact can lead to carbon erosion). The eroded carbons are followed in the same way as the D (their reflection coefficient and reflected energy, ρ Cr and E Cr , respectively, being calculated by SRIM) until complete deposition. The deposited carbon layer is assumed to increase the retention capability of the pore surface with the same capability as the original material (D/C = 0.47 at room temperature, the decrease with temperature being that displayed in Fig. 8c). At each place inside the pore, the trapping of deuterium stops when the surface is saturated or when the deposit plugs the pore. Self-erosion of carbon is not considered due to the low energy of the eroded particles, nor chemical sputtering and surface diffusion processes [33] (although they should be at work), because—considering what happens inside a pore—these processes lead more likely to a rearrangement of the retained fluence than to a net increase of the material retention capability. Last, the calculated retention in the very surface takes into account not only the contribution of the surface directly exposed to the beam (diminished from the openings of the pores), but also that of the outer part of the pores, which is in direct view of the beam, on a thickness 〈r〉/cos(〈θ〉).

a Example of simulated D concentration profile, showing the contribution of the different pore populations. b Evolution of the D concentration profile with b the incident fluence. c The sample temperature (full line simulation; shadowed zone: measurement [6, 28]). d D retention as a function of incident fluence. Experimental values (markers) and black full line are from Refs. [6, 28]

An example of simulated D concentration profile is displayed in Fig. 10a, where the correspondence between the C line-integrated density and the geometrical depth is calculated for a density of 1.8 g/cm3 (Ref. [9]). The blue lines correspond to the contributions of the three pore populations (see Fig. 1; Table 1). Input parameters for this calculation are the three pore populations listed in Table 1 (see Fig. 1), a sample temperature T = 50 °C, a D+ beam energy \( E = 350\; {\text{eV}}, \) and an incident fluence \( \Phi = 2 \times 10^{24} \; {\text{D}}/{\text{m}}^{2} \), close to that used for the two TPD samples (“Total D retention in the surface layer and in the bulk” section). The blue lines correspond to the contributions of the three pore populations, the red line to their sum. The total D concentration profile reproduces well the global structure of the measurements displayed in Fig. 2, exhibiting a narrow D-saturated layer followed by a wide tail of lower D content at larger depths. The tail contains 37 % of the total trapped deuterium, which is close to the ratio of the D2 released by the two TPD samples (~45 %, “Total D retention in the surface layer and in the bulk” section). The calculated profile and D content are robust with respect to the hypotheses of the model: changing the inclination angle of the pores by 30 % or/and using different angle distributions for the incident/reflected D and C ions for every impact (cosine law, uniform, specular) leads only to a variation of the D content within ~± 15 %.

µ-NRA D images were collected on relatively small areas (500 × 500 µm2) which do not represent the global complexity of the material structure as used in the model. Thus comparison between the simulations and the profiles displayed in Fig. 2 should not be pertinent. For this reason, measurements with large surface NRA were taken from literature, where results on the behavior of D retention with fluence and temperature [6, 28] are available. The comparison between simulations and experiments for the evolution of retention with incident fluence and sample temperature during implantation is displayed in Fig. 10b, c. The general behavior with fluence (constant surface concentration and height of the large depth tail, see Fig. 10b) is correctly reproduced, but not the progressive steepening of the tail with decreasing fluence. This is likely due to the model geometry when X-ray μ-tomography measurements show bents and abrupt changes in the porosity section [20]. Such an irregular shape could favor the local accumulation of particles, and therefore a faster plugging of the pore network, closer to the surface than what is predicted for a rectilinear regular shape. Using a more realistic pore network would probably lead to a better agreement. Additional gas-phase diffusion (desorption/diffusion/reincorporation) could also occur, modifying the initial deposition profile. Oppositely, neither the simplified pore distribution nor the 2D character of the model are supposed to play a significant role. Using a 3D calculation would lead to slightly flatter profiles and a more complex pore distribution to a smoother change in the slope of the D-concentration profiles, but always from a steeper slope to a flatter slope. It is also noticeable that the behavior with sample temperature during implantation is not reproduced (Fig. 10c). This may be due (1) either to the fact that the structure of the material evolves when it is heated at constant temperature for a long time under ion bombardment [31] (and this effect is not taken into account in the present model) or (2) to the other deuterated species which can be more mobile than the recorded mass 4 (D2) and therefore be desorbed at lower temperature.

Total retention results are summarized in Fig. 10d. The agreement between simulations and experimental data is contrasted: the rate and magnitude of the increase of D retention with incident fluence is well reproduced (in the absence of pores, retention would correspond to the black full line in Fig. 10d). It is interesting to note that the model predicts a saturation of D retention at very high fluences, due to the plugging of the pores by deposits. Such saturation was observed in PISCES B for CFC DMS 701 (Dunlop) [32]. However, once again, the substantial decrease of D retention with increasing sample temperature during implantation is not reproduced.

Summary

A set of surface analysis techniques was used for investigating the physical processes at the origin of deuterium retention in carbon fiber composite Sepcarb®NB31 following D+ irradiation.

