Abstract

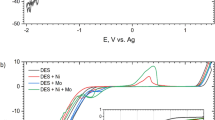

The effects of higher concentrations (5 and 10%) of an organic modifier, butanol, added to an aqueous electroplating solution for nickel deposition have been studied. Nickel coatings were deposited on steel substrates from a modified all-sulfate bath with 5 and 10% additions of butanol under acidic conditions, while a modified pulse potential was applied. X-ray diffraction of the resulting nickel coatings showed a preferred (220) orientation for the crystal structure. The coatings were nanocrystalline with particle sizes between 16 and 35 nm as calculated from Williamson–Hall analysis. No cracking of the films was observed in the scanning electron microscopy images, even as the percentage of butanol increased, as typically is observed in other aqueous-organic baths. Corrosion resistance of the nickel coatings in a 3.5% sodium chloride solution was best for coatings deposited from plating solutions containing 5 and 10% butanol. E corr was shifted from −0.405 V for the nickel coating from the additive-free bath to −0.234 V for the nickel coating from the 5% butanol solution. EIS results indicated a twofold improvement in charge transfer resistance for nickel coatings deposited when butanol was used in the plating bath. The advantages of using higher percentages of organic modifiers like butanol to enable the use of non-electroactive particles for production of composite coatings are discussed.

Graphical abstract

Similar content being viewed by others

References

Hihara LH (2015) Electrochemical aspects of corrosion-control coatings, Elsevier Inc., Amsterdam

Selvaraj R, Selvaraj M, Iyer SVK (2009) Studies on the evaluation of the performance of organic coatings used for the prevention of corrosion of steel rebars in concrete structures. Prog Org Coat 64(4):454–459

Elias L, Hegde CA (2015) Electrodeposition of laminar coatings of Ni–W Alloy and their corrosion behaviour. Surf Coat Technol 283:61–69

Thurber CR, Ahmad YH, Sanders SF, Al-Shenawa A, D’Souza N, Mohamed AMA, Golden TD (2016) Electrodeposition of 70–30 Cu–Ni nanocomposite coatings for enhanced mechanical and corrosion properties. Curr Appl Phys 16:387–396

Coskun MI, Karahan IH, Yucel Y, Golden TD (2016) Computer-assisted optimization of electrodeposited hydroxyapatite coating parameters on medical alloys. Metall Mater Trans A, 47(4):1828–1841

Parkinson R. (1997) Properties and applications of electroless nickel. Nickel Development Institute, Toronto, pp 1–33

Di Bari GA (2010) Electrodeposition of Nickel. In: Schlesinger M, Paunovic M (eds), Modern electroplating 5th edn. John Wiley & Sons, Inc., Hoboken, pp 79–114

Dennis JK, Such TE (1986) Nickel and Chromium Plating, 2nd edn. Butterworth and Co LTD, Cambridge, p 151

Lee RT, Liu CT, Chiou YC, Chen HL (2013) Effect of nickel coating on the shear strength of fsw lap joint between Ni–Cu alloy and steel. J Mater Process Tech 213(1): 69–74

Kumar KS, Suresh S, Chisholm MF, Horton JA, Wang P (2003) Deformation of electrodeposited nanocrystalline nickel. Acta Mater 51(2):387–405

Meng G, Sun F, Shaoa Y, Zhang T, Wang F, Dong C, Li X (2010) Effect of phytic acid on the microstructure and corrosion resistance of Ni coating. Electrochim Acta 55(20):5990–5995

Tang PT, Watanabe T, Andersen, JET, Bech-Nielsen G (1995) Improved corrosion resistance of pulse plated nickel through crystallisation control. J Appl Electrochem 25:347–352

Peng X, Zhang Y, Zhao J, Wang F (2006) Electrochemical corrosion performance in 3.5% NaCl of the electrodeposited nanocrystalline Ni Films with and without dispersions of Cr nanoparticles. Electrochim Acta 51:4922–4927

Walsh FC, Ponce de Leon C (2014) A review of the electrodeposition of metal matrix composite coatings by inclusion of particles in a metal layer: an established and diversifying technology. Trans Inst Met Finish 92(2):83–98

