Abstract

The data on coarsening of γ′-type precipitates (Ni3X, with the L12 crystal structure) in Ni–Al, Ni–Ga, Ni–Ge, Ni–Si, and Ni–Ti alloys are re-evaluated in the context of recent (TIDC) and classical (LSW) theories of coarsening, with the objective of ascertaining the best values possible of interfacial free energies, σ, of the γ/γ′ interfaces in these five alloy systems. The re-evaluations include fitting of the particle size distributions, reanalyzing all the available data on the kinetics of particle growth and kinetics of solute depletion, and using thermodynamic assessments of the binary alloy phase diagrams to calculate curvatures of the Gibbs free energies of mixing. The product of the work is two sets of interfacial free energies, one set for the analysis using the recent TIDC theory and the other for the analysis using the classical LSW theory. The TIDC-based analysis yields lower values of σ by about a factor of 2/3. All the interfacial energies are considerably larger, by factors ranging from ~4 to 10, than those previously reported, which were for the most part calculated from data on coarsening assuming ideal-solution thermodynamics. In the TIDC theory the width of the interface, δ, is allowed to increase with particle size, r. A simple equation relating σ to the ratio of the gradient energy and δ is used to show that σ can remain constant even though δ increases with r. Published work supporting this contention is presented and discussed.

Similar content being viewed by others

Introduction

Advances in one or more areas of research often impact the findings and conclusions drawn from analyses of data that predate these advances. The specific example in this work is the calculation of interfacial energies derived from the analyses of data on coarsening of precipitates. In the first theories of coarsening Lifshitz and Slyozov (LS) [1] and Wagner (W) [2] derived equations for the growth of a spherical particle of average radius 〈r〉. LS also derived an equation for the depletion of the small concentration of excess solute, \( X_{\alpha } - X_{{\alpha {\text{e}}}} \), that must accompany the growth of the average precipitate; X α is the solute concentration in the matrix at time t and X αe is its thermodynamic equilibrium value. The kinetics of the processes of growth and solute depletion were shown to obey the equations 〈r〉3 ≈ kt and \( X_{\alpha } - X_{{\alpha {\text{e}}}} \, \approx (\kappa t)^{ - 1/3} \), where k and κ are rate constants that depend on the thermo-physical parameters of the alloy system, including the chemical diffusion coefficient, \( \tilde{D} \), in the parent phase and the interfacial free energy, σ, between the precipitate and matrix phases. A remarkable ingredient of the LSW theory was an analytical equation describing the distribution of particle sizes (PSD). The PSD must exist as an essential component of the ensemble of particles, and its prediction was a significant advance over earlier theoretical efforts [3, 4] to describe the kinetics of growth of an ensemble of particles.

A brief history

In the original LSW theory the initial composition of the alloy, X o, was assumed to be so small that the free energy of mixing of the solid solution was quite reasonably taken as ideal. In this case the rate constant k is given by the equation

where V m is the partial molar volume of solute in the precipitate phase, R is the gas constant, and T is the absolute temperature.Footnote 1 In one of the earliest attempts to validate the LSW theory quantitatively, Ardell and Nicholson [5] used diffusion coefficients published in the literature to estimate the magnitude of σ for the interface between the Ni–Al solid solution (the γ phase) in equilibrium with Ni3Al (γ′) precipitates, finding it to be ~30 mJ/m2.

It was soon realized [6] that if the kinetics of growth and solute depletion could be measured independently the rate constants k and κ could also be determined independently, enabling σ to be estimated without the need to know the value of \( \tilde{D} \) and vice versa. Borrowing from original ideas of Ben Israel and Fine [7], and taking advantage of the very strong dependence on Al content of the ferromagnetic Curie temperature of Ni [8], the kinetics of solute depletion in Ni–Al alloys [9] were measured and the equation

was used to obtain the rate constant κ, which is related to the thermo-physical parameters of the system by the equation

Straightforward manipulation of Eqs. 1 and 3 produces the result

from which σ can be readily calculated. The parameter \( \ell \) has units of length and is called the capillary length. The application of Eq. 4 to data on the kinetics of particle growth [10] and new data on the kinetics of solute depletion [6] yielded a value of σ ≈ 14 mJ/m2. This was regarded as perfectly reasonable compared to 30 mJ/m2 because independent measurements of \( \tilde{D} \) often disagree by an order of magnitude or more.

Another advance beyond the original LSW theory involved modifications to describe the coarsening of an intermetallic compound [11, 12]. This is an important quantitative issue because the LSW theory assumes that the dispersed phase consists of pure B. The most rigorous modification is that of Calderon et al. [13], which describes the coarsening of a phase that is not necessarily a terminal solid solution, and at the same time removes the limitation that the parent (matrix) phase be a dilute solid solution. The rate constant k in the theory of Calderon et al. [13] is expressed by the equation

where X βe is the equilibrium concentration of solute in the precipitate (β) phase and \( G_{\text{m}}^{\prime \prime } \) is the curvature of the molar Gibbs free energy of mixing \( G_{\text{m}}^{\prime \prime } = \left( {{\text{d}}^{2} G_{\text{m}} /{\text{d}}X_{\alpha }^{2} } \right)_{{X_{{\alpha {\text{e}}}} }} \), evaluated at the equilibrium concentration of the α phase. The capillary length becomes

hence independent measurements of k and κ can still be used to evaluate σ and \( \tilde{D} \) from data on the kinetics of coarsening.

The next attempt to evaluate σ from data on coarsening [14] was made using Eq. 6, re-analyzing the data on Ni–Al, but also adding other data on coarsening of γ′-type Ni3Si and Ni3Ti precipitates in binary Ni–Si and Ni–Ti alloys, respectively.Footnote 2 At the time of that work there were no reliable estimates of \( G_{\text{m}}^{\prime \prime } \) for the Ni–Si and Ni–Ti solid solutions, so the only option was to assume an ideal solution, in which case \( G_{\text{m}}^{\prime \prime } \) becomes

at the equilibrium concentration of solute. On substituting Eq. 7 into Eq. 5, taking X βe ≈ 1 > > X αe, Eq. 5 reduces to Eq. 1. Since the work of Calderon et al. [13] included a thermodynamic model for the Ni–Al solid solution, it was possible to calculate \( G_{\text{m}}^{\prime \prime } \) for the non-ideal case. New estimates were obtained for the Ni(Al)/Ni3Al interface (~8 mJ/m2, including the influence of non-ideality), but for the other two alloys the values of σ for the Ni(Si)/Ni3Si (10.2 mJ/m2) and Ni(Ti)/Ni3Ti (13 mJ/m2) interfaces were calculated assuming ideal-solution thermodynamics.

Recent developments

Subsequent to the work published in 1995 [14] there have been several developments that directly impact the values of σ. Data on the kinetics of coarsening of γ′-type precipitates, including the kinetics of particle growth and solute depletion, have been published for Ni–Ga [15, 16] and Ni–Ge [17, 18] alloys. Thermodynamic models of the Ni-rich solid solutions have been published for all five binary alloy systems: Ni–Al [19–21], Ni–Ga [22], Ni–Ge [23], Ni–Si [24–26], and Ni–Ti [27]. There are also thermodynamic models of ternary Ni-rich solid solutions involving Al, Ga, Ge, Si, and Ti that are helpful in selecting data on G m [28–33]. As discussed recently by Costa e Silva et al. [34], the deviation from ideality can have a significant effect on the values of σ derived from data on coarsening, invariably increasing them because \( G_{\text{m}}^{\prime \prime } \) increases as the departure from ideal solution behavior increases. Though this is quite evident from Eqs. 5 and 6, the discussions of Costa e Silva et al. on σ in Ni–Al and other alloys forcefully drive home the point.

