Abstract

Results of enzymatic hydrolysis of pine kraft cellulosic pulps (Kappa numbers ranging from 17.2 to 86.2) and waste fines from paper production line suggest that they are potential feedstocks for biofuel production. Glucose (61–68 % d.w.) and reducing sugars (around 90 % d.w.) yields from the pine cellulosic pulps with Kappa numbers ranging between 17.2 and 47.7 were higher than from the two pulps with Kappa numbers of 60.9 and 86.2. Glucose and reducing sugars yields from the latter pulps were around 54 and 45 % d.w. and 78 and 67 % d.w., respectively. The highest yields of glucose and total reducing sugars on a pine wood dry weight basis (29.3 and 43.1 %, respectively) were derived from the pulp with the Kappa number of 47.7. Thus the complete lignin removal from pine wood was not necessary to obtain maximum yields of glucose and other reducing sugars. Enzymatic hydrolysis of the fines from pine wood processing in a paper mill yielded around 75 % glucose and 78 % total reducing sugars on a dry weight basis that corresponded to around 34 and 36 % on a pine wood dry weight basis.

Similar content being viewed by others

Introduction

Eventual depletion of fossil fuels and their contributions to greenhouse gasses have focused attention on renewable vegetal biomass as a principal alternative energy resource (Alvira et al. 2010). Since conversion of starch and plant oils into first generation biofuels may compete with food production, these raw materials have been increasingly replaced with lignocellulosic biomass, including wastes from forestry, agriculture, wood processing and papermaking, like woodchips and fines from paper mills. Lignocellulosic materials are an excellent source of polysaccharides since they contain around 70 % holocellulose on a dry weight basis. Production of biofuels via environmentally friendly technologies requires employing enzymes for polysaccharide saccharification. However, enzymatic degradation of cellulose and hemicelluloses contained in lignocellulosic biomass to simple sugars is not as easy as starch hydrolysis because of the complex, tightly bound and cross-linked, three dimensional structure of plant tissues and protective impact of lignin, resinous substances and waxes. The highly cross-linked lignin coating, surrounding fibers of cellulose and hemicelluloses is considered one of main causes of plant biomass recalcitrance since it restricts access of enzymes catalyzing depolymerization of polysaccharides (Alvira et al. 2010). Furthermore, the unproductive adsorption of cellulases and hemicellulases on lignin reduces the rate and degree of saccharification. Therefore, lignocellulosic biomass must be pretreated before enzymatic digestion to remove lignin and increase the accessible surface area of cellulose. Also crystallinity of the latter needs to be reduced since crystalline cellulose regions are much less susceptible to enzymatic degradation than the amorphous ones.

Wood is an attractive lignocellulosic feedstocks, despite the high mechanical durability and recalcitrance to enzymatic attack. It is estimated that global wood production reaches 3,410,357 thousand m3 (of debarked logs) [www.bdl.lasy.gov.pl]. Around a half of this biomass is used to produce heat and energy while the second half is used in papermaking, production of furniture and other goods, in construction etc. Pine wood is an abundant biomass, widely applied in various branches of industry, including papermaking. Like other sorts of softwood, it contains high amounts of lignin (around 28 % d.w.) and extractives (up to 5 % d.w.) that reduce the access of depolymerizing enzymes to cellulose (around 42 % d.w.) and hemicelluloses (around 27 % d.w.). The hemicelluloses from pine wood contain residues of xylose, arabinose, mannose, galactose, and uronic acids as well as acyl groups (Girio et al. 2010). Because of the high contents of cellulose and hemicelluloses, common availability and relatively low costs of cultivation and processing, pine wood is a promising feedstock for biotechnology despite strong resistance towards enzymatic depolymerization (Agarwal et al. 2013).

