Abstract

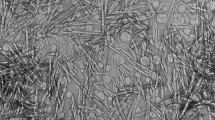

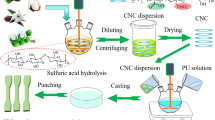

Polycaprolactone (PCL) was grafted to TEMPO-oxidized nanocellulose (TONCs) through a classical ring-opening polymerization reaction mediated by the surface TONC hydroxyl and carboxyl groups. The PCL increased the thermal stability and hydrophobicity without compromising the crystallinity. When TONCs and PCL-grafted TONCs (PTONC) were compared with respect to their perfusion within a segmented polyurethane matrix (CLPU), PTONC dispersed far better as evidenced by increased storage modulus and Young’s modulus. The mechanical strength of the PTONC nanocomposites was nearly that of unmodified TONCs while at a low content (<3 wt%). Furthermore, PTONC in CLPU promoted micro-phase separation of the matrix leading to a smaller decrease in loss factor and elongation at break for the nanocomposites, highly superior to unmodified TONCs. Thus, PTONC as a reinforcement agent enhanced the mechanical properties and ductility of CLPU.

Similar content being viewed by others

References

Adamus G, Kowalczuk M (2008) Anionic ring-opening polymerization of β-alkoxymethyl-substituted β-lactones. Biomacromolecules 9:696–703

Aranguren MI, Marcovich NE, Salgueiro W, Somoza A (2013) Shape memory polyurethane containing amorphous reversible phase. Polym Test 32:115–122

Auad ML, Contos VS, Nutt S, Aranguren MI, Marcovich NE (2008) Characterization of nanocellulose-reinforced shape memory polyurethanes. Polym Int 57:651–659

Auad ML, Mosiewicki MA, Richardson T, Aranguren MI, Marcovich NE (2010) Nanocomposites made from cellulose nanocrystals and tailored segmented polyurethanes. J Appl Polym Sci 115:1215–1225

Bistričić L, Baranović G, Leskovac M, Bajsić EG (2010) Hydrogen bonding and mechanical properties of thin films of polyether-based polyurethane–silica nanocomposites. Eur Polym J 46:1975–1987

Boufi S, Kaddami H, Dufresne A (2014) Mechanical performance and transparency of nanocellulose reinforced polymer nanocomposites. Macromol Mater Eng 299:560–568

Cao X, Dong H, Li CM (2007) New nanocomposite materials reinforced with flax cellulose nanocrystals in waterborne polyurethane. Biomacromolecules 8:899–904

Cao X, Habibi Y, Lucia LA (2009) One-pot polymerization, surface grafting, and processing of waterborne polyurethane-cellulose nanocrystal nanocomposites. J Mater Chem 19:7137–7145

Capadona JR, Shanmuganathan K, Trittschuh S, Seidel S, Rowan SJ, Weder C (2009) Polymer nanocomposites with nanowhiskers isolated from microcrystalline cellulose. Biomacromolecules 10:712–716

Chai X, Hou QX, Zhu JY, Chen S, Wang SF, Lucia LA (2003) Carboxyl groups in wood fibers. 1. Determination of carboxyl groups by headspace gas chromatography. Ind Eng Chem Res 42:5440–5444

Dufresne A (2000) Dynamic mechanical analysis of the interphase in bacterial polyester/cellulose whiskers natural composites. Compos Interface 7:53–67

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

Fujisawa S, Ikeuchi T, Takeuchi M, Saito T, Isogai A (2012) Superior reinforcement effect of TEMPO-oxidized cellulose nanofibrils in polystyrene matrix: optical, thermal, and mechanical studies. Biomacromolecules 13:2188–2194

Fujisawa S, Saito T, Kimura S, Iwata T, Isogai A (2013) Surface engineering of ultrafine cellulose nanofibrils toward polymer nanocomposite materials. Biomacromolecules 14:1541–1546

Fujisawa S, Saito T, Kimura S, Iwata T, Isogai A (2014) Comparison of mechanical reinforcement effects of surface-modified cellulose nanofibrils and carbon nanotubes in PLLA composites. Compos Sci Technol 90:96–101

Fukuzumi H, Saito T, Iwata T, Kumamoto Y, Isogai A (2008) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 10:162–165