Two other important factors have had a dramatic impact on the validity of the LSW theory itself under certain circumstances, and therefore whether it can be used without further modification to extract meaningful values of σ and \( \tilde{D} \) from data on coarsening. The first factor involves puzzling observations on the effect of equilibrium volume fraction, f e, on the kinetics of coarsening in all the aforementioned binary Ni alloys—there is simply no effect of f e when f e exceeds ~0.08 or so.Footnote 3 The conundrum arises from the theoretically sound expectation that when coarsening kinetics is diffusion-controlled, the rate constants k and κ should increase as f e increases; discussions can be found in several review articles [35–38].

The second important factor is that the γ/γ′ interface in Ni–Al alloys is not sharp, but diffuse, the transition from the γ′ to the γ phase in planar interfaces occurring over a distance of ~2 nm. The first evidence for this was reported by Harada et al. [39]. This early observation has been confirmed by atomistic modeling [40], recent experimental observations using modern atom-probe tomography [41] and high-resolution transmission electron microscopy [42]. A reconciliation of these findings, i.e., the independence of the rate constants on f e and the diffuse γ/γ′ interface, provided the stimulus for a new theory of coarsening by Ardell and Ozolins [43], who also showed that the interface is not only diffuse, but also quite ragged in structure. Ardell and Ozolins postulated that chemical diffusion through the interface controls the kinetics of coarsening when diffusion through the interface is slower than diffusion to the interface. This condition can prevail in Ni–Al alloys because diffusion in the ordered γ′ phase is generally much slower than diffusion in the disordered matrix [44–47]. The γ/γ′ interface thus becomes a bottleneck for diffusion, with significant consequences for the kinetics, leading to the so-called Trans-Interface-Diffusion-Controlled (TIDC) theory of coarsening. The consequences of the TIDC theory in obtaining values of σ from data on coarsening are described in the following sections.

The TIDC theory—quantitative predictions

The important predictions of the TIDC theory are that the kinetics of growth and solute depletion are given by the equations 〈r〉n ≈ k T t and \( X_{\alpha } - X_{{\alpha {\text{e}}}} \, \approx \, (\kappa_{\text{T}} t)^{ - 1/n} \) where n is an exponent that satisfies the condition 2 < n < 3. The rate constants k T and κ T are expressed as [48]

and

The parameter r min is the radius of a particle of minimum size and a o is a lattice constant. They are related to the radius, r, of the particle and the width of the interface, δ, by the equation

r min is a radius below which Eq. 10 is no longer valid. The exponent m satisfies the conditions 0 < m < 1 and n = m + 2. The other parameters in Eqs. 8 and 9 are \( \tilde{D}_{\text{I}} \), the chemical diffusion coefficient in the interface, ∆X e = X βe − X αe and the capillary length in the TIDC theory, which is expressed by the equation

where 〈u〉 = 〈r〉/r* and r* is a critical radius; particles of size r = r* are neither growing nor shrinking at time t. In the original LSW theory 〈u〉 = 1, but in the TIDC theory 〈u〉 < 1. The interfacial free energy in the TIDC theory is calculated from the equation

which is obtained from Eqs. 8 and 9 by straightforward algebraic manipulation.

The exponent n in the TIDC theory dictates the shape of the PSDs through the function h(z), expressed in terms of the variable z = r/r*, which is given by the equation

where p(z) is the function

and f(z) is related to z by the expression

For comparison with experimentally determined PSDs it is necessary to use the function g(u), where u = r/〈r〉 and g(u) = 〈u〉h(z). The maximum allowable scaled particle size in the distribution, u max, is

A restriction of the TIDC theory is that it should no longer be valid for particles larger than a transitional particle size, r T, defined by the condition \( r_{\text{T}} \ge \delta {{\tilde{D}} \mathord{\left/ {\vphantom {{\tilde{D}} {\tilde{D}_{\text{I}} }}} \right. \kern-\nulldelimiterspace} {\tilde{D}_{\text{I}} }} \) [43]. At such large sizes the flux of solute in the matrix to the interface is slower than the flux of solute through the interface, so the kinetics of coarsening become controlled by chemical diffusion in the matrix, i.e., LSW coarsening should prevail at larger particle sizes, or equivalently, longer aging times. In the Ni–Al, Ni–Ga, and Ni–Ti alloy systems the restriction does not apply because elastic interactions induce severe departures from equiaxed shapes at relatively small sizes (r < 20 nm). These interactions generally prevent meaningful average radii larger than this from being measured. Such is not the case for Ni–Si and Ni–Ge alloys, in which Ni3Si and Ni3Ge precipitates can grow large enough for the transition from TIDC to LSW kinetics to take effect. This will be evident in the following analyses of the data.

Examination of the data on binary Ni alloys

In this section data on the PSDs of γ′-type precipitates in binary Ni–Al, Ni–Ga, Ni–Ge, Ni–Si, and Ni–Ti alloys are re-examined for the purpose of determining the values of n used subsequently to re-examine the data on kinetics of particle growth and solute depletion. The rate constants k T and κ T can then be extracted from the data and used to calculate σ via Eq. 12. As in previous work [43, 48, 49], a Mathematica subroutine was fitted to the experimental data on the PSDs in a least-squares sense using trial values of n until the value of n producing the smallest deviation was found. In most, but not all, cases it was possible to obtain a value of n satisfying the condition 2 ≤ n ≤ 3; only these values of n were used in the subsequent analyses. The main significant procedural difference between this and previous work is that populations of data (aging times at a specific temperature) were evaluated individually, yielding average values of n with their variances, which were then used to calculate the average values for all populations. For example, the PSDs of γ′ precipitates in Ni–Al alloys reported by Ardell and Nicholson [10] for their three aging conditions, and those reported by Jayanth and Nash [50] and Irisarri et al. [51], were all evaluated as individual populations, each of which produced an average value of n with its own variance. Previously, the values of n obtained by fitting the individual PSDs were averaged irrespective of source and aging conditions. The average values of n differ slightly, but the new procedure provides more statistically significant results. The collective PSDs of Ardell and Nicholson [10] are shown in Fig. 1a and the PSDs of Jayanth and Nash [50] and Irisarri et al. [51] are shown in Fig. 1b.

Fitting of the γ′ particle size distributions in Ni–Al alloys. The data of Ardell and Nicholson [10] are shown in a. The data of Jayanth and Nash [50] (cross) and Irisarri et al. [51] (circle) are shown in b. The solid curves show the PSD of the TIDC theory for n = 2.424 and the dashed curves show the PSD of the LSW theory

The data on the other four binary alloys were taken from the following sources: Ni–Ga [15, 16], Ni–Ge [17, 18], Ni–Si [52], and Ni–Ti [49]. The fits to the collective data on each alloy are shown in Fig. 2. The theoretical PSDs of the TIDC and LSW theories are shown in each plot in Figs. 1 and 2. In the case of Ni–Al the data clearly indicate that the fit to the TIDC is better than for the LSW theory. This is not so obvious for the other alloys for a variety of different reasons. One is that the counting statistics were much better for Ni–Al: Ardell and Nicholson [10] measured more than 400 particles, Jayanth and Nash [50] measured over 1000 particles and Irisarri et al. [51] measured 350 particles on average. For many of the other sets of data fewer than 300 particles were counted, so the spread in the values of g(u) at any given value of u is far larger for the other alloys than for Ni–Al. It is also the case for the Ni–Ga and Ni–Ti alloys that the γ′ precipitates interact very strongly [15, 16], which makes measurements at longer aging times more difficult as the particles deviate increasingly from an equiaxed shape. This, combined with the smaller number of particles counted at larger particle sizes, increases the uncertainties in the PSDs and results in more uncertain values of n. As was the case for the Ni–Ti alloys re-examined previously [49], there were Ni–Ga PSDs that could not be fitted (2 for the data of Kim and Ardell [15], 3 for the data of Wimmel and Ardell [16]) and one Ni–Ge PSD that could not be fitted [18].

