Abstract

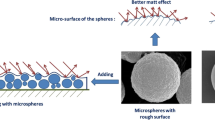

This paper describes the fabrication of porous poly(methyl methacrylate) (PMMA) and PMMA/TiO2 composite microspheres by electrospraying in a humid chamber. The effects of polymer concentration, co-solvent ratio, and relative humidity on morphology were evaluated to prepare microspheres with well-defined porous structures. Dichloromethane and hexanol were used as the solvent and co-solvent in solvent mixture for PMMA, respectively. The optimized conditions were established as 4 wt% for PMMA concentration, 10 wt% for hexanol ratio, and 60 % for relative humidity. The resultant PMMA microspheres exhibited a spherical morphology and a highly porous structure. Among the process variables, relative humidity was found to be a critical factor for the development of large surface pores. In addition, PMMA/TiO2 composite microspheres with a highly porous structure were prepared by simply mixing TiO2 nanopowders in a PMMA solution before electrospraying. Energy-dispersive X-ray spectroscopy confirmed that the TiO2 nanopowders were well distributed throughout the composite microspheres. Our results clearly indicate that porous PMMA and PMMA/TiO2 microspheres have potential uses as catalyst carriers, sensors, and in cosmetics, among other possibilities.

Similar content being viewed by others

References

Gokmen MT, Du Prez FE (2012) Porous polymer particles—a comprehensive guide to synthesis, characterization, functionalization and applications. Prog Polym Sci 37:365–405

Moon S-K, Oh M-J, Paik D-H, Ryu T-K, Park K, Kim S-E, Park J-H, Kim J-H, Choi S-W (2013) A facile method for the preparation of monodisperse beads with uniform pore sizes for cell culture. Macromol Rapid Commun 34:399–405

Choi S-W, Yeh Y-C, Zhang Y, Sung H-W, Xia Y (2010) Uniform beads with controllable pore sizes for biomedical applications. Small 6:1492–1498

Lu X, Zhang H, Ni Y, Zhang Q, Chen J (2008) Porous nanosheet-based ZnO microspheres for the construction of direct electrochemical biosensors. Biosens Bioelectron 24:93–98

Schmuhl R, Nijdam W, Sekulić J, Chowdhury SR, van Rijn CJ, van den Berg A, ten Elshof JE, Blank DH (2005) Si-supported mesoporous and microporous oxide interconnects as electrophoretic gates for application in microfluidic devices. Anal Chem 77:178–184

Qian L, Zhang H (2011) Controlled freezing and freeze drying: a versatile route for porous and micro-/nano-structured materials. J Chem Technol Biotechnol 86:172–184

Nam YS, Park TG (1999) Porous biodegradable polymeric scaffolds prepared by thermally induced phase separation. J Biomed Mater Res 47:8–17

Son HY, Lee DJ, Lee JB, Park CH, Seo M, Jang J, Kim SJ, Yoon MS, Nam YS (2014) In situ functionalization of highly porous polymer microspheres with silver nanoparticles via bioinspired chemistry. RSC Adv 4:55604–55609

Silverstein MS (2014) Emulsion-templated porous polymers: a retrospective perspective. Polymer 55:304–320

Kulinowski KM, Jiang P, Vaswani H, Colvin VL (2000) Porous metals from colloidal templates. Adv Mater 12:833–838

Krishnan V, Sasikumar S, Dass FP, Vijayaraghavan R (2010) Effect of pore forming agents on the physical characteristics and release kinetics of levofloxacin hemihydrate from floating alginate drug delivery system—an in vitro study. Trends Biomater Artif Organs 24:139–145

Xiao C-D, Shen X-C, Tao L (2013) Modified emulsion solvent evaporation method for fabricating core–shell microspheres. Int J Pharm 452:227–232

Balazs AC, Emrick T, Russell TP (2006) Nanoparticle polymer composites: where two small worlds meet. Science 314:1107–1110

Hasell T, Yang JX, Wang WX, Li J, Brown PD, Poliakoff M, Lester E, Howdle SM (2007) Preparation of polymer–nanoparticle composite beads by a nanoparticle stabilised suspension polymerization. J Mater Chem 17:4382–4386

Zhang QC, Liu J, Wang XJ, Li MX, Yang J (2010) Controlling internal nanostructures of porous microspheres prepared via electrospraying. Colloid Polym Sci 288:1385–1391

Cho EC, Hwang YK, Jeong U (2014) Functionalized raspberry-like microparticles obtained by assembly of nanoparticles during Electrospraying. Bull Korean Chem Soc 35:1784–1788

Liu B, Nakata K, Sakai M, Saito H, Ochiai T, Murakami T, Takagi K, Fujishima A (2011) Mesoporous TiO2 core-shell spheres composed of nanocrystals with exposed high-energy facets: facile synthesis and formation mechanism. Langmuir 27:8500–8508

Almería B, Deng W, Fahmy TM, Gomez A (2010) Controlling the morphology of electrospray-generated PLGA microparticles for drug delivery. J Colloid Interface Sci 343:125–133

Rodoplu D, Mutlu M (2012) Effects of electrospinning setup and process parameters on nanofiber morphology intended for the modification of quartz crystal microbalance surfaces. J Eng Fiber Fabr 7:118–123

Nezarati RM, Eifert MB, Cosgriff-Hernandez E (2013) Effects of humidity and solution viscosity on electrospun fiber morphology. Tissue Eng Part C Methods 19:810–819

Pelipenko J, Kristl J, Janković B, Baumgartner S, Kocbek P (2013) The impact of relative humidity during electrospinning on the morphology and mechanical properties of nanofibers. Int J Pharm 456:125–134

Huang Z-M, Zhang Y-Z, Kotaki M, Ramakrishna S (2003) A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol 63:2223–2253

Gao J, Wong JS-P, Hu M, Li W, Li RKY (2014) Facile preparation of hierarchically porous polymer microspheres for superhydrophobic coating. Nanoscale 6:1056–1063

Wu Y, Clark RL (2007) Controllable porous polymer particles generated by electrospraying. J Colloid Interface Sci 310:529–535

Paik D-H, Choi S-W (2014) Entrapment of protein using electrosprayed poly(d, l-lactide-co-glycolide) microspheres with a porous structure for sustained release. Macromol Rapid Commun 35:1033–1038

Gao J, Li W, Wong JS-P, Hu M, Li RKY (2014) Controllable morphology and wettability of polymer microspheres prepared by nonsolvent assisted electrospraying. Polymer 55:2913–2920

Acknowledgements

This study was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (NRF-2014R1A1A1005826), a grant from the “GRRC” Project of the Gyeonggi Provincial Government, Korea, and Amorepacific R&D Center.

Author information

Authors and Affiliations

Corresponding author

Additional information

Hyunsuk Lee and Dong-Hyun Paik have equally contributed to this article.

Rights and permissions

About this article

Cite this article

Lee, H., Paik, DH., Jeong, KY. et al. Fabrication of poly(methyl methacrylate) and TiO2 composite microspheres with controlled morphologies and porous structures by electrospraying. J Mater Sci 50, 6531–6538 (2015). https://doi.org/10.1007/s10853-015-9216-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9216-5