Fukuzumi H, Saito T, Okita Y, Isogai A (2010) Thermal stabilization of TEMPO-oxidized cellulose. Polym Degrad Stabil 95:1502–1508

Gao Z, Peng J, Zhong T, Sun J, Wang X, Yue C (2012) Biocompatible elastomer of waterborne polyurethane based on castor oil and polyethylene glycol with cellulose nanocrystals. Carbohyd Polym 87:2068–2075

Garvey CJ, Parker IH, Simon GP (2005) On the interpretation of x-ray diffraction powder patterns in terms of the nanostructure of cellulose I fibres. Macromol Chem Phys 206:1568–1575

Goetz L, Mathew A, Oksman K, Gatenholm P, Ragauskas AJ (2009) A novel nanocomposite film prepared from crosslinked cellulosic whiskers. Carbohyd Polym 75:85–89

Goffin A, Raquez J, Duquesne E, Siqueira G, Habibi Y, Dufresne A, Dubois P (2011) Poly(ɛ-caprolactone) based nanocomposites reinforced by surface-grafted cellulose nanowhiskers via extrusion processing: morphology, rheology, and thermo-mechanical properties. Polymer 52:1532–1538

Guo Y, Wang X, Shen Z, Shu X, Sun R (2013) Preparation of cellulose-graft-poly (ɛ-caprolactone) nanomicelles by homogeneous ROP in ionic liquid. Carbohyd Polym 92:77–83

Habibi Y, Goffin A, Schiltz N, Duquesne E, Dubois P, Dufresne A (2008) Bionanocomposites based on poly (e-caprolactone)-grafted cellulose nanocrystals by ring-opening polymerization. J Mater Chem 18:5002–5010

Holt BL, Stoyanov SD, Pelan E, Paunov VN (2010) Novel anisotropic materials from functionalised colloidal cellulose and cellulose derivatives. J Mater Chem 20:10058–10070

Isogai A, Kato Y (1998) Preparation of polyuronic acid from cellulose by TEMPO-mediated oxidation. Cellulose 5:153–164

Iwamoto S, Kai W, Isogai A, Iwata T (2009) Elastic modulus of single cellulose microfibrils from tunicate measured by atomic force microscopy. Biomacromolecules 10:2571–2576

Jeong HM, Lee SY, Kim BK (2000) Shape memory polyurethane containing amorphous reversible phase. J Mater Sci 35:1579–1583

Jian C, Gong C, Wang S, Wang S, Xie X, Wei Y, Yuan J (2014) Multifunctional comb copolymer ethyl cellulose-g-poly (ε-caprolactone)-rhodamine B/folate: synthesis, characterization and targeted bonding application. Eur Polym J 55:235–244

Lendlein A, Behl M, Hiebl B, Wischke C (2010) Shape-memory polymers as a technology platform for biomedical applications. Expert Rev Med Devices 7:357–379

Li Z, Renneckar S, Barone J (2010) Nanocomposites prepared by in situ enzymatic polymerization of phenol with TEMPO-oxidized nanocellulose. Cellulose 17:57–68

Lin N, Chen GJ, Huang J (2009) Effects of polymer-grafted natural nanocrystals on the structure and mechanical properties of poly (lactic acid): a case of cellulose whisker-graft-polycaprolactone. J Appl Polym Sci 113:3417–3425

Lin N, Chang PR, Feng J, Yu J (2011) Surface acetylation of cellulose nanocrystal and its reinforcing function in poly (lactic acid). Carbohyd Polym 83:1834–1842

Lin N, Bruzzese C, Dufresne A (2012) TEMPO-oxidized nanocellulose participating as crosslinking aid for alginate-based sponges. ACS Appl Mater Inter 4:4948–4959

Liu Q, Zhu M, Wu W, Qin Z (2009) Reducing the formation of six-membered ring ester during thermal degradation of biodegradable PHBV to enhance its thermal stability. Polym Degrad Satabil 94:18–24

Löfgren A, Albertsson A, Dubois P, Jérôme R (1995) Recent advances in ring-opening polymerization of lactones and related compounds. J Macromol Sci Part C Polym Rev 35:379–418

Luo H, Hu J, Zhu Y (2011) Tunable shape recovery of polymeric nano-composites. Mater Lett 65:3583–3585