In papermaking, wood processing begins with comminution to chips, which undergo chemical delignification by the sulfate method, yielding cellulosic pulps of various residual lignin contents. Sulfate method of wood processing is a fully mature technology. Nowadays, more than 150 million metric tons of cellulosic pulps are produced in this way. The sulfate method fulfills most of 12 principles of green chemistry and enables full recovery of chemicals used in the process. Cellulosic pulps obtained from low quality wood, e.g., partly degraded by microorganisms, may have insufficient characteristics to be used for production of paper because of shortened cellulose fibers. However, these pulps are excellent sources of virtually pure cellulose for biotechnology since they are almost deprived of lignin and extractives, inhibiting not only enzymatic hydrolysis but also fermentation processes. Another attractive raw material for biotechnology is the waste from papermaking, consisting of small particles (mainly shortened cellulose fibers), named fines. This fraction contains almost completely delignified cellulose and is characterized by a high specific surface area, facilitating an access of cellulases to cellulose chains.

The objective of this study was to evaluate the potential of pine kraft pulps with Kappa numbers ranging between 17.2 and 86.2 as well as fines from pine wood processing in a paper mill as feedstocks for biofuels production. These materials were subjected to enzymatic hydrolysis, mediated by a multienzyme commercial preparation, containing cellulases and hemicellulases. To assess the effect of wood delignification by the sulfate method on the efficiency of enzymatic hydrolysis, pine woodchips (0.43–0.8 mm) that were obtained from the same wood, which was used to produce the pulps, were hydrolyzed under the same conditions as the latter.

Materials and methods

Woodchips

Pine woodchips (particle size of 0.43–0.8 mm) were prepared by drilling of larger pieces of pine wood using an electric 6388AA Skil driller (Lowe’s Co., USA) equipped with a Metabo drill (Poland) no 10 (10.0 mm in diameter). Then the chips were sieved through a series of sieves to separate the 0.43–0.8 mm fraction. This fraction was subjected to enzymatic saccharification.

Kraft wood pulps

Pine cellulosic pulps (Kappa numbers of 17.2–86.2) were prepared by the sulfate method as described in Modrzejewski et al. (1969) from woodchips (25 mm × 15 mm × 8 mm), containing 7–8 % humidity. The chips were obtained from wood after the inner and outer barks and knots had been mechanically removed. The disintegrated materials were kept in hermetically closed vials to avoid any changes in the humidity before the treatment with NaOH and Na2S solutions [at chips:solvent ratio of 1:4 (w/v)], which were prepared freshly before the usage. Delignification processes were conducted in 15 l stainless steel reactor with regulation of temperature. Suspensions of woodchips were heated for 120 min to achieve the temperature of 172 °C and incubated at this temperature for the next 120 min. Then the temperature was decreased to the ambient one (22 ± 1 °C) using cold tap water and the insoluble residue was separated by filtration on Buchner funnel, washed several times with demineralized water and incubated overnight in demineralized water to remove residues of the alkali-soluble fractions. The solids were disintegrated for 4 min (12 000 revolutions) in a laboratory propeller pulp disintegrator (type R1 from Labor-Meks, Poland), and the fibers were screened using membrane screener (gap 0.2 mm). Fibers were collected and left for 48 h so as to dry in ambient conditions (22 ± 1 °C) and then weighed. Triplicate samples of these fibers were analyzed for the humidity and contents of cellulose, hemicelluloses and residual lignin (Kappa number) using standard methods as described in Modrzejewski et al. (1969). The yields of production of six pine cellulosic pulps with Kappa numbers ranging between 17.2 and 86.2 varied from 39.1 to 54 % on a wood dry weight basis, respectively (Table 1).

Industrial fines fraction

Residual fines fraction, which was subjected to enzymatic hydrolysis, was obtained from technological line in one of Polish paper mills. White water (30 l), containing fines, was sampled from a wire tank. Due to the low concentration of fines, this sample was placed in a vessel and left for 30 min so as to sediment the solids. Than the upper water layer was discarded and the decanted fraction was filtered. The concentration of filtered fines fraction was 8–10 %. The size of particles was measured using Kajaani FS-200 device and in all samples its maximal value was below 0.2 mm.

