Abstract

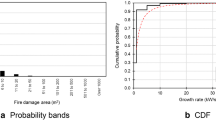

Since the publication of NUREG/CR-6850/EPRI 1011989 in 2005, the US nuclear industry has sought to re-evaluate the default peak heat release rates (HRRs) for electrical enclosure fires typically used as fire modeling inputs to support fire probabilistic risk assessments (PRAs), considering them too conservative. HRRs are an integral part of the fire phenomenological modeling phase of a fire PRA, which consists of identifying fire scenarios which can damage equipment or hinder human actions necessary to prevent core damage. Fire ignition frequency, fire growth and propagation, fire detection and suppression, and mitigating equipment and actions to prevent core damage in the event fire damage still occurred are all parts of a fire PRA. The fire growth and propagation phase incorporates fire phenomenological modeling where HRRs have a key effect. A major effort by the Electric Power Research Institute and Science Applications International Corporation in 2012 was not endorsed by the US Nuclear Regulatory Commission (NRC) for use in risk-informed, regulatory applications. Subsequently the NRC, in conjunction with the National Institute of Standards and Technology, conducted a series of tests for representative nuclear power plant electrical enclosure fires designed to definitively establish more realistic peak HRRs for these often important contributors to fire risk. The results from these tests are statistically analyzed to develop two probabilistic distributions for peak HRR per unit mass of fuel that refine the values from NUREG/CR-6850, thereby providing a fairly simple means by which to estimate peak HRRs from electrical enclosure fires for fire modeling in support of fire PRA. Unlike NUREG/CR-6850, where five different distributions are provided, or NUREG-2178, which now provides 31, the peak HRRs for electrical enclosure fires can be characterized by only two distributions. These distributions depend only on the type of cable, namely qualified versus unqualified, for which the mean peak HRR per unit mass is 11.3 and 23.2 kW/kg, respectively, essentially a factor of two difference. Two-sided, 90th percentile confidence bounds are 0.0915 to 41.2 kW/kg for qualified cables, and 0.0272 to 95.9 kW/kg for unqualified cables. From the mean (~70th percentile) upward, the peak HRR/kg for unqualified cables is roughly twice that for qualified, increasing slightly with higher percentile, an expected phenomenological trend. Simulations using variable fuel loadings are performed to demonstrate how the results from this analysis may be used for nuclear power plant applications.

Similar content being viewed by others

Notes

The authors recognize that other combustible materials (e.g., circuit breakers, circuit cards) will normally be present within an electrical enclosure. Traditionally, assessment of HRRs for electrical cabinet fires in the nuclear power industry focus solely on the combustible content from cables (insulation) as this typically dominates any contribution from non-cable materials. This assumption was maintained throughout the HELEN-FIRE program and remains in effect for the analysis presented here.

The authors recognize that burning within an electrical enclosure will be a combination of both horizontal and vertical fire propagation. This comparison uses data only for horizontal configurations. Nonetheless, since only the relative, not absolute, burning rates are relevant for the comparison, it seems reasonable to assume that the ratios would remain at least approximately equivalent for vertical burning as for horizontal, as the composition of the combustibles remains the same.

References

USNRC/EPRI, EPRI/NRC-RES (Office of Nuclear Regulatory Research) (2005) Fire PRA methodology for nuclear power facilities, NUREG/CR-6850/EPRI 1011989

USNRC (1987) An experimental investigation of internally ignited fires in nuclear power plant control cabinets: part 1—cabinet effects tests, NUREG/CR-4527/1.

USNRC (1987) An experimental investigation of internally ignited fires in nuclear power plant control cabinets: part 2—room effects tests, NUREG/CR-4527/2

Mangs J, Keski-Rahkonen O (1994) Full-scale fire experiments on electronic cabinets, Technical Research Centre of Finland, VTT Publications 186, Espoo

Mangs J, Keski-Rahkonen O (1996) Full-scale fire experiments on electronic cabinets II. Technical Research Centre of Finland, VTT Publications 269, Espoo

EPRI (2012) Evaluation of peak heat release rates in electrical cabinet fires (Reanalysis of Table G-1 of NUREG/CR-6850 and EPRI 1011989), EPRI 1022993

Mangs J, Paananen J, Keski-Rahkonen O (2003) Calorimetric fire experiments on electronic cabinets. Fire Saf J 38:165–186

Melis S, Rigollet L, Such JM, Casselman C (2004) Modelling of electrical cabinet fires based on the CARMELA experimental program. Eurosafe Forum

