Abstract

Biogas produced from an upflow anaerobic sludge blanket (UASB) reactor is a clean and an environmentally friendly by-product that could be used to meet partial energy needs. In this study, a modified methane generation model (MMGM) was developed on the basis of mass balance principles to predict and increase methane production rate in a UASB reactor during anaerobic fermentation of brewery wastewater. Model coefficients were determined using the data collected from a full-scale reactor. The results showed that the composition of wastewater and operational conditions of the reactor strongly influence the kinetics of the digestion process. Simulation of the reactor process using the model was used to predict the effect of organic loading rate and temperature on methane production with an optimum methane production at 29 °C and 8.26 g COD/L/day. Methane production rate increased from 0.29 to 1.46 L CH4/g COD, when the loading rate was increased from 2.0 to 8.26 g COD/L/day. The results showed the applicability of MMGM to predict usable methane component of biogas produced during anaerobic digestion of brewery wastewater. This study would help industries to predict and increase the generation of renewable energy by improving methane production from a UASB reactor. To the best of our knowledge, MMGM is the first reported developed model that could serve as a predictive tool for brewery wastewater treatment plant available in the literature.

Similar content being viewed by others

Abbreviations

- B:

-

Actual volume of methane produced (in litres) per gram of COD (substrate) added to the reactor at S.T.P.

- NH3 :

-

Ammonia

- AD:

-

Anaerobic digestion

- CO2 :

-

Carbon dioxide

- COD:

-

Chemical oxygen demand

- Xe :

-

Concentration of biomass in the effluent (g/L)

- Xi :

-

Concentration of biomass in the influent (g/L)

- Xr :

-

Concentration of biomass in the reactor (g/L)

- S:

-

Concentration of substrate (g COD/L)

- Sr :

-

Concentration of substrate in the reactor (g/L)

- b:

-

Dimensionless kinetic parameter

- Se :

-

Effluent substrate concentration (g/L)

- Kd :

-

Endogenous decay coefficient (/day)

- K:

-

First-order kinetic constant

- Q:

-

Flow rate (L/day)

- P:

-

Fraction of biodegradable COD

- Y:

-

Growth yield coefficient (g/g)

- θ h :

-

Hydraulic retention time (/time)

- Si :

-

Influent substrate concentration (g/L)

- μ max :

-

Maximum growth rate of microorganisms when the substrate is being used at its maximum rate

- CH4 :

-

Methane

- X:

-

Microbial cell concentration (g/L)

- T:

-

Operational temperature (°C)

- \( \frac{dS}{dt} \) :

-

Rate of substrate removal (g/L/day)

- Vr :

-

Reactor volume (L)

- \( \frac{dX}{dt} \) :

-

Rate of change in microbial mass (g/L/day)

- μ :

-

Specific growth rate of microorganisms (/day)

- Bo :

-

Ultimate methane yield coefficient under normal conditions of temperature and pressure per gram of substrate (COD) added for complete utilization of substrate or at an infinite hydraulic retention time

- Yv :

-

Volumetric methane production rate (L methane/g COD added/day)

References

Abtahi, S.M., Amin, M.M., Nateghi, R., Vosoogh, A., & Dooranmahalleh, M.G. (2012). Prediction of effluent COD concentration of UASB reactor using kinetic models of monod, contois, second-order Grau and modified Stover-Kincannon. International Journal of Environmental Health Engineering, 1(8), http://www.ijehe.org.

Acharya, B. K., Mohana, S., & Madamwar, D. (2008). Anaerobic treatment of distillery spent wash—a study on upflow anaerobic fixed film bioreactor. Bioresource Technology, 99, 4621–4626.

Acharya, B. K., Pathak, H., Mohana, S., Shouche, Y., Singh, V., & Madamwar, D. (2011). Kinetic modelling and microbial community assessment of anaerobic biphasic fixed film bioreactor treating distillery spent wash. Water Research, 45(14), 4248–4259. doi:10.1016/j.watres.2011.05.048.

Anderson, G. K., Kasapgil, B., & Ince, O. (1996). Microbial kinetics of a membrane anaerobic reactor system. Environmental Technology, 17, 449–464.

APHA–AWWA–WPCF. (1998). Standard methods for the examination of water and wastewater (20th ed.). Washington: American Public Health Association/American Water Works Association/Water Environment Federation.

Babaee, A., & Shayegan, J. (2011). Anaerobic digestion of vegetable waste. Chemical Engineering Transactions, 24, 1291–1296.

