Abstract

Anaerobic digestion (AD) is a unit process that integrates beneficially and sustainably into many bioprocesses. This study assesses and compares the production of methane from the biomass of the microalga Scenedesmus sp. and the cyanobacterium Spirulina sp. in batch anaerobic digesters. Anaerobic digestion of whole cell Spirulina resulted in a substantially higher methane productivity (0.18 L CH4 Lreactor −1 day−1) and methane yield (0.113 L CH4 g−1 volatile solids (VS)) compared to the digestion of whole cell Scenedesmus (0.12 L CH4 Lreactor −1 day−1 and 0.054 L CH4 g VS−1). Spirulina, possibly due to a combination of osmotic shock, the filamentous nature of the cells and lower mechanical strength of the non-cellulosic cell wall, was more readily degraded by hydrolytic and acidogenic microorganisms, resulting in the generation of a greater amount of acetic acid. This in turn provided greater substrate for methanogens and hence higher methane yields. In addition, Spirulina cells could be disrupted mechanically more quickly (1 h) than Scenedesmus cells (4 h) in a bead mill. Mechanical pre-treatment improved the final methane yields (L CH4 g VS−1) obtained from digestion of both substrates; however, the improvement was greater for Scenedesmus. Mechanical pre-treatment resulted in a 47 % increase in methane production for Spirulina compared to 76 % increase for Scenedesmus fed digesters. The more substantial increase observed for Scenedesmus was due to the relatively inefficient digestion of the whole, unruptured cells.

Similar content being viewed by others

Introduction

Microalgae have great potential as biocatalysts in the fields of wastewater treatment, bioremediation and carbon dioxide sequestration, as well as for the production of food, feeds, biofuels and high value products such as proteins, pigments and lipids. They have been reported to be more productive than higher plants on an areal basis and can be grown in poor quality or non-potable water (Illman et al. 2000). Major challenges in the application of microalgae in a variety of fields, particularly in the production of renewable fuels, include the sustainable and economic provision of nutrients such as nitrogen, phosphorous and CO2 and the minimisation of energy use (Borowitzka and Moheimani 2013; Chisti 2013). Anaerobic digestion (AD) is a simple, low-cost unit operation that could be advantageously integrated into many bioprocesses. Either whole algal biomass or the biomass residue after product extraction could be fed to an AD reactor, either as the sole feed or in combination with other substrates. AD offers the opportunity to recover and recycle nutrients, carbon dioxide and energy from the substrate, thereby yielding a more sustainable, cost-effective and energetically feasible process (Borowitzka and Moheimani 2013; Ward et al. 2014; Harrison et al. 2014).

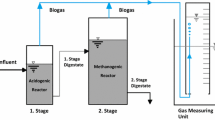

AD involves a series of reactions, including hydrolysis, acidogenesis, acetogenesis and methanogenesis, during which microorganisms break down biodegradable material in the absence of oxygen to produce biogas, as well as a liquid effluent rich in ammonia and phosphate (Borowitzka and Moheimani 2013). Biogas from AD is usually rich in methane (65–70 %) and carbon dioxide (30–35 %), with small amounts of hydrogen and hydrogen sulphide (Gunaseelan 1997; McKendry 2002). The biogas can be utilised directly or indirectly to derive energy in a number of processes. These include use in a combined heat and power unit (CHP), where the gas is combusted to produce heat and electricity, direct compression or liquefaction to produce a transport fuel (De Schamphelaire and Verstraete 2009) or purification for use in the production of traditional transport fuels such as petroleum or diesel (De Schamphelaire and Verstraete 2009). The CO2 in the biogas, as well as that generated by combustion of the methane, if carried out on site, could be recycled to algal ponds. The liquid effluent can be recycled to the algal cultures, reducing the requirement for fresh nutrients (Ward et al. 2014).

There are several challenges associated with AD of algal biomass, including ammonia and sulphur toxicity due to a high protein content, salinity of the biomass, if marine algal species are used, and recalcitrance of algal cells walls, leading to slow hydrolysis and low digestibility (Ras et al. 2011; Ward et al. 2014). AD of algal biomass has typically resulted in a lower performance than that of traditional energy crops (Braun et al. 2010), yet values of 0.5 m3 biogas per kg algal organic dry matter have been obtained (62.5 % CH4) (Golueke et al. 1957). The anaerobic digestion of Spirulina maxima resulted in a biogas yield of 0.3–0.37 m3 biogas kg−1 volatile solids (VS), with 70 % methane and conversion efficiencies up to 48 % (Samson and LeDuy 1982, 1983a, b, 1986). Maximum yields were obtained with a retention time of 30 days and an initial algal concentration of 20 kg VS m−3. In contrast to the study of Golueke et al. (1957), a mesophilic temperature (35 °C) was found most preferable for the degradation of the algal biomass (Samson and Leduy 1986). Biochemical methane potential (BMP) tests with Scenedesmus have suggested a potential yield of 0.4 m3 biogas kg−1 VS (McGinn et al. 2012).

