Abstract

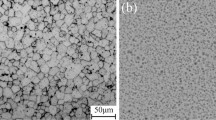

Hot flow behavior of hot isostatically processed experimental nickel-based superalloy is investigated over temperature and strain rate ranging from 1000–1200 °C and 0.001–1 s−1, respectively by carrying out constant true strain rate isothermal compression tests up to true strain of 0.69. True stress–true strain curves corrected for adiabatic temperature rise exhibited rapid strain hardening followed by flow softening behavior irrespective of temperature and strain rate regimes investigated, although anomalous flow behavior is observed at 1200 °C. Variation of peak flow stress with temperature is corroborated to the microstructural changes pertaining to the morphology and relative volume fraction of the phases present. From the experimental results, constitutive model incorporating the effects of strain rate, strain, and temperature is established to describe the hot flow behavior of investigated alloy. Dependence of peak flow stress on strain rate and temperature described by Zener–Hollomon (Z) parameter indicated increase in peak flow stress with Z. Additionally Cingara-Queen equation is employed to predict flow curve up to peak stress. The reliability of developed constitutive models is validated statistically and the results indicate reasonable agreement with experimental findings.

Similar content being viewed by others

References

Sakai T, Belyakov A, Kaibyshev R, Miura H, Jonas JJ (2014) Dynamic and post dynamic recrystallization under hot cold and severe plastic deformation condition. Prog Mater Sci 60:130–207

Faccoli M, Roberti R (2013) Study of hot deformation behaviour of 2205 duplex stainless steel through hot tension tests. J Mater Sci. doi:10.1007/s10853-013-7307-8

Guo S, Li D, Guo Q, Wu Z, Peng H, Hu J (2012) Investigation on hot workability characteristics of Inconel 625 superalloy using processing maps. J Mater Sci. doi:10.1007/s10853-012-6488-x

Aghaie-Khafri M, Golarzi N (2008) Dynamic and metadynamic recrystallization of Hastelloy X superalloy. J Mater Sci. doi:10.1007/s10853-008-2604-3

Medeiros SC, Prasad YVRK, Frazier WG, Srinivasan R (2000) Microstructural modeling of metadynamic recrystallization in hot working of IN718 alloy. Mater Sci Eng A 293:198–207

Lin YC, Chen MS (2009) Study of microstructural evolution during static recrystallization in a low alloy steel. J Mater Sci. doi:10.1007/s10853-008-3120-1

Marchattiwar A, Sarkar A, Chakravartty JK, Kashyap BP (2013) Dynamic recrystallization during hot deformation of 304 stainless steel. J Mater Eng Perform 22:2168–2175

Sheppard T, Duan X (2003) Modelling of static recrystallization by the combination of empirical models with the finite element method. J Mater Sci 38:1747–1754. doi:10.1023/A:1023283911730

Zhang JM, Gao ZY, Zhuang JY, Zhong ZY (1999) Mathematical modeling of the hot-deformation behavior of superalloy IN718. Metall Mater Trans A 30:2703–2712

Lin YC, Fang X, Wang YP (2008) Prediction of metadynamic softening in a multi-pass hot deformed low alloy steel using artificial neural network. J Mater Sci. doi:10.1007/s10853-008-2832-6

Zhao J, Ding H, Zhao W, Huang M, Wei D, Jiang Z (2014) Modelling of the hot deformation behaviour of a titanium alloy using constitutive equations and artificial neural network. Comput Mater Sci 92:47–56

Han F, Tang B, Kou H, Li J, Feng Y (2013) Cellular automata modeling of static recrystallization based on the curvature driven subgrain growth mechanism. J Mater Sci. doi:10.1007/s10853-013-7530-3

Han F, Tang B, Kou H, Cheng L, Li J, Feng Y (2014) Static recrystallization simulations by coupling cellular automata and crystal plasticity finite element method using a physically based model for nucleation. J Mater Sci. doi:10.1007/s10853-014-8031-8

Lin YC, Chen XM (2011) A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater Des 32:1733–1759

Liang R, Khan AS (1999) A critical review of experimental results and constitutive models of bcc and fcc metals over a wide range of strain rates and temperatures. Int J Plast 15:823–831

Maheshwari AK, Pathak KK, Ramakrishnan N, Narayan SP (2010) Modified Johnson–Cook material flow model for hot deformation processing. J Mater Sci. doi:10.1007/s10853-009-4010-x

Ryan ND, McQueen HJ (1990) Dynamic softening mechanisms in 304 austenitic stainless steels. Can Metall Q 29:147–162

Poliak EI, Jonas JJ (1996) A one parameter approach to determining the critical parameters for the initiation of dynamic recrystallization. Acta Metall Mater 44:127–136

Najafizadeh A, Jonas JJ (2006) Predicting the critical stress for initiation of dynamic recrystallization. ISIJ Int 46:1679–1684

Momeni A, Dehghani K, Ebrahimi GR (2011) Modeling the initiation of dynamic recrystallization using a dynamic recovery model. J Alloys Compd 509:9387–9393

Pollock TM, Tin S (2006) Nickel-based superalloys for advanced turbine engines: chemistry, microstructure and properties. J Propuls Power 22:361–374

