Abstract

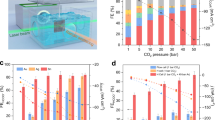

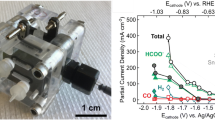

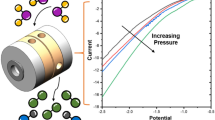

The electrochemical reduction of carbon dioxide into formate was studied using gas diffusion electrodes (GDE) with Sn as electrocatalyst in order to overcome mass transport limitations and to achieve high current densities. For this purpose, a dry pressing method was developed for GDE preparation and optimized with respect to mechanical stability and the performance in the reduction of CO2. Using this approach, GDEs can be obtained with a high reproducibility in a very simple, fast, and straightforward manner. The influence of the metal loading on current density and product distribution was investigated. Furthermore, the effect of changing the electrolyte pH was evaluated. Under optimized conditions, the GDE allowed current densities up to 200 mA cm−2 to be achieved with a Faradaic efficiency of around 90 % toward formate and a substantial suppression of hydrogen production (<3 %) at ambient pressure. At higher current densities mass transport issues come into effect and hydrogen is increasingly produced. The corresponding cathode potential was found to be 1.57 V vs. SHE.

Similar content being viewed by others

References

Aresta M, Dibenedetto A (2007) Utilisation of CO2 as a chemical feedstock: opportunities and challenges. Dalton Trans 28:2975–2992. doi:10.1039/b700658f

Hu B, Guild C, Suib SL (2013) Thermal, electrochemical, and photochemical conversion of CO2 to fuels and value-added products. J CO2 Util 1:18–27. doi:10.1016/j.jcou.2013.03.004

Ausfelder F, Bazzanella A (2008) Dechema Diskussionspapier: Verwertung und Speicherung von CO2. Dechema e.V.

Hori Y (2008) Electrochemical CO2 reduction on metal electrodes. Mod Asp Electrochem 42:89–189. doi:10.1007/978-0-387-49489-0_3

Scibioh M, Viswanathan B (2004) Electrochemical reduction of carbon dioxide: a status report. Proc Indian Natl Sci Acad 70:407–462

Whipple DT, Kenis PJA (2010) Prospects of CO2 utilization via direct heterogeneous electrochemical reduction. J Phys Chem Lett 1:3451–3458. doi:10.1021/jz1012627

Oloman C, Li H (2008) Electrochemical processing of carbon dioxide. ChemSusChem 1:385–391. doi:10.1002/cssc.200800015

Ma S, Lan Y, Perez GMJ, Moniri S, Kenis PJA (2014) Silver supported on titania as an active catalyst for electrochemical carbon dioxide reduction. ChemSusChem 7:866–874. doi:10.1002/cssc.201300934

Dufek EJ, Lister TE, McIlwain ME (2011) Bench-scale electrochemical system for generation of CO and syn-gas. J Appl Electrochem 41:623–631. doi:10.1007/s10800-011-0271-6

Alvarez-Guerra M, Quintanilla S, Irabien A (2012) Conversion of carbon dioxide into formate using a continuous electrochemical reduction process in a lead cathode. Chem Eng J 207–208:278–284. doi:10.1016/j.cej.2012.06.099

Prakash GS, Viva FA, Olah GA (2013) Electrochemical reduction of CO2 over Sn-Nafion® coated electrode for a fuel-cell-like device. J Power Sources 223:68–73. doi:10.1016/j.jpowsour.2012.09.036

Loges B, Boddien A, Gärtner F, Junge H, Beller M (2010) Catalytic generation of hydrogen from formic acid and its derivatives: useful hydrogen storage materials. Top Catal 53:902–914. doi:10.1007/s11244-010-9522-8

Makowski P, Thomas A, Kuhn P, Goettmann F (2009) Organic materials for hydrogen storage applications: from physisorption on organic solids to chemisorption in organic molecules. Energy Environ Sci 2:480–490. doi:10.1039/b822279g

