Abstract

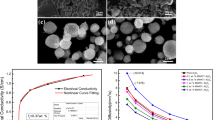

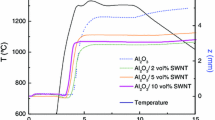

Alumina composites reinforced with multiwalled carbon nanotubes (MWCNTs) at up to 3.7 vol% are prepared by a precursor method followed by a spark plasma sintering. We systematically and quantitatively investigate the effects of acid-treatment time of the MWCNTs on not only bending strength and fracture toughness of the composites but also on the mechanical strength and dispersibility of the MWCNTs, the grain size of the alumina matrix, and the interfacial strength between MWCNT and alumina. The main objective of this study is to evaluate how these parameters influence the mechanical properties with the aid of multiple regression analysis. We demonstrate that the matrix grain size, the mechanical strength of the MWCNTs, and the interfacial strength have little impact on the mechanical properties for the composites prepared in this study. On the other hand, the dispersibility of MWCNTs has the significant influence on the mechanical properties. Both the dispersibility of the MWCNTs and the mechanical properties of the composites increase as the acid-treatment time increases up to 2 h at low MWCNT content (0.9 vol%). Conversely, at a higher amount of MWCNTs, the degradation in the mechanical properties is shown to be associated with the deterioration of MWCNTs’ dispersibility. As MWCNT agglomerates are anticipated to act as imperfections, they may override the effects of the strength of MWCNTs, matrix grain size, and interfacial strength. By means of the multiple regression analysis, we quantitatively show that improving MWCNTs’ dispersibility is one of the most important factors in enhancing the mechanical properties of MWCNT/alumina composites.

Similar content being viewed by others

References

Yu MF, Files BS, Arepalli S, Ruoff RS (2000) Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys Rev Lett 84(24):5552–5555

Yu MF, Lourie O, Dyer MJ, Moloni K, Kelly TF, Ruoff RS (2000) Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 287(5453):637–640

Mielke SL, Troya D, Zhang S, Li JL, Xiao S, Car R, Ruoff RS (2004) The role of vacancy defects and holes in the fracture of carbon nanotubes. Chem Phys Lett 390:413–420

Barber AH, Andrews R, Schadler LS, Wagner HD (2005) On the tensile strength distribution of multiwalled carbon nanotubes. Appl Phys Lett 87(20):203106

Barber AH, Kaplan-Ashiri I, Cohen SR et al (2005) Stochastic strength of nanotubes: an appraisal of available data. Compos Sci Technol 65:2380–2384

Peng B, Locascio M, Zapol P, Li S, Mielke SL, Schatz GC, Espinosa HD (2008) Measurements of near-ultimate strength for multiwalled carbon nanotubes and irradiation-induced crosslinking improvements. Nat Nanotechnol 3:626–631

Yamamoto G, Suk JW, An JH, Piner RD, Hashida T, Takagi T, Ruoff RS (2010) The influence of nanoscale defects on the fracture of multi-walled carbon nanotubes under tensile loading. Diam Relat Mater 19(7–9):748–751

Yamamoto G, Shirasu K, Nozaka Y, Sato Y, Takagi T, Hashida T (2014) Structure-property relationships in thermally annealed multi-walled carbon nanotubes. Carbon 66:219–226

Iijima S, Brabec C, Maiti A, Bernholc J (1996) Structural flexibility of carbon nanotubes. J Chem Phys 104(5):2089–2095

Falvo MR, Clary GJ, Taylor RM, Chi V, Brooks FP, Washburn S (1997) Bending and buckling of carbon nanotubes under large strain. Nature 389:582–584

Palaci I, Fedrigo S, Brune H, Kinke C, Chen M, Riedo E (2005) Radial elasticity of multiwalled carbon nanotubes. Phys Rev Lett 94(17):175502

Spitalsky Z, Tasis D, Papagelis K, Galiotis C (2010) Carbon nanotube–polymer composites: chemistry, processing, mechanical and electrical properties. Prog Polym Sci 35:357–401

