Abstract

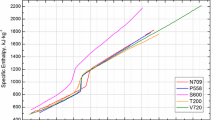

This work investigates the temperature-dependent thermal conductivity of the heat-treatable steels C45, 40CrMnMo7, and X42Cr13 in a high-tempered condition. The results reveal that the temperature-dependent evolution of the thermal conductivity is strongly influenced by alloying composition. Furthermore, not only the thermal diffusivity but also the specific isobaric heat capacity has a major impact on the resulting thermal conductivity at higher temperatures. The results are discussed with respect to the resulting microstructures and under consideration of Calphad calculations. The results are relevant for the thermal design of tools, particularly those used for high-pressure die casting.

Similar content being viewed by others

References

Anderson MJ, McGuire K, Zante RC, Ion WJ, Rosochowski A, Brooks JW (2013) Identifying the dominant failure mode in the hot extrusion tooling used to forge nickel based superalloy. J Mater Process Technol 213(1):111

Firrao D, Matteis P, Russo Spena P, Gerosa R (2013) Influence of the microstructure on fatigue and fracture toughness properties of large heat-treated mold steels. Mater Sci Eng A 559:371–383

Valls I, Casas R, Rodriguez N, Paar U (2010) Benefits from using high thermal conductivity tool steels in the hot forming of steels. La Metallurgia Italiana 11–12:23–28

Klobcar D, Tusek J, Taljat B (2008) Thermal fatigue of materials for die-casting tooling. Mater Sci Eng A 472:198–207

Valls I, Casas B, Rodriguez N (2009) Importacce of tool material thermal conductivity. In: Beiss P, Broeckmann C, Franke S, Keysselitz B (eds) The die longevity and product quality in HPDC. in Tool steels - deciding factor in worldwide production, vol 1. Mainz, Aachen, pp 127–140

Hamasaiid A, Valls I, Heid R, Eibisch H (2012) A comparative experimental study on the use of two hot work tool steels for high pressure die casting of aluminum alloys: High thermal conductivity HTCS\(\textregistered \) and conventional 1.2343 (AISI 11). In: Leitner H, Kranz R, Tremmel A (eds) TOOL 2012. Verlag Gutenberghaus, Knittelfeld, pp 153–161

Zhang B, Chen W, Poirier DR (2000) Effect of solidification cooling rate on the fatigue life of A356.2-T6 cast aluminium alloy. Fatigue & Fracture of Engineering Materials & Structures 23(5):417–423

Hill H (2011) Neuartige Metallmatrixverbundwerkstoffe (MMC) zur Standzeiterhöhung verschleißbeanspruchter Werkzeuge in der polymerverarbeitenden Industrie. Eigenverlag des Lehrstuhls Werkstofftechnik der Ruhr-Universität Bochum, Bochum

Liu XF, Liu FQ, Yu BH, Bi C, Zhang B (2012) Pelletization quality simulation for operation uncertainty of die-plate based on liquid-solid-liquid coupling model. Adv Mater Res 557–559:2266–2273

Geiger M, Merklein M, Hoff C (2005) Basic Investigations on the Hot Stamping Steel 22MnB5. Adv Mater Res 6–8:795–804

Lenze FJ, Sikora S, Banik J, Straube O (2009) Hot forming-new potentials for innovative manufacturing. Steel Grips 7(6):428–432

Wilzer JJ, Lüdtke FS, Weber S, Theisen W (2013) The influence of heat treatment and resulting microstructures on the thermophysical properties of martensitic steels. J Mater Sci 48(24):8483–8492. doi:10.1007/s10853-013-7665-2

Berns H, Theisen W (2008) Eisenwerkstoffe: Stahl und Gusseisen, 4th edn. Springer, Berlin

Kohlhaas R, Kierspe W (1965) Wärmeleitfähigkeit von reinem Eisen und einigen ferritischen und austenitischen Stählen zwischen der Temperatur der flüssigen Luft und Raumtemperatur. Archiv für das Eisenhüttenwesen 36(4):301–309

Richter F, Kohlhaas R (1965) Wärmeleitfähigkeit des reinen Eisens zwischen -180 und 1000\(^{\circ }\)C unter besonderer Berücksichtigung von Phasenumwandlungen. Archiv für das Eisenhüttenwesen 36(11):827–833