The degradability of algal biomass in anaerobic digestions is species dependent. In some cases, cell walls resistant to degradation can be one of the major limiting factors in the digestion of algal biomass (Ward et al. 2014; Sialve et al. 2009). Chen and Oswald (1998) reported that up to 60 % of whole, untreated algal biomass could remain undigested in an AD reactor. More recently, Tartakovsky et al. (2013) reported that only 52–53 % of the algal biomass fed to an anaerobic digester was degraded at a retention time of 16 days, largely due to the limited hydrolysis of the algal biomass. Algal biomass is typically characterised by a relatively high cellulose (7.1 %) and hemicellulose content (16.3 %) (Ververis et al. 2007). Hydrolysis of cellulose does occur during AD, but is slow and may be rate limiting if present in high concentrations (Yen and Brune 2007). Algal cell walls protect the cell from extracellular enzymes produced by the anaerobic microbes, creating a strong resistance to hydrolysis. Golueke et al. (1957) and Sanchez and Travieso (1993) reported the presence of whole cells in their digesters after long periods of time, confirming the resistance to degradation.

Mechanical and thermochemical pre-treatments have been applied to algal biomass to increase the biodegradability (Golueke and Oswald 1959; Chen and Oswald 1998; Gonzalez-Fernandez et al. 2012a, b; Samson and Leduy 1983a). Chen and Oswald (1998) investigated pre-treatment with various combinations of heat and sodium hydroxide. All pre-treatment scenarios yielded better results than untreated controls, with a maximum increase in methane production of 33 % with pretreatment at 100 °C for 8 h. Gonzalez-Fernandez et al. (2012a) reported an increase in methane production of 9 % with thermal pretreatment at 70 °C and 59 % at 90 °C for 1 h in Scenedesmus sp. Samson and Leduy (1983b) investigated the thermo-chemical and mechanical pre-treatment of Arthrospira (Spirulina) maxima biomass. They report that ultrasonic degradation for 10 min was as efficient as thermal pre-treatment at 150 °C for 1 h. They also showed that freezing of the biomass could result in enhanced solubilisation.

Algal cell wall composition and degradability are species dependent (Mussgnug et al. 2010). Scenedesmus sp. has a recalcitrant cell wall with a highly resistant trilaminar structure composed of cellulose, algaenan and glucosamine-containing biopolymers and glycoproteins (Voigt et al. 2014). Spirulina has a much more easily degraded cell wall composed of protein, polysaccharides and peptidoglycans (Van Eykelenburg 1977). This study assesses and compares the efficiency of digestion and the production of methane from the biomass of the microalga Scenedesmus sp. and the cyanobacterium Spirulina sp. in batch anaerobic digesters. The conversion of solid to soluble chemical oxygen demand (COD) as well as the evolution of volatile fatty acids (VFAs) were analysed with and without mechanical pre-treatment of the biomass in order to better understand the effect of species choice and biomass pre-treatment on the efficiency of digestion.

Most studies conducted on AD of algal biomass have used a semi-continuous system, in which feed is added to the digesters at a specific load of volatile matter and desired retention period. However, few studies consider fundamental batch data before proceeding to operate a semi-continuous or continuous mode digester. By conducting these studies in batch reactors, with rigorous analytical analysis, the effect of the treatments on the different stages of AD can be better elucidated in order to inform continuous AD process design. One of the potential limitations of batch experiments is that they may not identify problems from the buildup of inhibitory substances, e.g. sulphur and ammonia, that can occur during the continuous operation of anaerobic digesters. Inhibitory levels may not be reached during a batch experiment when compared to the continuous operation of digesters.

Methods

Algal cultivation

Scenedesmus sp. (isolated from algal ponds in Uppington, South Africa) and Spirulina sp. (isolated from tannery effluent ponds, Wellington, South Africa) were maintained in 3 N BBM medium (Bold 1949) and Zarrouk’s medium (Zarrouk 1966), respectively. Cultures were grown in 3.2 L airlift photobioreactors and a 50-L raceway pond. The glass and steel photobioreactors were 600 mm high, with a 100-mm diameter column and a 50-mm diameter draught tube. Reactors were sparged at 2 L min−1 with either regular air (for Spirulina sp.) or air enriched with 2900 ppm CO2 (for Scenedesmus sp.). Light was supplied continuously by three Osram 18 W cool white fluorescent bulbs at a distance of 3 cm from the column surface, providing 300 μmol photons m-2 s−1. A 50-L Perspex raceway pond with a paddle wheel was used for larger scale algal cultivation. Scenedesmus sp. cultures were sparged with air (25 L min−1) through a 6.35 mm stainless steel tube, with 1 mm holes drilled every 20 cm, positioned on the reactor floor. Spirulina sp. cultures were not sparged, as the primary carbon source was bicarbonate (HCO3 −), not CO2. Circulation of the media was achieved using a four bladed paddle wheel at 20 rpm for Scenedesmus sp. and at 10 rpm for Spirulina sp. The liquid depth was 10 cm, and the total surface area was 0.51 m2. Six 58 W and two 36 W fluorescent bulbs provided continuous light to the cultures. Algal biomass concentration was determined daily by measuring optical density at 750 nm with a Helios spectrophotometer and converting these to dry mass concentration using a calibration curve. Biomass dry weight was measured by filtration of a 5 mL sample through a pre-weighed 0.22 μm filter, which was then dried at 80 °C overnight before being re-weighed.

