Abstract

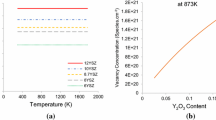

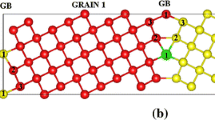

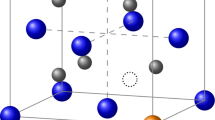

A model based on the effect of a modest applied dc electric field on grain growth is proposed for the contribution of the space charge to the grain boundary (GB) energy in 3 mol % yttria-stabilized zirconia (3 YSZ). The model considers that the total GB energy \( \gamma_{\text{b}}^0 \) (the capillary driving force for grain growth) consists of three major components: (a) \( \gamma_{\text{b}}^\varSigma \) due to the misorientation between neighboring grains, (b) \( \gamma_{\text{b}}^{\text{s}} \) due to the size misfit between the segregated solute and the solvent cations, and (c) \( \gamma_{\text{b}}^{\text{e}} \) the electrostatic (space charge) component, which results from the segregation of the aliovalent yttrium ions to the grain boundaries. The former two components combined comprise 40 % of the total GB energy in 3 YSZ and the electrostatic component 60 %. Based on the model, the calculated magnitudes of the three components were in qualitative accord with theoretical considerations and with values reported in the literature. A reduction in \( \gamma_{\text{b}}^{\text{e}} , \) and in turn in \( \gamma_{\text{b}}^0 , \) results from the bias exerted by the applied field on the space charge potential that occurs with the segregation of the yttrium ions to the grain boundaries. The observed reduction of grain growth in 3 YSZ by an applied electric field is attributed mainly to the reduction in \( \gamma_{\text{b}}^{\text{e}} \) by the field.

Similar content being viewed by others

References

Kingery WD, Bowen HK, Uhlmann DR (1996) Introduction to ceramics, 2nd edn. Wiley, New York

Yang Di, Conrad H (1997) Influence of an electric field on the superplastic deformation of 3Y-TZP. Scr Mater 36:1431–1435

Ghosh S, Chokshi AH, Lee P, Raj R (2009) A huge effect of weak electric fields on grain growth in zirconia. J Am Ceram Soc 92:1856–1859

Conrad H, Yang Di (2011) Dependence of the sintering rate and related grain size of yttria-stabilized zirconia (3Y-TZP) on the strength of an applied DC electric field. Mater Sci Eng A 528:8523–8529

Conrad H (2012) Retardation of grain growth in nanocrystalline zirconia by an electric field. Emerg Mater Res Inst Civil Eng 1:11–16

Starnes S, Conrad H (2008) Grain size distribution in ultrafine-grained yttria-stabilized zirconia deformed without and with an electric field. Scr Mater 59:1115–1118

Obare J, Griffin WD, Conrad H (2012) Effect of heating rate and DC electric field on the grain size distribution in fully-sintered zirconia polycrystals stabilized with 3 mol% yttria (3Y-TZP). J Mater Sci 47:5141–5147. doi:10.1007/s10853-012-6391-5

Winnubst AA, Kroot PJM, Burggraaf AJ (1983) AES/STEM grain boundary analysis of stabilized zirconia ceramics. J Phys Chem Solids 44:955–960

Hwang S-L, Chen I-W (1990) Grain size control of tetragonal zirconia polycrystals using the space charge concept. J Am Ceram Soc 73:3269–3277

Theunissen GSAM, Winnubst AJA, Burggraaf AJ (1992) Surface and grain boundary analysis of doped zirconia ceramics studied by AES and XPS. J Mater Sci 27:5057–5066. doi:10.1007/BF01105274

Stemmer S, Vdeugels J, Vand der Beist O (1998) Grain boundary segregation in high-purity, yttria-stabilized tetragonal zirconia polycrystals (Y-TZP). J Eur Ceram Soc 18:1565–1570

Hines JA, Ikuhara Y, Chokshi AH, Sakuma T (1998) The influence of trace impurities on the mechanical characteristics of a superplastic 2 mol% yttria stabilized zirconia. Acta Mater 46:5557–5568

Dickey EC, Fan Z, Pennyeook SJ (2001) Structure and chemistry of yttria-stabilized cubic-zirconia symmetric tilt grain boundaries. J Am Ceram Soc 84:1361–1368

Flewitt PEJ, Wild RK (2001) Grain boundaries: their microstructure and chemistry. Wiley, Chichester