Enzyme preparation

A commercial, industrial grade enzyme preparation NS-22086, containing activities of cellulases and xylanases was kindly supplied by Novozymes A/S (Denmark). Activities of these enzymes were assayed by the 3,5-dinitrosalicylic acid (DNS) method (Miller 1959) at pH 5.0 and 50 °C for 0.5 % carboxymethylcellulose and 0.5 % birch xylan, respectively (reaction time of 5 min). Activities of both the glycosidases were expressed as micromoles of reducing sugars released from the polysaccharide substrates in 1 min (U). The filter paper activity was determined at pH 5.0 and 50 °C according to Adney and Baker (2008) and expressed as FPU/ml. Total reducing sugars and glucose concentrations in NS-22086 were assayed as described below.

Enzymatic hydrolysis

Substrates (around 0.3 g d.w. each) were suspended in 0.1 M sodium-acetate buffer solution (pH 5.0, 20 ml) and incubated for 15 min in a water bath at 50 °C. Then 1 ml aliquot of the NS-22086 (diluted sixfold in the same buffer) was added (with vigorous mixing) to each of these suspensions to initiate enzymatic digestion, which was conducted at 50 °C. The hydrolysates were sampled just after addition of the enzyme (to determine initial concentrations of glucose and total reducing sugars) and after 1, 3, 6, 24, 48 and 72 h of the process (to estimate the progress of enzymatic hydrolysis). Hydrolysis of pulps and fines was terminated after 48 h while the chips required 72 h digestion. All samples of enzymatic hydrolysates were filtered through a medium-fast filter paper and the filtrates were subjected to analyses. Enzymatic hydrolysis of the pine pulp with Kappa number of 17.2 was also conducted at its concentration around 7.4 % w/w, which was the highest initial concentration of this pulp at which mixing of the dense slurry was possible. Enzymatic hydrolysis was carried out at enzyme:substrate ratio of around 8.06 U:1 g dry weight for cellulases and 19.25 U:1 g dry weight for xylanases (around 1 ml of the NS-22086 preparation per 10 g d.w. pulp). The dense suspension of the pulp in demineralized water was thoroughly mixed with the enzyme preparation just after its addition and the process was conducted for 48 h at 50 °C with intermittent mixing.

Results of enzymatic attack on wood pulp fibers were monitored using a MPI3/SK12 PZO (Poland) optical microscope (at 200× magnification). Changes in the appearance of the surface of pine woodchips during their enzymatic digestion were observed using an electron scanning microscope S-4700 Hitachi SEM/EDS (at 200× magnification).

Analytical methods

Reducing sugars concentration was determined according to Miller (1959) using the alkaline DNS solution. Mono- and disaccharide profiles of the hydrolysates were determined by HPLC using an Ultimata 3000 Dionex liquid chromatograph equipped with a Rezex RPM-Monosaccharide Pb2+ column (8 μm, 7.8 × 300 mm) and a Shodex-RI-10 refractive index detector. The temperature of the column and RI detector was 80 and 40 °C, respectively. Samples of hydrolysates were filtered through a nylon syringe filter (0.45 μm) before HPLC analysis. The volume of injected samples was 10 μl. HPLC grade water (Sigma) was used as the mobile phase at a flow rate of 0.6 ml/min. Results of sugar resolution were recorded over 35 min. To verify results of HPLC analysis, glucose concentration was also determined according to Barham and Trinder (1972), using a commercial diagnostic kit employing glucose oxidase and peroxidase (Biomaxima, Poland). The assay was conducted according to the instruction from the manufacturer of the kit.

Both hydrolysis processes and analyses of the hydrolysates were carried out in at least triplicate. Their results are presented as mean ± standard deviation (SD).

Yield calculations

Glucose and total reducing sugars yields from the pulps, woodchips and fines dry weight were calculated according to the equations:

The correction factors of 0.9, 0.88 and 0.95, corresponding to hexoses, pentoses and cellobiose (Van Dyk and Pletschke 2012), were used in the calculations to compensate for the addition of a water molecule during hydrolysis of each glycosidic bond.

