Abstract

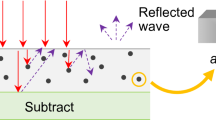

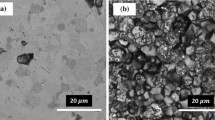

Theoretical calculations and experimental studies were carried out on polyurethane (PU)–TiO2 composite coatings on bright and matte aluminium surfaces with an aim to understand and tailor the light scattering from particles incorporated into an anodised layer for designing the optical appearance of anodised surfaces. PU matrix was selected for its matching refractive-index (n = 1.7) with anodic alumina layer. Three different TiO2 particle size distributions were dispersed in PU and spin coated onto bright high-gloss and matte caustic-etched aluminium substrates. The reflectance spectra of coated surfaces in the visible region were analysed using an integrating sphere-spectrophotometer. Data showed that the coated surfaces have a high diffuse reflectance due to the multiple scattering from TiO2 particles and the coating–substrate interface. The diffuse reflectance spectra of the coated surfaces varied weakly with TiO2 particle concentration and reached a steady state value at 1 wt% but were dependent on the substrate type used. Using Kubelka–Munk two-stream model, the scattering and absorption coefficient of TiO2 in PU was predicted. The studies presented in this paper provide insight into generating bright white-anodised aluminium surfaces based on aluminium–TiO2 composites.

Similar content being viewed by others

References

Mohagheghi S, Hatefi A, Kianvash A (2013) Effect of H3PO4 anodising variations on Al-epoxy adhesion strength. Surf Eng 29:737–742. doi:10.1179/1743294413Y.0000000158

Sheasby PG, Pinner R (2001) The surface treatment and finishing of aluminium and its alloys, vol 1, 6th edn. ASM International, Finishing Publications, pp 1–596

Grubbs CA (1995) Decorative and architectural anodizing. Met Finish 93:449–459. doi:10.1016/0026-0576(95)93394-H

Spies HJ (2010) Surface engineering of aluminium and titanium alloys: an overview. Surf Eng 26:126–134. doi:10.1179/174329409X451146

Grubbs CA (2007) Anodizing of aluminum. Met Finish 105:397–412. doi:10.1016/S0026-0576(07)80359-X

Thompson GE, Wood GC (1981) Porous anodic film formation on aluminium. Nature 290:230–232. doi:10.1038/290230a0

Sheasby PG (1990) The weathering of anodized aluminium. Alum 2000:8–28

Selvam M (2011) Colouring of anodised aluminium by electroless method. Surf Eng 27:711–718. doi:10.1179/1743294411Y.0000000022

Rezagholi H, Zangeneh-Madar K, Mirjani M, Ahangarkani M (2014) Study on electropolished/anodised aluminium foil before and after dyeing. Surf Eng 30:165–171. doi:10.1179/1743294413Y.0000000243

Burresi M, Cortese L, Pattelli L et al (2014) Bright-white beetle scales optimise multiple scattering of light. Sci Rep 4:6075. doi:10.1038/srep06075

DuPont (2007) DuPont™ Ti-pure titanium dioxide—titanium dioxide for coatings

Yerokhin AL, Nie X, Leyland A et al (1999) Plasma electrolysis for surface engineering. Surf Coat Technol 122:73–93. doi:10.1016/S0257-8972(99)00441-7

Curran JA, Clyne TW (2005) Thermo-physical properties of plasma electrolytic oxide coatings on aluminium. Surf Coat Technol 199:168–176. doi:10.1016/j.surfcoat.2004.09.037

Bagheri S, Guagliano M (2009) Review of shot peening processes to obtain nanocrystalline surfaces in metal alloys. Surf Eng 25:3–14. doi:10.1179/026708408X334087

Priestner R, Priestner DM (1991) Importance of substrate in surface engineering. Surf Eng 7:53–59

Gudla VC, Jensen F, Simar A et al (2015) Friction stir processed Al–TiO2 surface composites: anodising behaviour and optical appearance. Appl Surf Sci 324:554–562. doi:10.1016/j.apsusc.2014.10.151

