Abstract

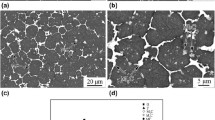

The densification and microstructural evolution during co-sintering of M2 tool steel/316L stainless steel composite layers with and without boron addition was studied. A pressureless sintering method in conjunction with a powder layering technique was used to fabricate the stepwise graded composite layers. Isothermal and non-isothermal sintering response of the individual and composite layers was examined and the microstructural features of the bonding zone were studied. Shear strength and microhardness of the bonding zone were also measured. It was shown that an enhanced densification is obtained in the composite layers due to (i) sintering shrinkage incompatibility between two steels, (ii) interlayer diffusion of the alloying elements and formation of a dual δ-ferrite/austenite phase at high temperature, and (iii) formation of a low temperature eutectic Fe (C)-B phase at the interface in the samples containing boron. The morphology of carbides in M2/316L is significantly changed as the sintering temperature increases, i.e., they appeared as fine intergranular carbides at low temperatures (1,240 °C), thick film at 1,260 °C and herringbone shape eutectic at 1,290 °C. Elongated grains with an intergranular boride phase were seen in the bonding zone of M2/316L + B layers. The shear strength of the interface of the composite layers was found to be superior to that of the individual layers.

Similar content being viewed by others

References

Tan LK, Baumgartner R, German RM (2001) In: Advances in powder metallurgy and particulate materials, vol 4. Compiled by W.B. Eisen and S. Kassam, Metal Powder Industries Federation (MPIF), Princeton, NJ, p 191

Alcock JR, Logan PM, Stephenson DJ (1998) Surf Coat Technol 105:65

Heaney DF, Suri P, German RM (2003) J Mater Sci 38:1

Simchi A, Rota A, Imgrund P (2006) Mater Sci Eng 424 A:282

Simchi A (2006) Metal Mater Trans 37A:2549

Tamjid E, Simchi A, Hartwig T (2006) In: Proc. of the First Conference on Nanoscience and Nanotechnology. University of Tehran, Tehran

Dourandish M, Godlinski D, Simchi A and Firouzdor V (2007) Mater Sci Eng A (in press)

Imgrund F, Rota A, Prtzoldt F, Simchi A (2007) Int. J. Adv Manuf Technol 33:176

Simchi A, Petzoldt F, Hartwig T (2005) In: Proc. of Euro PM2005 Conference and Congress, vol 2. European Powder Metallurgy Association (EPMA), Shrewsbury, UK, p 357

Pest A, Petzoldt F, Eifert H, Veltl G, Hartwig T, German RM (1996) In: Proc. of Powder Metallurgy and Technology World Congress. Metal Powder Industries Federation (MPIF), vol 5, part 19. Granada, Spain, p 171

Liu ZY, Loh NH, Khor KA, Tor SB (2000) Mater Sci Eng 293A:46

Varez A, Levnfeld B, Torralba JM, Matula G, Dobrzanski LA (2004) Mater Sci Eng 366A:318

ASM Metals Handbook, 9th edn., vol 9 (1985) ASM International, Metals Park, OH, p 282

Sindo K (2002) Welding metallurgy, 2nd edn. John Wiley & Sons, Inc., Publication

Porter DA, Easterling KE, Phase (1983) Transformations in meals and alloys. Van Nostrand Reinhold Co. Ltd., Berkshire, England, p 89

Shewmon P (1989) Diffusion in solids, 2nd edn. TMS Publication, p 132

Shu GJ, Hwang KS, Pan YT (2006) Acta Mater 54:1335

Tandon R, German RM (1998) Inter J Powder Metall 34:40

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Firouzdor, V., Simchi, A. & Kokabi, A.H. An investigation of the densification and microstructural evolution of M2/316L stepwise graded composite during co-sintering. J Mater Sci 43, 55–63 (2008). https://doi.org/10.1007/s10853-007-2077-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2077-9