Fitting of the particle size distributions of the γ′-type precipitates in Ni–Ga, Ni–Ge, Ni–Si, and Ni–Ti alloys. A few data points for u > 2 have been omitted, and some of the data have been omitted for clarity. The solid curves show the PSDs of the TIDC theory for n = 2.318 (Ni–Ga), n = 2.385 (Ni–Ge), n = 2.444 (Ni–Si), and n = 2.281 (Ni–Ti). The dashed curves are the PSD of the LSW theory

The values of n resulting from the averaging method used, and their standard deviations, are summarized in Table 1. The values of n are reported to three significant figures, which belies the accuracy of the measurements. Nevertheless, they are represented this way, as are the values of other parameters calculated from the data, to enable the interested reader to check the validity of the calculations in this work. The rate constants k T and κ T were obtained for all the alloys by plotting the data on kinetics using the equations 〈r〉n ≈ k T t and \( X_{\alpha } - X_{{\alpha {\text{e}}}} \approx \, (\kappa_{\text{T}} t)^{ - 1/n} \). As is evident from the work of Ardell and Ozolins [43], the fits to the data on coarsening of γ′ precipitates in Ni–Al are nearly as good using n = 2 as they are with n = 3, and as shown more recently by Ardell [48] the comparison is even better for n = 2.4. The same is true for the data on all the other alloys using the values of n in Table 1. The data on each alloy are considered in turn.

Ni–Al

The data on coarsening of γ′ precipitates in the context of the TIDC theory were analyzed recently by Ardell [48], so there is little to add here other than that the slightly different method of averaging produced a slightly higher value of n = 2.424 compared to the previous n = 2.4.

Ni–Ga

The data of Kim and Ardell [15] and Wimmel and Ardell [16], analyzed in the context of the TIDC theory, are shown in Fig. 3 (kinetics of particle growth) and Fig. 4 (kinetics of solute depletion). Kim and Ardell measured the kinetics of solute depletion only for the alloy containing 18.31% Ga. The microstructure of the aged alloy contained many non-equiaxed Ni3Ga particles, so only the data for the smallest three aging times were used in the present analysis, as was the case originally [15]; i.e., the data in Fig. 3a correspond to the first three data points in Fig. 4 of Kim and Ardell [15]. It is not shown here, but the kinetics is described equally well by the TIDC (n = 2.318) and LSW theories.

Data on the kinetics of particle growth of Ni3Ga precipitates, plotted as average radius to the 2.318 power, 〈r〉2.318, vs. aging time, t: a data of Kim and Ardell [15], aging temperature = 628 °C, 18.31% Ga; b data of Wimmel and Ardell [16], aging temperature = 700 °C, open circles 15.70% Ga, open squares 16.44% Ga

Data on the kinetics of solute depletion during coarsening of Ni3Ga precipitates, plotted as solute concentration, X Ga vs. aging time to the −1/2.318 power, t −1/2.318: a Data of Kim and Ardell [15], b data of Wimmel and Ardell [16]. The alloys, aging conditions, and plotting symbols are identical to those described in Fig. 3

Ni–Ge

The data of Kim and Ardell [17] and Wimmel and Ardell [18] on the kinetics of particle growth, analyzed in the context of the LSW and TIDC (n = 2.385) theories, are shown in Fig. 5. It is apparent in Fig. 5b that the linear fit in the TIDC analysis is excellent up to t ≈ 1.1 × 105 s, but there is significant deviation at longer aging times. The average “radius”, or half edge length, of the cuboidal-shaped particles at this aging time is 70–75 nm. It is postulated here that the radius of 70–75 nm corresponds to the transition radius \( r_{\text{T}} \ge \delta {{\tilde{D}} \mathord{\left/ {\vphantom {{\tilde{D}} {\tilde{D}_{\text{I}} }}} \right. \kern-\nulldelimiterspace} {\tilde{D}_{\text{I}} }} \) of the TIDC theory and that LSW coarsening should prevail for 〈r〉 > r T. An estimate of r T will be postponed for now, but the interpretation offered here is that the data used to obtain both k T and κ T are limited to particle “radii” below 70 nm in Ni–Ge alloys. Though not shown specifically, the linear fits to the data in Fig. 5b (n = 2.385) are actually better than the fits to the data in Fig. 5a (n = 3).

Data of Kim and Ardell [17] on the kinetics of particle growth of Ni3Ge precipitates at 724 °C: a plotted as average radius, 〈r〉3 vs. aging time t for consistency with the LSW theory; b plotted as 〈r〉2.385 vs. aging time, t, for consistency with the TIDC theory. The compositions of the alloys are inset in each figure

The kinetics of solute depletion is shown in Figs. 6 and 7. Figure 6 shows the data of Kim and Ardell [17], excluding data on aging times for which 〈r〉 > 70 nm, while Fig. 7 shows the data of Wimmel and Ardell [18]. In the latter investigation the average particle radius never exceeded 28 nm, so all the data are included in the analysis. The kinetics of particle growth for the data of Wimmel and Ardell are not shown because there is no additional point to be made by showing them; the fits of these data to plots of 〈r〉2.385 vs. t and 〈r〉3 vs. t are comparable.

Data of Kim and Ardell [17] on the kinetics of solute depletion during coarsening of Ni3Ge precipitates at 724 °C, plotted as solute concentration, X Ge vs. aging time to the −1/2.385 power, t −1/2.385. The compositions of the alloys are inset in each figure

Data of Wimmel and Ardell [18] on the kinetics of solute depletion during coarsening of Ni3Ge precipitates at 700 °C, plotted as average solute concentration, X Ge, vs. aging time to the −1/2.385 power, t −1/2.385. The compositions of the alloys are inset in each figure

Ni–Si

There are several sets of data on the coarsening of Ni3Si precipitates in binary Ni–Si alloys that can be used to calculate σ. Two of these, the aforementioned results of Rastogi and Ardell [52] and data of Polat et al. [53], were analyzed previously [54] and shown to yield results in reasonably good agreement, the data of Polat et al. producing somewhat larger values using an analysis based on LSW kinetics. The data on kinetics considered here are those of Rastogi and Ardell and Cho and Ardell [55].

The data of Rastogi and Ardell on the kinetics of particle growth are shown in Fig. 8, while Fig. 9 shows the data on the kinetics of solute depletion. The data on the kinetics of particle growth are described slightly better by the TIDC theory, Fig. 8b, while the kinetics of solute depletion are described essentially equally well by the LSW and TIDC theories, Fig. 9. The marked deviation from linearity seen in Fig. 9 is associated by the loss of coherency of the Ni3Si precipitates at the rather high aging temperature used by Rastogi and Ardell [52]. The largest particle radius plotted in Fig. 8 is ~75 nm, obtained after 8 h at 775 °C. The three data points that deviate from linearity in Fig. 9 represent measurements taken after 16 h of aging; Rastogi and Ardell [52] showed examples of semicoherent Ni3Si precipitates observed at these longer aging times.