Mechanical pre-treatment of algal biomass

Batch phase bead milling was used as the mechanical pre-treatment to rupture the algal cells. One litre of concentrated algal slurry at concentrations of 40 or 20 g L−1 was loaded into a cylindrical 1 L glass reactor with four 10 mm wall baffles. Glass beads (1 mm diameter beads for the smaller Scenedesmus sp. and 4 mm diameter beads for the filamentous Spirulina sp. cells) were loaded at 35 % vol/vol. The mixture was agitated at 900 rpm using a 20-mm diameter Rushton turbine for 1 h for Spirulina and 4 h for Scenedesmus. Both Spirulina and Scenedesmus were milled until no whole cells could be identified by light microscopy and the increase in soluble COD had stabilised. Milling of Spirulina resulted in a significant increase in soluble COD (18,250 to 41,250 mg COD L−1) and decrease in solid COD (46,400 to 24,400 mg COD L−1). The soluble COD of the Scenedesmus slurry increased from 5700 to 10,300 mg COD L−1, while that of the solid matter decreased (43,300 to 39,000 mg COD L−1) during milling.

Anaerobic digester inoculum preparation

A mixture of two different inocula was used to provide the required anaerobic microbes in all anaerobic digesters. The first inoculum was obtained from an anaerobic digester treating brewery effluent located at South African Breweries (SAB), Newlands, Cape Town, South Africa. The second component of the inoculum was obtained from a 1-L stock reactor maintained on Spirulina sp. and sodium acetate (1 g L−1). The stock reactor was inoculated with 20 % (vol/vol) activated sewerage sludge. The stock digester was operated in fed batch mode with intermittent loading of Spirulina sp. biomass. Gas production and composition were monitored to ensure that the digester was operating efficiently. The digester was harvested when necessary, and the volume gradually increased back to the operating volume of 1 L by addition of Spirulina sp. slurries. The method of inoculation utilised in this study ensured a relatively consistent initial population of microorganisms in each digester.

Anaerobic digester operation

The digestion experiments were carried out in continuously mixed bench-top batch reactors constructed from 1 L Duran Schott bottles. The reactors were operated with minimal headspace, at 37 ± 2 °C, and were continuously mixed at 140 rpm on an orbital shaker. Biogas was collected using water displacement vessels filled with saturated sodium chloride (NaCl) solution to minimise the dissolution of CO2. To prevent any backflow of NaCl into the reactors, 1 L trap bottles were inserted on all biogas lines. These trap bottles were fitted with a secondary biogas sampling point. The volume of biogas produced was corrected for normal temperature and pressure (STP). The digester pH was controlled by injecting 5 M sodium hydroxide (NaOH).

Triplicate digesters were loaded with 20 g DW of the appropriate substrate (either whole, wet biomass or a slurry of ruptured cells with an initial loading of 20 g DW). Tap water was added to a total volume of 800 mL. The reactor was inoculated with 100 mL of the stock (digesting Spirulina) inoculum and 100 mL of the SAB inoculum. The reactor was made airtight using a custom cast silicone seal, which fitted inside the screw cap. The sampling and gas collection port were connected and the reactor prepared for anaerobic operation by sparging with nitrogen for 5 min. All ports, with the exception of the gas exhaust port, that fed the gas collection system, were sealed.

Analytical techniques

The methane content of the biogas was determined using flame ionisation detection gas chromatography (FID GC). All FID GC measurements were conducted on a Perkin Elmer Autosystem Gas Chromatograph using a Supelco wax column (1.2 mm × 37 m), a detector temperature of 280 °C, an oven temperature of 50 °C and an injection volume of 100 μL. Nitrogen, at a flow rate of 1.5 mL min−1, was used as the carrier gas. The chromatograph was calibrated with a standard gas containing 52.8 % CH4 vol/vol.

All COD measurements were carried out using the Merck reagent test protocol for high (1500–10,000 mg L−1) concentrations. A full volatile fatty acid (VFA) profile analysis was conducted to quantify the concentration of lactic, acetic, propionic, iso-butyric, butyric, iso-valeric and valeric acids present in all digesters over the duration of digestion. The concentration of each VFA was determined using HPLC on a Waters Breeze 2 HPLC system equipped with a Bio-Rad Organic Acids ROA column and a UV (210 nm wavelength) detector. The system was run isocratically using a mobile phase of 0.01 M H2SO4 at a flow rate of 0.6 mL min−1. The pressure in the column did not exceed 137,895 hPa. Sample injection volumes of 100 μL were used. Total solids (TS), volatile solids and pH were measured using the standard methods (American Public Health Association 1992).

Results

Substrate analysis

Characteristics of the Spirulina and Scenedesmus biomass relevant to their anaerobic digestion are listed in Table 1. The key differences were in the different C/N ratios and the difference in cell morphology.