Simunkova H, Pessenda-Garcia P, Wosik J, Angerer P, Kronberger H, Nauer GE (2009) The fundamentals of nano- and submicro-scaled ceramic particles incorporation into electrodeposited nickel layers: zeta potential measurements. Surf Coat Technol 203(13):1806–1814

Khoramkhorshid S, Alizadeh M, Taghvaei AH, Scudino S (2016) Microstructure and mechanical properties of Al-based metal matrix composites reinforced with Al84Gd6Ni7Co3 glassy particles produced by accumulative roll bonding. Mater Des 90:137–144

Shibli SMA, Chacko F (2008) Development of nano CeO2-incorporated high performance hot-dip zinc coating. Surf Coat Technol 202(20):4971–4975

Ahmad YH, Tientong J, D'Souza N, Golden TD, Mohamed AMA (2014) Surface & coatings technology salt water corrosion resistance of electrodeposited Ni-layered silicate nanocomposite coatings from Watts’ type solution. Surf Coat Technol 242:170–176

Addi Y, Duverneuil P, Khouider A (2011) Zinc nickel codeposition in ammonium sulfate combined effect of cadmium and boric acid. ECS Trans 33(26):75–82

Hoare JP (1987) Boric acid as a catalyst in nickel plating solutions. J Electrochem Soc 134(12):3102–3103

Karwas C, Hepel T (1987) Influence of boric acid on electrodeposition and stripping of Ni-Zn alloys. J Electrochem Soc 135(4):839–844

Supicova M, Rozik R, Trnkova L, Orinakova R, Galova M (2006) Influence of boric acid on the electrochemical deposition of Ni. J Solid State Electrochem 10: 61–68

Addi Y, Khouider A (2013) Electrodeposition of Ni–Zn alloys on steel from acidic solution in presence of boric acid. ECS Trans 45(24):79–85

Ji J, Cooper C, Dreisinger DB, Peters E (1995) Surface pH measurements during nickel electrodeposition. J Appl Electrochem 25: 642–650

Dávalos CE, López JR, Ruiz H, Méndez A, López RA, Trejo G (2013) Study of the role of boric acid during the electrochemical deposition of Ni in a sulfamate bath. Int J Electrochem Sci 8:9785–9800

Conrad HA, McGuire MR, Zhou T, Coskun MI, Golden TD (2015) Improved corrosion resistant properties of electrochemically deposited zinc-nickel alloys utilizing a borate electrolytic alkaline solution. Surf Coat Technol 272:50–57

Costavaras T, Froment M, Hugot-Le Goff A, Georgoulis C (1973) The influence of unsaturated organic molecules in the electrocrystallization of nickel. J Electrochem Soc 4: 867–874

Srivastava HK, Tikoo PK (1987) Electrodeposition of nickel from N, N-dimethylformamide. Surf Coatings Technol 31(4):343–350

Bakhit B, Akbari A (2014) A comparative study of the effects of saccharin and b-SiC nano-particles on the properties of Ni and Ni–Co alloy coatings. Surf Coat Technol 253: 76–82

Wu W, Eliaz N, Gileadi E (2016) Electrodeposition of Re–Ni alloys from aqueous solutions with organic additives. Thin Solid Films 616: 828–837

Mirzamohammadi S, Khorsand H, Aliofkhazraei M (2017) Effect of different organic solvents on electrodeposition and wear behavior of Ni–Alumina nanocomposite coatings. Surf Coat Technol 313: 202–213

Seleim SM, Ahmed AM, El Adl AF (2014) Electroplating in steel in presence of isopropanol-water mixture. Int J Electrochem Sci 9(4):2016–2028

Rao NN, Singh VB (1985) Behavior of copper formamide-water mixtures. Corros Sci 25(7):471–482

Sultan S, Tikoo PK (1984) Hardness and structure of nickel electrodeposited from a nickel acetate-N, N-dimethylformamide-water bath. Surf Technol 21(3):239–244

Tripathi MK, Singh DK, Singh VB (2013) Electrodeposition of Ni-Fe/Bn nano-composite coatings from a non-aqueous bath and their characterization. Int J Electrochem Sci, 8(3):3454–3471

An MZ, Wang JL, Sun DZ (2001) Electrodeposition of La–Ni alloy films in a nonaqueous system. J Appl Electrochem 31: 891–896