Lange KW (1970) Zur Temperaturleitfähigkeit des Eisens. Archiv für das Eisenhüttenwesen 41(6):559–562

Bungardt K, Spyra W (1965) Wärmeleitfähigkeit unlegierter und legierter Stähle und Legierungen bei Temperaturen zwischen 20 und 700\(^{\circ }\)C. Archiv für das Eisenhüttenwesen 36(4):257–267

Richter F (1973) ie wichtigsten physikalischen Eigenschaften von 52 Eisenwerkstoffen: Mitteilung aus dem Forschungsinstitut der Mannesmann AG, vol Heft 8. Stahleisen, Düsseldorf

Richter F (1983) Physikalische eigenschaften von Stählen und ihre temperaturabhängigkeit: polynome und graphische darstellungen, vol Heft 10. Stahleisen, Düsseldorf

Maurer E (1936) Wärmeleitfähigkeit von chromhaltigen Stählen bei hohen Temperaturen. Archiv für das Eisenhüttenwesen 10(4):145–155

Esser H, Eilender W, Pütz E (1938) Die Wärmeleitfähigkeit von technisch reinem Eisen und verschiedenen Stählen. Archiv für das Eisenhüttenwesen 11(12):619–622

Terada Y, Ohkubo K, Mohri T, Suzuki T (2002) Effects of alloying additions on thermal conductivity of ferritic iron. ISIJ Int 42(3):322–324

Mayerhofer J (2012) Aspect of machining advanced mould and die steels. In: Leitner H, Kranz R, Tremmel A (eds) TOOL 2012. Verlag Gutenberghaus, Knittelfeld, pp 325–333

Berns H, Kettel J (1976) Ermittlung der Zusammensetzung von Grundmasse und Carbiden durch Rückstandsisolierung bei ledeburitischen Chromstählen. Archiv für das Eisenhüttenwesen 47(6):391–393

P. Shi, B. Sundmann. Tcc™: Thermo-calc\(\textregistered \) software, Stockholm (2010)

Hust JG (1983) Thermal conductivity and thermal diffusivity. In: Reed RP, Clark AF (eds) Materials at low temperatures. American Society for Metals, Metals Park, pp 133–161

Tritt T, Weston D (2010) Measurement techniques and considerations for determining thermal conductivity of bulk materials. In: Tritt T (ed) Thermal conductivity. Springer, New York, pp 187–203

Patterson J, Morris E (1994) Measurement of absolute water density, 1\(^{\circ }\)C to 40\(^{\circ }\)C. Metrologia 31(4):277–288

Parker WJ, Jenkins RJ, Butler CP, Abbott GL (1961) Flash method of determining thermal diffusivity, heat capacity, and thermal conductivity. J Appl Phys 32(9):1679–1684

Kaschnitz E, Ebner R (2007) Thermal diffusivity of the aluminum alloy Al-17Si-4Cu (A390) in the solid and liquid states. Int J Thermophys 28(2):711

Kaschnitz E, Küblböck M (2008) Thermal diffusivity of the aluminum alloy Al-5Mg-2Si-Mn (Magsimal-59) in the solid and liquid states. High Temp High Press 37:221–230

Pepperhoff W, Acet M (2001) Constitution and magnetism of iron and its alloys. Springer, Berlin

Krauss G, Grossmann MA (1980) Principles of heat treatment of steel. American Society for Metals, Metals Park. http://www.worldcat.org/oclc/6357331

Porter D, Easterling KE, Sherif M (2009) Phase transformations in metals and alloys, 3rd edn. CRC Press, Boca Raton

Bjärbo A, Hättestrand M (2001) Complex carbide growth, dissolution, and coarsening in a modified 12 pct chromium steel: an experimental and theoretical study. Metall Mater Trans A 32:19–27

Schneider A, Inden G (2005) Simulation of the kinetics of precipitation reactions in ferritic steels. Acta Materialia 53:519–531

Rokhmanov NY, Sirenko AF, Bakharev SA (1997) Thermal expansion of cementite in hypereutectoid iron-carbon alloy. Met Sci Heat Treat 39(1–2):7–10

Friedrich C, Berg G, Broszeit E, Berger C (1997) Datensammlung zu Hartstoffeigenschaften. Materialwissenschaft und Werkstofftechnik 28:59–76

Weiss RJ, Tauer KJ (1956) Components of the thermodynamic functions of iron. Phys Rev 102(6):1490–1495