-

Adsorption isotherm measurements and Hg porosimetry were used for characterizing the porous network, which represents about 7 % of the sample volume and exhibits an effective surface larger than 0.1 m2/g.

-

In situ µ-NRA analyses following D beam exposure assessed that D penetration up to large depths is almost simultaneous to implantation. The D concentration at the near surface is high, independent on the incident fluence and local pore density, and homogeneously distributed. Conversely, in-bulk deuterium (>1 µm) varies strongly with the local pore concentration and is located on the pore surfaces and can be found at depths up to 500 µm in relation with the material porosity distribution.

-

TEM pictures and Raman spectroscopy showed that D irradiation leads to the formation of a thin (30–40 nm), amorphous, D-saturated layer at the sample surface. Raman mapping highlighted preferential trapping sites for deuterium at the interface between fibers and matrix, which are not visible with µ-NRA resolution.

-

Last, TPD analysis showed that two different trapping sites for D are present in the CFC, in different proportions in the amorphous layer close to the surface, where bonds with sp3 carbons dominate, and in the bulk, where the bonds with sp3 and sp2 carbons are more equally distributed.

It follows from these results that D retention is due to two concomitant phenomena: implantation of D ions in the surface layer (a few 10 nm) and simultaneous migration/trapping of D atoms in the porous network. We proposed that the latter happens through successive Coulomb scattering processes at the pore internal surface. For assessing the global consistency of the proposed picture and its ability to reproduce the behavior of D retention in CFC NB31, a 2D Monte Carlo model was built, which couples the propagation of D and C atoms in a network of rectilinear pores and plasma–surface interaction parameters obtained from SRIM. Main limitations of this model are due to the assumed linear and symmetric porosities considered, while bents and shape irregularities can provide for additional preferential accumulation sites. Simulations are shown to reproduce satisfactorily the main features of the measured D concentration profile and the behavior of the retained D amount with incident fluence. Conversely, the influence of the sample temperature during beam exposition on D retention is not correctly reproduced. Globally, the simulation results demonstrate the complementarity of the surface analysis techniques performed on the samples and validate the physical picture of D retention in CFC as due to the simultaneous implantation of the incident ions in the very surface and penetration of atoms deeper in the material through the pore network.

References

Roth J et al (2009) Recent analysis of key plasma wall interactions issues for ITER. J Nucl Mater 390–91:1–9. doi:10.1016/j.jnucmat.2009.01.037

JT-60SA, Advanced superconducting tokamak: www.jt60sa.org

Wendelstein 7-X: www.ipp.mpg.de/16900/w7x

Pégourié B (2009) Particle balance and fuel retention in Tore Supra. Fusion Sci Technol 56:1334

Pisarev A et al (2009) Deuterium accumulation in carbon materials at high fluence. J Nucl Mater 390–391:677–680. doi:10.1016/j.jnucmat.2009.01.186

Alimov VKh, Roth J (2007) Hydrogen isotope retention in plasma-facing materials: review of experimental results. Phys Scr T128:6–13. doi:10.1088/0031-8949/2007/T128/002

Bernier N et al (2009) Localization by TEM and EELS of deuterium trapping sites in CFC exposed to plasma irradiation in Tore Supra. J Nucl Mater 385:601–605. doi:10.1016/j.jnucmat.2009.01.031

Alves LC et al (2010) Erosion and re-deposition processes in JET tiles studied with ion beams. Nucl Instrum Methods Phys. Res Sect B 268:1991–1996. doi:10.1016/j.nimb.2010.02.115

Merola M, Wu CH (2004) Development of carbon materials and plasma facing components for ITER. Phys Scr T111:152–156. doi:10.1238/Physica.Topical.111a00152

Richou M et al (2007) Physico-chemical characteristics of carbon deposits collected in TEXTOR and Tore Supra tokamaks. Carbon 45:2723–2731. doi:10.1016/j.carbon.2007.09.039

Martin C et al (2007) Multiscale study of the porosity of carbon deposits collected in Tore Supra. J Nucl Mater 363–365:1251–1255. doi:10.1016/j.jnucmat.2007.01.231

Rouquerol F, Rouquerol J, Sing K (1999) Adsorption by powders & porous solids. Academic Press, London

Brunauer S et al (1938) Edward Teller adsorption of gases in multimolecular layers. J Am Chem Soc 60:309–319

Bernard E, Khodja H, Chene J, Pégourié B, Martin C, Pardanaud C (2013) Simultaneous deuterium implantation and ion beam microanalyses in CFC NB31: understanding the in-bulk migration. J Nucl Mater 438:S975–S978. doi:10.1016/j.jnucmat.2013.01.212

Anton R et al (2000) Design and performance of a versatile, cost-effective microwave electron cyclotron resonance plasma source for surface and thin film processing. Rev Sci Instrum 71:1177–1180. doi:10.1063/1.1150420

Mayer M (1997) SIMNRA user’s guide, technical report IPP 9/113. Max-Planck-Institut fur Plasmaphysik, Garching