The data of Rastogi and Ardell [52] on the kinetics of particle growth of Ni3Si precipitates in a Ni–12.68% Si alloy aged at 775 °C: a plotted as the cube of the average radius, 〈r〉3 vs aging time, t, for consistency with the LSW theory; b plotted as 〈r〉2.444 vs. t for consistency with the TIDC theory

The data of Rastogi and Ardell [52] on the kinetics of solute depletion during coarsening of Ni3Si precipitates in a Ni–12.68% Si alloy aged at 775 °C: a plotted as solute concentration in the matrix, X Si, vs. aging time to the −1/3 power, t −1/3, for consistency with the LSW theory; b plotted as X Si vs. t −1/2.444 for consistency with the TIDC theory

The data of Cho and Ardell [55] on four alloys aged at 650 °C are shown in Figs. 10 and 11. The largest particles observed at the longer aging times (t > 60 h) had average radii exceeding 80 nm, but at this aging temperature the particles were, nevertheless, fully coherent. The data are reasonably well described by the LSW theory, as seen in Fig. 10a, though they exhibit a perceptible negative curvature. When the data are plotted for consistency with the TIDC theory, Fig. 10b, there is a significant departure from linearity seen at aging times exceeding ~2 × 106 s, which corresponds to 〈r〉 ≈ 80 nm. The precipitate microstructures for Ni3Si resemble those of Ni3Ge in that neither coalescence nor impingement is ever observed. As is the case for Ni3Ge precipitates, it is postulated that the average radius of the larger Ni3Si precipitates exceeds the transition radius, r T, and that LSW coarsening kinetics obtain for 〈r〉 > r T ≈ 80 nm. Subsequent analysis involving the TIDC theory uses only the data incorporated in the linear fits in Fig. 10b.

Data of Cho and Ardell [55] on the kinetics of particle growth of Ni3Si precipitates at 625 °C: a plotted as average radius, 〈r〉3 vs. aging time t for consistency with the LSW theory; b plotted as 〈r〉2.444 vs. aging time t for consistency with the TIDC theory. The compositions of the alloys are inset in each figure

Data of Cho and Ardell [55] on the kinetics of solute depletion during coarsening of Ni3Si precipitates at 625 °C, plotted as solute concentration in the matrix, X Si, vs. aging time to the -1/2.444 power, t −1/2.444. The compositions of the alloys are inset in each figure

The kinetics of solute depletion is shown in Fig. 11, plotted for consistency with the predictions of the TIDC theory. The fits with plots of X Si vs. t −1/3 are comparable. The data in Fig. 11 represent aging times for which 〈r〉 < 80 nm, so all the data are included in the linear fitting.

Ni–Ti

The kinetics of coarsening of Ni3Ti precipitates has been investigated by Ardell [56] and Kim and Ardell [57]. These data were evaluated according to the predictions of the TIDC theory by Ardell et al. [49], so the figures will not be reproduced here. The main difference between the evaluation of the data by Ardell et al. and this work is that the value of n is somewhat lower; n = 2.281 cf. 2.375. This is due partly to the inclusion of the data for t = 4 h, partly to the way the average value of n was calculated and partly due to a minor change in the conversion of the original histograms to the representation shown in Fig. 2. The fits to the data for n = 2.281 are comparable to those seen in the paper by Ardell et al. [49].

Thermodynamics

Curvatures of the free energy functions

The calculations of σ for the five alloys using Eq. 12 require estimates of \( G_{\text{m}}^{\prime \prime } \). Values of σ can then be obtained from the experimental data on the rate constants using the appropriate rate constants from either the LSW or TIDC theories. Fortunately, the five alloy systems relevant here have been subjected to thermodynamic assessments with the objectives of describing the phase diagrams and their thermodynamic properties using a variety of experimental data; this is the essence of the CALPHAD method. These assessments require, as input, equations describing the Gibbs free energies of mixing, G m, as functions of compositions for all the phases. For this work all that is needed are the equations describing G m for the terminal γ solid solution phases as functions of composition and temperature. The necessary differentiations can then be performed to obtain \( G_{\text{m}}^{\prime \prime } \) evaluated at their appropriate equilibrium compositions.

The Gibbs free energy of mixing is given by the sum of three terms,

where G m,id is the free energy of mixing of an ideal solution, G m,exc is the excess free energy of mixing and represents the departure from ideal solution behavior of the solid solution and G m,mag is an additional contribution to the free energy that exists when the majority phase is ferromagnetic [58]. This contribution exists even above the ferromagnetic Curie temperature, T C, [59, 60] and can be important, in principle. Equations for the second derivatives with respect to composition for each of these quantities will be presented in turn.

The second derivative of G m,id, Eq. 7, is valid for any value of X, not just at thermodynamic equilibrium. In all subsequent equations X represents the concentration of solute; subscripts identifying the solute will be added as needed.

The excess free energy in the lexicon of thermodynamic assessments of phase diagrams is universally represented by the Redlich–Kister [61] equation, which is written here in the form

where L RK is a summation that takes one of two forms for an A–B binary solid solution, depending on whether or not the elements A and B are represented alphabetically in the thermodynamic modeling scheme. This seems like a trivial issue, but for the researcher who is unaccustomed to probing the literature on thermodynamic modeling, and must rely on the equations to understand its predictions, the wrong choice can lead to completely erroneous results. Since A and B are not universally chosen alphabetically, the equations for L RK are presented here for the two possible cases.

Case 1:

Case 2:

The coefficients L j in the sums depend only on T and are obtained by fitting the free energy functions to the phase boundaries in the phase diagrams and other relevant available data.

For both cases the curvature of the excess free energy is given by the equation

where the prime and double prime indicate second derivatives with respect to X. The expressions for the derivatives of L RK depend on whether Case 1 or Case 2 applies. For the alloys considered in this work the thermodynamic models involve at most four terms in the summations in Eq. (19). The equations for the derivatives in Cases 1 and 2 are therefore expressed as follows:

Case 1:

Case 2:

The magnetic contribution to the free energy is expected to be small, since T C for the Ni–Al, Ni–Ga, Ni–Ge, Ni–Si, and Ni–Ti alloys decreases sharply with composition (see [9, 16, 18, 52, 56] and references therein for representative dependencies of T C on X), and the aging temperatures in the experiments on coarsening significantly exceeded T C. Nevertheless, it is at least worthwhile to calculate \( G_{\text{m,mag}}^{\prime \prime } \) to see if neglecting its contribution is justifiable. It is shown in the Appendix 1 that this contribution is negligibly small.

Thermodynamic models and equilibrium solubility limits of the γ and γ′ phases

Equations describing the L j obtained from the thermodynamic assessments of the five phase diagrams are presented in Table 2. For the Ni–Ti alloy system the thermodynamic models involve equilibrium between the f.c.c. Ni–Ti solid solution and the hexagonal ordered η phase whereas the data on coarsening involve the metastable L12 Ni3Ti phase. The function describing the free energy of the f.c.c. solid solution is, of course, unaffected.

The remaining parameters needed to calculate σ using the equations of either the LSW or TIDC theories are the equilibrium solubility limits of both the γ and γ′ phases and the partial atomic volumes. As to the solubility limits, there are many options to choose from, since there are contributions to the phase diagrams from numerous investigators. The values of X γe (= X αe) chosen here were obtained from data on the kinetics of solute depletion, plotted according to the LSW version, Eq. 2, where extrapolation to t −1/3 = 0 provides a value of X γe. As pointed out by Rastogi and Ardell [14], the equilibrium solubility limits so obtained represent the solubilities of the coherent precipitates. These do not necessarily differ much from the incoherent solubility limits, but it seems a reasonable choice to use them. In the case of the L12 form of the Ni3Ti phase, the only other measurements of its solubility limits are those of Hashimoto and Tsujimoto [62], which agree well with those of Rastogi and Ardell. It is important to point out that when the same data on the kinetics of solute depletion are analyzed using the counterpart to Eq. 2 in the TIDC theory, the values of X γe so obtained are very slightly smaller than those obtained from the LSW analysis; the typical difference is less than 0.01% and is ignored in this work.

With the exception of the solvus curve for L12 Ni3Ti precipitates, equations for the solvus curves of all the other alloys have been summarized previously [63]. These equations are presented in Table 3. The equation for the solubility limit of Ni3Ti used here is the one published by Rastogi and Ardell [14].

