Abstract

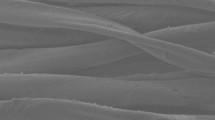

In the textile and fashion industry, cotton knitted fabric is commonly used for making apparel. To achieve different functional effects of the cotton knitted fabric, chemical treatments are commonly used, but due to increased environmental restrictions, physical treatment, e.g., with a laser, has recently been introduced to the market as an environmentally friendly way to treat the surface of cotton fabric. Thus, the aim of the present study is to evaluate the impact of laser treatment on the physical and mechanical properties of 100% cotton single jersey knitted fabrics with different yarn counts. The fabrics had been treated using a carbon dioxide laser (CO2) with different levels of intensity in terms of the resolution and treatment time, i.e., the resolution (28, 32, 36, 40 dpi) and pixel time (100, 110, 120, 130 μs). The laser power density resulting from the different combinations of laser variables was measured. Various evaluation tests including scanning electron microscopy, fabric weight, fabric thickness and fabric bursting strength were used to study the effect of laser treatment on the knitted fabrics. Grooves and microcracks appeared on the fibers after laser treatment. With increasing resolution and pixel time, these changes became more distinct on the fiber surface. The highest number of pores was found on the yarn with a higher yarn count and lower yarn twist. According to the results of knitted fabrics treated with a laser, the largest difference was found for the aspects of weight, thickness and whiteness values of the fabric knitted with the thickest yarn. Furthermore, it was confirmed that not only the yarn count affects the change in weight and thickness, but also the fabric structure such as the number of courses affected the laser treatment result.

[Hung et al. 2016 with permission from SAGE Publications (license no. 4044771493535)]

Similar content being viewed by others

References

Bahners T, Kesting W, Schollmeyer E (1993) Designing surface properties of textile fibers by UV-laser irradiation. Appl Surf Sci 69:12–15

CIE (2004) Colorimetry. Commission Internationale De l’eclairage, CIE Central Bureau, Vienna

Dascalu T, Acosta-Ortiz SE, Ortiz-Morales M, Compean I (2000) Removal of the indigo color by laser beam–denim interaction. Opt Lasers Eng 34(3):179–189

Fatima E, Helena A (2007) Effect of CO2 laser radiation on surface and dyeing properties of synthetic fibers. Res J Text Appar 11(3):42–47

Hung ON, Song LJ, Chan CK, Kan CW, Yuen CWM (2011) Using artificial neural network to predict colour properties of laser-treated 100% cotton fabric. Fibers Polym 12(8):1069–1076

Hung ON, Song LJ, Chan CK, Kan CW, Yuen CWM (2012) Laser-engraved color properties on cotton-spandex fabric predicted by artificial neural network. AATCC Rev 12(3):57–63

Hung ON, Chan CK, Kan CW, Yuen CWM, Song LJ (2014) Artificial neural network approach for predicting color properties of laser treated denim fabrics. Fibers Polym 15(6):1330–1336

Hung ON, Chan CK, Kan CW, Yuen CWM (2016) Microscopic study of the surface morphology of CO2 laser-treated cotton and cotton/polyester blended fabric. Text Res J. doi:10.1177/0040517516648511

Hung ON, Chan CK, Kan CW, Yuen CWM (2017) An analysis of some physical and chemical properties of CO2 laser treated cotton-based fabrics. Cellulose. 24:363–381

Izadyar E, Amir K, Mazeyar PG, Mohammad HN (2011) Atmospheric-air plasma enhances coating of different lubricating agents on polyester fiber. Eur Phys J Appl Phys 56(1):10801

Jucienė M, Urbelis V, Juchnevičienė Ž, Čepukonė L (2014) The effect of laser technological parameters on the color and structure of denim fabric. Text Res J 84(6):662–670

Kan CW (2014a) CO2 laser treatment as a clean process for treating denim fabric. J Clean Prod 66:624–631

Kan CW (2014b) Colour fading effect of indigo-dyed cotton denim fabric by CO2 laser. Fibers Polym 15(2):426–429

Kesting W, Bahners T, Schollmeyer E (1990) Controlling structuring of polymer surfaces by UV-laser irradiation. Appl Surf Sci 46:326–329

Lau K, Chan PW, Yeung KW, Chan K, Gong WZ (1997) Surface properties of polyester fabrics induced by excimer laser processing. J Mater Process Technol 63:524–528

Nooralian Z, Parvinzadeh M, Ebrahimi I (2016) Fabrication of a multifunctional graphene/polyvinylphosphonic acid/cotton nanocomposite via facile spray layer-by-layer assembly. RSC Adv 6(28):23288–23299

Ondogan Z, Pamuk O, Ondogan EN, Ozguney A (2005) Improving the appearance of all textile products from clothing to home textile using laser technology. Opt Laser Technol 37(8):631–637

Ortiz-Morales M, Poterasu M, Acosta-Ortiz SE, Compean I, Hernadez-Alvarado MR (2003) A comparison between characteristics of various laser-based denim fading processes. Opt Lasers Eng 39:15–24

Parvinzadeh M, Almasian A (2013) Citric acid/ZrO2 nanocomposite inducing thermal barrier and self-cleaning properties on protein fibers. Compos B Eng 52:340–349

Parvinzadeh M, Hajiraissi R (2008) Effect of nano and micro emulsion silicone softeners on properties of polyester fibers. Tenside Surfactants Deterg 45(5):254–257

Parvinzadeh M, Almasian A, Parvinzadeh MG (2012) Preparation of electromagnetic reflective wool using nano-ZrO2/citric acid as inorganic/organic hybrid coating. Sens Actuators A 187:1–9

Parvinzadeh M, Alireza P, Ehsani H, Parvinzadeh MG (2013a) Surface oxidation of cellulose by ozone-gas in a vacuum cylinder to improve the functionality of fluoromonomer. Vacuum 91:7–13

Parvinzadeh M, Alireza E, Parvinzadeh MG (2013b) UV radiation inducing succinic acid/silica-kaolinite network on cellulose fiber to improve the functionality. Compos B Eng 48:158–166

Rajagopal K (2008) Textbook of engineering physics. Prentice-Hall of India Pvt. Ltd, New Dehli

Ready JF (1997) Industrial applications of lasers. Academic Press, New York

Stepankova M, Wiener J, Dembicky J (2010) Impact of laser thermal stress on cotton fabric. Fibers Text East Eur 18(3):70–73

Stepankova M, Wiener J, Rusinova K (2011) Decolourization of vat dyes on cotton fabric with infrared laser light. Cellulose 18:469–478

Tarhan M, Sariisik M (2009) A comparison among performance characteristics of various denim fading processes. Text Res J 79(4):301–309

Yuan GX, Jiang SX, Newton E, Fan JT, Au WM (2011) Fashion design using laser engraving technology. In: 8ISS Symposium panel on transformation, pp 65–69

Acknowledgments

The authors would like to thank the financial support from The Hong Kong Polytechnic University for this work (project account: 1-ZE27 and G-UA5U).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hung, O.N., Chan, C.K., Kan, C.W. et al. Effect of the CO2 laser treatment on properties of 100% cotton knitted fabrics. Cellulose 24, 1915–1926 (2017). https://doi.org/10.1007/s10570-017-1224-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1224-y