Abstract

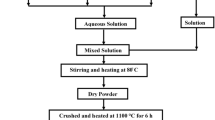

low-κ dielectric LTCC was developed, to realize successful co-firing with NiCuZn ferrite tapes. A critical high-temperature process in the production of highly integrated LTCC modules is the migration of silver from inner conductors into the LTCC glass phase. Intensive silver migration causes strong deformation of LTCC multilayers during firing in air. Silver migration into the LTCC glass phase depends on oxygen content of the sintering atmosphere and can be minimized by sintering in nitrogen atmosphere. However, partial decomposition of NiCuZn-ferrite and formation of cuprite was observed during sintering in nitrogen and, consequently, the permeability of the ferrite decreases. As shown by a combined XRD/thermogravimetric study the co-firing of LTCC modules with silver metallization and integrated ferrite layer demands precise adjustment of oxygen partial pressure.

Similar content being viewed by others

References

Y. Imanaka, Multilayered low temperature Co-fired ceramics (LTCC) technology, (Springer Science + Business Media, Inc., 2005)

L. J. Golonka, Bull. Pol. Acad. Sci. 54(2), 221 (2006)

B. Brandt, M. Gemeinert, T. Rabe, J. Bolte, Int. J. Appl. Ceram. Technol. 10(3), 413 (2013)

A. Heunisch, B. Schulz, T. Rabe, IMAPS/ACerS 8th Int. CICMT Conference (2012), Proceedings CD-ROM, 000097–000102.

J.-H. Jean, C.-H. Lee, Jpn. J. Appl. Phys. 38, 3508 (1999)

J.-H. Jean, C.-H. Lee, J. Am. Ceram. Soc. 82, 343 (1999)

J. Jeong, Y. H. Han, B. C. Moon, J. Mater, Sci. - Materials in Electronics 15, 303 (2004)

J. Mürbe, J. Töpfer, J. Electroceramics 15, 215 (2005)

J. Mürbe, J. Töpfer, J. Electroceramics 16, 199 (2006)

J. Mürbe, J. Töpfer, J. Magn. Magn. Mater. 324, 578 (2012)

R. Matz, D. Götsch, R. Karmazin, R. Männer, B. Siessegger, J. Electroceram, 27 [1–3], 209 (2009)

H. Naghib-zadeh, R. Karmazin, T. Rabe, J. Electroceram. 31(1–2), 88 (2013)

K. Ahadi, S. M. Mahdavi, A. Nemati, M. Kianinia, J. Mater. Sci. Mater. Electron. 22, 815 (2011)

E. R. Twiname, G. L. Messing, C. A. Randall, Int. J. Microcircuits Electr. Packag. 24, 105 (2001)

T. Rabe, M. Eberstein, W. A. Schiller, Ceram. Trans. 198, 173 (2007)

C. Glitzky, T. Rabe, M. Eberstein, W. A. Schiller, J. Töpfer, S. Barth, A. Kipka, J. Microelectron. Electron. Packag. 6(1), 1 (2009)

T. Rabe, H. Naghib-zadeh, C. Glitzky, J. Töpfer, Int. J. Appl. Ceram. Technol. 9(1), 18 (2012)

Y.-H. Lee, W.-C. Kuan, W.-H. Tuan, J. Eur. Ceram. Soc. 33, 95 (2013)

B. Brandt, H. Naghib-zadeh, T. Rabe, J. Am. Ceram. Soc. 96(3), 726 (2013)

K. B. Shim, N. T. Cho, S. W. Lee, J. Mater. Sci. 35, 813 (2000)

J.-H. Jean, C.-R. Chang, J. Am. Ceram. Soc. 87(7), 1244 (2004)

D. Tramosljika, J. Schaefer, G. Rixecker, F. Aldinger, Proceedings of conference on ceramic interconnect and ceramic microsystems technologies (CICMT), Baltimore (2005)

A. Roesler, J. Schare, C. Hetler, D. Abel, G. Slama, D. Schofield, Proceedings 60th Electronic Components and Technology Conference (2010) pp. 720–726

C.-S. Hsi, Y.-R. Chen, H.-I. Hsiang, J. Mater. Sci. 46, 4695 (2011)

M. Eberstein, M. Wenzel, C. Feller, T. Seuthe, F. Gora, Proceedings 8th international CICMT conference and exhibition, Erfurt (2012), 000018–000024

M. Eberstein, T. Rabe, W. A. Schiller, Int. J. Appl. Ceram. Technol. 3(6), 428 (2006)

T. Rabe, C. Glitzky, H. Naghib-zadeh, G. Oder, M. Eberstein, J. Töpfer, Proceedings 5th international conference and exhibition on ceramic interconnect and ceramic microsystem technology (CICMT), Denver (2009), 000085–000093

R. Dieckmann, Phys. Chem. 86, 112 (1982)

J. Töpfer, R. Dieckmann, J. Eur. Ceram. Soc. 24, 603 (2004)

Acknowledgments

This work was supported by the German Federal Ministry of Education and Research within the framework of research project “ALFERMO” (FKZ 13 N10666). The authors thank B. Capraro and S. Barth (Fraunhofer IKTS, Hermsdorf, Germany) for casting the ferrite tapes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naghib zadeh, H., Oder, G., Hesse, J. et al. Effect of oxygen partial pressure on co-firing behavior and magnetic properties of LTCC modules with integrated NiCuZn ferrite layers. J Electroceram 37, 100–109 (2016). https://doi.org/10.1007/s10832-016-0043-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-016-0043-0