The values of X βe = X γ′e for the Ni–Al and Ni–Ge systems are calculated from equations that describe the (γ + γ′)/γ′ phase boundaries in these two alloys. The equation for the Ni–Al alloy system is taken from the work of Ma and Ardell [64]:

where T is in °C. The corresponding equation for the Ni–Ge system is

Equation 24, in which T is in °C, is somewhat awkward, but produces an excellent fit to the combined data of Ma and Ardell (unpublished research) and Ikeda et al. [65]. The data on X γ′e for Ni3Ga, Ni3Si, and Ni3Ti indicate that there is no change, or at best only a small variation, of concentration with temperature. The values used here are taken from Ikeda et al. [65] (Ni3Ga), Oya and Suzuki [66] (Ni3Si), and Jia et al. [67] (Ni3Ti). Jia et al. actually measured the concentration of the equilibrium η phase, which is essentially constant at ~23.2% Ti over the temperature range 700–900 °C. Other measurements indicate that the L12 form of Ni3Ti is hypostoichiometric, with a composition of ~22 ± 2% Ti [68–70]. The value of X γ′e for the metastable Ni3Ti L12 phase is not known precisely, and is taken here as temperature-independent and slightly smaller than that of the η phase, specifically 23.0% Ti. The values of X γ′e used in all the calculations of σ are summarized in Table 4.

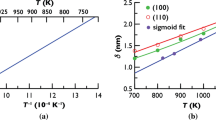

The partial molar (atomic) volumes of the solute atoms in the γ′-type phases were calculated from the equilibrium lattice constants at the relevant temperatures using the relationship \( V_{\text{m}} = a_{\text{o}}^{3} {{N_{\text{A}} } \mathord{\left/ {\vphantom {{N_{\text{A}} } 4}} \right. \kern-\nulldelimiterspace} 4} \), where N A is Avogadro’s number. For Ni3Al, Ni3Ga, Ni3Ge, and Ni3Si the lattice constants were taken from the data of Kamara et al. [71]. These data take thermal expansion into account, but not the variations of equilibrium composition with T, so Vegard’s law was assumed to apply and corrections for variations with composition were assumed (Ardell, unpublished research). The values of V m so obtained are summarized in Table 4. The numbers shown in Table 4 differ slightly from those published previously because of the variations of a o with temperature and composition that were not considered in previous work.

The only measurements of the lattice constants of L12 Ni3Ti are those of Hashimoto and Tsujimoto [62]. Their reported lattice constants decrease slightly with increasing temperature over the range 600–900 °C. They suggest that this is due to a variation in composition of the Ni3Ti phase from ~14.2% (900 °C) to 17.1% (600 °C) Ti, but their suggestion is based on very old data on the variation of lattice constant with composition. It is worth pointing out that at the aging temperature of 600 °C the data of Hashimoto and Tsujimoto indicate that the lattice mismatch between L12 Ni3Ti and the matrix phase is ~0.84%, which agrees well with the room-temperature value reported by Sass et al. [72]. This suggests that the compositions reported in their Fig. 4 are too low, and that the lattice constants they measured are close to their equilibrium values. Taking all these factors into account leads to the values of \( G_{\text{m}}^{\prime \prime } \) shown in Table 4.

Calculations of σ

The parameters needed to calculate σ for all the alloys in the contexts of the TIDC and LSW theories are summarized in Tables 5 and 6, respectively. The values of σ are presented in Table 7 and are calculated from those in Tables 5 and 6 after compensating for their variances (i.e., the squares of the standard deviations shown in the two tables). In some cases, e.g., the data of Wimmel and Ardell [16] on the kinetics of solute depletion in Ni–Ga alloys shown in Fig. 4b, the variances are very large, producing the large standard deviations in the individually calculated values of σ seen in Tables 5 and 6. In such cases the contributions of these particular measurements to the weighted average values of σ presented in Table 7 are relatively small.

The estimated errors in Table 7 are very conservative, because there are many other factors that can affect the calculations. These include the exponent n in the TIDC theory and the equilibrium concentrations of both phases. Additionally, there is some flexibility in choosing the thermodynamic model used to calculate \( G_{\text{m}}^{\prime \prime } \), and the reliability of the models themselves. With regard to the models selected, the curvatures of the Gibbs free energy of mixing of the Ni–Al solid solution calculated using the model of Du and Clavaguera [20] are about 25% larger than those from the model of Ansara et al. [19]. This would produce comparably larger values of σ. The model of Bellen et al. [27] of the Ni–Ti solid solution yields values of \( G_{\text{m}}^{\prime \prime } \) only slightly smaller than obtained from the model of De Keyzer et al. [30]. Matsumoto et al. [33] modeled the binary Ni–Ti phase diagram as part of their assessment of the ternary Nb–Ni–Ti system. The values of \( G_{\text{m}}^{\prime \prime } \) from their model are roughly 6–7% smaller than those from the model of De Keyzer et al. [30], so the models predict curvatures of the free energy of mixing that agree quite well. The values of σ reported in Table 7 for Ni–Al, Ni–Ga, Ni–Ge, and Ni–Ti alloys can therefore be considered to be as reliable as current analysis allows.

Unfortunately, the consistency among various models of the Ni–Al and Ni–Ti thermodynamics is not found for Ni–Si alloys. The model of Tokunaga et al. [26], which has been used to calculate σ in Table 7, overestimates the β1 (γ′-type) solvus, though it provides a better fit than the models of Lindholm and Sundman [25] or Du and Schuster [24]. The model of Miettinen [32] actually provides the best fit to the β1 solvus. If the values of \( G_{\text{m}}^{\prime \prime } \) from any of these other models are used to calculate σ from the data on coarsening, the results are much smaller in magnitude. The results of calculations of σ using the thermodynamic models of Du and Schuster [24] and Miettinen [32] are shown in Table 8. It is evident that the values of \( G_{\text{m}}^{\prime \prime } \) are much smaller than those obtained from the model of Tokunaga et al. [26] (see Table 4), yielding values of σ that are about 1/2 to 2/3 those shown in Fig. 7. This is a huge discrepancy, which cannot be reconciled without independent measurements of σ, or clear confirmation that one of the thermodynamic models is superior to the other.

Discussion

It is not evident from the numbers in Table 7, but the influence of non-ideality of the solid solutions on the calculated values of σ is quite large, ranging from a factor of about 4 for Ni–Ga alloys to over a factor of 10 for Ni–Si alloys. For the reader who is not familiar with the data on coarsening of the γ′-type precipitates in these alloys, it should be obvious on viewing Figs. 5, 6, 7, 8, 9, 10, and 11 that there is no effect of initial alloy concentration on the kinetics of coarsening, which means that there is no effect of f e either. For some of the data shown f e varies by as much as a factor of 10, so if any of the theories noted in the review articles cited [35–38] were correct, the effect on kinetics would have to be considered in the calculations of σ. The TIDC theory completely obviates this issue since no effect of f e is predicted.

In assessing the reliability of the calculated values of σ, independently measured or calculated values would be immensely helpful. Unfortunately, except for the important Ni–Al alloy system such calculations have not been made. Since the γ/γ′ interface is so technologically important, the Ni(Al)/Ni3Al interfacial energy has been estimated by several groups using atomistic calculations. All these calculations assume that pure Ni is in equilibrium with stoichiometric Ni3Al, so the calculated values represent upper limits of the energies at 0 K. The first such calculation was that of Farkas et al. [73] using embedded atom potentials. They calculated σ ≈ 22 mJ/m2. Price and Cooper [74] used a different atomistic method and obtained values of 25 or 63 mJ/m2, with the differences due to the treatment of magnetic effects. Mishin [40] used newer embedded atom potentials and found that σ varied depending on the orientation of the interface, being lowest for the (111) interface (12 mJ/m2) and highest for the (100) interface (46 mJ/m2). Somewhat similar results were obtained by Costa et Silva et al. [34], whose first-principles calculations also produced anisotropic values of σ, namely 39.6 and 63.8 mJ/m2 for the (100) and (110) interfaces, respectively. On comparing these theoretical estimates with the experimental results in this work, two factors need to be considered. The first is the theoretically predicted anisotropy of σ, and the second is effect of temperature, since the values of σ obtained from the data on coarsening are values representative of T ≫ 0 K.