USNRC (2012) Recent fire PRA Methods Review Panel Decisions and EPRI 1022993, ‘Evaluation of Peak Heat Release Rates in Electrical Cabinet Fires’,” Letter from Joseph Giitter, Director, Division of Risk Assessment, Office of Nuclear Reactor Regulation, NRC, to Biff Bradley, Director, Risk Assessment, NEI, June 21, 2012 (ADAMS Accession No. ML12172A406)

USNRC (2015) Refining and characterizing heat release rates from electrical enclosures during fire (RACHELLE-FIRE)—volume 1: peak heat release rates and effect of obstructed plume, NUREG-2178

IEEE (2015) 383-2015, IEEE standard for qualifying electric cables and splices for nuclear facilities

USNRC (2012) Cable heat release, ignition, and spread in tray installations during fire (CHRISTI-FIRE), NUREG/CR-7010, vol 1

USNRC (2015) Heat release rates of electrical enclosure fires (HELEN-FIRE), NUREG/CR-7197

USNRC/EPRI (2014) Nuclear power plant fire ignition frequency and non-suppression probability estimation using the updated fire events database, NUREG 2169/EPRI 3002002936

Worrell C, Rochon C (2016) Fire probabilistic risk assessment and its applications in the nuclear power industry. Fire Technol 52(2):443–467

Gallucci RHV (2009) Thirty-three years of regulating fire protection at commercial U.S. nuclear power plants: dousing the flames of controversy. Fire Technol 45(4):355–380

Gallucci RHV (2016) Statistical characterization of cable electrical failure temperatures due to fire for nuclear power plant risk applications. Fire Technol 1–12. doi:10.1007/s10694-016-0616-0

McGrattan K, Peacock R, Overholt K (2016) Validity of fire models applied to nuclear power plant safety. Fire Technol 52(1): 5–24 (2016)

Acknowledgements

The authors wish to thank Dr. Marc Janssens and Osvaldo Pensado of the Center for Nuclear Waste Regulatory Analyses at the Southwest Research Institute for their comments and suggestions that improved this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

The views expressed herein are strictly the authors’ personal ones and do not necessarily represent any opinion or position by the U.S. Nuclear Regulatory Commission.

An erratum to this article is available at http://dx.doi.org/10.1007/s10694-017-0650-6.

Appendices

Appendix I: Sensitivity Study on Potential Effect of Door Position

As a sensitivity study on the potential effect of door position, the results from adjusting the two distributions for qualified (Q) and unqualified (UQ) cables were compared, via scaling based on the ratio of the means for the closed and open groupings for each to the means for the overall distributions, to gamma distributions fit to the closed and open groupings in the same manner as for the overall groupings. As mentioned in Section 3.1, for the closed groupings, this implied a reduction for the closed door position of 13% for Q and 25% for UQ, and increase for the open door position of 94% for Q and 34% for UQ). The results are shown in Table 7. The various columns are as follows:

- (U)Q (All):

-

kW/kg based on primary gamma distribution for cable type

- (U)Q (All) Reduced:

-

kW/kg based on adjusting (U)Q (All) by ratio of means of (U)Q (Closed) to (U)Q (All)

- (U)Q (Closed):

-

kW/kg based on gamma distribution using only closed door position data

- (U)Q (All) Increased:

-

kW/kg based on adjusting (U)Q (All) by ratio of means of (U)Q (Open) to (U)Q (All)

- (U)Q (Open):

-

kW/kg based on gamma distribution using only open door position data

The largest relative variation occurs at the 50th percentile for Q in the closed groupings, where the peak HRR per fuel mass metric for the reduced overall distribution is ~12% lower than the corresponding value from the gamma distribution fit to the closed grouping (5.02 versus 5.73 kW/kg). The largest absolute variation occurs at the 98th percentile for UQ in the open groupings, where the peak HRR per fuel mass metric for the increased overall distribution is ~10 kW/kg higher than the corresponding value from the gamma distribution fit to the open grouping (186 vs. 176 kW/kg). The remaining variations are less. By definition of the scaling, the means are the same. At the 75th percentiles, the adjusted values are practically the same as those obtained from the additional gamma fits. At the 98th percentiles, the adjusted values are slightly higher, but by no more than ~10% (Q [all]—Reduced vs. Q [Closed], 49.3 vs. 44.9 kW/kg) and the 10 kW/kg previously cited. This suggests that the simple use of just two distributions, with scaling adjustments if desired to address the potential effect of door position as a surrogate if an enclosure is confirmed to be tightly sealed, is quite practical.