Biodegradability of whole cell biomass

The progress of hydrolysis in AD reactors fed with whole cell Spirulina and Scenedesmus biomass was monitored by measuring solid and soluble COD concentrations (Fig. 1). Spirulina solid COD decreased to 50 % of the starting concentration within the first 4 days. This was accompanied by an increase in soluble COD. Both solid and soluble COD then decreased slowly to a residual concentration of approx. 4000 mg L−1. Scenedesmus solid COD remained at a level equivalent to the starting concentration for the first 12 days, then decreased slowly to day 30 and more rapidly thereafter. Relatively high concentrations of solid COD remained in the reactor after 48 days of AD. Scenedesmus soluble COD reached a maximum between days 6 and 14 and then decreased to negligible values.

VFA profiles for whole cell biomass

The two types of unruptured algal biomass had very different VFA production profiles (Figure S1, supplementary information). Reactors loaded with Spirulina sp. had much higher total VFA accumulation (8000 mg Total VFAs L-1) compared to those loaded with Scenedesmus sp. (2800 mg Total VFAs L−1). This indicates that hydrolysis is the rate-limiting step in Scenedesmus digestion, while methanogenesis is rate limiting in the Spirulina-fed reactors. The ratio in which the key acids (acetate/butyrate/propionate) were accumulated was 8:4:1 in the Spirulina digesters and 3:2:1 in the Scenedesmus digesters at the maximum total VFA concentration.

Methane production of whole-cell biomass

The biogas productivity profiles (Figure S2, supplementary information) for the digestion of Spirulina and Scenedesmus followed a similar trend. Biogas production was maximum within the first 2 days; however, the methane concentration of the biogas was very low (10–20 %) (Figure S3, supplementary information). Gas production then ceased until day 10 for Scenedesmus and day 16 for Spirulina. Between days 10 and 30, biogas production increased and corresponded to high methane contents and elevated rates of acetic acid consumption (Figure S1). Methane production was delayed in Spirulina relative to Scenedesmus.

Combining the methane content and biogas productivity data yielded the methane productivity of the AD systems (Fig. 2). The Spirulina AD reactors showed an increase in both biogas production and methane content after approximately 15 days. After 18 days, the biogas productivity started to increase substantially, reaching a peak after 27 days at 0.23 L biogas Lreactor −1 day−1. At this same point, the methane content was at a maximum of 84 %, resulting in a maximum methane productivity of 0.18 L CH4 Lreactor −1 day−1. After this point, both the methane content and biogas productivity steadily decreased, resulting in lower methane productivities. The Scenedesmus digesters followed a similar trend. The key difference, which related directly to the biogas productivity, was that the maximum methane production occurred earlier (16 days) and at a lower rate (0.12 L CH4 Lreactor −1 day−1) in the Scenedesmus reactors.

Impact of mechanical pre-treatment

The main purpose of performing a mechanical pre-treatment was to release the intracellular contents, such that digestion was not limited by hydrolysis. The disruption efficiency was determined by microscopy and through quantifying the increase in soluble COD of the slurry. Milling had a proportionally greater effect on the solid and soluble COD values for Spirulina (see methods section for details of COD values before and after milling).

The VFA profile obtained for the ruptured Spirulina (Figure S4a, supplementary information) was very similar to that of the unruptured biomass (Figure S1a, supplementary information), both in terms of VFA production and consumption. AD of the ruptured Scenedesmus cells resulted in significantly different VFA profiles (Figure S4b, supplementary information) compared to whole cell digestion (Figure S1b, supplementary information). After 15 days, the ruptured cell digesters averaged approximately 5600 mg total VFA L−1 whereas the whole cell digesters averaged 2800 mg total VFA L−1. Mechanical pre-treatment resulted in significantly higher VFA concentrations during AD for Scenedesmus, but not for Spirulina.

For Spirulina sp., the liberation of key organics through disruption resulted in a greater maximum methane productivity of 0.26 L CH4 Lreactor −1 day−1 compared to 0.18 L CH4 Lreactor −1 day−1 for the whole cell digesters during the linear VFA consumption phase. With the exception of the higher peak, rupturing did not significantly alter the profile.

The methane productivity profiles for the Scenedesmus sp. digesters indicated that the disruption of the algal cells resulted in a significant rise in methane production across digestion. However, the maximum average productivity remained lower than that for the Spirulina sp. digesters (0.14 L CH4 Lreactor −1 day−1 compared to 0.26 L CH4 Lreactor −1 day−1). The final methane yield for Spirulina sp. increased from 0.113 L CH4 g−1 VS loaded to 0.166 L CH4 g−1 VS loaded with the inclusion of mechanical pre-treatment. The methane yield from Scenedesmus sp. digestion increased from 0.054 to 0.097 L CH4 g−1 VS with disruption (Fig. 3). There was a significant lag in methane production, which was not reduced by cell disruption. This may have been caused by the relatively high initial substrate loading rate.