There is no experimental evidence for an orientation dependence of the interfacial energy in Ni-base γ/γ′ alloys. Indeed, there is overwhelming evidence that the shapes of γ′-type precipitates are governed uniquely by the competition between elastic and interfacial energies. Review articles by Doi [75] and Fratzl et al. [76] show transmission electron micrographs of γ′ precipitates in ternary alloys with compositions deliberately selected to alter the elastic mismatch between the precipitate and matrix phases. The shapes of the γ′ precipitates are invariably spherical when the elastic mismatch is close to zero no matter how large the precipitates are, with no evidence whatsoever of faceting. There is currently no explanation for the discrepancy with Mishin’s atomistic calculations. Regarding the effect of temperature, the values of σ would be expected to decrease as T increases from 0 K. The interfacial energy would also decrease on taking the chemistry of the precipitates into account. The apparent agreement among the theoretically calculated values of σ for the Ni(Al)/Ni3Al interface and those seen in Table 7 must clearly be regarded as fortuitous.

It is legitimate to question whether a constant value of σ during coarsening is physically meaningful if the width of the interface is allowed to vary, as specified by Eq. 10. The width of the interface is a manifestation of the gradient energy, χ, in these alloy systems, and as demonstrated nicely in the paper by Lass et al. [77], δ is expected to increase as χ increases because of the energy penalty the system must pay if the interface is relatively sharp and χ is relatively large. Since σ is proportional to χ [78], the interfacial energy should also vary as δ varies. Such considerations would appear to obviate the basis of the TIDC-based analysis of the data in this paper. A solution to this apparent conundrum lies in a simple relationship between σ, χ and δ derived in Appendix 2. The relationship is given by the equation

where C is a numerical constant.

Inspection of Eq. 25, recalling Eq. 10, indicates that σ cannot remain approximately constant as r (hence δ) increases unless the increase in size is accompanied by an increase in χ. Over the range of average particle sizes of the precipitates analyzed in this work, Eq. 10 predicts that δ should increase by factors of about 1.4 (Ni–Ga), 1.7 (Ni–Al, Ni–Ge, and Ni–Ti), and 2 (Ni–Si). The question therefore is whether there is any evidence that χ can possibly increase by a comparable amount in order that the values of σ shown in Table 7 remain approximately constant, at least over the ranges of temperatures of the experiments on coarsening.

There are two studies that support the idea that χ can increase as r (hence δ) increases. One is found in a recent paper by Hoyt [79], who investigated the thermodynamic equilibrium conditions for Cu-rich droplets in the Cu–Pb system using molecular dynamics simulations. Hoyt compared the gradient energies of planar and curved solid Cu–liquid Pb interfaces and found that χ at 1000 K for a droplet 5.3 nm in diameter is 1.27 × 10−10 J/m compared to 2.18 × 10−10 J/m for a planar Cu–Pb interface. The factor of ~1.7 increase in χ is comparable to the increases in δ predicted by Eq. 10. This is a fortuitous, but nevertheless encouraging, result.

The other piece of evidence is found in Fig. 4 of a paper by Booth-Morrison et al. [80] on the coarsening of γ′ precipitates in a ternary Ni–Al–Cr alloy. They measured concentration profiles across interfaces using atom-probe tomography at aging times of 1, 4, and 4096 h. The maximum absolute values of the concentration gradients of Al and Ni, \( \left| {{{{\text{d}}X_{\text{Al}} } \mathord{\left/ {\vphantom {{{\text{d}}X_{\text{Al}} } {{\text{d}}y}}} \right. \kern-\nulldelimiterspace} {{\text{d}}y}}} \right|_{ \max } \,{\text{and}}\,\left| {{{{\text{d}}X_{\text{Ni}} } \mathord{\left/ {\vphantom {{{\text{d}}X_{\text{Ni}} } {{\text{d}}y}}} \right. \kern-\nulldelimiterspace} {{\text{d}}y}}} \right|_{ \max } \) in the notation used in Appendix 2, at 1 h of aging are a factor of 1.5 to 1.6 larger than those at 4096 h of aging. Assuming that these gradients are proportional to the average gradients, 〈dX Al/dy〉 and 〈dX Ni/dy〉, respectively (see Appendix 2), δ must increase as the interfacial concentration gradients increase, with increases comparable to those of the maximum gradients. The computer simulations of Hoyt [79] and the measurements of Booth-Morrison et al. [80] do not prove conclusively that χ varies with r, but their work provides clear evidence that it is reasonable to assume that σ can remain approximately constant while δ increases.

The interfacial free energies calculated using the TIDC theory are approximately 2/3 those calculated using the LSW theory, with the exception of the Ni–Si system where the ratio is ~3/4. The reason for the smaller difference in Ni–Si alloys is that the data on the 2 longest aging times in the results of Cho and Ardell [55] were omitted in the TIDC analysis but used in the LSW analysis. A similar treatment was accorded the data on the Ni–Ge alloys, but only one point was omitted and its omission has only a relatively small effect on σ calculated using the TIDC theory.

The rationale stated earlier for excluding the data at longer aging times is that 〈r〉 exceeds \( r_{\text{T}} > \delta {{\tilde{D}} \mathord{\left/ {\vphantom {{\tilde{D}} {\tilde{D}_{\text{I}} }}} \right. \kern-\nulldelimiterspace} {\tilde{D}_{\text{I}} }} \) ≈ 80 nm. There are no data on diffusion in Ni3Si, so it is not possible to estimate \( \tilde{D}_{\text{I}} \), which is expected to be slightly larger than \( \tilde{D}_{{{\text{Ni}}_{3} {\text{Si}}}} \) though of course smaller than chemical diffusion in the matrix. It is, nevertheless, instructive to see if the data on chemical diffusion in Ni–Ge alloys can be used to rationalize the exclusion of the long-time data in this system. Chemical diffusion coefficients in both Ni3Ge and the Ni–Ge solid solution have been measured by Komai et al. [81]. Using the empirical equations reported for the Ni–Ge solid solution (10% Ge) and Ni3Ge (23.5% Ge), \( \tilde{D}_{{{\text{Ni}} - 10\% \,{\text{Ge}}}} = 6.29 \times 10^{ - 5} { \exp }\left( {{{ - 233,000} \mathord{\left/ {\vphantom {{ - 233,000} {RT}}} \right. \kern-\nulldelimiterspace} {RT}}} \right) \) and \( \tilde{D}_{{{\text{Ni}}_{3} {\text{Ge}}}} = 9.03 \times 10^{ - 5} { \exp }\left( {{{ - 248,000} \mathord{\left/ {\vphantom {{ - 248,000} {RT}}} \right. \kern-\nulldelimiterspace} {RT}}} \right) \), respectively, the ratio \( {{\tilde{D}} \mathord{\left/ {\vphantom {{\tilde{D}} {\tilde{D}_{\text{I}} }}} \right. \kern-\nulldelimiterspace} {\tilde{D}_{\text{I}} }} \) is about 4.5 at 700 °C. With δ = 2 nm the transition radius r T is r T ≈ 9 nm. This is about a factor of 10 smaller than the assumed transition radius, but it should be kept in mind that chemical diffusion in the Ni–Ge matrix is strongly dependent on concentration. Judging from the data of Komai et al. [81] reported in their Fig. 10 chemical diffusion in an alloy containing ~11.8% Ge, which is within the range of equilibrium concentrations in the matrix of the aged Ni–Ge alloys (see Table 4), \( \tilde{D} \) would increase by a factor of 3–4, leading to a concomitant increase in r T by the same amount for this value of δ. Whereas these arguments do not fully justify the exclusion of data for which 〈r〉 > r T, they provide sensible rationale for doing so.