Wang YY, Ni ZH, Shen ZX, Wang HM, Wu YH (2008) Interference enhancement of Raman signal of graphene. Appl Phys Lett 92:043121. doi:10.1063/1.2838745

Scharf TW, Singer IL (2003) Thickness of diamond-like carbon coatings qualified with Raman spectroscopy. Thin Solid Films 440:138–144. doi:10.1016/S0040-6090(03)00703-X

Pardanaud C et al (2012) Raman micro-spectroscopy as a tool to measure the absorption coefficient and the erosion rate of hydrogenated amorphous carbon films heat-treated under hydrogen bombardment. Diam Relat Mater 22:92–95. doi:10.1016/j.diamond.2011.12.015

Tiseanu I, Tsitrone E, Kreter A et al (2011) X-ray micro-tomography studies on carbon based composite materials for porosity network characterization. Fusion Eng Des 86:1646–1651. doi:10.1016/j.fusengdes.2011.04.079

Ziegler JF (1985) The stopping and range of ions in solids. Pergamon, New York

Martin C et al (2011) Structure of the carbon layers deposited on the toroidal pump limiter of Tore Supra. J Nucl Mater 415:S258–S261. doi:10.1016/j.jnucmat.2010.11.006

Casiraghi C, Ferrari AC, Robertson J (2005) Raman spectroscopy of hydrogenated amorphous carbons. Phys Rev B 72:085401. doi:10.1103/PhysRevB.72.085401

Pardanaud C et al (2013) Raman spectroscopy investigation of the H content of heated hard amorphous carbon layers. Diam Relat Mater 34:100–104. doi:10.1016/j.diamond.2013.02.009

Tsitrone E, Brosset C, Pégourié B, Gauthier E, Bouvet J, Bucalossi J, Carpentier S, Corre Y, Delchambre E, Desgranges L, Dittmar T, Douai D, Ekedahl A, Escarguel A, Ghendrih Ph, Grisolia C, Grosman A, Gunn J, Hong SH, Jacob W, Kazarian F, Kocan M, Khodja H, Linez F, Loarer T, Marandet Y, Martinez A, Mayer M, Meyer O, Monier Garbet P, Moreau P, Pascal JY, Pasquet B, Rimini F, Roche H, Roure I, Rosanvallon S, Roubin P, Roth J, Saint-Laurent F, Samaille F, Vartanian S (2009) Deuterium inventory in Tore Supra: reconciling particle balance and post-mortem analysis. Nucl Fusion 49:075011. doi:10.1088/0029-5515/49/7/075011

Biener J et al (1994) Spectroscopic investigation of electronic and vibronic properties of ion-beam-deposited and thermally treated ultrathin C–H films. Phys Rev B 49:17307–17318. doi:10.1103/PhysRevB.49.17307

Hodille EA et al (2014) Hydrogen trapping in carbon film: from laboratories studies to tokamak applications. Int J Hydrog Energy 39:20054–20061. doi:10.1016/j.ijhydene.2014.09.027

Roth J et al (2007) Deuterium retention in carbon fibre composites NB31 and N11 irradiated with low-energy D ions. J Nucl Mater 363–365:822–826. doi:10.1016/j.jnucmat.2007.01.164

Ahmad A, Carrère M, Layet JM, Kumar P, Engeln R (2012) Production of negative ions on graphite surface in H-2/D-2 plasmas: experiments and SRIM calculations. Phys Plasmas 19:063503. doi:10.1063/1.4725188

Balden M et al (2003) Deuterium retention by implantation in carbide-doped graphites. Phys Scr T103:38–42. doi:10.1238/Physica.Topical.103a00038

Niwase K (1995) Irradiation-induced amorphization of graphite. Phys Rev B 52:15785–15798

Pugno R, Schmid K, Baldwin MJ et al (2008) Saturation in deuterium retention of CFC graphite targets exposed to beryllium-seeded plasmas on PISCES-B. J Nucl Mater 375:168–172. doi:10.1016/j.jnucmat.2007.11.007

Skinner CH, Haasz AA, Alimov VKh et al (2008) Recent advances on hydrogen retention in ITER’s plasma-facing materials: beryllium, carbon, and tungsten. Fusion Sci Technol 54:891–895

Acknowledgements

The authors are grateful to all the members of the nuclear microprobe team (LEEL, CEA Saclay) for their fruitful help and support. This work was carried out within the framework of the European Fusion Development Agreement and the French Research Federation for Fusion Studies. It was supported by the European Communities under the contract of Association between Euratom and CEA and by the ANR French agency under the Grant No. ANR-06-BLAN-0008. The views and opinions expressed herein do not necessarily reflect those of the European Commission.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bernard, E., Khodja, H., Pégourié, B. et al. Multi-technique coupling for analysis of deuterium retention in carbon fiber composite NB31. J Mater Sci 50, 7031–7042 (2015). https://doi.org/10.1007/s10853-015-9256-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9256-x