Abstract

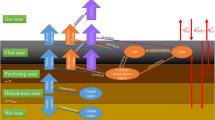

Polymer foam encapsulants provide mechanical, electrical, and thermal isolation in engineered systems. It can be advantageous to surround objects of interest, such as electronics, with foams in a hermetically sealed container in order to protect them from hostile environments or from accidents such as fire. In fire environments, gas pressure from thermal decomposition of foams can cause mechanical failure of sealed systems. In this work, a detailed uncertainty quantification study of polymeric methylene diisocyanate (PMDI)-polyether-polyol based polyurethane foam is presented and compared to experimental results to assess the validity of a 3-D finite element model of the heat transfer and degradation processes. In this series of experiments, 320 kg/m3 PMDI foam in a 0.2 L sealed steel container is heated to 1,073 K at a rate of 150 K/min. The experiment ends when the can breaches due to the buildup of pressure. The temperature at key location is monitored as well as the internal pressure of the can. Both experimental uncertainty and computational uncertainty are examined and compared. The mean value method (MV) and Latin hypercube sampling (LHS) approach are used to propagate the uncertainty through the model. The results of the both the MV method and the LHS approach show that while the model generally can predict the temperature at given locations in the system, it is less successful at predicting the pressure response. Also, these two approaches for propagating uncertainty agree with each other, the importance of each input parameter on the simulation results is also investigated, showing that for the temperature response the conductivity of the steel container and the effective conductivity of the foam, are the most important parameters. For the pressure response, the activation energy, effective conductivity, and specific heat are most important. The comparison to experiments and the identification of the drivers of uncertainty allow for targeted development of the computational model and for definition of the experiments necessary to improve accuracy.

Similar content being viewed by others

References

Beyler C, Hirschler M (2001) Thermal decomposition of polymers, SFPE handbook of fire protection engineering, pp 110–131. National Fire Protection Association, Quincy

Pau DSW, Fleischmann CM, Spearpoint MJ, Li KY (2013) Determination of kinetic properties of polyurethane foam decomposition for pyrolysis modeling. J Fire Sci 1:1–29

Ramroth WT, Asaro RJ, Zhu B, Krysl P (2010) Finite element modelling of fire degraded FRP composite panels using a rate dependent constitutive model. Composite: Part A 37:1015–1023

Overholt KJ, Ezekoye OA (2014) Quantitative testing of fire scenario hypotheses: a Bayesian inference approach. Fire Technol. doi:10.1007/s10694-013-0384-z

Matala A, Hostikka S (2009) Probabilistic simulations of cable fires in a cable tunnel. In: 20th international conference on structural mechanics in reactor technology, Helsinki, Finland

Summers PT, Lattimer BY, Case S, Feih S (2012) Predicting compression failure of composite laminates in fire. Composite: Part A 43:773–782

Summers PT, Lattimer BY, Case S, Feih S (2012) Sensitivity of thermo-structural model for composites laminates in fire. Composite: Part A 43:783–792

Enright PA, Fleischmann CM (1999) Uncertainty of heat release rate calculation of the ISO5660-1 cone calorimeter stand test method. Fire Technol 35(2):153. doi:10.1023/A:1015416005888

Erickson KL, Dodd AB, Hogan RE, Dowding KJ (2010) Heat transfer, foam decomposition, and container pressurization: comparison of experimental and modeling results. Interscience Communications Ltd., Interflam, Nottingham

Erickson KL, Dodd AB, Quintana EC (2011) Physical behavior and container pressurization during thermal decomposition of polyurethane foams. In: Proceedings of BCC 2011, Stamford, CT

Erickson KL, Dodd AB, Hogan RE (2010) Modeling pressurization caused by thermal decomposition of highly charring foam in sealed containers. In: Proceedings of BCC 2010, Stamford, CT

Sierra Core Team (2014) Sierra thermal/fluids code. Sandia National Laboratories, Albuquerque, NM

Larsen ME, Dodd AB (2013) Uncertainty quantification for foam in can experiment. Sandia Internal Memorandum, Sandia National Laboratories, Albuquerque, NM

Erickson KL, Celina MC, Hogan RE, Nicolette VF, Aubert JH (2009) Fire and materials. Interscience Commun. Ltd., London, pp 353–365

Erickson KL (2007) J Therm Anal Calor 89:427–440

Erickson KL, Oelfke J (2013) Fire and polymers V. In: Wilkie CA, Morgan AB, Nelson GL (eds) ACS symposium series 1013, pp 387–407. ACS

Taylor RE, Groot H, Ferrier J (1998) Thermophysical properties of two foams, TPRL 1964, Thermophysical Properties Res. Lab., West Lafayette, IN

Neet TE (1994) Development of non-TDI polyurethane encapsulation foams, PDO 705898 final report, Sept 1994

Jin G, Venkatesan G, Chyu MC, Zheng JX (1998) Measurement of thermal conductivity and heat capacity of foam insulation during transient heating, AV7569 final report, Department of Mechanical Engineering, Texas Tech University

Siegel R, Howell JR (1982) Thermal radiation heat transfer, 2nd edn. Hemisphere Publishing, Cambridge, 497–501

Reichman J (1973) Appl Opt 12(8):1811–1815

Scott SN, Templeton JA, Ruthruff JR, Hough PD, Peterson JP (2013) Computational solution verification applied to a thermal model of a ruggedized instrumentation package, computational methods and experimental measurements XVI, A Coruña, Spain, 2–4 July (2013)

Hughes TJR (2000) The finite element method. Dover, Mineola

Saltelli A, Chan K, Scott EM (2000) Sensitivity analysis (Chap. 6), Wiley, New York

Helton JC, Davis FJ, Latin hypercube sampling and the propagation of uncertainty in analyses of complex systems, SAND2001-0417. Sandia National Laboratories, Albuquerque

Adams BM, Ebeida MS, Eldred MS, Jakeman JD, Swiler LP, Bohnhoff WJ, Dalbey KR, Eddy JP, Hu KT, Vigil DM, Bauman LE, Hough PD (2009) DAKOTA, a multilevel parallel object-oriented framework for design optimization, parameter estimation, uncertainty quantification, and sensitivity analysis, Version 5.4 users manual, SAND2010-2183. Sandia National Laboratories, Albuquerque

Scott SN, Larsen ME, Dodd AB, Erickson KL (2013) Model validation of thermal decomposition and container pressurization of polyurethane foam. Interflam, Windsor

Helton JC, Johnson JD, Sallaberry CJ, Storlie CB (2006) Survey of sampling-based methods for uncertainty and sensitivity analysis. Reliab Eng Syst Saf 91:1175–1209

Ghanem RG, Spanos PD (1991) Stochastic finite elements: a spectral approach. Springer, New York

Sacks J, Schiller SB, Welch W (1989) Design for computer experiments. Technometrics 31:41–47

Acknowledgments

The authors would like to thank Patty Hough, Tim Koehler, and Roy Hogan for reviewing this paper. Sandia is a multi-program laboratory operated by Sandia Corporation, a Lockheed Martin Company, for the United States Department of Energy’s National Nuclear Security Administration under Contract DE-AC04-94AL85000. This is document SAND2014-16560J.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Scott, S.N., Dodd, A.B., Larsen, M.E. et al. Validation of Heat Transfer, Thermal Decomposition, and Container Pressurization of Polyurethane Foam Using Mean Value and Latin Hypercube Sampling Approaches. Fire Technol 52, 121–147 (2016). https://doi.org/10.1007/s10694-014-0448-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-014-0448-8