Abstract

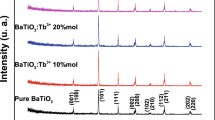

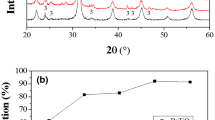

The structural, microstructural, optical, electrical and dielectrical properties of nanocrystalline Fe substituted BaTiO3 synthesized by sol-gel auto combustion have been investigated. The X-ray diffraction (XRD) analysis revealed the existence of the tetragonal phase for lower Fe content (x = 0.0–0.3) whereas, coexistence of the tetragonal and hexagonal structure of higher Fe content (x = 0.4 and 0.5). The lattice constant (a and c) and unit cell volume (V) increases with increase in Fe content; and an average crystallite size (t) was recorded in the range of ~14–20 nm. The surface morphology as examined using field emission scanning electron microscopy (FESEM) and the compositional stoichiometry was confirmed by energy dispersive spectrum (EDS) analysis. The UV-Vis spectra showed that the band gap energy sensitively depends on the Fe concentration x. DC-electrical conductivity (σ) was recorded in the temperature range of 333–714 K which was found to be increases with increasing temperature and Fe concentration; indicating that an electrical conduction was a thermally activated process. The type of temperature dependent DC conductivity indicates that the electrical conduction in the material is a thermally activated process. The dependencies of the conductivity contributions were predicted from the simple defect model presented, in which oxygen vacancies charge compensate Fe substitution of Ti. Dielectrical property was measured as a function of frequency in the range 50 Hz - 5 MHz at room temperature which was found to be higher at lower frequencies. Dielectric constant (ε’) and loss tangent (tan δ) shows strong compositional as well as frequency dependences.

Similar content being viewed by others

References

C. K. Su Sheng, Ong. Microelectron Eng 87, 1932–1934 (2010)

K. Ecija, A. Vidal, A. Larrañaga, L. Martínez-Amesti, M. I. Ortega-San-Martín, Arriortua. Solid State Ionics 235, 14–21 (2013)

D. Sette, V. Kovacova, E. Defay, Thin Solid Films 589, 111–114 (2015)

X. Jin, D. Sun, M. Zhang, Y. Zhu, J. Qian, J Electroceram 22, 285–290 (2009)

J. S. Capurso, A. A. Bologna, W. A. Schulze, J Am Ceram Soc 78, 2476–2480 (1995)

J. Qi, Z. Gui, Y. Wang, Q. Zhu, Y. Wu, L. Li, Ceram Int 28, 141–143 (2002)

M. Bibes, A. Barthelemy, Nat Mater 7, 425 (2008)

G. Catalan, J. F. Scott, Adv Mater 21, 2463 (2009)

F. Lin, D. Jiang, X. Ma, W. Shi, J Magn Magn Mater 320, 691–694 (2008)

Y. H. Lin, S. Zhang, C. Deng, Y. Zhang, X. Wang, C. W. Nan, Appl Phys Lett 92, 112501 (2008)

Y. W. Cho, T. S. Hyun, S. K. Choi, J Electroceram 13, 251–255 (2004)

G. B. Li, S. X. Liu, F. H. Liao, S. J. Tian, X. P. Jing, J. H. Lin, Y. Uesu, K. Kohn, K. Saitoh, M. Terauchi, N. Di, Z. J. Cheng, Sol State Chem 177, 1695–1703 (2004)

J. Xu, J. Zhai, X. J. Yao, J. Alloys, Compd 467, 567–571 (2009)

S. Sen, R. N. Choudhary, P. Pramanik, Mater Lett 58, 3486–3490 (2004)

Z. Wang, J. Hu, M. Yu, Nanotechnology 18, 235203–235204 (2007)

J. Spanier, A. Kolpak, J. Urban, I. Grinberg, L. Ouyang, W. Yun, A. Rappe, H. Park, Nano Lett 6, 735–739 (2006)

F. Lin, D. Jiang, X. Ma, W. Shi, J Magn Magn Mater 320, 691–694 (2008)

Zhong, W., David Vanderbilt, K. M. Rabe, Physical Review Letters 73.13 (1994) 1861.

F. Lin, D. Jiang, X. Ma, W. Shi, Physica B 403(17), 2525–2529 (2008)

A. Von Hippel, Rev Mod Phys 22(3), 221 (1950)

P. T. Phong, B. T. Huy, Y.-I. Lee, I.-J. Lee, J Alloys Compd 583, 237 (2014)

J. Dickson, G. L. Katz, W. Roland, J Am Chem Soc 83(14), 3026–3029 (1961)

B. Xu, K.B. Yin, J. Lin, Y.D. Xia, X.G. Wan, J. Yin, X.J. Bai, J. Du, Z.G. Liu, Phys Rev B 79 (2009) 134109.

Ha M. Nguyen, N.V. Dang, P.-Y. Chuang, T.D. Thanh, C.-W. Hu, T.-Y. Chen, V.D. Lam, C.-H. Lee, L.V. Hong, Appl. Phys. Lett. 99 (2011) 202501–202503.