pH

The optimum pH for digestion is between 6.5 and 7.6 (Parkin and Owen 1986). During the initial days of the experiment, the pH of the whole-cell Spirulina sp. culture decreased from pH 6.5 to pH 6.1 and the Scenedesmus sp. culture from pH 6.6 to pH 6.2. This indicates an accumulation of VFAs, as the acids formed at a higher rate than acetic acid consumption by the methanogenic microbes. The additional alkalinity in the Spirulina sp. substrate may have buffered the system, resulting in a lower pH drop despite a higher concentration of VFAs. In the digesters fed with disrupted Scenedesmus, there was an initial decrease in pH from pH 6.60 to pH 4.59. The Spirulina digesters did not suffer from a decrease in pH, presumably since residual alkalinity buffered the pH. After this initial decrease in pH, active control using 5 M NaOH was initiated to maintain the pH above 7.0 and ensure maximum methanogen activity. This drop in reactor pH could indicate that the initial loading rate of the batch reactors may have been too high, although Samson and LeDuy (1986) reported maximum methane yield (0.35 m3 kg−1 VS) at a loading of 20 kg VS m−3. If the reactor pH had not been manually controlled, the reactors may have crashed due to low pH. This could explain the long lag times in methane production (Figs. 2, S2 and S5) and could indicate that an equivalent loading rate in continuous culture would be too high.

Efficiency of digestion

The efficiency of AD can also be represented by the overall destruction of COD (both solid and soluble), VFAs and VSs (Table 2). The values for VS destruction are low compared to those for COD destruction. This could be because the calculation employed (Varel’s equation) relies on accurate measurement of CO2 and CH4 evolution. It is possible that some output carbon data could be missing due to dissolved CO2 trapped in the liquid portion of the reactors and other soluble products not converted into biogas.

Discussion

Spirulina and Scenedesmus represent quite different substrates for AD. The differences in cell size and morphology, as well as the differences in cell wall composition, suggest that Spirulina would be more easily digested and more susceptible to mechanical breakage than Scenedesmus. The optimum C/N ratio for AD is reported to be between 20 and 30 (Yen and Brune 2007); therefore, Spirulina has a less favourable C/N ratio (5.33) compared to Scenedesmus (11.5). Digestion of the Spirulina biomass with a relatively high protein content (60 %) and low lipid content (3 %) could be expected to lead to ammonia accumulation in the digester, causing inhibition of the methanogens (Ward et al. 2014). This inhibition was not experienced in the batch experiments conducted here (at no stage for the whole-cell or ruptured biomass of either algal species did accumulation of any indicator VFA for ammonium inhibition occur); however, inhibition may only become apparent in continuous studies.

The culture medium used for Spirulina (Zarrouk’s medium) had a high salt concentration (conductivity ± 20 mS cm−1 compared to only 2 mS cm−1 for the 3 N BBM medium used for Scenedesmus); therefore, resuspension of the slurry in pure water could cause osmotic damage to the cells. The alkalinity of the Spirulina slurries was higher, probably due to residual media transferred along with the biomass. The increased alkalinity can act as a buffer to stabilise the pH and reduce the possible inhibition by VFAs and NH3 (Samson and LeDuy 1986).

The progress of AD was monitored by measuring solid and soluble COD in the reactors over time. For the Spirulina digesters, a large initial decrease in solid COD was accompanied by an increase in soluble COD (days 0 to 4, Fig. 1) indicating that insoluble, complex organic molecules were broken down into their component parts by hydrolytic enzymes. The cyanobacterium Spirulina has a soft cell wall made of complex sugars and proteins, unlike the cellulosic walls of most algae, as well as a filamentous structure, making it more easily disrupted and digested (Van Eykelenburg 1977). This was confirmed by the significant decrease in solid COD from days 0 to 30. The residual soluble COD suggests the presence of soluble components that are not readily utilised by methanogenic organisms.

The solid COD in the Scenedesmus digesters only decreased significantly at a later stage (day 26, Fig. 1), indicating lower biodegradability, than Spirulina. The cell walls of Scenedesmus are composed of degradation resistant, polyether, non-hydrolysable aliphatic biopolymers (Blokker et al. 1998). Further, the cell walls contain large amounts of hemicelluloses that hydrolyse slowly in AD systems (Yen and Brune 2007). The soluble COD concentration of the Scenedesmus digesters was decreased to the detection limit. This related directly to the slow biomass degradation, which was the rate-limiting step.

The higher concentration of VFAs produced from Spirulina biomass was directly related to the availability of easily fermentable organics and readily degradable biomass within the digesters (Angelidaki et al. 1999). Scenedesmus sp. has a strong cell wall made up of complex biopolymers resistant to hydrolysis; therefore, fewer readily available organics were present in the aqueous phase of the slurry for conversion to VFAs during the initial stages of digestion. After the initial high rate of production of these specific acids, the total VFA concentrations stabilised. The high initial concentration of VFAs, as well as the initial drop in pH, indicated that the initial substrate loading rate may have been too high. This would have affected the activity of the microbial consortia, requiring it to acclimatise to the new environment (Angelidaki et al. 1999), and resulting in the long lag phase before significant methane production (Fig. 2). The methanogenic activity increased after a shorter period (10 days) for the Scenedesmus sp. digesters than the Spirulina sp. digesters (18 days). The latter produced three times the total VFAs during the initial stages of digestion, resulting in a longer stabilisation or acclimatisation period.