Cho J, Boccaccini AR, Shaffer MSP (2009) Ceramic matrix composites containing carbon nanotubes. J Mater Sci 44(8):1934–1951. doi:10.1007/s10853-009-3262-9

Zapata-Solvas E, Gómez-García D, Domínguez-Rodríguez A (2012) Towards physical properties tailoring of carbon nanotubes-reinforced ceramic matrix composites. J Eur Ceram Soc 32:3001–3020

Laurent Ch, Peigney A, Dumortier O, Rousset A (1998) Carbon nanotubes-Fe-alumina nanocomposites. Part II: microstructure and mechanical properties of the hot-pressed composites. J Eur Ceram Soc 18:2005–2013

Peigney A, Laurent Ch, Flahaut E, Rousset A (2000) Carbon nanotubes in novel ceramic matrix nanocomposites. Ceram Int 26:677–683

Zhan G-D, Kuntz JD, Wan J, Mukherjee AK (2003) Single-wall carbon nanotubes as attractive toughening agents in alumina-based nanocomposites. Nat Mater 2:38–42

Boccaccini AR, Acevedo DR, Brusatin G, Colombo P (2005) Borosilicate glass matrix composites containing multi-wall carbon nanotubes. J Eur Ceram Soc 25(9):1515–1523

Ye F, Liu LM, Wang YJ, Zhou Y, Peng B, Meng QC (2006) Preparation and mechanical properties of carbon nanotube reinforced barium aluminosilicate glass-ceramic composites. Scr Mater 55(10):911–914

Jiang DT, Thomson K, Kuntz JD, Ager JW, Mukherjee AK (2007) Effect of sintering temperature on a single-wall carbon nanotube toughened alumina-based nanocomposite. Scr Mater 56:959–962

Yamamoto G, Omori M, Yokomizo K, Hashida T (2008) Mechanical properties and structural characterization of carbon nanotube/alumina composites prepared by precursor method. Diam Relat Mater 17(7–10):1554–1557

Yamamoto G, Omori M, Yokomizo K, Hashida T, Adachi K (2008) Structural characterization and frictional properties of carbon nanotube/alumina composites prepared by precursor method. Mater Sci Eng, B 148(1–3):265–269

Yamamoto G, Omori M, Hashida T, Kimura H (2008) A novel structure for carbon nanotube reinforced alumina composites with improved mechanical properties. Nanotechnology 19(31):315708

Estili M, Kawasaki A (2008) An approach to mass-producing individually alumina-decorated multi-walled carbon nanotubes with optimized and controlled compositions. Scr Mater 58(10):906–909

Otieno G, Koos AA, Dillon F, Wallwork A, Grobert N, Todd RI (2010) Processing and properties of aligned multi-walled carbon nanotube/aluminoborosilicate glass composites made by sol-gel processing. Carbon 48(8):2212–2217

Inam F, Yan HX, Jayaseelan DD, Pejis T, Reece MJ (2010) Electrically conductive alumina–carbon nanocomposites prepared by spark plasma sintering. J Eur Ceram Soc 30(2):153–157

Ahmad I, Cao H, Chen H, Zhao H, Kennedy A, Zhu YQ (2009) Carbon nanotube toughened aluminium oxide nanocomposites. J Eur Ceram Soc 30:865–873

Cho J, Inam F, Reece MJ, Chlup Z, Dlouhy I, Shaffer MSP, Boccaccini AR (2011) Carbon nanotubes: do they toughen brittle matrices? J Mater Sci 46(14):4770–4779. doi:10.1007/s10853-011-5387-x

Ueda N, Yamakami T, Yamaguchi T, Kitajima K, Usui Y, Aoki K, Endo M, Saito N, Taruta S (2012) Microstructure development and fracture toughness of acid-treated carbon nanofibers/alumina composites. J Ceram Soc Jpn 120(1408):560–568

Estili M, Sakka Y, Kawasaki A (2013) Unprecedented simultaneous enhancement in strain tolerance, toughness and strength of Al2O3 ceramic by multiwall-type failure of a high loading of carbon nanotubes. Nanotechnology 24(15):155702