To determine the impact of lignin content on the degree of cellulose saccharification, glucose yields from cellulose contained in the pulps and woodchips were calculated according to Kumar and Wyman (2009):

Results and discussions

Enzyme preparation

The preparation NS-22086, which was used in this study for hydrolysis of pine cellulosic pulps with Kappa numbers ranging from 17.2 to 86.2, pine woodchips (0.43–0.8 mm) and fines from paper mill, was selected as described by Buzała et al. (2015). It displayed the activities of cellulases and xylanases (Table 2). Our previous study showed that NS-22086 preparation rapidly degraded cellulosic fibers contained in pine pulp, which was confirmed by microscopic observations. Like many other enzyme preparations NS-22086 contains reducing sugars, including free glucose. Their concentrations (68.6 and 42.0 mg/ml, respectively) were taken into consideration when the yields of enzymatic saccharification of the substrates were calculated. To reduce amounts of sugars added into reaction mixtures with this enzyme preparation, it was diluted sixfold before mixing with substrates. The hydrolysis was conducted at enzyme:substrate ratio of 13.43 U:0.3 g dry weight (18.69 FPU:0.3 g d.w.) for cellulases, and 32.08 U:0.3 g d.w. for xylanases.

Chemical composition of cellulosic pulps

The main component of the kraft cellulosic pulps was cellulose (Table 3). Its content increased with a decrease in the Kappa number and ranged from almost 72 % d.w. for the highest lignin content (Kappa number of 86.2, 12.93 % d.w. lignin) to above 94 % d.w. for the pulp almost devoid of lignin (Kappa number of 17.2, 2.58 % d.w. lignin). The contents of hemicelluloses were positively correlated with the lignin levels and negatively correlated with the cellulose contents. They varied from 2.54 to 9.11 % d.w.

Enzymatic hydrolysis of pine woodchips

To assess the effect of lignin removal from pine wood by the sulfate method on saccharification efficiency, pine woodchips that were obtained from the same wood, which was used to produce the six cellulosic pulps of different residual lignin content, were digested under the same conditions as the pulps. The presence of lignin in the woodchips caused that the degree of cellulose and hemicelluloses hydrolysis was relatively low, which was reflected by small yields of glucose and total reducing sugars, of only 3.4 and 20.0 % on a wood dry weight basis, respectively (Table 4). The increase in glucose content in the hydrolysates of woodchips was observed for the first 30 h of enzymatic digestion (Fig. 1a, b). Glucose concentration was constant after 30 h.

HPLC analysis of enzymatic hydrolysates obtained by 72 h digestion of the pine woodchips revealed that glucose accounted for around 27 % of the sum of 5 detected sugars while the level of its reducing dimer—cellobiose was more than twice higher (64 % w/w) (Table 5). This might be a consequence of a relatively high activity of cellobiohydrolase in the preparation NS-22086 and inhibition of β-glucosidase despite very low glucose concentration (around 0.8 mg/ml). Apart from these two sugars, also mannose (8.8 % w/w) and xylose (0.4 % w/w) were contained in the hydrolysates.

Changes in the appearance of the surface of pine chips, caused by the attack of enzymes on accessible polysaccharide fibers, were visible under the electron scanning microscope (Fig. 2). The size of pores in their surface increased with time.

Enzymatic hydrolysis of pine pulps

Pine pulps rank among most popular softwood pulps in papermaking. To determine the effect of residual lignin on their digestibility and glucose yields, six pine pulps with Kappa numbers ranging from 17.2 to 86.2 were digested by the preparation NS-22086. Concentrations of glucose and total reducing sugars in the hydrolysates as well as their yields were monitored over 48 h (Table 4). These yields depended on the Kappa numbers of the six pulps. The largest amounts of glucose (61–68 % d.w.) and reducing sugars (around 90 % d.w.) were derived from the cellulosic pulps with Kappa numbers ranging between 17.2 and 47.7 (Table 4). The maximum yields of glucose and total reducing sugars on the pine wood dry weight basis (29.3 and 43.1 %, respectively) were obtained from the pulp with the Kappa number of 47.7. Also the glucose yield from cellulose (98.9 % d.w.) was the highest for this pulp (Table 6). Interestingly, glucose yields from cellulose contained in the pulps increased from 88.9 to 98.9 % d.w. with an increase in Kappa number from 17.2 to 47.7 and then decreased to 87.6 % d.w. with a rise in Kappa number to 86.2. For comparison, glucose yield from cellulose contained in the woodchips was only 41.8 % d.w. These results demonstrate that the complete lignin removal from wood is not necessary to maximize glucose yields from cellulose (the pulp with Kappa number of 47.7 contained around 7 % w/w lignin, only fourfold less than the original wood).