Biogas production peaked during the first 2 days after inoculation, after which it ceased. This was consistent with the VFA concentration profiles that showed a “lag” period, where minimal changes in VFA concentration occurred (Figure S1, supplementary information). When methanogenic activity began to increase, biogas production increased simultaneously. The subsequent peak in biogas productivity related directly to the maximum rate of consumption of VFAs in both species. The higher maximum biogas productivity of the Spirulina digesters (0.21 L Biogas Lreactor −1 day−1) than that of the Scenedesmus digesters (0.15 L Biogas Lreactor −1 day−1) was consistent with the greater change in VFA concentrations.

For both Spirulina and Scenedesmus digesters, the initial DW loading was 20 g L−1, which corresponded to 16.8 g VS L−1 for Spirulina sp. and 16.3 g VS L−1 for Scenedesmus sp. The ultimate yield for the Spirulina digesters (0.11 L CH4 g−1 VS loaded) was greater than that of the Scenedesmus digesters (0.06 L CH4 g−1 VS loaded). Organic loading rates vary widely across studies (Table 3). The initial loading rate of the batch digesters in this study may have been too high for continuous operation. In addition, the high protein content of the Spirulina biomass could potentially lead to ammonia and sulphur inhibition in continuous operation. The biogas yields measured in this work are low compared to those found in other studies (Table 3).

Mechanical pre-treatment had little effect on the VFA profile of Spirulina digestion. Spirulina filaments appeared to degrade rapidly under the conditions in the AD reactors, both with and without mechanical pre-treatment. While milling increased the soluble COD of the Spirulina slurry by over 100 %, this was not reflected in the VFA values, suggesting that the soluble intracellular components were primarily proteins, carbohydrates and long chain fatty acids. The data differ significantly from that presented by Samson and LeDuy (1983b), who investigated the impact of ultrasonic pre-treatment (mechanical disintegration) of Spirulina on digestion efficiency. The semi-continuous AD system had an average VFA concentration of 8685 mg CH3OOHequivalent L−1 when digesting the ruptured substrate compared to 3249 mg CH3OOHequivalent L−1 for the whole cell biomass. The difference may be accounted for by the lower retention time (20 days) and increased VS loading rate (2 kg VS m−3 day−1).

The higher VFA concentrations in the digesters fed with disrupted Scenedesmus (Figure S4b, supplementary information) as opposed to whole cell Scenedesmus (Figure S1b, supplementary information) highlighted the benefit of disruption in liberating complex organic molecules that could be converted to VFAs. This immediately increased the BMP of the system. The higher initial VFA production resulted in an extended lag phase (18 days compared to 10 days) as more time was needed for the microbial consortia to acclimatise to the change in environment.

Mechanical disruption of Spirulina resulted in a methane yield 47 % greater than without disruption. This can be attributed to increased microbial activity during the early stages of digestion, as well as to the extended period of methane production. Samson and LeDuy (1983b) reported that the mechanical pre-treatment of S. maxima positively influenced acidogenic bacteria, but did not increase methane production. The results shown in the current study indicate that an increase in VFA production results in a greater consumption of acetic acid by methanogens and so a greater methane yield. Unless the concentrations become inhibitory, this should always be the case. AD of mechanically disrupted Scenedesmus resulted in a methane yield 76 % greater than without disruption. The substantial increase related to the greater amount of acetic acid produced and consumed. This agrees with studies by Gonzalez-Fernandez et al. (2012a, b) who found a 2-fold increase in methane production from Scenedesmus biomass disrupted by ultrasound (2012a) and a 2-fold increase in the biodegradability of Scenedesmus biomass heat treated at 90 °C (2012b), compared to untreated biomass.

The results in Table 2 confirm that Spirulina sp. degraded more easily than Scenedesmus sp. The larger consumption of both total and solid COD as well as the total destruction of VS supported this result. The residual, apparently indigestible, biomass resulted in a solid COD value in the region of 4800 mg L−1, which remained relatively unchanged from day 30 for the whole cell digesters and day 34 for the digesters fed ruptured biomass. The destruction profiles for the Scenedesmus sp. whole cell and ruptured cell digesters revealed that mechanical disruption of the cells allowed more of the original solid COD to be consumed. The result differs from the Spirulina sp. digesters where the residual solid COD was not affected by mechanical pre-treatment. The difference is largely due to the extent of disruption. From the images taken during milling, partially disrupted cells were seen after bead mill operation had stopped, which contributed to solid COD. However, these cells degrade more easily through digestion, increasing the concentration of soluble organics. This also led to a high net destruction of solid COD. The low destruction of solid COD in the whole cell digesters supported this result and highlighted the resistance of Scenedesmus sp. to degradation. This confirmed that breakdown of COD in the ruptured cell digesters was most likely not a result of cell fragment degradation. In an intact cell, the soluble intracellular components still count as solid COD because they are trapped in the cell.

In conclusion, the anaerobic digestion of the whole cell or mechanically disrupted biomass of the microalgae Spirulina sp. and Scenedesmus sp. was investigated through analysis of the rate of solubilisation of COD, production of VFAs and evolution of methane over time in batch anaerobic reactors. Anaerobic digestion of whole cell Spirulina resulted in a substantially higher methane productivity (0.18 L CH4 Lreactor −1 day−1) and methane yield (0.113 L CH4 g−1 VS) compared to the digestion of whole cell Scenedesmus (0.12 L CH4 Lreactor −1 day−1 and 0.054 L CH4 g−1 VS). This can be attributed to a higher production of VFAs in the Spirulina digesters as a direct result of the greater degradability of the algal biomass. The higher resistance of Scenedesmus sp. to degradation resulted in reduced methane yields.

