Abstract

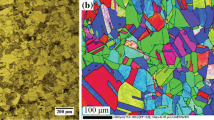

In this paper, microstructure and texture development in a Fe–24Ni–0.3C metastable austenitic steel processed by accumulative roll bonding (ARB) and subsequent annealing was studied. Microstructural observations and crystallographic analysis were carried out by FE-SEM/EBSD. The results showed that elongated ultrafine-grained austenite having 300 nm in thickness surrounded by high angle boundaries was obtained after 6 cycles of the ARB process. It was found that 1-cycle ARB-processed specimen exhibited Copper ({112} 〈111〉) component as main texture, while by increasing the number of ARB cycles, it deviated to S component ({123} 〈634〉) at 2 cycles or Brass component ({110} 〈112〉) at 6-cycle. Annealing of 6-cycle ARB-processed specimen at 873 K for 1.8 ks resulted in the formation of an austenite with mean grain size of 2.5 µm having strong Cube recrystallization texture ({100} 〈001〉).

Similar content being viewed by others

References

Valiev RZ, Zehetbauer MJ, Estrin Y, Höppel HW, Ivanisenko Y, Hahn H, Wilde G, Roven HJ, Sauvage X, Langdon TG (2007) The innovation potential of bulk nanostructured materials. Adv Eng Mater 9:527–533

Tsuji N (2007) Unique mechanical properties of nanostructured metals. J Nanosci Nanotechnol 7:3765–3770

Saito Y, Tsuji N, Utsunomiya H, Sakai T (1999) Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process. Acta Mater 47:579–583

Valiev RZ, Krasilnikov NA, Tsenev NK (1991) Plastic deformation of alloys with submicron-grained structure. Mater Sci Eng A 137:35–40

Horita Z, Smith DJ, Furukawa M, Nemoto N, Valiev RZ, Langdon TG (1996) An investigation of grain boundaries in submicrometer-grained Al–Mg solid solution alloys using high-resolution electron microscopy. J Mater Res 11:1880–1890

Richert M, Liu Q, Hansen N (1999) Microstructural evolution over a large strain range in aluminium deformed by cyclic-extrusion–compression. Mater Sci Eng A 260:275–283

Park KT, Kwon HJ, Kim WJ, Kim YS (2001) Microstructural characteristics and thermal stability of ultrafine grained 6061 Al alloy fabricated by accumulative roll bonding process. Mater Sci Eng A 316:145–152

Slamova M, Homola P, Karlik M (2007) Thermal stability of twin-roll cast Al–Fe–Mn–Si sheets accumulative roll bonded at different temperatures. Mater Sci Eng A 462:106–110

Huang X, Tsuji N, Hansen N, Minamino Y (2002) Microtexture of lamellar structures in Al heavily deformed by accumulative roll-bonding (ARB). Mater Sci Forum 408–412:715–720

Kim HW, Kang SB, Tsuji N, Minamino Y (2005) Deformation textures of AA8011 aluminum alloy sheets severely deformed by accumulative roll bonding. Metall Mater Trans A 36:3151–3163

Kamikawa N, Tsuji N, Huang X, Hansen N (2006) Quantification of annealed microstructures in ARB processed aluminum. Acta Mater 54:3055–3066

Chowdhury SG, Dutta A, Ravikumar B, Kumar A (2006) Textural evolution during accumulative roll bonding of an Al–Li alloy. Mater Sci Eng A 428:351–357

Huang CX, Yang G, Wang C, Zhang ZF, Wu SD (2011) Mechanical behaviors of ultrafine-grained 301 austenitic stainless steel produced by Equal-Channel Angular Pressing. Metall Mater Trans A 42A:2061–2071

Hansen N, Juul Jensen D (1994) Grain subdivision during deformation of polycrystalline aluminum. Mater Sci Forum 156–157:1211–1218

Tsuji N, Saito Y, Utsunomiya H, Tanigawa S (1999) Ultra-fine grained bulk steel produced by accumulative roll-bonding (ARB) process. Scripta Mater 40:795–800

Hansen N, Juul Jensen D (1999) Development of microstructure in FCC metals during cold work. Philos Trans R Soc Lond A 357:1447–1469

Hansen N (2001) New discoveries in deformed metals. Metall Mater Trans A 32A:2917–2935

Leffers T, Ray RK (2009) The brass-type texture and its deviation from the copper-type texture. Prog Mater Sci 54:351–396

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena. Elsevier, Boston

Acknowledgements

This study was done during Hamidreza Jafarian’s stay in Dept. of Materials Science & Engineering Kyoto University, which was supported by the Ministry of Science, Research and Technology (MSRT) of Iran. The support is gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jafarian, H., Eivani, A. Texture development and microstructure evolution in metastable austenitic steel processed by accumulative roll bonding and subsequent annealing. J Mater Sci 49, 6570–6578 (2014). https://doi.org/10.1007/s10853-014-8254-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8254-8