Sugars released by the preparation NS-22086 from polysaccharides into the liquid fraction were identified and quantified by HPLC (Table 5). HPLC analyses revealed that apart from glucose (71–77 % w/w) the hydrolysates of pulps contained some cellobiose (16–21 % w/w) and mannose (around 7 % w/w). The presence of the latter hexose provides evidence of the occurrence of some hemicellulose residues in the pulps. Interestingly, mannose was not detected in the hydrolysates of pine woodchips and fines, which contained xylose and arabinose.

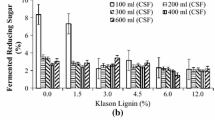

The curves presenting the course of enzymatic hydrolysis of the pulps with Kappa numbers ranging from 17.2 to 86.2 and pine woodchips are shown in Fig. 1a. The hydrolysis of the six pine pulps was much more dynamic than the hydrolysis of woodchips. The yields of glucose released within the first 6 h ranged between 18 and 44 % on a dry weight basis. All these pulps were completely converted into soluble sugars within 24 h. The further small increase in glucose and total reducing sugars levels (about 3 %) until 48 h is thought to be caused by hydrolysis of soluble oligosaccharides and cellobiose.

High yields of glucose and total reducing sugars released by the preparation NS-22086 from the pine pulp of Kappa number of 34.5 (Table 4) were correlated with visible changes in the appearance of fibers contained in this pulp. Microscopic images shown in Fig. 3, which present successive steps of gradual deconstruction of cellulosic fibers, provide evidence that the attack of cellulolytic and hemicellulolytic enzymes caused their complete degradation within 48 h.

As it was mentioned above, pine wood is characterized by the high recalcitrance to enzymatic attack. Mou et al. (2013) pretreated milled birch and pine wood by ionic liquid, hydrothermal and hydrotropic methods before enzymatic hydrolysis using a mixture of commercial cellulolytic enzymes (Celluclast 1.5 and Novozym 188). The most efficient pretreatment in terms of lignin removal was its extraction with a hydrotrope (30 % sodium xylenesulphonate, 120 min, 150 °C), giving rise to glucose yields from pine and birch woods of 15.5 and 84 % d.w., respectively. Zhu et al. (2009) who pretreated pine wood by the sulfite method (SPORL) before mechanical size reduction using disc refining and enzymatic treatment for 48 h, obtained glucose yields of 37 % on a wood dry weight basis. These hydrolysates obtained this way contained low amounts of fermentation inhibitors such as furfural and 5-hydroxymethylfurfural. Agarwal et al. (2013) applied acid chlorite treatment (using a mixture of glacial acetic acid and sodium chlorite at 70 °C) to remove lignin from pine wood and obtained cellulosic pulps with Klason lignin concentrations of 5.5–22.6 %. Sugar yields derived by 72 h enzymatic hydrolysis of these pulps (using Celluclast 1.5 and Novozyme 188) ranged between 9.5 and 93.3 % d.w., respectively. It was found that lignin removal by the applied pretreatment method caused also the loss of a part of hemicelluloses.

Enzymatic hydrolysis of the pine pulp at 7.4 % (w/w) concentration

Enzymatic hydrolysis of the pine pulp (Kappa number of 17.2) was also conducted at its higher concentration (around 7.4 % w/w) that enabled to increase glucose concentration in the hydrolysate from around 11 to 81 mg/ml (Table 7). Enzymatic hydrolysis was carried out for 48 h at 50 °C with intermittent mixing at enzyme:substrate ratio of around 8.06 U:1 g dry weight for cellulases and 19.25 U:1 g dry weight for xylanases (around 1 ml of the NS-22086 preparation per 10 g d.w. pulp). The yield of glucose from the first step was almost 41 % d.w. of the pulp (around 16 % d.w. of pine wood). The insoluble residue was washed twice with demineralized water to remove soluble sugars adsorbed to the insoluble fraction. Noteworthy, the amount of glucose eluted from the insoluble residue reached around 16 % d.w. of the pulp. It was comparable with the yield of glucose from the second step of hydrolysis (conducted in the same conditions as the first one with an exception of around 6.6 % w/w substrate concentration) which was around 17.6 % d.w. of the pulp. The total glucose yield was around 75 % d.w. (from the two steps and washing) while the insoluble fraction accounted for around 14 % of the pine pulp dry weight.