Azuma M (1990) Electrochemical reduction of carbon dioxide on various metal electrodes in low-temperature aqueous KHCO3 media. J Electrochem Soc 137:1772–1776. doi:10.1149/1.2086796

Hori Y, Wakebe H, Tsukamoto T, Koga O (1994) Electrocatalytic process of CO selectivity in electrochemical reduction of CO2 at metal electrodes in aqueous media. Electrochim Acta 39:1833–1839. doi:10.1016/0013-4686(94)85172-7

Noda H, Ikeda S, Oda Y, Imai K, Maeda M, Ito K (1990) Electrochemical reduction of carbon dioxide at various metal electrodes in aqueous potassium hydrogen carbonate solution. Bull Chem Soc Jpn 63:2459–2462. doi:10.1246/bcsj.63.2459

Mahmood MN, Masheder D, Harty CJ (1987) Use of gas-diffusion electrodes for high-rate electrochemical reduction of carbon dioxide. I. Reduction at lead, indium- and tin-impregnated electrodes. J Appl Electrochem 17:1159–1170. doi:10.1007/BF01023599

Whipple DT, Finke EC, Kenis PJA (2010) Microfluidic reactor for the electrochemical reduction of carbon dioxide: the effect of pH. Electrochem Solid-State Lett 13:B109–B111. doi:10.1149/1.3456590

Furuya N, Yamazaki T, Shibata M (1997) High performance Ru-Pd catalysts for CO2 reduction at gas-diffusion electrodes. J Electroanal Chem 431:39–41. doi:10.1016/S0022-0728(97)00159-9

Hara K (1997) Electrocatalytic formation of CH4 from CO2 on a Pt gas diffusion electrode. J Electrochem Soc 144:539–545. doi:10.1149/1.1837445

Cook RL (1990) High rate gas phase CO2 reduction to ethylene and methane using gas diffusion electrodes. J Electrochem Soc 137:607–608. doi:10.1149/1.2086515

Dufek EJ, Lister TE, Stone SG, McIlwain ME (2012) Operation of a pressurized system for continuous reduction of CO2. J Electrochem Soc 159:F514–F517. doi:10.1149/2.011209jes

Gülzow E, Schulze M, Wagner N, Kaz T, Reissner R, Steinhilber G, Schneider A (2000) Dry layer preparation and characterisation of polymer electrolyte fuel cell components. J Power Sources 86:352–362. doi:10.1016/S0378-7753(99)00451-6

Yu J, Yoshikawa Y, Matsuura T, Islam MN, Hori M (2005) Preparing gas-diffusion layers of PEMFCs with a dry deposition technique. Electrochem Solid-State Lett 8:A152–A155. doi:10.1149/1.1854119

Li H, Oloman C (2006) Development of a continuous reactor for the electro-reduction of carbon dioxide to formate—Part 1: process variables. J Appl Electrochem 36:1105–1115. doi:10.1007/s10800-006-9194-z

Wagner N (2004). Verfahren und Vorrichtung zur Herstellung einer Elektrode. Patent No. DE 19940015 B9. Germany

Park S, Lee J, Popov BN (2012) A review of gas diffusion layer in PEM fuel cells: materials and designs. Int J Hydrog Energy 37:5850–5865. doi:10.1016/j.ijhydene.2011.12.148

Wagner N, Schulze M, Gülzow E (2004) Long term investigations of silver cathodes for alkaline fuel cells. J Power Sources 127:264–272. doi:10.1016/j.jpowsour.2003.09.022

Lv W, Zhang R, Gao P, Lei L (2014) Studies on the faradaic efficiency for electrochemical reduction of carbon dioxide to formate on tin electrode. J Power Sources 253:276–281. doi:10.1016/j.jpowsour.2013.12.063

Li H, Oloman C (2007) Development of a continuous reactor for the electro-reduction of carbon dioxide to formate—Part 2: scale-up. J Appl Electrochem 37:1107–1117. doi:10.1007/s10800-007-9371-8