Batstone, D. J., Keller, J., Newell, R. B., & Newland, M. (2000). Modelling anaerobic degradation of complex wastewter. I: model development. Bioresource Technology, 75, 67–74.

Batstone, D., Keller, J., Angelidaki, I., Kalyhuzhnyi, S., Pavlostathis, S., Rozzi, A., Sanders, W., Siegrist, H., & Vavilin, V. (2002). The IWA Anaerobic Digestion Model No.1 (ADM1). Water Science Technology, 45(10), 65–73.

Bhunia, P., & Ghangrekar, M. M. (2008). Analysis, evaluation, and optimization of kinetic parameters for performance appraisal and design of UASB reactors. Bioresource Technology, 99(7), 2132–2140. doi:10.1016/j.biortech.2007.05.053.

Blumensaat, F., & Keller, J. (2002). Modelling of two-stage anaerobic digestion using the IWA Anaerobic Digestion Model No. 1 (ADM1). Water Research, 39, 171–183.

Cecchi, F., Mata-Alvarez, J., Pavan, P., Vallini, G., & De Poli, F. (1992). Seasonal effects on anaerobic digestion of the source sorted organic fraction of municipal solid waste. Waste Management and Research, 10(5), 435–443. doi:10.1016/0734-242x(92)90117-4.

Chae, K. J., Jang, A., Yim, S. K., & Kim, I. S. (2007). The effect of digestion temperature and temperature shock on the biogas yields from the mesophilic anaerobic digestion of swine manure. Bioresource Technology, 99(1), 1–6.

Chen, Y. R., & Hashimoto, A. G. (1978). Kinetics of methane fermentation. Biotechnology and Bioengineering Symposium, 8, 269–282.

Colussi, I., Cortesi, A., Gallo, V., Fernandez, A. S. R., & Vitanza, R. (2012). Modelling of an anaerobic process producing biogas from winery wastes. Chemical Engineering Transactions, 27, 301–306.

Contois, D. E. (1959). Kinetics of microbial growth: relationship between population density and specific growth rate of continuous culture. Journal of General Microbiology, 21(1), 40–54.

Demirel, B., Scherer, P., Yenigun, O., & Onay, T. T. (2010). Production of methane and hydrogen from biomass through conventional and high-rate anaerobic digestion processes. Critical Reviews in Environmental Science and Technology, 40, 116–146. doi:10.1080/10643380802013415.

Enitan, A. M., Kumari, S., Swalaha, F. M., Adeyemo, J., Ramdhani, N., & Bux, F. (2014). Kinetic modelling and characterization of microbial community present in a full-scale UASB reactor treating brewery effluent. Microbial Ecology, 67, 358–368. doi:10.1007/s00248-00013-00333-x.

Faisal, M., & Unno, H. (2001). Kinetic analysis of palm oil mill wastewater treatment by a modified anaerobic baffled reactor. Biochemical Engineering Journal, 9, 25–31.

Fdez-Güelfo, L. A., Álvarez-Gallego, C., Sales, D., & García, L. I. R. (2012). Dry-thermophilicanaerobic digestion of organic fraction of municipal solid waste: methane production modelling. Waste Management, 32, 382–388.

Ghaly, A. E., Sadaka, S. S., & Hazza'a, A. (2000). Kinetics of an intermittent-flow, continuous-mix anaerobic reactor. Energy Sources, 22(6), 525–542.

Gunaseelan, V. (2007). Regression models of ultimate methane yields of fruits and vegetable solid wastes, sorghum and napiergrass on chemical composition. Bioresource Technology, 98, 1270–1277.

Iqbal, J., & Guria, C. (2009). Optimization of an operating domestic wastewater treatment plant using elitist non-dominated sorting genetic algorithm. Chemical Engineering Research and Design, 87, 1481–1496.

Jeong, H.-S., Suh, C.-W., Lim, J.-L., & Shin, H.-S. (2005). Analysis and application of ADM1 for anaerobic methane production. Bioprocess Biosystem Engineering, 27, 81–89.

Khalid, A., Arshad, M., Anjum, M., Mahmood, T., & Dawson, L. (2011). The anaerobic digestion of solid organic waste. Waste Management, 31, 1737–1744.

Khuri, A. I., & Cornell, J. A. (1987). Response surfaces: Design and analysis. New York: Marcel Decker Inc.

Krishna, R. H. (2013). Role of factors influencing on anaerobic process for production of biohydrogen: future fuel. International Journal of Advanced Chemistry, 1(2), 31–38.

