Abstract

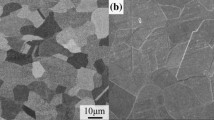

Incorporation of ceria particles into the Ni matrix was found to improve the corrosion resistance of pure Ni coatings. With the aim of further improving the corrosion resistance of Ni-ceria, yttria was doped with ceria and used as distributed phase. About 8-mol% yttria doped ceria (8YDC) particles synthesized by a solution combustion process were dispersed in a nickel sulfamate bath and electrodeposition was carried out to prepare Ni–8YDC composite coatings at various current densities. The microhardness of the composite coatings was determined. Optical microscopy confirmed the incorporation of 8YDC particles into the Ni matrix. Potentiodynamic polarization and electrochemical impedance spectroscopy were used to characterize the corrosion behavior of the Ni–8YDC coatings. Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray Analysis (EDAX) were used to characterize the corroded samples. The results were compared with those for Ni and Ni–CeO2 coatings. The wear behavior of Ni–8YDC was studied. Wear tracks were characterized by MicroRaman Spectroscopy.

Similar content being viewed by others

References

Powel BR, Bloink RL, Erkel CC (1988) J Am Ceram Soc 71:C104

Moller A, Hahn H (1999) Nanostruct Mater 12:259

Müller B, Ferkel H (1999) Z Metallkd 90:868

Shao I, Vereecken PM, Chien CL, Searson PC, Cammarata RC (2002) J Mater Res 17:1412

Zhou M, de Tacconi NR, Rajeshwar K (1997) J Electroanal Chem 421:111

Benea L, Borello PL, Martelli S (2002) Wear 249:995

Xu H, Yang Z, Li M-K, Shi Y-L, Huang Y, Li H-L (2005) Surf Coat Technol 191:161

Balathandan S, Seshadri SK (1992) Met Finish 90:51

Gyftou P, Stroumbouli M, Pavlatou EA, Asimidis P, Spyrellis N (2005) Electrochim Acta 50:4544

Balaraju JN, Kalavati, Rajam KS (2006) Surf Coat Technol 200:3933

Szczygiel B, Kolodziej M (2005) Electrochim Acta 50:4188

Xue Y-J, Jia X-Z, Zhou Y-W, Ma W, Li J-S (2006) Surf Coat Technol 200:5677

Aruna ST, Bindu CN, Ezhil Selvi V, William Grips VK, Rajam KS (2006) Surf Coat Technol 200:6871

Kaiya H, Ookawa T (1995) J Alloys Compd 231:598

Maurel F, Leblanc P, Knosp B, Backaus-Ricoult M (2000) J Alloys Compd 309:88

Zhang T, Li DY (2001) Wear 251:1250

Patil KC, Aruna ST, Ekambaram S (1997) Curr Opin Solid State Mater Sci 2:158

Klug H, Alexander L (1974) X-ray diffraction procedures for polycrystalline and amorphous materials. John Wiley, New York

Tsuru Y, Nomura M, Foulkes FR (2000) J Appl Electrochem 30:231

Holm R (1946) Electric contacts. Almquist and Wiksells, Stockholm, Section 40

Archard JF (1953) J Appl Phys 24:981

Zha S, Fu Q, Lang Y, Xia C, Meng G (2001) Mater Lett 47:351

Buelens C, Fransaer J, Celis JP, Roos JR (1992) Bull Electrochem 8:371

Lyons EH Jr (1963) In: Lowenheim FA (ed) Modern electroplating. John Wiley & Sons Inc, New York, pp 23

Yao Y, Yao S, Zhang L, Wang H (2007) Mater Lett 61:67

Low CTJ, Wills RGA, Walsh FC (2006) Surf Coat Technol 201:371

Benea L, Bonora PL, Borello A, Martelli S (2002) Mater Corros 53:23

Szczygiel B, Kolodziej M (2005) Trans Inst Met Finish 83:181

Mishra R, Balasubramaniam R (2004) Corros Sci 46:3019

Rabinowicz E (1984) Wear 100:533

Acknowledgements

The authors gratefully acknowledge financial support received from the CSIR Task force program on “Custom tailored special materials”. The authors thank the Director, NAL for permission to publish this work. The authors also thank Ms. C. N. Bindu for help in carrying out some of the experiments. The authors are thankful to Mr. Siju for the microhardness measurements, Mr. Venkataswamy for the SEM and Dr. Anjana Jain for the XRD measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aruna, S.T., William Grips, V.K., Ezhil Selvi, V. et al. Studies on electrodeposited nickel–yttria doped ceria composite coatings. J Appl Electrochem 37, 991–1000 (2007). https://doi.org/10.1007/s10800-007-9338-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-007-9338-9