Mechanical pre-treatment improved the final methane yields in both substrates, from 0.113 to 0.166 L CH4 g−1 VS for Spirulina and 0.054 to 0.097 L CH4 g−1 VS for Scenedesmus. The effect of pre-treatment was greater for Scenedesmus due to the relatively inefficient digestion of the whole unruptured cells, attributable to the highly recalcitrant cell wall. This study suggests that hydrolysis is the rate-limiting step in anaerobic digestion of microalgae. Without pre-treatment, methane yield is dependent on cell wall composition, which affects resistance to bacterial degradation. It was shown that mechanical cell disruption of recalcitrant microalgal species, such as Scenedesmus, can alleviate this limitation, resulting in improved degradation efficiencies and higher final methane yield, to a level comparable with that of less recalcitrant biomass such as cyanobacteria. Despite pre-treatment, the methane yields achieved here are substantially lower than the theoretical methane potential calculated from their average elemental composition: 0.319 L g−1 VS for Spirulina platensis and 0.260 L g−1 VS for Scenedesmus dimorphus (Ward et al. 2014), and lower than those found in comparable studies (Table 3). This is likely largely due to the fact that the AD process was not optimised in this study.

Different species of algae result in different COD, VFA and methane production profiles during AD. Of the two species tested here, Spirulina appears to be the more promising substrate for AD due to its higher digestibility. This species does not require pre-treatment, however, the effects of the greater salinity of the biomass and the potential of the high protein content to lead to ammonia and sulphur inhibition in continuous operation should be taken into account.

References

American Public Health Association (1992) Standard methods for the examination of water and wastewater, 18th edn. 1015 Fifteenth Street, NW, Washington, DC 2005–2605

Angelidaki I, Ellegaard L, Ahring BK (1999) A comprehensive model of anaerobic bioconversion of complex substrates to biogas. Biotechnol Bioeng 63:363–372

Blokker P, Schouten S, van den Ende H, de Leeuw JW, Hatcher PG, Sinninghe Damste JS (1998) Chemical structure of algaenans from the fresh water algae Tetraedron minimum, Scenedesmus communis and Pediastrum boryanum. Org Geochem 29:1453–1468

Bold HC (1949) The morphology of Chlamydomonas chlamydogama sp. nov. Bull Torrey Bot Club 76:101–108

Borowitzka MA, Moheimani NR (2013) Sustainable biofuels from algae. Mitig Adapt Strateg Glob Change 18:13–25

Braun R, Weiland P, Wellinger A (2010) Biogas fom energy crop digestion. IEA Bioenergy report: Task 37 – energy from biogas and landfill gas. Available at http://www.iea-biogas.net/files/daten-redaktion/download/energycrop_def_Low_Res.pdf

Chen PH (1987) Factors influencing methane fermentation of microalgae. Doctoral thesis, University of California, Berkley, USA

Chen PH, Oswald WJ (1998) Thermochemical treatment for algal fermentation. Environ Int 24:889–897

Chisti Y (2013) Constraints to commercialization of algal fuels. J Biotechnol 167:201–214

De Schamphelaire L, Verstraete W (2009) Revival of the biological sunlight-to-biogas energy conversion systems. Biotechnol Bioeng 103:296–304

Golueke CG, Oswald WJ (1959) Biological conversion of light energy to the chemical energy of methane. Appl Environ Microbiol 7:219–227

Golueke CG, Oswald WJ, Gotaas HB (1957) Anaerobic digestion of algae. Appl Environ Microbiol 5:47–55

Gonzalez-Fernandez C, Sialve B, Bernet N, Steyer JP (2012a) Comparison of ultrasound and thermal pretreatment of Scenedesmus biomass on methane production. Bioresour Technol 110:610–616

Gonzalez-Fernandez C, Sialve B, Bernet N, Steyer JP (2012b) Thermal pretreatment to improve methane production of Scenedesmus biomass. Biomass Bioenergy 40:105–111

Gunaseelan VN (1997) Anaerobic digestion of biomass for methane production: a review. Biomass Bioenergy 13:83–114

Harrison STL, van Hille RP, Mokone T, Motleleng L, Legrand C, Marais T (2014) Addressing the challenges facing biological sulphate reduction as a strategy for ARD treatment: analysis of the reactor stage: raw materials, products and process kinetics. South African Water Research Commission Report: WRC2110/1/2014, June 2014, pp100. Available at http://www.wrc.org.za

Illman AM, Scragg AH, Shales SW (2000) Increase in Chlorella strains calorific values when grown in low nitrogen medium. Enzyme Microb Technol 27:631–635

Inglesby AE, Fisher AC (2012) Enhanced methane yields from anaerobic digestion of Arthrospira maxima biomass in an advanced flow-through reactor with an integrated recirculation loop microbial fuel cell. Energy Environ Sci 5:7996–8006