Ahmad I, Unwin M, Cao H, Chen H, Zhao H, Kennedy A, Zhy YQ (2010) Multi-walled carbon nanotubes reinforced Al2O3 nanocomposites: mechanical properties and interfacial investigations. Compos Sci Technol 70(8):1199–1206

Wei T, Fan Z, Luo G, Wei F (2008) A new structure for multi-walled carbon nanotubes reinforced alumina nanocomposite with high strength and toughness. Mater Lett 62:641–644

Ning J, Zhang J, Pan Y, Guo J (2004) Surfactants assisted processing of carbon nanotube-reinforced SiO2 matrix composites. Ceram Int 30:63–67

Morisada Y, Miyamoto Y, Takaura Y (2007) Mechanical properties of SiC composites incorporating SiC-coated multi-walled carbon nanotubes. Int J Refract Metals Hard Mater 25:322–327

Peigney A, Garcia F, Estournès C et al (2010) Toughening and hardening in double-walled carbon nanotube/nanostructured magnesia composites. Carbon 48:1952–1960

Wang WL, Yamamoto G, Shirasu K et al (2013) Microstructure and mechanical properties of multi-walled carbon nanotube/alumina composites prepared by a novel flocculation method. In: Proceedings of ECCM 2014: 16th European conference on composite materials, Seville, Spain

Kelly A, Tyson WR (1965) Tensile properties of fibre-reinforced metals: copper/tungsten and copper/molybdenum. J Mech Phys Solids 13(6):329–350

Curtin WA (1991) Theory of mechanical properties of ceramic-matrix composites. J Am Ceram Soc 74(11):2837–2845

Li L, Xia ZH, Curtin WA, Yang YQ (2009) Molecular dynamics simulations of interfacial sliding in carbon-nanotube/diamond nanocomposites. J Am Ceram Soc 92:2331–2336

Li L, Niu JB, Xia ZH et al (2011) Nanotube/matrix interfacial friction and sliding in composites with an amorphous carbon matrix. Scr Mater 65:1014–1017

Nozaka Y, Wang W, Shirasu K et al (2014) Inclined slit-based pullout method for determining interfacial strength of multi-walled carbon nanotube–alumina composites. Carbon 78:439–445

Shaffer MSP, Fan X, Windle AH (1998) Dispersion and packing of carbon nanotubes. Carbon 36(11):1603–1612

Yamamoto G, Shirasu K, Nozaka Y et al (2014) Microstructure–property relationships in pressureless-sintered carbon nanotube alumina composites. Mater Sci Eng A 617:179–186

Xia Z, Riester L, Curtin W et al (2004) Direct observation of toughening mechanisms in carbon nanotube ceramic matrix composites. Acta Mater 52:931–944

Nozaka Y, Yamamoto G, Shirasu K et al (2013) Evaluation of mechanical properties and microstructures of multi-walled carbon nanotube/alumina composites prepared by pressureless sintering. Trans Jpn Soc Mech Eng Part A 79:764–768

Acknowledgements

The authors thank Dr. T. Miyazaki of the Technical Division, the School of Engineering, Tohoku University, for technical assistance in the TEM analysis. Dr. M. Watanabe, Industry Creation Hatchery Center, Tohoku University, is gratefully appreciated for his help in multiple regression analysis. This research was partially supported by the Grant-in-Aid for Scientific Research (S) 21226004 and Grant-in-Aid for Japan Society for the Promotion of Science (JSPS) 243582 and 2402358. This work was performed under the inter-university cooperative research program of the Advanced Research Center of Metallic Glasses, the Institute for Materials Research, Tohoku University.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shirasu, K., Yamamoto, G., Nozaka, Y. et al. Relationship between microstructure and mechanical properties in acid-treated carbon nanotube-reinforced alumina composites. J Mater Sci 50, 6688–6699 (2015). https://doi.org/10.1007/s10853-015-9223-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9223-6