Wu J, Sharma PP, Harris BH, Zhou X (2014) Electrochemical reduction of carbon dioxide: IV dependence of the Faradaic efficiency and current density on the microstructure and thickness of tin electrode. J Power Sources 258:189–194. doi:10.1016/j.jpowsour.2014.02.014

Zhang S, Kang P, Meyer TJ (2014) Nanostructured tin catalysts for selective electrochemical reduction of carbon dioxide to formate. J Am Chem Soc 136:1734–1737. doi:10.1021/ja4113885

Zhang S, Kang P, Ubnoske S, Brennaman MK, Song N, House RL, Glass JT, Meyer TJ (2014) Polyethylenimine-enhanced electrocatalytic reduction of CO2 to formate at nitrogen-doped carbon nanomaterials. J Am Chem Soc 136:7845–7848. doi:10.1021/ja5031529

Hara K, Kudo A, Sakata T (1995) Electrochemical reduction of carbon dioxide under high pressure on various electrodes in an aqueous electrolyte. J Electroanal Chem 391:141–147. doi:10.1016/0022-0728(95)03935-A

Todoroki M, Hara K, Kudo A, Sakata T (1995) Electrochemical reduction of high pressure CO2 at Pb, Hg and In electrodes in an aqueous KHCO3 solution. J Electroanal Chem 394:199–203. doi:10.1016/0022-0728(95)04010-L

Agarwal AS, Zhai Y, Hill D, Sridhar N (2011) The electrochemical reduction of carbon dioxide to formate/formic acid: engineering and economic feasibility. ChemSusChem 4:1301–1310. doi:10.1016/0022-0728(95)03935-A

Chen Y, Li CW, Kanan MW (2012) Aqueous CO2 reduction at very low overpotential on oxide-derived Au nanoparticles. J Am Chem Soc 134:19969–19972. doi:10.1021/ja309317u

Wu J, Risalvato FG, Ke F, Pellechia PJ, Zhou X (2012) Electrochemical reduction of carbon dioxide I. Effects of the electrolyte on the selectivity and activity with Sn electrode. J Electrochem Soc 159:F353–F359. doi:10.1149/2.049207jes

Innocent B, Liaigre D, Pasquier D, Ropital F, Léger J, Kokoh KB (2009) Electro-reduction of carbon dioxide to formate on lead electrode in aqueous medium. J Appl Electrochem 39:227–232. doi:10.1007/s10800-008-9658-4

Gattrell M, Gupta N, Co A (2006) A review of the aqueous electrochemical reduction of CO2 to hydrocarbons at copper. J Electroanal Chem 594:1–19. doi:10.1016/j.jelechem.2006.05.013

Hori Y, Suzuki S (1982) Electrolytic reduction of carbon dioxide at mercury electrode in aqueous solution. Bull Chem Soc Jpn 55:660–665. doi:10.1246/bcsj.55.660

Gupta N, Gattrell M, MacDougall B (2006) Calculation for the cathode surface concentrations in the electrochemical reduction of CO2 in KHCO3 solutions. J Appl Electrochem 36:161–172. doi:10.1007/s10800-005-9058-y

Acknowledgments

The authors would like to thank the German BMWi (Bundesministerium für Wirtschaft und Energie) for the financial support (03ET1037B), Ina Plock (DLR) for taking SEM images, Alexander Bauder (DLR) and the project partners (DLR, INVENIOS Europe GmbH, Plinke GmbH) for their collaboration. Special thanks also go to Prof. Albert Renken, EPFL Lausanne, for the fruitful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kopljar, D., Inan, A., Vindayer, P. et al. Electrochemical reduction of CO2 to formate at high current density using gas diffusion electrodes. J Appl Electrochem 44, 1107–1116 (2014). https://doi.org/10.1007/s10800-014-0731-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-014-0731-x