The other factor involved in the transition from TIDC to LSW kinetics is the behavior of the PSDs. In principle, when the kinetics of coarsening is controlled by diffusion in the matrix phase the PSDs are broader than predicted by the original LSW theory owing to the effect of volume fraction [35–38]. In practice, experimental PSDs tend to be broader than the LSW PSD anyway, even if there is no effect of f e on the kinetics. Given the relatively poor statistics involved in the measurements of the PSDs, it is impossible to characterize the PSDs discussed in this work accurately enough to distinguish any possible mechanism that might be responsible for broadening. In other words, any expected changes in the shape of the PSDs in the transition from TIDC to LSW kinetics are not detectable.

It is natural to conjecture about the relative magnitudes of σ for the different alloy systems. As noted some time ago [10] interfacial free energies in γ/γ′ alloys are dominated by second- and higher-order neighbor interactions. It is reasonable to conclude that these interactions for the covalent Group IV elements Si and Ge are stronger than those for the Group III elements Al and Ga. This is consistent with the larger Ni(Si)/Ni3Si and Ni(Ge)/Ni3Ge interfacial energies compared to the Ni(Al)/Ni3Al and Ni(Ga)/Ni3Ga interfacial energies. Moreover, since bond energies tend to decrease as the atomic number increases, i.e., bonding in Ge and Ga is weaker than bonding in Si and Al, respectively, the Ni(Al)/Ni3Al interfacial energy should be larger than the Ni(Ga)/Ni3Ga energy, and the Ni(Si)/Ni3Si energy should exceed the Ni(Ge)/Ni3Ge interfacial energy. These expectations are confirmed by the values of σ seen in Table 7, with the sole exception for the relative interfacial energies in the Ni–Si and Ni–Ge alloys calculated using the LSW analysis of the data, which produces roughly equal values of σ in the two systems.

The only independent measurements of thermodynamic quantities that support this argument are those of Martosudirjo and Pratt [82], who report that the heat of solution of Ge in Ni at 836 K is about 13 times larger than that of Ga at 778 K. These measurements indicate that first nearest-neighbor interactions in Ni–Ge are significantly larger than in Ni–Ga, and by inference the higher-order interactions are also larger. It is not possible to extend this argument to the transition metal Ti, but since the valence state of Ti is generally larger than that of Al and Ga it would be expected that larger values of σ for the Ni(Ti)/Ni3Ti system would be observed, which is also consistent with the data in Table 7.

Given the uncertainties in the magnitudes of all the parameters associated with these estimates, it is concluded that the TIDC theory successfully describes the data on coarsening in all five alloys. The consideration of bonding also provides justification for the validity of the thermodynamic model of Tokunaga et al. [26] in describing the thermodynamics of the Ni–Si alloy system. The other two thermodynamic models used to calculate σ in Table 8 yield magnitudes that appear to be too small. Whether the values of σ obtained using the TIDC-based analyses are more “accurate” than those obtained from the LSW-based analyses awaits confirmation. This will come when atomistic calculations can properly account for the equilibrium compositions of the γ and γ′-type phases at temperatures in the range 800–1000 K, as well as the absence of an orientation dependence of σ in the absence of elastic mismatch.

Notes

In the original LSW theory no distinction was made between various kinds of diffusion coefficients. It was unnecessary because the solution was assumed to be very dilute, in which case the tracer and chemical diffusion coefficients are equal.

Ni3Si and Ni3Ti both exist with the L12 crystal structure. The Ni3Si phase is stable and is called β1. Ni3Ti is metastable. The stable phase is called η and has the hexagonal DO24 crystal structure.

The rate constants for coarsening in all five alloys actually decrease as f e increases when f e is very small (f e < 0.05). This anomalous behavior awaits a satisfactory explanation.

The gradient energy χ differs by a factor of 2 in various treatments of decomposition from supersaturated solid solution. These distinctions are ignored here because the magnitude of χ is immaterial to the discussion in this paper.

References

Lifshitz IM, Slyozov VV (1961) J Phys Chem Solids 19:35

Wagner C (1961) Zeitschrift Fur Elektrochemie 65:581

Greenwood GW (1956) Acta Metall 4:243

Todes OM, Khrushchov VV (1947) Zh Fiz Khim 21:301

Ardell AJ, Nicholson RB (1966) Acta Metall 14:1295

Ardell AJ (1967) Acta Metall 15:1772

Ben Israel DH, Fine ME (1963) Acta Metall 11:1051

Marian V (1937) J Phys Radium 8:313

Ardell AJ (1968) Acta Metall 16:511

Ardell AJ, Nicholson RB (1966) J Phys Chem Solids 27:1793

Chaix JM, Eustathopoulos N, Allibert CH (1986) Acta Metall 34:1589

Trivedi RK (1975) In: Lectures on the theory of phase transformations, AIME, p 51

Calderon HA, Voorhees PW, Murray JL, Kostorz G (1994) Acta Metall Mater 42:991

Rastogi PK, Ardell AJ (1969) Acta Metall 17:595

Kim DM, Ardell AJ (2004) Metall Mater Trans A 35A:3063

Wimmel J, Ardell AJ (1994) J Alloys Compd 205:215

Kim DM, Ardell AJ (2003) Acta Mater 51:4073. doi:10.1016/S1359-6454(03)00227-1

Wimmel J, Ardell AJ (1994) Mater Sci Eng A 183:169

Ansara I, Dupin N, Lukas HL, Sundman B (1997) J Alloys Compd 247:20

Du Y, Clavaguera N (1996) J Alloys Compd 237:20

Zhang F, Chang YA, Du Y, Chen SL, Oates WA (2003) Acta Mater 51:207. doi:10.1016/s1359-6454(02)00392-0

Yuan WX, Qiao ZY, Ipser H, Eriksson G (2004) J Phase Equilib Diffusion 25:68. doi:10.1361/10549710417696

Liu YQ, DJ Ma, Du Y (2010) J Alloys Compd 491:63. doi:10.1016/j.jallcom.2009.11.036

Du Y, Schuster JC (1999) Metall Mater Trans A 30A:2409

Lindholm M, Sundman B (1996) Metall Mater Trans A 27A:2897

Tokunaga T, Nishio K, Ohtani H, Hasebe M (2003) Calphad 27:161. doi:10.1016/s0364-5916(03)00049-x

Bellen P, Kumar K, Wollants P (1996) Zeitschrift Fur Metallkunde 87:972

Dupin N, Ansara I, Sundman B (2001) Calphad 25:279

Schuster J (2006) Intermetallics 14:1304. doi:10.1016/j.intermet.2005.11.027

De Keyzer J, Cacciamani G, Dupin N, Wollants P (2009) Calphad 33:109. doi:10.1016/j.calphad.2008.10.003

Du Y, CY He, Schuster JC, Liu SH, Xu HH (2006) Int J Mater Res 97:543

Miettinen J (2005) Calphad 29:212

Matsumoto S, Tokunaga T, Ohtani H, Hasebe M (2005) Mater Trans 46:2920

Costa e Silva A, Agren J, Clavaguera-Mora MT et al (2007) Calphad 31:53. doi:10.1016/j.calphad.2006.02.006

Ardell AJ (1988) In: Lorimer GW (ed) Phase transformation ‘87. The Institute of Metals, London, p 485

Baldan A (2002) J Mater Sci 37:2171. doi:10.1023/A:1015388912729

Voorhees PW (1992) Annu Rev Mater Sci 22:197

Jayanth CS, Nash P (1989) J Mater Sci 24:3041. doi:10.1007/BF01139016

Harada H, Ishida A, Murakami Y, Bhadeshia H, Yamazaki M (1993) Appl Surf Sci 67:299