Matsui K, Yashida H, Ikuhara Y (2008) Grain boundary structure and microstructure development mechanism in 2–8 mol% yttria-stabilized zirconia polycrystals. Acta Mater 56:1315–1325

Chaim R (2008) Activation energy and grain growth in nanocrystalline Y-TZP ceramics. Mater Sci Eng A 486:439–446

Cahn JW (1962) The impurity-drag effect in grain boundary motion. Acta Metall 10:789–798

Yan MF, Cannon R, Bowen H (1977) Grain boundary migration in ceramics. In: Fulrath RM, Pask JA (eds) Ceramic Microstructures, II processing, Westview Press, Boulder, pp 276–307

Wang J, Yang Di, Conrad H (2013) Transient-regime grain growth in nanocrystalline yttria-stabilized zirconia annealed without and with a DC electric field. Scr Mater 69:351–353

Gottstein G, Shvindlerman LS (1999) Grain boundary migration in metals. CRC Press, New York, p 112

Yan MF, Cannon RM, Bowen HK (1983) Space charge, electric field, and dipole contributions to equilibrium solute segregation at interfaces. J Appl Phys 54:764–776

Eshelby JD (1956) The continuum theory of lattice defects. In: Seitz F, Turnbull D (eds) Solid state physics. Academic Press, New York

Eshelby JD (1957) Determination of the elastic field of an ellipsoidal inclusion and the related problems. Proc R Soc Lond A 241:376–396

Tsoga A, Nikolopoulos P (1996) Surface and grain boundary energies in yttria-stabilized zirconia (YSZ-8 mol %). J Mater Sci 31:5409–5413. doi:10.1007/BF01159310

Verkerk MJ, Middelhuis BJ, Burgraff AJ (1982) Effect of grain boundaries on the conductivity of high-purity ZrO2–Y2O3 ceramics. Solid State Ionics 6:159–170

Guo X, Maier J (2001) Grain boundary blocking effect in zirconia: a Schottky barrier analysis. J Electrochem Soc 148:E121–E126

Guo X (2001) Defect structure modification in zirconia by alumina. Phys Stat Sol (a) 183:261–271

Guo X, Sigle W, Fleig J, Maier J (2002) Role of space charge in the grain boundary blocking effect in doped zirconia. Solid State Ionics 154–155:555–561

Guo X, Zhang Z (2003) Grain size dependent grain boundary defect structure: case of doped zirconia. Acta Mater 51:2539–2547

Bingham D, Tasker PW, Cormack AN (1989) Simulated grain-boundary structures and ionic conductivity in tetragonal zirconia. Phil Mag A 60:1–14

Kingery WD (1974) Plausible concepts necessary and sufficient for interpretation of ceramic grain-boundary phenomena: I. Grain-boundary characteristics, structure and electrostatic potential. J Am Ceram Soc 57:1–8

Ikeda JA, Chiang Y-M (1993) Space charge segregations at grain boundaries in titanium oxide: I. Relationship between lattice defect chemistry and space charge potential. J Am Ceram Soc 76:2437–2446

Huey BD, Lisjak D, Bonnell DA (1999) Nanometer-scale variations in interface potential by scanning probe microscopy. J Am Ceram Soc 82:1941–1944

Han J-H, Kim D-Y (2001) Interactions and chemistry of defects at the grain boundaries of ceramics. J Am Ceram Soc 84:539–550

Guo X, Wasser R (2006) Electrical properties of the grain boundaries of oxygen ion conductors: acceptor-doped zirconia and ceria. Progr Mater Sci 51:151–210

Wang J, Du A, Yang D, Raj R, Conrad H (2013) Grain boundary resistivity of yttria-stabilized zirconia at 1400°C. J Ceram Article ID 370603:1–4

Wang J, Conrad H (2013) Grain boundary resistivity in yttria-stabilized zirconia. In: Bansai NP et al (eds) Processing and properties of advanced ceramics and composites, vol 240. Wiley, New York, pp 175–188

Acknowledgements

This research was funded by NSF Grant No. DMR-1002751, Dr. Lynnette Madsen, Manager Ceramics Program, Materials Science Division. The authors wish to thank Dr. Di Yang and Ms. A. H. Du for their contributions to the grain size measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Conrad, H. Contribution of the space charge to the grain boundary energy in yttria-stabilized zirconia. J Mater Sci 49, 6074–6080 (2014). https://doi.org/10.1007/s10853-014-8331-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8331-z