Diebold U (2003) The surface science of titanium dioxide. Surf Sci Rep 48:53–229. doi:10.1016/S0167-5729(02)00100-0

Winkler J (2013) Titanium dioxide: production, properties and effective usage, 2nd edn. Vincentz Network GmbH & C, pp 1–152

Yao JK, Huang HL, Ma JY et al (2009) High refractive index TiO2 film deposited by electron beam evaporation. Surf Eng 25:257–260. doi:10.1179/026708408X329498

Dai WX, Chen X, Li E et al (2009) Influence of pH value of TiO2 sol on surface gloss of corresponding TiO2 film coated on ceramic tiles. Surf Eng 25:106–110. doi:10.1179/174329408X326498

Khan I, Leach J, Wilkins N (1966) The thickness and optical properties of films of anodic aluminium oxide. Corros Sci 6:483–497. doi:10.1016/S0010-938X(66)80065-3

Pastore GF (1985) Transmission interference spectrometric determination of the thickness and refractive index of barrier films formed anodically on aluminum. Thin Solid Films 123:9–17. doi:10.1016/0040-6090(85)90036-7

Thornton JT (2000) Metal surface investigation by scanning probe microscopy. Surf Eng 16:287–293. doi:10.1179/026708400101517224

Johnson RA, Miller I, Freund JE (2011) Miller & Freund’s probability and statistics for engineers. Prentice Hall, Upper Saddle River, pp 1–544

Murphy AB (2006) Modified Kubelka–Munk model for calculation of the reflectance of coatings with optically-rough surfaces. J Phys D Appl Phys 39:3571–3581. doi:10.1088/0022-3727/39/16/008

Kubelka P, Munk F (1931) An article on optics of paint layers. Z Tech Phys 12:593–601

Auger JC, Barrera RG, Stout B (2003) Scattering efficiency of clusters composed by aggregated spheres. J Quant Spectrosc Radiat Transf 79–80:521–531. doi:10.1016/S0022-4073(02)00305-9

Bohren CF, Huffman DR (2004) Absorption and scattering of light by small particles. Wiley-VCH Verlag, pp 1–530

Vargas WE, Niklasson GA (1997) Generalized method for evaluating scattering parameters used in radiative transfer models. J Opt Soc Am A 14:2243–2252. doi:10.1364/JOSAA.14.002243

Palik ED (1997) Refractive index, handbook of optical constants of solids. In: Palik ED (ed) Handbook of optical constants of solids. Academic, Burlington, pp 5–114

Asbeck WK, Van Loo M (1949) Critical pigment volume relationships. Ind Eng Chem 41:1470–1475. doi:10.1021/ie50475a042

Bierwagen GP, Rich DC (1983) The critical pigment volume concentration in latex coatings. Prog Org Coat 11:339–352. doi:10.1016/0033-0655(83)85007-9

Canulescu S, Rechendorff K, Borca CN et al (2014) Band gap structure modification of amorphous anodic Al oxide film by Ti-alloying. Appl Phys Lett 104:121910. doi:10.1063/1.4866901

Van Gils S, Mast P, Stijns E, Terryn H (2004) Colour properties of barrier anodic oxide films on aluminium and titanium studied with total reflectance and spectroscopic ellipsometry. Surf Coat Technol 185:303–310. doi:10.1016/j.surfcoat.2004.01.021

Acknowledgements

The authors would like to thank Kai Dirscherl, Danish Fundamental Metrology, for help with the AFM measurements. Mette Larsen, Chemical Engineering Dept., DTU is thanked for help with the particle size analysis. The Danish National Advanced Technology Foundation is gratefully acknowledged for the financial funding. The ODAAS project partners are acknowledged for their help.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gudla, V.C., Johansen, V.E., Canulescu, S. et al. Simulation of reflectance from white-anodised aluminium surfaces using polyurethane–TiO2 composite coatings. J Mater Sci 50, 4565–4575 (2015). https://doi.org/10.1007/s10853-015-9005-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9005-1