Martínez-Sanz M, Abdelwahab MA, Lopez-Rubio A, Lagaron JM, Chiellini E, Williams TG, Wood DF, Orts WJ, Imam SH (2013) Incorporation of poly (glycidylmethacrylate) grafted bacterial cellulose nanowhiskers in poly (lactic acid) nanocomposites: improved barrier and mechanical properties. Eur Polym J 49:2062–2072

Meng QJ, Li HL, Fu SY, Lucia LA (2014) The non-trivial role of native xylans on the preparation of TEMPO-oxidized cellulose nanofibrils. React Funct Polym 85:142–150

Merlatti C, Perrin FX, Aragon E, Margaillan A (2008) Natural and artificial weathering characteristics of stabilized acrylic–urethane paints. Polym Degrad Stabil 93:896–903

Montanari S, Roumani M, Heux L, Vignon MR (2005) Topochemistry of carboxylated cellulose nanocrystals resulting from TEMPO-mediated oxidation. Macromolecules 38:1665–1671

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:1–10

Rueda L, Saralegui A, Arlas BFD, Zhou Q, Berglund LA, Corcuera MA, Mondragon I, Eceiza A (2013) Cellulose nanocrystals/polyurethane nanocomposites. Study from the viewpoint of microphase. Carbohyd Polym 92:751–757

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491

Seydibeyoğlu MÖ, Oksman K (2008) Novel nanocomposites based on polyurethane and micro fibrillated cellulose. Compos Sci Technol 68:908–914

Seydibeyoğlu MÖ, Misra M, Mohanty A, Blaker JJ, Lee K, Bismarck A, Kazemizadeh M (2013) Green polyurethane nanocomposites from soy polyol and bacterial cellulose. J Mater Sci 48:2167–2175

Suttiwijitpukdee N, Sato H, Zhang J, Hashimoto T, Ozaki Y (2011) Intermolecular interactions and crystallization behaviors of biodegradable polymer blends between poly (3-hydroxybutyrate) and cellulose acetate butyrate studied by DSC, FT-IR, and WAXD. Polymer 52:461–471

Tian C, Fu S, Chen J, Meng Q, Lucia LA (2014a) Graft polymerization of epsilon-caprolactone to cellulose nanocrystals and optimization of grafting conditions utilizing a response surface methodology. Nord Pulp Pap Res J 29:58–68

Tian C, Fu S, Habibi Y, Lucia LA (2014b) Polymerization topochemistry of cellulose nanocrystals: a function of surface dehydration control. Langmuir 30:14670–1467928

Yang JH, Chun BC, Chung Y, Cho JH (2003) Comparison of thermal/mechanical properties and shape memory effect of polyurethane block-copolymers with planar or bent shape of hard segment. Polymer 44:3251–3258

Yohe ST, Colson YL, Grinstaff MW (2012) Superhydrophobic materials for tunable drug release: using displacement of air to control delivery rates. J Am Chem Soc 134:2016–2019

Yu ZJ, Liu LJ (2004) Effect of microwave energy on chain propagation of poly (ε-caprolactone) in benzoic acid-initiated ring opening polymerization of ε-caprolactone. Eur Polym J 40:2213–2220

Yu ZJ, Liu LJ, Zhuo RX (2003) Microwave-improved polymerization of ε-caprolactone initiated by carboxylic acids. J Polym Sci Part A Polym Chem 41:13–21

Zhang Q, Wang B, Hong K, Zhu Q (1994) Ring-opening polymerization of ε-caprolactone in the presence of dicarboxylic acids. Macromol Chem Phys 195:2401–2407

Zhou YM, Fu SY, Zheng LM, Zhan HY (2012) Effect of nanocellulose isolation techniques on the formation of reinforced poly (vinyl alcohol) nanocomposite films. Express Polym Lett 6:794–804

Acknowledgments

The financial support of the Natural Science Foundation of Guangdong Province, China (2014A030311030), the Guangdong-Hongkong joint innovation program, (2014B050505019), and the Scientific Research Foundation of Guangdong Educational Commission, China (No. 2013KJCX0016) are cheerfully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tian, C., Fu, S.Y., Meng, Q.J. et al. New insights into the material chemistry of polycaprolactone-grafted cellulose nanofibrils/polyurethane nanocomposites. Cellulose 23, 2457–2473 (2016). https://doi.org/10.1007/s10570-016-0980-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0980-4