Mishin Y (2004) Acta Mater 52:1451. doi:10.1016/j.actamat.2003.11.026

Sudbrack CK, Yoon KE, Noebe RD, Seidman DN (2006) Acta Mater 54:3199. doi:10.1016/j.actamat.2006.03.015

Srinivasan R, Banerjee R, Hwang JY et al (2009) Phys Rev Lett 102:086101. doi:10.1103/PhysRevLett.102.086101

Ardell AJ, Ozolins V (2005) Nat Mater 4:309. doi:10.1038/nmat1340

Fujiwara K, Horita Z (2002) Acta Mater 50:1571

Ikeda T, Almazouzi A, Numakura H, Koiwa M, Sprengel W, Nakajima H (1998) Acta Mater 46:5369

Janssen MMP (1973) Metall Trans 4:1623

Watanabe M, Horita Z, Sano T, Nemoto M (1994) Acta Metall Mater 42:3389

Ardell AJ (2010) Acta Mater 58:4325. doi:10.1016/j.actamat.2010.04.018

Ardell AJ, Kim DM, Ozolins V (2006) Zeitschrift Fur Metallkunde 97:295

Jayanth CS, Nash P (1990) Mater Sci Technol 6:405

Irisarri AM, Urcola JJ, Fuentes M (1985) Mater Sci Technol 1:516

Rastogi PK, Ardell AJ (1971) Acta Metall 19:321

Polat S, Chen H, Epperson JE (1989) Metall Trans A 20A:699

Ardell AJ (1995) Interface Sci 3:119

Cho J-H, Ardell AJ (1998) Acta Mater 46:5907

Ardell AJ (1970) Metall Trans 1:525

Kim DM, Ardell AJ (2000) Scripta Mater 43:381

Zener C (1955) Trans Am Inst Min Metall Engrs 203:619

Inden G (1975) Zeitschrift Fur Metallkunde 66:577

Miodownik AP (1977) Calphad 1:133

Redlich O, Kister AT (1948) Ind Eng Chem 40:345

Hashimoto K, Tsujimoto T (1978) Trans Jpn Inst Met 19:75

Ardell AJ (1994) In: Morral JE, Schiffman RS, Merchant SM (eds) Experimental methods of phase diagram determination. TMS, Warrendale, PA, p 57

Ma Y, Ardell AJ (2003) Zeitschrift Fur Metallkunde 94:972

Ikeda T, Nose Y, Korata T, Numakura H, Koiwa M (1999) J Phase Equilib 20:626

Oya Y, Suzuki T (1983) Zeitschrift Fur Metallkunde 74:21

Jia C, Ishida K, Nishizawa T (1994) In: Morral JE, Schiffman RS, Merchant SM (eds) Experimental methods of phase diagram determination. TMS, Pittsburgh, PA, p 31

Grune R (1988) Acta Metall 36:2797

Sinclair R, Leake JA, Ralph B (1974) Phys Status Solidi A 26:285

Vyskocil P, Pedersen JS, Kostorz G, Schonfeld B (1997) Acta Mater 45:3311

Kamara AB, Ardell AJ, Wagner CNJ (1996) Metall Mater Trans A 27A:2888

Sass SL, Mura T, Cohen JB (1967) Philos Mag 16:679

Farkas D, Decampos MF, Desouza RM, Goldenstein H (1994) Scripta Metall Mater 30:367

Price DL, Cooper BR (1996) In: Kaxiras E, Joannopoulos J, Vashishta P, Kalia RK (eds) Materials theory, simulations, and parallel algorithms, vol 408, MRS, p 463

Doi M (1996) Prog Mater Sci 40:79

Fratzl P, Penrose O, Lebowitz JL (1999) J Stat Phys 95:1429

Lass EA, Johnson WC, Shiflet GJ (2006) Calphad 30:42. doi:10.1016/j.calphad.2005.11.002

Cahn JW, Hilliard JE (1958) J Chem Phys 28:258

Hoyt JJ (2007) Phys Rev B 76:094102. doi:10.1103/PhysRevB.76.094102

Booth-Morrison C, Zhou Y, Noebe RD, Seidman DN (2010) Philos Mag 90:219. doi:10.1080/14786430902806660

Komai N, Watanabe M, Horita Z (1995) Acta Metall Mater 43:2967

Martosudirjo S, Pratt JN (1976) Thermochim Acta 17:183

Inden G (1981) Phys B & C 103:82

Hillert M, Jarl M (1978) Calphad 2:227

Cahn JW, Hilliard JE (1959) J Chem Phys 31:688

Asta M, Hoyt JJ (2000) Acta Mater 48:1089

Wang Y, Banerjee D, CC Su, Khachaturyan AG (1998) Acta Mater 46:2983

Wang JC, Osawa M, Yokokawa T, Harada H, Enomoto M (2007) Comput Mater Sci 39:871. doi:10.1016/j.commatsci.2006.10.014

Acknowledgements

I am very grateful to Dr. Nathalie Dupin, Calcul Thermodynamique, for her help in unraveling the mysteries (to me) of thermodynamic assessments of the Ni–Al phase diagram and, by inference, others. I also thank Professor Y.Q. Liu, China University of Geosciences, Beijing, for her help in dealing with the thermodynamic assessment of the Ni–Ge phase diagram. Professor Vidvuds Ozolins, UCLA, provided very helpful discussions of bonding in the five alloys, and his valuable insights are greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

The general expression for G m,mag is [83]

where β is the average magnetic moment in the alloy, expressed as Bohr magnetons, τ = T/T C and f(τ) is given by the equation [84]

where the constant 0.4269 is operative for f.c.c. alloys. Allowing for the possibility that β depends on X, as well as τ via the dependence of T C on X, the expression for \( G_{\text{m,mag}}^{\prime \prime } \) is

where the primes again denote derivatives with respect to composition,

and

The derivatives of τ are given by the equations

and

Most of the thermodynamic assessments cited in this paper do not include detailed estimates of G m,mag, even though its existence is noted. An exception is the model of Tokunaga et al. [26]. They represent the variations of β and T C by the equations

and

respectively. On performing the necessary differentiations and substituting the results into Eqs. 29 to 32, then into Eq. 28, the values of \( G_{\text{m}}^{\prime\prime } \) for the aging temperatures of 650 and 775 °C are negative and very small, −416 and −106 J/mol, respectively. Since the variations of T C and β for all the alloys are expected to be similar, it is safe to conclude that the magnetic contributions can be ignored.

Appendix 2

Following Cahn and Hilliard [78, 85], the change in molar free energy, ∆G m, accompanying a composition gradient dX/dy, can be expressed asFootnote 4

and the interfacial energy is given by the equation

Substitution of Eq. 35 into Eq. 36 gives the result

The average value of dX/dy can be obtained from the equation

so that σ can be expressed as

On expressing the average gradient across the interface as

where C is a numerical constant, we arrive at the simple expression for σ given by eq. (25).

In the derivation of Eq. 39 the gradient energy has been taken as constant. In fact χ generally varies with composition (see [86] for a representative evaluation), but for the relatively small difference between X γ and \( X_{{\gamma^{\prime } }} \) (~12%) the assumption of constancy of χ in the integral, Eq. 36, is reasonable. There is also a contribution to χ from the gradient in long-range order [87], but in phase-field simulations the magnitude of this contribution generally varies from 10 [87] to ~400 times [88] smaller than the chemical contribution.

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License ( https://creativecommons.org/licenses/by-nc/2.0 ), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Ardell, A.J. A1-L12 interfacial free energies from data on coarsening in five binary Ni alloys, informed by thermodynamic phase diagram assessments. J Mater Sci 46, 4832–4849 (2011). https://doi.org/10.1007/s10853-011-5395-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5395-x