Abstract

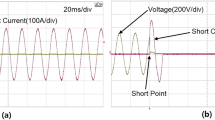

Many fire investigators believe the presence of a rounded mass of re-solidified copper at the end of a small-diameter copper conductor means the conductor was energized at the time of the fire. While testing performed in the course of fire investigations by others and in this work has demonstrated that beads of re-solidified copper may be present on conductors known to have voltage present at the time of the fire, there may also be globules of re-solidified copper on conductors known not to have been energized. Even if the copper conductor orientation during a fire is considered, the external appearance of these beads and globules on small, 34 AWG conductors has not been found to be a reliable indicator of the cause of formation, often requiring further analysis. In an effort to identify and determine potential differences between beads created by electrical faulting alone and globules created by fire attack, testing was performed in which 34 AWG conductors were exposed to laboratory flames and burning bedding with and without being energized. The resulting beads and globules were then analyzed considering both their external appearances and internal microstructures. The analysis of the internal microstructures considering grain boundaries, voids, damage, and signs of re-melting provided insight concerning the cause of such features on tinned, 34 AWG conductors that can be found at fire scenes. Specifically, in unpowered 34 AWG conductors the copper microstructure variations between globules and the immediately adjacent wires has shown that at least a 432°C temperature differential can be created without electrical faulting in this work. Beads created by electrical faulting alone have been found to have characteristics that distinguish them from globules caused by fire attack in this work as well. The microstructures in beads resemble the heat-affected and fusion zones of a fusion weld, while the proximal unmelted wires do not reach the annealing temperature of copper. This condition creates a sharp line of demarcation between the melted and unmelted conductor surfaces as a result of the localized heat from electrical faulting seen within the beads. This sharp line of demarcation can be used to identify beads as opposed to globules.

Similar content being viewed by others

References

National Fire Protection Association (2014) NFPA 921: Guide for Fire and Explosion Investigations 2014 Edition. National Fire Protection Association. 921-14, 110, 111, 115

Ettling BV (1978) Electrical wiring in building fires. Fire Technol 14:317–325. doi:10.1007/BF01998391

Henderson R, Manning C, Barnhill S (1998) Questions concerning the use of carbon content to identify “cause” vs. “result” beads in fire investigations. Fire Arson Investig 48:26–27

Hoffmann JM, Hoffmann DJ, Kroll EC, Wallace JW, Kroll MJ (2001) Electrical power cord damage from radiant heat and fire exposure. Fire Technol 37:129–141. doi:10.1023/A:1011645701985

Babrauskas VB (2003) Fires due to electrical arcing: can ‘cause’ beads be distinguished from ‘victim’ beads by physical or chemical testing?. Fire Mater 189–201

Clarke CK (2006) Evaluation of fire damaged copper wire. Adv Mater Process 164:1–3

Davis JR (2001) ASM specialty handbook: copper and copper alloys, ASM International, Materials Park

Buc EC, Reiter D, Battley J, Sting TB, Sing TM (2013) Method to characterize damage to conductors from fire scenes. In: Proceedings of the Fire and Materials Conference. pp. 957–665

Phase Diagrams & Computational Thermodynamics Pb-Sn System. http://www.metallurgy.nist.gov/phase/solder/pbsn.html. Accessed 28 May 2013

Baker H, Okamoto H (1992) ASM handbook: alloy phase diagrams, vol 3. ASM International, Materials Park

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wright, S.A., Loud, J.D. & Blanchard, R.A. Globules and Beads: What Do They Indicate About Small-Diameter Copper Conductors that Have Been Through a Fire?. Fire Technol 51, 1051–1070 (2015). https://doi.org/10.1007/s10694-014-0455-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-014-0455-9