Macheras J, Vouros D, Kollia C, Spyrellis N (1996) Nickel electrocrystallization: influence of unsaturated organic additives on the mechanism of oriented crystal growth. Trans Inst Met Finish 74(2):55–58

Nakamura Y, Kaneko N, Watanabe M, Nezu H (1994) Effects of saccharin and aliphatic alcohols on the electrocrystallization of nickel. J Appl Electrochem 24: 227–232

Belkis U, Esma S, Ramazan K (2013) The investigation of electrochemical effect of diol compounds in nickel electroplating bath. J Mater Sci Eng Adv Technol 8(2):55–68

Niederberger M, Garnweitner G, Buha J, Polleux J, Ba J, Pinna N (2006) Nonaqueous synthesis of metal oxide nanoparticles: review and indium oxide as case study for the dependence of particle morphology on precursors and solvents. J Sol-Gel Sci Technol 40:259–266

Graham LM, Cho S, Kim SK, Noked M, Lee SB (2014) Role of boric acid in nickel nanotube electrodeposition: a surface-directed growth mechanism. Chem Commun 50: 527–529

Henderson WG, How MJ, Kennedy GR, Mooney EF (1973) The interconversion of aqueous boron species and the interaction of borate with diols: A 11B N.M.R. study. Carbohydr Res 28: 1–12

Zhitomirsky I (2002) Cathodic electrodeposition of ceramic and organoceramic materials. Fundam Asp 97:279–317

De Hazan Y, Knies F, Burnat D, Graule T, Yamada-Pittini Y, Aneziris C, Kraak M (2012) Homogeneous functional Ni–P/Ceramic nanocomposite coatings via stable dispersions in electroless nickel electrolytes. J Colloid Interface Sci 365:163–171

Conrad H, Corbett J, Golden TD (2012) Electrochemical deposition of g-Phase zinc-nickel alloys from alkaline solution. J Electrochem Soc 159(1):C29–C32

Abel S, Freimuth H, Lehr H, Mensinger H (1999) Defined crystal orientation of nickel by controlled microelectroplating. J Micromech Microeng 4:47–54

Cortes A, Riveros G, Palma JL, Denardin JC, Marotti RE, Dalchiele EA, Gomez H (2009) Single-crystal growth of nickel nanowires: influence of deposition conditions on structural and magnetic properties. J Nanosci Nanotechnol 9(3):1992–2000

Rashidi AM, Hayati M, Rezaei A (2011) Prediction of the relative texture coefficient of nanocrystalline nickel coatings using artificial neural networks. Solid State Sci 13(8):1589–1593

Magana-Zavala CR, Angeles-San Martin ME, Rodriguez-Gomez FJ, Acosta DR, Avila-Godoy R, Hidalgo-Prada B (2010) Electrochemical impedance spectroscopy (EIS) modelling of different behaviours of Ni and Ni oxide thin films for corrosion prevention in sour media. Anti-Corros Methods Mater 57(3):118–125

Hashemzadeh M, Raeissi K, Khorsund AS (2015) Effect of ammonia chloride on microstructures, super-hydrophobicity and corrosion resistance of nickel coatings. Surf Coat Technol 283:318–328

Meng G, Li Y, Shao Y, Zhang T, Wang Y, Wang F, Cheng X, Dong C, Li X (2015) Effect of microstructures on corrosion behavior of nickel coatings: (i) abnormal grain size effect on corrosion behavior. J Mater Sci Technol 31:1186–1192

Drevet R, Aaboubi O, Benhayoune H (2012) In vitro corrosion behavior of electrodeposited calcium phosphate coatings on Ti6Al4V Substrates. J Solid State Electrochem 16(9): 3069–3077

Acknowledgements

The authors thank Casey Thurber and Stephen Sanders for obtaining SEM data and Dr. Heidi Conrad for helpful scientific discussions. The authors also acknowledge the Center for Advanced Research and Technology (CART) and AMMPI (Advanced Materials and Manufacturing Processes Institute) at the University of North Texas.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Daugherty, R.E., Zumbach, M.M. & Golden, T.D. The influence of an aqueous-butanol plating bath on the microstructure and corrosion resistance of electrodeposited nickel coatings. J Appl Electrochem 47, 467–477 (2017). https://doi.org/10.1007/s10800-017-1056-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-017-1056-3