Liu, Y., Xu, H.-L., Yang, S.-F., & Tay, J.-H. (2003). Mechanisms and models for anaerobic granulation in upflow anaerobic sludge blanket reactor. Water Research, 37(3), 661–673. doi:10.1016/s0043-1354(02)00351-2.

Lübken, M., Wichern, M., Schlattmann, M., Gronauer, A., & Horn, H. (2007). Modelling the energy balance of an anaerobic digester fed with cattle manure and renewable energy crops. Water Research, 41, 4085–4096.

Maya-Altamira, L., Baun, A., Angelidaki, I., & Schmidt, J. E. (2008). Influence of wastewater characteristics on methane potential in food processing industry wastewaters. Water Research, 42, 2195–2203.

Mu, S. J., Zeng, Y., Wu, P., Lou, S. J., & Tartakovsky, B. (2008). Anaerobic digestion model no. 1-based distributed parameter model of an anaerobic reactor: I. Model development. Bioresource Technology, 99(9), 3665–3675. doi:10.1016/j.biortech.2007.07.060.

Nadais, H., Barbosa, M., Capela, I., Arroja, L., Ramos, C. G., Grilo, A., et al. (2011). Enhancing wastewater degradation and biogas production by intermittent operation of UASB reactors. Energy, 36, 2164–2168.

Oktem, Y., & Tufekei, N. (2006). Treatment of brwery wastewater by pilot scale upflow anaerobic brewery wastewater by pilot scale upflow anaerobic sludge blanket reactor in mesophilic temperature. Journal of Scientific and Industrial Research, 65, 248–257.

Parsamehr, M. (2012). Modeling and Analysis of a UASB Reactor. (Master of Science Environmental Engineering, Master of Science Thesis. Luleå University of Technology.

Rajput, V. S., Sharma, A. K., Ranjan, R. K., & Singh, S. (2012). Recovery of energy from waste generated in biogas power plant. International Journal of Scientific Research Engineering and Technology, 1(5), 068–072.

Reungsang, A., Pattra, S., & Sittijunda, S. (2012). Optimization of key factors affecting methane production from acidic effluent coming from the sugarcane juice hydrogen fermentation process. Energies, 5, 4746–4757. doi:10.3390/en5114746.

Rincón, B., Borja, R., González, J. M., Portillo, M. C., & Saiz-Jiménez, C. S. (2008). Influence of organic loading rate and hydraulic retention time on the performance, stability and microbial communities of one-stage anaerobic digestion of two-phase olive mill solid residue. Biochemical Engineering Journal, 40, 253–261.

Senturk, E., Ýnce, M., & Engin, G. O. (2013). Assessment of kinetic parameters for thermophilic anaerobic contact reactor treating food-processing wastewater. International Journal of Environmental Research, 7(2), 293–302.

Sykes, R. M. (1995). Biological water treatment processes. In W. F. Chen (Ed.), The civil engineering handbook. New York: CRC Press LLC.

Thorin, E., Nordlander, E., Lindmark, J., Dahlquist, E., Yan, J., & Fdhila, R.B. (2012). Modeling of the biogas production process- a review. Paper presented at the International Conference on Applied Energy (ICAE) Suzhou, China. Paper ID: ICAE2012- A10732.

Tiwari, M. K., Guha, S., Harendranath, C. S., & Tripathi, S. (2006). Influence of extrinsic factors on granulation in UASB reactor. Applied Microbiology Biotechnology, 71, 145–154.

Turkdogan-AydInol, F. I., & Yetilmezsoy, K. (2010). A fuzzy-logic-based model to predict biogas and methane production rates in a pilot-scale mesophilic UASB reactor treating molasses wastewater. Journal of Hazardous Materials, 182, 460–471.

Ward, J. A., HobbsPhil, J., Holliman, P. J., & Jones, D. L. (2008). Optimisation of the anaerobic digestion of agricultural resources. Review Bioresource Technology, 99, 7928–7940.

Wiegant, W.M. (2001). Experiences and potentials of anaerobic wastewater treatment in tropical regions Anearobic digstion of sustainable Development Farewell Seminar of Prof Dr Ir. Gatze Lettinga Wageningen - The Netherlands, EP & RC, 111–118.

Yadvikaa, S., Sreekrishnanb, T. R., Kohlic, S., & Ranaa, V. (2004). Enhancement of biogas production from solid substrates using different techniques––a review. Bioresource Technology, 95(1), 1–10.