Ducrocq C, Lasalmonie A, Honnarat Y (1988) N18, a new damage tolerant PM superalloy for high temperature turbine discs. In: Reichman S, Duhl DN, Maurer G, Antolovich S, Lund C (eds) Superalloys. TMS, Warrandale, pp 63–82

Raisson C, Davidson JH (1990) N18, a new generation PM superalloy for critical turbine components. In: Bachelet E et al (eds) High temperature materials for power engineering. Kluwer Academy, Liege, pp 1405–1416

Guedou JY, Lautridou JC, Honnorat Y (1993) N18, Powder metallurgy superalloy for disks: development and applications. J Mater Eng Perform 2:551–556

Sellars CM, Tegart WJ (1972) Hot workability. Int Metall Rev 17:1–24

Zhang J, Di H, Wang H, Mao K, Ma T, Cao Y (2012) Hot deformation behavior of Ti-15-3 titanium alloy: a study using processing maps, activation energy map, and Zener–Hollomon parameter map. J Mater Sci. doi:10.1007/s10853-012-6253-1

Zhang H, Zhang K, Lu Z, Zhao C, Yang X (2014) Hot deformation behavior and processing map of a γ′ hardened nickel based superalloy. Mater Sci Eng A 604:1–8

Li HY, Liu Y, Lu XC, Su XJ (2012) Constitutive modeling for hot deformation behavior of ZA27 alloy. J Mater Sci. doi:10.1007/s10853-012-6427-x

Cingara A, McQueen HJ (1992) New formula for calculating flow curves from high temperature constitutive data for 300 austenitic steels. J Mater Process Technol 36:31–42

Lin YC, Wen DX, Deng J, Liu G, Chen J (2014) Constitutive models for high temperature flow behaviours of a Ni-based superalloy. Mater Des 59:115–123

Monajati H, Jahazi M, Yue S, Taheri AK (2005) Deformation characteristics of isothermally forged UDIMET 720 Nickel base superalloy. Metal Mater Trans A 36:895–905

Dieter GE, Kuhn HA, Semiatin SL (2003) Handbook of workability and process design. ASM International Materials Park, Ohio

Liu Y, Hu R, Li J, Kou H, Li H, Chang H, Fu H (2009) Characterization of hot deformation behavior of Haynes230 by using processing maps. J Mater Process Technol 209:4020–4026

Wang J, Dong J, Zhang M, Xie X (2013) Hot working characteristics of nickel-base superalloy740H during compression. Mater Sci Eng A 566:61–70

Wen DX, Lin YC, Li HB, Chen XM, Deng J, Li LT (2014) Hot deformation behavior and processing map of a typical Ni-based superalloy. Mater Sci Eng A 591:183–192

Ning Y, Yao Z, Lei Y, Guo Y, Fu MW (2011) Hot deformation behavior of the post-cogging FGH4096 superalloy with fine equiaxed microstructure. Mater Charact 62:887–893

Asaro RJ, Rice JR (1977) Strain localization in ductile single crystals. J Mech Phys Solids 25:309–338

Byun TS, Hashimoto N, Farrell K (2004) Temperature dependence of strain hardening and plastic instability behaviors in austenitic stainless steels. Acta Mater 52:3889–3899

Sui F-L, Xu L-X, Chen L-Q, Liu X-H (2011) Processing map for hot working of Inconel 718 alloy. J Mater Process Technol 211:433–440

Bi Z, Zhang M, Dong J, Luo K, Wang J (2010) A new prediction model of steady state stress based on the influence of the chemical composition of nickel based superalloys. Mater Sci Eng A 527:4373–4382

Nie L, Zhang L, Zhu Z, Xu W (2013) Constitutive modeling of dynamic recrystallization kinetics and processing maps of solution and aging FGH96 superalloy. J Mater Eng Perform 22:3728–3734

Bauer A, Neumeier S, Pyczak F, Singer RF, Goken M (2012) Creep properties of different γ′ strengthened Co-base superalloys. Mater Sci Eng A 550:333–341

Wu HY, Zhu FJ, Wang SC, Wang WR, Wang CC, Chiu CH (2012) Hot deformation characteristics and strain-dependent constitutive analysis of Inconel 600 superalloy. J Mater Sci. doi:10.1007/s10853-012-6250-4

Kang FW, Zhang GQ, Sun JF, Li Z, Shen J (2008) Hot deformation behavior of a spray formed superalloy. J Mater Process Technol 204:147–151

Acknowledgements

Authors thank Dr.Amol A Gokhale, Director DMRL for permitting us to publish the work. Authors also thank Dr A K Gogia, Division Head, Aeronautical Materials Division for his constant encouragement. Authors acknowledge support rendered by members of Metal Forming & Tribology Lab, Materials Technology Division, IGCAR, Kalpakkam, India for carrying out hot compression experiments. Authors acknowledge the funding provided by Defence Research Development Organization (DRDO) for carrying out this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Satheesh Kumar, S.S., Raghu, T., Bhattacharjee, P.P. et al. Constitutive modeling for predicting peak stress characteristics during hot deformation of hot isostatically processed nickel-base superalloy. J Mater Sci 50, 6444–6456 (2015). https://doi.org/10.1007/s10853-015-9200-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9200-0