Abstract

The influences of work hardening behavior of materials on ductile fracture, and especially on void growth and coalescence, have been investigated in model materials by in-situ X-ray computed tomography (XCT) coupled with tensile deformation. The model materials contain an artificial void array embedded in a metal matrix. By producing such materials with different metal matrices (pure copper, brass, Glidcop = copper strengthened by \(\text{ Al}_{2}\text{ O}_{3}\) nanoparticles), the influences of the work hardening behaviors on void growth and coalescence/linkage process are analyzed. This set of experiments were performed at Japanese synchrotron radiation facility SPring-8 BL20XU beamline, whereby the X-ray tomography setup with one of the highest spatial resolution in the world is available. This beamline however provides less brilliant X-rays compared to the ESRF ID15 beamline where the our previous experiments were performed Hosokava et al. (Acta Mater, 60:2829–2839, 2012), (Acta Mater, 61:1021–1036, 2013). To compensate for the X-ray absorption problems, the specimens to be tested have to be much smaller, making the experiments more difficult. Nevertheless, the growth and linkage behaviors of the artificial voids were successfully visualized, and the plastic strain whereby the linkage takes place (referred to as the linkage strain, hereafter) were quantitatively captured. The models for void coalescence developed by Thomason and by Pardoen and Hutchinson both predict coalescence rather well for both brass and Glidcop, even though the linkage events were found to be dominated by the meso/macro shear localization process.

Similar content being viewed by others

Notes

Radiographs and projections are essentially the same but opposite contrast; denser region is represented by brighter contrast in projections.

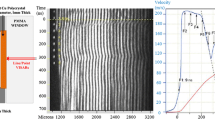

Fig. 6

References

Argon AS, Im J, Safoglu R (1975) Cavity formation from inclusions in ductile fracture. Metall Trans A 6A:825

Benzerga AA (2002) Micromechanics of coalescence in ductile fracture. J Mech Phys Solids 50(6):1331–1362

Brown LM, Embury JD (1973) The initiation and growth of voids at second phase particles. In: Proceedings of the thid international conference on the strength of metals and alloys. Institute of Metals, p 164

Buffière JY, Maire E, Cloetens P, Lormand G, Fougeres R (1999) Characterization of internal damage in a mmcp using X-ray synchrotron phase contrast microtomography. Acta Mater 47(5):1613–1625

Cox TB, Low JRJ (1974) Investigation of the plastic fracture of aisi 4340 and 18 nickel-200 grade maraging steels. Metall Trans 5:1457–1470

Gammage JJ, Wilkinson DS, Embury JD, Maire E (2001) Damage studies in heterogeneous aluminium alloys using X-ray tomography. Philos Mag 85:26–27. doi:10.1080/14786430500154588

Garrison WM, Moody NRJ (1987) Ductile fracture. J Phys Chem Solids 48:1035–1074

Gologanu M, Leblond JB, Perrin G, Devaux J (2001) Theoretical models for void coalescence in porous ductile solids. I. coalescence. Int J Solids Struct 38(32–33):5581–5594. doi:10.1016/S0020-7683(00)00354-1

Goods S, Brown LM (1979) The nucleation of cavities by plastic deformation. Acta Metall 27:1–15

Hosokawa A, Wilkinson DS, Kang J, Maire E (2012) Effect of triaxiality on void growth and coalescence in model materials investigated by X-ray computed tomography. Acta Mater 60:2829–2839

Hosokawa A, Wilkinson DS, Kang J, Maire E (2013) Onset of void coalescence in uniaxial tension studied by X-ray computed tomography. Acta Mater 61:1021–1036. doi:10.1016/j.actamat.2012.08.002

Kocks UF, Mecking H (2003) Physics and phenomenology of strain hardening: the fcc case. Prog Mater Sci 48:171–273

Le Roy G, Embury JD, Edwards G, Ashby MF (1981) A model of ductile fracture based on the nucleation and growth of voids. Acta Metall 29:1509

Leblond J, Mottet G (2008) A theoretical approach of strain localization within thin planar bands in porous ductile materials. C R Mecanique 336:176–189

Lecarme L, Tekog̃lu C, Pardoen T (2011) Void growth and coalescence in ductile solids with stage III and stage IV strain hardening. Int J Plast 27:1203–1223

Martin CF, Josserond C, Salvo L, Blandin1 JJ, Cloetens P, Boller E, (2000) Characterisation by X-ray micro-tomography of cavity coalescence during superplastic deformation. Scr Mater 42(4):375–381. doi:10.1016/S1359-6462(99)00355-3

McClintock FA (1968) A criterion for ductile fracture by the growth of holes. J Appl Mech 35:363–371

Murr LE (1975) Interfacial phenomena in metals and alloys. Addison-Wesley, Reading

Pardoen T, Hutchinson JW (2000) An extended model for void growth and coalescence. J Mech Phys Solids 48(12):2467–2512

Puttick KE (1959) Ductile fracture in metals. Philos Mag 4:964–969

Rice J, Tracey D (1969) On the ductile enlargement of voids in triaxial stress fields. J Mech Phys Solids 17:201–217

Teko g̃lu C, Leblond JB, Pardoen T (2012) A criterion for the onset of void coalescence under combined tension and shear. J Mech Phys Solids 60:1363–1381

Thomason PF (1968) A theory for ductile fracture by internal necking of cavities. J Inst Metal 96:360

Thomason PF (1990) Ductile fracture of metals. Pergamon Press, Oxford

Toda H, Sinclair I, Buffière JY, Maire E, Connolley T, Joyce M, Khor K, Gregson P (2003) Assessment of the fatigue crack closeure phenomenon in damage-tolerant aluminum alloy by in-situ high-resolution synchrotron X-ray microtomography. Philos Mag 83:2429–2448

Toda H, Sinclair I, Buffière JY, Maire E, Khor KH, Gregson P, Kobayashi T (2004) A 3d measurement procedure for internal local crack driving forces via synchrotron X-ray microtomography. Acta Mater 52(5):1305–1317. doi:10.1016/j.actamat.2003.11.014

Weck A, Crawford THR, Borowiec A, Wilkinson DS, Preston JS (2007) Femtosecond laser-based fabrication of a new model material to study fracture. Appl Phys A Mater Sci Process 86:55–61. doi:10.1007/s00339-006-3730-x

Weck A, Wilkinson DS, Maire E, Toda H (2008) Visualization by X-ray tomography of void growth and coalescence leading to fracture in model materials. Acta Mater 56(12):2919–2928. doi:10.1016/j.actamat.2008.02.027

Acknowledgments

The authors would like to acknowledge the support of the National Science and Engineering Research Council (NSERC). Prof. Ke Han from Florida State University is acknowledged for the support of the Glidcop sheet. Special thanks also go to the beamline scientists at SPring-8 BL20XU, Dr. Kentaro Uesugi, Dr. Yoshio Suzuki and Dr. Akihisa Takeuchi.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hosokawa, A., Wilkinson, D.S., Kang, J. et al. Void growth and coalescence in model materials investigated by high-resolution X-ray microtomography. Int J Fract 181, 51–66 (2013). https://doi.org/10.1007/s10704-013-9820-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-013-9820-9