Appendix II: Overview of the HELEN-FIRE Test Program (as Extracted from NUREG/CR-7197 [13])

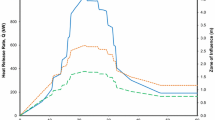

To better quantify the heat release rate (HRR) and burning behavior of electrical enclosures, 112 full-scale experiments were conducted at the Chesapeake Bay Detachment of the Naval Research Laboratory [Maryland, USA]. Eight electrical enclosures were acquired from Bellefonte Nuclear Generating Station, a plant owned by the Tennessee Valley Authority located in Hollywood, Alabama [Figures 3 , 4 , 5 , 6 , 7 , 8 ]. The enclosures were installed in the early 1980s, but the plant was never operated. The enclosures were originally low voltage control cabinets, but in the experiments they were reconfigured with various amounts and types of electrical cable to represent other kinds of enclosures that would be found in a typical plant [Figure 9 ; Table 8 ]…. An oxygen consumption calorimeter was built on site to measure the HRR of the fire as a function of time. Of particular interest is the peak HRR, the time to peak, and the total energy released. Thermocouples were positioned at various heights within the enclosures to monitor internal temperatures.

The…Chesapeake Bay Detachment of the Naval Research Laboratory…has a large-scale calorimeter that is nominally 6.1 m by 6.1 m (20 ft by 20 ft), designed to measure the HRR of fires ranging from approximately 100 kW to 10 MW. However, its instruments are not sensitive enough to measure accurately the HRR of the small fires that were expected in many of the enclosure experiments. For this reason, a smaller calorimeter (see Figure 10 ) was built to fit underneath the large hood (see Figure 11 ). The smaller hood was 2.4 m by 2.4 m (8 ft by 8 ft), and 2.4 m (8 ft) off the floor. Its 46 cm (18 in) duct was instrumented with a Rosemount Annubar ® to measure the volume flow, four thermocouples to measure the gas temperature, and a gas extraction tube to measure the oxygen concentration of the exhaust gases. The instruments were located approximately 4 m (13 ft) from the vertical centerline of the hood…. Three types of ignition sources were used in the experiments: cartridge heaters, line burners, and pans of liquid fuel. A cartridge heater is a surrogate for an over-heated electrical component or cable. The line burner is a surrogate for a small fire that could result from an over-heated wire or component. The pan fire is a surrogate for a relatively large fire whose origin is difficult to specify exactly, but most likely due to an event such as a high energy arc fault or similar malfunction resulting in the ignition of a relatively large amount of combustible material.

The experiments were conducted from late October of 2013 through early March of 2014…. The facility was not heated, and temperatures ranged from approximately 0°C (32°F) to 20°C (68°F). Typically, electrical enclosures are operated at 32°C (90°F), but in the experiments, the enclosures were not powered. For some experiments, a pan of ethanol or acetone was placed at the base of the enclosure away from the combustibles to raise the interior enclosure temperature. These same pans of alcohol were sometimes used to ignite the combustibles directly…. The propane line burner was typically positioned within a bundle of cable as if it were just another cable. Wire was used to hold the burner firmly in place. The exact placement of the burner varied from test to test, and there was no particular emphasis on a “standard” ignition system. Rather, the burner position and HRR were varied as would be expected in actual fire events. The cables and wiring were not installed in a particularly systematic way either. Typically, bundles of cables would be hung using wires on either the left or right side of the enclosure, as had been observed in enclosures found on the plant visits. Sometimes the cables and/or individual conductors would be tightly bundled using plastic wire or “zip ties,” and at other times they would be left to hang in no particular arrangement. It was observed that “loose” or non-bundled cables or wires led to higher HRRs, even though bundling was necessary to accumulate enough combustible mass in the vicinity of the igniter to facilitate fire spread. The total combustible mass refers to the mass of cable jacketing and insulation material derived from the measured length of cable multiplied by the mass of non-metallic materials per unit length…

Rights and permissions

About this article

Cite this article

Gallucci, R.H.V., Metzger, B. Statistical Characterization of Heat Release Rates from Electrical Enclosure Fires for Nuclear Power Plant Applications. Fire Technol 53, 1249–1271 (2017). https://doi.org/10.1007/s10694-016-0633-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-016-0633-z