McGinn PJ, Dickinson KE, Park KC, Whitney CG, MacQuarrie SP, Black FJ, Frigon JC, Guiot SR, O’Leary SJB (2012) Assessment of the bioenergy and bioremediation potentials of the microalga Scenedesmus sp. AMDD cultivated in municipal wastewater effluent in batch and continuous mode. Algal Res 1:155–165

McKendry P (2002) Energy production from biomass (part 2): conversion technologies. Bioresour Technol 83:47–54

Mussgnug JH, Klassen V, Schlüter A, Kruse O (2010) Microalgae as substrates for fermentative biogas production in a combined biorefinery concept. J Biotechnol 150:51–56

Parkin GF, Owen WF (1986) Fundamentals of anaerobic digestion of wastewater sludge. J Environ Eng 112:867–920

Ras M, Lardon L, Bruno S, Bernet N, Steyer JP (2011) Experimental study on a coupled process of production and anaerobic digestion of Chlorella vulgaris. Bioresour Technol 102:200–206

Samson R, LeDuy A (1982) Biogas production from anaerobic digestion of Spirulina maxima algal biomass. Biotechnol Bioeng 24:1919–1924

Samson R, LeDuy A (1983a) Improved performance of anaerobic digestion of Spirulina maxima algal biomass by addition of carbon-rich wastes. Biotech Lett 5:677–682

Samson R, LeDuy A (1983b) Influence of mechanical and thermochemical pretreatments on anaerobic digestion of Spirulina maxima algal biomass. Biotech Lett 5:671–676

Samson R, LeDuy A (1986) Detailed study of anaerobic digestion of Spirulina maxima algal biomass. Biotechnol Bioeng 28:1014–1023

Sanchez EP, Travieso L (1993) Anaerobic digestion of Chlorella vulgaris for energy production. Resour Conserv Recycl 9:127–132

Sialve B, Bernet N, Bernard O (2009) Anaerobic digestion of microalgae as a necessary step to make microalgal biodiesel sustainable. Biotechnol Adv 27:409–416

Tartakovsky B, Matteau-Lebrun F, McGinn PJ, O’Leary SJB, Guiot SR (2013) Methane production from the microalga Scenedesmus sp. AMDD in a continuous anaerobic reactor. Algal Res 2:394–400

Tran KC, Mendoza Martin JL, Heaven S, Banks CJ, Acien Fernandez FG, Molina Grima E (2014) Cultivation and anaerobic digestion of Scenedesmus spp. grown in a pilot-scale open raceway. Algal Res 5:95–102

Van Eykelenburg C (1977) On the morphology and ultrastructure of the cell wall of Spirulina platensis. Antonie Van Leeuwenhoek 43:89–99

Varel VH, Chen TH, Hashimoto AG (1988) Thermophilic and mesophilic methane production from anaerobic degradation of the cyanobacterium Spirulina maxima. Resour Conserv Recycl 1:19–26

Ververis C, Georghiou K, Danielidis D, Hatzinikolaou DG, Santas P, Santas R, Corleti V (2007) Cellulose, hemicelluloses, lignin and ash content of some organic materials and their suitability for use as paper pulp supplements. Bioresour Technol 98:296–301

Voigt J, Stolarczyk A, Zych M, Malec P, Burczyk J (2014) The cell-wall glycoproteins of the green alga Scenedesmus obliquus. The predominant cell-wall polypeptide of Scenedesmus obliquus is related to the cell-wall glycoprotein gp3 of Chlamydomonas reinhardtii. Plant Sci 215–216:39–47

Ward AJ, Lewis DM, Green FB (2014) Anaerobic digestion of algae biomass: a review. Algal Res 5:204–214

Yang Z, Guo R, Xu X, Fan X, Luo S (2011) Hydrogen and methane production from lipid extracted microbial biomass residues. Int J Hydrog Energy 36:3465–3470

Yen H-W, Brune DE (2007) Anaerobic co-digestion of algal sludge and waste paper to produce methane. Bioresour Technol 98:130–134

Zamalloa C, Vrieze JD, Boon N, Verstraete W (2012) Anaerobic digestibility of marine microalgae Phaeodactylum tricornutum in a lab-scale anaerobic membrane bioreactor. Bioenergy Biofuels 93:859–869

Zarrouk C (1966) Contribution à l’e étude d’une cyanophycée. Influence de divers facteurs physiques et chimiques sur la croissance et la photosynthése de Spirulina maxima. Doctoral thesis, Université de Paris

Acknowledgments

This work is based upon research supported by the South African Research Chairs Initiative (SARChI) of the Department of Science and Technology and the National Research Foundation (NRF). The financial assistance of these organisations is hereby acknowledged. Any opinion, finding and conclusion or recommendation expressed in this material is that of the authors and SARChI and the NRF do not accept any liability in this regard.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 341 kb)

Rights and permissions

About this article

Cite this article

Inglesby, A.E., Griffiths, M.J., Harrison, S.T.L. et al. Anaerobic digestion of Spirulina sp. and Scenedesmus sp.: a comparison and investigation of the impact of mechanical pre-treatment. J Appl Phycol 27, 1891–1900 (2015). https://doi.org/10.1007/s10811-015-0669-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-015-0669-3