Braun M, Kohlhaas R (1965) Die spezifische Wärme von Eisen, Kobalt und Nickel im Bereich hoher Temperaturen. Physica Status Solidi 12(1):424–429

Cezairliyan A, Ho CY, Anderson AC (1988) Specific heat of solids, vol I–2. Hemisphere Publishing Corporation, New York

Richter F, Born L (1984) Die spezifische Wärmekapazität von metallischen Werkstoffen: 1. Teil: Ferritische, umwandlungsfähige Stähle. Archiv für das Eisenhüttenwesen 55(3):127–132

Olsson P, Abrikosov IA, Wallenius J (2006) Electronic origin of the anomalous stability of Fe-rich bcc Fe-Cr alloys. Phys Rev B 73:104416

Lavrentiev MY, Dudarev SL, Nguyen-Manh D (2011) Magnetic cluster expansion model for high-temperature magnetic properties of iron and iron-chromium alloys. J Appl Phys 109:07E123

Xiong W, Hedström P, Selleby M, Odqvist J, Thuvander M, Chen Q (2011) An improved thermodynamic modeling of the Fe–Cr system down to zero kelvin coupled with key experiments. CALPHAD 35:355–366

Lavrentiev MY, Mergia K, Gjoka M, Nguyen-Manh D (2012) Magnetic cluster expansion simulation and experimental study of high temperature magnetic properties of Fe–Cr alloys. J Phys Condense Matter 24:326001

Ruban AV, Razumovskiy VI (2012) First-principles based thermodynamic model of phase equilibria in bcc Fe–Cr alloys. Phys Rev B 86:174111

Reed RP, Clark AF (eds.) (1983) Materials at low temperatures. American Society for Metals, Metals Park. http://www.worldcat.org/oclc/9726458

The American Society for Testing and Materials (2001) Standard test method for thermal diffusivity by the flash method, 1st edn. ASTM, West Conshohocken

Carslaw HS, Jaeger JC (1986) Conduction of heat in solids, 2nd edn. Clarendon Press, Oxford

Venkanna BK (2010) Fundamentals of heat and mass transfer. PHI Learning Private Limited, New Delhi

Bürgel R, Maier HJ, Niendorf T (2011) Handbuch Hochtemperatur-Werkstofftechnik: Grundlagen, Werkstoffbeanspruchungen, Hochtemperaturlegierungen und -beschichtungen, 4th edn. Vieweg + Teubner, Wiesbaden

Gavriljuk VG, Shanina BD, Berns H (2000) On the correlation between electron structure and short range atomic order in iron-based alloys. Acta Materialia 48:3879–3893

Korzhavyi PA, Ruban AV (2009) Electronic structure and effective chemical and magnetic exchange interactions in bcc Fe-Cr alloys. Phys Rev B 79(5): 054202 (1–16)

Fert A, Campell IA (1968) Two-current conduction in nickel. Phys Rev Lett 21(16):1190–1192

Fert A (2008) Ursprung, Entwicklung und Zukunft der Spintronik: Nobel-Vortrag. Angewandte Chemie 120:6042–6054

Bäcklund NG (1961) An experimental investigation of the electrical and thermal conductivity of iron and some dilute iron alloys at temperatures above 100 K. J Phys Chem Solids 20(1/2):1–16

Yang J (2010) Theory of Thermal Conductivity. In: Tritt T (ed) Thermal conductivity. Springer, New York, pp 1–20

Uher C (2010) Thermal Conductivity of Metals. In: Tritt T (ed) Thermal conductivity. Springer, New York, pp 22–88

Kittel C (2006) Einführung in die Festkörperphysik, 14th edn. Oldenbourg, München

Hofmann JA, Paskin A, Tauer KJ, Weiss RJ (1956) Analysis of ferromagnetic and antiferromagnetic second-order transitions. J Phys Chem Solids 1:45–60

Acknowledgements

The authors gratefully acknowledge financial support from the Deutsche Forschungsgemeinschaft (DFG) under support code TH531/13-1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wilzer, J., Küpferle, J., Weber, S. et al. Temperature-dependent thermal conductivities of non-alloyed and high-alloyed heat-treatable steels in the temperature range between 20 and 500 °C. J Mater Sci 49, 4833–4843 (2014). https://doi.org/10.1007/s10853-014-8183-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8183-6