Thus around 5.7 kg glucose may be produced from 10 kg pulp d.w. by only one-step enzymatic hydrolysis, conducted at around 7.4 % w/w initial concentration of this pine pulp, using 1 l NS-22086 preparation, and followed by washing of the insoluble residue to release the absorbed soluble sugars. Theoretically, alcohol fermentation may yield around 2.9 kg ethanol from 5.7 kg glucose. Because around 3.9 kg of this pulp is derived from 10 kg d.w. of pine woodchips so as much as 1.1 kg ethanol may be obtained from 10 kg wood d.w. Another product will be energy derived from incineration of the lignin-rich fraction from the kraft pulping. Also the insoluble residue from enzymatic digestion may be used to produce energy.

Another solution, enabling to reduce the overall process costs, consists of recycling the enzymes depolymerizing cellulose and hemicelluloses. These proteins may be separated from much smaller molecules of mono- and disaccharides, which are hydrolysis products, using membranes or liquid chromatography techniques and applied again for cellulosic pulp saccharification. The assays of residual activities of cellulases and xylanases from the preparation NS-22086 at the end of cellulosic pulps hydrolysis, which were performed in this study, showed that these enzymes retained around 80 % of the initial activities. The high residual activity of these hydrolases suggests that their recycling is feasible.

Enzymatic hydrolysis of the waste fines fraction

The fines derived from pine wood in one of Polish paper—mills represent an abundant and under-utilized waste material. Their hydrolysis by the NS-22086 preparation was very dynamic (Fig. 1b) that resulted in almost complete hydrolysis to soluble saccharides within the first 6 h. Glucose and total reducing sugars yields after 24 h hydrolysis were around 75 and 78 % d.w. (Table 4). Glucose accounted for around 84 % w/w of the sum of four detectable sugars while cellobiose content was relatively low (around 9 % w/w) (Table 5). The presence of arabinose (around 4 % w/w) and xylose (around 3 % w/w) in the hydrolysate meant that the fines contained residual hemicelluloses apart from cellulose. Because of the sugar profile, these hydrolysates may be used as feedstocks for fermentation processes.

Conclusions

Pine cellulosic pulps, characterized by the Kappa numbers ranging between 17.2 and 86.2, and the waste fines from papermaking were found to be attractive substrates for enzyme-mediated production of high-glucose hydrolysates (glucose content above 70 % w/w soluble sugars) using an appropriate multienzyme preparation, containing cellulases and hemicellulases, like the NS-22086 preparation from Novozymes. Enzymatic digestion of the pulps caused almost complete degradation of cellulosic fibers that was visible under optical microscope. The yields of production of these six pulps from pine wood increased with the Kappa number and ranged from around 39 to 54 % d.w. Determination of cellulose, hemicelluloses and lignin contents in the tested pulps showed that apart from lignin also a part of hemicelluloses was removed by kraft pulping. The contents of hemicelluloses in the pulps increased from around 2.54 to 9.11 % d.w. with the rise in Kappa number from 17.2 to 86.2. The outcomes of enzymatic hydrolysis depended on the residual lignin contents in the tested pulps that may be ascribed to either restricted access of cellulases and hemicellulases to the polysaccharides, protected by lignin, or binding the enzymes by the latter polymer. The higher amounts of glucose (61–68 % d.w.) and reducing sugars (around 90 % d.w.) were derived from the cellulosic pulps with Kappa numbers ranging between 17.2 and 47.7 compared to the two pulps containing the highest levels of residual lignin (Kappa numbers of 60.9 and 86.2, the glucose and reducing sugars yields below 55 and 79 % d.w. pulp, respectively). The maximum yields of glucose and other reducing sugars on the pine wood dry weight basis (29.3 and 43.1 %, respectively) were obtained from the pulp with the Kappa number of 47.7. Interestingly, also the glucose yield from cellulose (98.9 % d.w.) was the highest in case of this pulp. These results demonstrate that the complete lignin removal from wood is not necessary to obtain maximum glucose yields from cellulose. Reassuming, kraft pulping proved to be an attractive alternative to lignocellulosic biomass pretreatment since cellulosic pulps obtained by this method are susceptible to enzymatic saccharification and around twice more soluble sugars (on a wood dry weigh basis) may be obtained from the pulps than from pine woodchips under the same hydrolysis conditions. Enzymatic saccharification of low quality pulps, which cannot be used for paper production, and recycling of enzymes depolymerizing cellulose and hemicelluloses may reduce costs of conversion of wood biomass to simple sugars. Also enzymatic hydrolysis of the residual fines from pine wood processing, which were virtually deprived of lignin, was highly efficient and yielded around 75 % d.w. glucose and 78 % d.w. total reducing sugars (around 34 and 36 % on a pine wood dry weight basis, respectively). Biofuel production from hydrolysates of this waste may be an attractive route of its valorization.

