Abstract

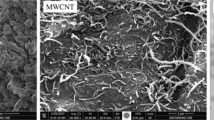

The goal of the present work is the refinement of the pore morphology of aluminum integral foam castings. Integral foam molding, a modified high pressure die casting process, is used where a mixture of melt and blowing agent particles (magnesium hydride, MgH2) is injected at high velocity into a permanent steel mold. At the mold surface, decomposition of the blowing agent and pore formation is suppressed due to the high solidification rate whereas solidification of the core is much slower allowing blowing agent decomposition, pore nucleation, and growth. Blowing agent particles not only act as gas suppliers but also represent pore nuclei. Thus, microcellular foam cores can be attained by increasing the number of MgH2 particles. But increasing the number of powder particles by powder milling strongly decreases the flowability and strong particle agglomeration as a result of the increasing cohesive forces leads to inhomogeneous foams. Flowability of the powder can be restored by coating it with SiO2-nano-particles resulting in a homogeneous microcellular foam morphology.

Similar content being viewed by others

References

Körner C, Singer RF (2000) Adv Eng Mater 2:159

Nosko M, Simančik F, Florek R (2010) Mater Sci Eng, A 527:5900

Bin J, Zejun W, Naiqin Z (2007) Scr Mater 56:169

Andrews EW, Gioux G, Onck P, Gibson LJ (2001) Int J Mech Sci 43:701

Wen CE, Yamada Y, Shimojima K, Chino Y, Hosokawa H, Mabuchi M (2004) Mater Lett 58:357

García-Moreno F, Mukherjee M, Solórzano E, Banhart J (2010) Int J Mater Res 101:1134

Körner C, Hirschmann M, Bräutigam V, Singer RF (2004) Adv Eng Mater 6:385

Körner C (2008) Integral foam molding of light metals: technology, foam physics and foam simulation. Springer-Verlag, Berlin, Heidelberg

Hartmann J, Trepper A, Körner C (2011) Adv Eng Mater 13:1050

Linsenbühler M, Wirth K-E (2005) Powder Technol 158:3

Campbell C, Keaveny B (2011) In: Houson I (ed) Process understanding: for scale-up and manufacture of active ingredients. Wiley-VCH, Weinheim

Körner C, Arnold M, Singer RF (2005) Mater Sci Eng, A 396:28

Stanzick H, Wichmann M, Weise J, Helfen L, Baumbach T, Banhart J (2002) Adv Eng Mater 4:814

Acknowledgements

The authors acknowledge the financial support of the Deutsche Forschungsgemeinschaft (DFG), Grant No. KO 1984/5-2.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hartmann, J., Blümel, C., Ernst, S. et al. Aluminum integral foam castings with microcellular cores by nano-functionalization. J Mater Sci 49, 79–87 (2014). https://doi.org/10.1007/s10853-013-7668-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7668-z