Abstract

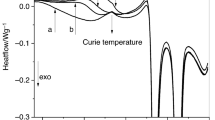

Grain boundary wetting transitions were previously observed in the Al–Mg system. The melting of as-cast Al–5 wt% Mg and Al–10 wt% Mg alloys was studied by the differential scanning calorimetry. The asymmetric shape of the melting curve permitted the observation of the thermal effect of grain boundary wetting. The difference in the shape of the melting curve for the two studied alloys is explained by the different temperature dependence of the fraction of completely wetted grain boundaries.

Similar content being viewed by others

References

Furukawa M, Horita Z, Nemoto M, Valiev RZ, Langdon TG (1996) Acta Mater 44:4619

Mazilkin AA, Straumal BB, Rabkin E, Baretzky B, Enders S, Protasova SG, Kogtenkova OA, Valiev RZ (2006) Acta Mater 54:3933

Roven HJ, Liu M, Murashkin MY, Valiev RZ, Kilmametov AR, Ungár T, Balogh L (2008) Mater Sci Forum 604:179

Lee Z, Zhou F, Valiev RZ, Lavernia EJ, Nutt SR (2004) Scripta Mater 51:209

Straumal BB, López G, Mittemeijer EJ, Gust W, Zhilyaev AP (2003) Def Diff Forum 216:307

Straumal BB, Baretzky B, Kogtenkova OA, Straumal AB, Sidorenko AS (2010) J Mater Sci 45:2057. doi:10.1007/s10853-009-4014-6

German RM, Suri P, Park SJ (2009) J Mater Sci 44:1

Watson EB (1982) Geology 10:236

Laporte D, Watson EB (1995) Chem Geol 124:161

Gabrisch H, Dahmen U, Johnson E (1998) Microsc Res Tech 42:241

Felberbaum L, Rossoll A, Mortensen A (2005) J Mater Sci 40:3121. doi:10.1007/s10853-005-2673-5

Empl D, Felberbaum L, Laporte V, Chatain D, Mortensen A (2009) Acta Mater 57:2527

Cahn JW (1977) J Chem Phys 66:3667

Ebner C, Saam WF (1977) Phys Rev Lett 38:1486

Straumal BB, Gust W (1996) Mater Sci Forum 207:59

Straumal BB, Gust W, Watanabe T (1999) Mater Sci Forum 294:411

López GA, Mittemeijer EJ, Straumal BB (2004) Acta Mater 52:4537

Amouyal Y, Divinski SV, Klinger L, Rabkin E (2008) Acta Mater 56:5500

Straumal BB, Kogtenkova OA, Protasova SG, Zięba P, Czeppe T, Baretzky B, Valiev RZ (2011) J Mater Sci 46:4243. doi:10.1007/s10853-011-5257-6

Stølen S, Grønvold F (1999) Thermochim Acta 327:1

Della Gatta G, Richardson M, Sarge SM et al. (2006) Pure Appl Chem 78:1455

Sun JQ, Zhang RY, Liu ZP et al (2007) Energy Convers Manag 48:619

Dean JA (1995) The analytical chemistry handbook. McGraw Hill, New York (Standards ASTM D 3417, ASTM D 3418, ASTM E 1356, ISO 11357)

Massalski TB (ed) (1990) Binary alloy phase diagrams. ASM International, Materials Park

Straumal BB, Kogtenkova O, Zięba P (2008) Acta Mater 56:925

Straumal B, Valiev R, Kogtenkova O, Zieba P, Czeppe T, Bielanska E, Faryna M (2008) Acta Mater 56:6123

Wynblatt P, Takashima M (2001) Interface Sci 9:265

Chatain D (2008) Ann Rev Mater Res 38:45

Randle V, Rohrer GS, Hu Y (2008) Scr Mater 58:183

Downey ST II, Bembridge N, Kalu PN, Miller HM, Rohrer GS, Han K (2007) J Mater Sci 42:9543. doi:10.1007/s10853-007-1959-1

Bernardini J, Chatain D, Monchoux JP, Rabkin E (2002) J Physique IV 12:229

Straumal BB, Polyakov SA, Mittemeijer EJ (2006) Acta Mater 54:167. doi:10.1016/j.acatamat.2005.08.037

Schölhammer J, Baretzky B, Gust W, Mittemeijer E, Straumal B (2001) Interface Sci 9:43. doi:10.1023/A:1011266729152

Straumal BB, Klinger LM, Shvindlerman LS (1984) Acta Metall 32:1355. doi:10.1016/0001-6160(84)90081-6

Acknowledgements

Authors thank the Russian Foundation for Basic Research (contract 11-03-01198), Program of bilateral cooperation between Russian and Polish Academies of sciences, the grant of President of Russian Federation for young scientists (MK-3748.2011.8), and Polish National Science Centre (grant UMO-2011/01/M/ST8/07822) for the financial support. Authors cordially thank Prof. R.Z. Valiev and Dr. A. Gornakova for stimulating discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kogtenkova, O.A., Protasova, S.G., Mazilkin, A.A. et al. Heat effect of grain boundary wetting in Al–Mg alloys. J Mater Sci 47, 8367–8371 (2012). https://doi.org/10.1007/s10853-012-6786-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6786-3