D. Ginting, S. C. Yu, T. L. Phan, N. V. Dang, T. D. Thanh, V. D. Lam, J. Korean Phys, Soc 62, 2128–2132 (2013)

L. Testino, L. Mitoseriu, V. Buscaglia, I. Pallecchi, A. S. Albuquerque, V. Calzona, D. A. Marre, A. S. Siri, P. Nanni, J Eur Ceram Soc 231, 323–327 (2006)

G. P. Duong, R. Groessinger, R. S. Turtelli, J Magn Magn Mater 310, 361–365 (2007)

M. B. F. van Raap, F. H. Sanchez, C. E. R. Torres, L. Casas, A. Roig, E. J. Molins, Phys: Condens Matter 17, 6519–6531 (2005)

P. Moriarty, Rep Prog Phys 64, 297–381 (2001)

A. S. Edelstein, R. C. Cammaratra (eds.), Nanomaterials: synthesis, properties and applications (CRC Press, 1998)

K. Samuvel, K. Ramachandran, Spectrochim Acta A Mol Biomol Spectrosc 136, 437–442 (2015)

F. Lin, W. Shi, Physica B 448, 451–456 (2012)

L. G. Hubert-Pfalzgraf, New J Chem 11, 663–675 (1987)

J. Livage, M. Henry, C. Sanchez, Progress in Solid State Chemistry 18, 259–342 (1988)

L. Springer, M.F. Yan in “Ultrastructure Processing of Ceramics, Glasses and Composites”, ed. L. L. Hench, D. R. Ulrich, Wiley, New York, (1984) p.464.

D. Bipul, S. Ravi, A. Perumal, D. Pamu, Physica B 448, 204–206 (2014)

N. V. Dang, N. T. Dung, P. T. Phong, I.-J. Lee, Physica B 457, 103–107 (2015)

R. Yimnirun, J. Tangsritrakul, S. Rujirawat, S. Limpijumnong, Ferroelectrics 381, 130 (2009)

D. Marrocchelli, N. H. Perry, R. Sean, Bishop, Physical Chemistry Chemical Physics 17(15), 10028–10039 (2015)

S. D. Birajdar, V. R. Bhagwat, A. B. Shinde, K. M. Jadhav, Mater Sci Semicond Process 41, 441–449 (2016)

R. Pornprasertsuk, C. Yuwapttanawong, S. Permkittikul, T. Tungtidtham, International Journal of Precision Engineering and Manufacturing Vol. 13 10 (2012) 1813–1819.

S. Yamanaka, K. Kurosaki, T. Maekawa, T. Matsuda, S.-i. Kobayashi, M. Uno, J Nucl Mater 344, 61–66 (2005)

R. D. Shannon, Acta Crystallogr A32, 751–767 (1976)

V. Pillai, D. O. Shah, J Magn Magn Mater 163, 243–248 (1996)

Ashiri R, Nemati A, Ghamsari M.S, Aadelkhani H.J. Non-Cryst Solids, 355 (2009) 2480–2484.

Benramache, S., Arif, A., Belahssen, O., Guettaf, A. 3(1) (2013) 1–6.

Y.-C. Lee, Y. s. Chang, L. G. Teoh, L. H. Yi, Y. C. Shen, J sol-gel Sci Technol 56(1), 33–38 (2010)

J. Yu, J. Chu, M. Zhang, Applied Physics A 74(5), 645–647 (2002)

M. Kaczmarek, R. W. Eason, I. Mnushkina, Applied Physics B 68(5), 813–817 (1999)

N. V. Dang, N. T. Dung, P. T. Phong, I.-J. Lee, Physica B 457, 103–107 (2015)

W. Heywang, Semiconducting barium titanate. J Mater Sci 6(9), 1214–1224 (1971)

F. A. Kroger, H. J. Vink, Solid State Phys 3, 307–435 (1956)

Kroger, F. A. and Vink, H. J., in Solid State Physics, Vol. 3, (cd. F. Seitzand D. Tumbull). Academic Press, NewYork, (1956) 307.

Bieger, T., Maier, J. and Waser, R., Proc. 7th Cimtec Conf (cd. P. Vincenzini) E.lsevier Sci. Publishers B.V., Montecatini, Italy, (1991) 623

T. Bieger, J. Maier, R. Waser, Solid State Ionics 578, 53–56 (1992)

Abbate, M., de Groot, F. M. F., Fuggle, J. C., Fujimori, A., Strebd, O., Lopez, F., Domke, M., Kaindl, G., Sawatzky, G. A.,Takano, M.,Takeda, Y., Eisaki, H. and Uchida, S., Phys. Rev. B., 1992–114, 6, 4511

M. Willander, O. Nur, M. Q. Israr, A. B. Abou Hamad, F. G. El Desouky, M. A. Salem, I. K. Battisha, J Crystallization Process Technol 2, 1–11 (2012)

N. Moso, H. Beltran, E. Cordoncillo, P. Escribano, A. R. West, J Mater Chem 16, 1626–1633 (2006)

C. Sameera, G. S. Devi, G. Kumar, Prasad, Spectrochemica Acta Part A: Molecular and Biomolecular Spectroscopy 136, 366–372 (2015)

V. Vinayak, P. P. Khirade, S. D. Birajdar, R. C. Alange, K. M. Jadhav, J. Supercond, Nov Magn 28, 3351–3356 (2015)

Z. Yu, Chen Ang. J Appl Phys 91(2), 794–797 (2002)

R. V. Mangalaraja, P. Manohar, F. D. Gnanam, J. Mater, Sci 39, 2037 (2004)

Z. Guo, L. Pan, C. bi, H. Qiu, X. Zhao, L. Yang, M.Y.Rafique, J Magn Magn Mater 325, 24–28 (2013)

M. A. Pena, J. L. G. Fierro, Chem Rev 101, 1981–2017 (2001)

Acknowledgments

The author Mr. Pankaj P. Khirade is very much thankful to Department of Physics, IIT Mumbai for providing X-ray diffraction (XRD) and North Maharashtra University, Jalgaon for scanning electron microscopy (FESEM) characterization facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khirade, P.P., Birajdar, S.D., Raut, A.V. et al. Effect of Fe – substitution on phase transformation, optical, electrical and dielectrical properties of BaTiO3 nanoceramics synthesized by sol-gel auto combustion method. J Electroceram 37, 110–120 (2016). https://doi.org/10.1007/s10832-016-0044-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-016-0044-z