References

Adney B, Baker J (2008) Measurements of cellulose activities. NREL/TP-510-42628

Agarwal UP, Zhu JY, Ralph SA (2013) Enzymatic hydrolysis of loblolly pine: effects of cellulose crystallinity and delignification. Holzforschung 67(4):371–377

Alvira P, Tomas-Pejo E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861

Barham D, Trinder P (1972) An improved color reagent for the determination of blood glucose by the oxidase system. Analyst 97:142–145

Buzała K, Przybysz P, Rosicka-Kaczmarek J, Kalinowska H (2015) Production of glucose-rich enzymatic hydrolysates from cellulosic pulps. Cellulose 22:663–674

Girio FM, Fonseca C, Carvalheiro F, Duarte LC, Marques S, Bogel-Łukasik R (2010) Hemicelluloses for fuel ethanol: a review. Bioresour Technol 101:4775–4800. http://www.bdl.lasy.gov.pl/portal/lasy-na-swiecie-cd

Kumar R, Wyman CE (2009) Effects of cellulase and xylanase enzymes on the deconstruction of solids from pretreatment of poplar by leading technologies. Biotechnol Prog 25:302–314

Miller GL (1959) Use of dinitrosalicylic reagent for determination of reducing sugar. Anal Chem 31:426–428

Modrzejewski K, Olszewski J, Rutkowski J (1969) In: Analyses in papermaking industry. Editorial Office of the Lodz University of Technology, Lodz, pp 60–89, 206–250

Mou H-Y, Orblin E, Kruus K, Fardim P (2013) Topochemical pretreatment of wood biomass to enhance enzymatic hydrolysis of polysaccharides to sugars. Bioresour Technol 142:540–545

Van Dyk JS, Pletschke BJ (2012) A review of lignocellulose bioconversion using enzymatic hydrolysis and synergistic cooperation between enzymes—factors affecting enzymes, conversion and synergy. Biotechnol Adv 30:1458–1480

Zhu JY, Pan XJ, Wang GS, Gleisner R (2009) Sulfite pretreatment (SPORL) for robust enzymatic saccharification of spruce and red pine. Bioresour Technol 100:2411–2418

Acknowledgments

This work was financially supported by the National Center of Research and Development in Poland (Project Number LIDER/042/407/l-4/12/NCBR/2013 and PBS1/A8/16/2013). The authors are also grateful to Mrs. Katarzyna Kowal for her support in the elaboration of experimental data.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Przybysz Buzała, K., Przybysz, P., Kalinowska, H. et al. Evaluation of pine kraft cellulosic pulps and fines from papermaking as potential feedstocks for biofuel production. Cellulose 23, 649–659 (2016). https://doi.org/10.1007/s10570-015-0808-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0808-7