Yetilmezsoy, K. (2012). Integration of kinetic modeling and desirability function approach for multi-objective optimization of UASB reactor treating poultry manure wastewater. Bioresource Technology, 118(89–101), 118 189–101.

Yetilmezsoy, K., & Sakar, S. (2008). Development of empirical models for performance evaluation of UASB reactors treating poultry manure wastewater under different operational conditions. Journal of Hazardous Materials, 153(1–2), 532–543. doi:10.1016/j.jhazmat.2007.08.087.

Yuan, X., Liu, J., Zeng, G., Shi, J., Tong, J., & Huang, G. (2008). Optimization of conversion of waste rapeseed oil with high FFA to biodiesel using response surface methodology. Renewable Energy, 33, 1678–1684.

Zainol, N. (2012). Kinetic of biogas production from banana stem waste.

Zhao, B., Mu, Y., Dong, F., Ni, B., Zhao, J., Sheng, G., et al. (2010). Dynamic modelling of the anaerobic reactor startup process. Industrial & Engineering Chemistry Research, 49, 7193–7200.

Zhou, H., Löffler, D., & Kranert, M. (2011). Model-based predictions of anaerobic digestion of agricultural substrates for biogas production. Bioresource Technology, 102, 10819–10828.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

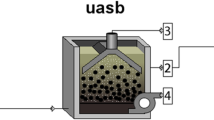

1.1 The Microbial Mass Balance

The microbial mass balance of an UASB reactor (Fig. 8) was described as follows by Ghaly et al. [20]:

The microbial growth rates in a batch experiment have traditionally been measured, in which a single species of microorganisms passes through a logarithmic growth phase during the conversion of the organic substrate. The microbial growth rate, dX/dt, is described by

which can be written as

During steady-state conditions, the biomass concentration in the influent is negligible (X i ≈ 0), compared to the biomass concentration in the reactor. In addition, X r is equal to X e due to perfect mixing in a completely mixed reactor. The rate of substrate removal from the reactor is therefore neglected. In steady-state conditions, dX/dt = 0 and Eq. (A.3) can be rearranged to obtain Eq. (A.4). Thus,

Eq. (A.4) can be rewritten as

The hydraulic retention time, θh, is defined as V/Q. The inverse of θ h can be substituted into Eq (A.4) as

As shown in Eq. (A.6), the net specific growth rate is μ − K d.

1.2 Substrate Mass Balance and Effluent Substrate Concentration

The rate of substrate balance in the UASB reactor can be expressed using Eq. (A.7)

Mathematically, Eq. (A.7) can be written as

At steady state, Eq. (A.8) was divided by V, and Q/V was substituted for θh. At equilibrium the substrate balance of a working system was obtained as

Thus, under perfect mixing of the reactor content (Xr = Xe), the microbial mass concentration in the effluent can be written as Eq. (A.10). This gives the concentration of microorganism in the effluent as

where (S i –S e)/θ h is the rate of substrate utilization. Contois [15] defined the relationship between limiting substrate concentration and specific growth rate for effluent substrate concentration as

Under perfect mixing (S e = S r and X e = X r), the association between the rate-limiting substrate concentration and specific growth rate can be expressed as

Equations derived from the combination and rearrangement of Eqs. (A.6), (A.10) and (A.12) are:

where Eq. (A.14) shows that the influent substrate concentration is inversely proportional to the substrate concentration in the final effluent.

1.3 Biogas Production

In the reactor, the biodegradable COD is proportional to (B o − B). Bo is directly proportional to the biodegradable COD loading rate [48]. Therefore, from Eq. (A.14), the methane yield (B) is described by

Methane production per gram of substrate (COD) added, B is described by

Since B is equal to the volume of methane produced per unit of COD added, the volumetric methane production rate, Y v is equal to B, multiplied by the organic loading rate, S i/θ h . The equations describing the theoretical methane output rate per unit of reactor volume therefore are written as Eqs. (A.17) and (A.18):

Appendix 2

Appendix 3

Appendix 4

Appendix 5

Rights and permissions

About this article

Cite this article

Enitan, A.M., Adeyemo, J., Swalaha, F.M. et al. Anaerobic Digestion Model to Enhance Treatment of Brewery Wastewater for Biogas Production Using UASB Reactor. Environ Model Assess 20, 673–685 (2015). https://doi.org/10.1007/s10666-015-9457-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10666-015-9457-3