Abstract

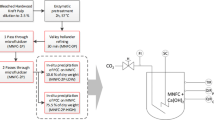

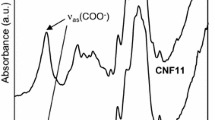

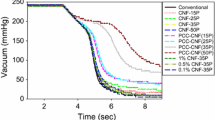

Nanofibrillated cellulose (NFC) has potential for use as a strength-enhancing additive in paper and paperboard applications. In this work, the effect of NFC on the mechanical and air resistance properties of semichemical fluting handsheets with and without talc filler was studied. Nanofibrillated dicarboxyl acid cellulose (DCC NFC) was prepared using sequential periodate–chlorite oxidation followed by nanofibrillation using either microfluidization or high-pressure homogenization. The high-pressure homogenization led to uniformly sized nanofibrils whereas the microfluidized DCC NFC contained larger fibril bundles in addition to fine nanofibrils. Both DCC NFCs had a positive effect on the tensile strength (19–21 % improvement), flat crushing resistance (24–26 % improvement) and edgewise compression strength (22–32 % improvement) of the handsheets with 2 wt% dosage. Increased air resistance is frequently observed when NFC is used as a paper additive, but in this study the microfluidized DCC NFC decreased the air permeability properties of the handsheets only slightly while the homogenized DCC had a larger adverse influence. Use of talc filler as an additive in the fluting medium decreased its mechanical properties, but the addition of the DCC NFC compensated for the strength loss caused by the filler.

Similar content being viewed by others

References

Afra E, Yousefi H, Hadilam MM, Nishino T (2013) Comparative effect of mechanical beating and nanofibrillation of cellulose on paper properties made from bagasse and softwood pulps. Carbohydr Polym 97:725–730. doi:10.1016/j.carbpol.2013.05.032

Ämmälä A, Liimatainen H, Burmeister C, Niinimäki J (2013) Effect of tempo and periodate–chlorite oxidized nanofibrils on ground calcium carbonate flocculation and retention in sheet forming and on the physical properties of sheets. Cellulose 20:2451–2460. doi:10.1007/s10570-013-0012-6

Besbes I, Vilar MR, Boufi S (2011) Nanofibrillated cellulose from alfa, eucalyptus and pine fibres: preparation, characteristics and reinforcing potential. Carbohydr Polym 86:1198–1206. doi:10.1016/j.carbpol.2011.06.015

Delgado-Aguilar M, González I, Pèlach MA et al (2014) Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 22:789–802. doi:10.1007/s10570-014-0473-2

Djafari Petroudy SR, Syverud K, Chinga-Carrasco G et al (2014) Effects of bagasse microfibrillated cellulose and cationic polyacrylamide on key properties of bagasse paper. Carbohydr Polym 99:311–318. doi:10.1016/j.carbpol.2013.07.073

Eriksen O, Syverud K, Gregersen O (2008) The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nord Pulp Pap Res J 23:299

González I, Vilaseca F, Alcalá M et al (2013) Effect of the combination of biobeating and NFC on the physico-mechanical properties of paper. Cellulose 20:1425–1435. doi:10.1007/s10570-013-9927-1

González I, Alcalà M, Chinga-Carrasco G et al (2014) From paper to nanopaper: evolution of mechanical and physical properties. Cellulose 21:2599–2609. doi:10.1007/s10570-014-0341-0

Guimond R, Chabot B, Law K-N, Daneault C (2010) The use of cellulose nanofibres in papermaking. J Pulp Pap Sci 36:55–61

Hassan EA, Hassan ML, Oksman K (2011) Improving bagasse pulp paper sheet properties with microfibrillated cellulose isolated from xylanase-treated bagasse. Wood Fiber Sci 43:76–82

Hellström P, Heijnesson-Hultén A, Paulsson M et al (2014) Fenton pre-treated microfibrillated cellulose evaluated as a strength enhancer in the middle ply of paperboard. Nord Pulp Pap Res J 29:732–740

Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43:3434–3441. doi:10.1016/j.eurpolymj.2007.05.038

Hii C, Gregersen ØW, Chinga-Carrasco G, Eriksen Ø (2012) The effect of MFC on the pressability and paper properties of TMP and GCC based sheets. Nord Pulp Pap Res J 27:388–396. doi:10.3183/NPPRJ-2012-27-02-p388-396

Hult E-L, Iotti M, Lenes M (2010) Efficient approach to high barrier packaging using microfibrillar cellulose and shellac. Cellulose 17:575–586. doi:10.1007/s10570-010-9408-8

Iwamoto S, Nakagaito A, Yano H, Nogi M (2005) Optically transparent composites reinforced with plant fiber-based nanofibers. Appl Phys Mater Sci Process 81:1109–1112

Jonoobi M, Mathew AP, Oksman K (2012) Producing low-cost cellulose nanofiber from sludge as new source of raw materials. Ind Crops Prod 40:232–238. doi:10.1016/j.indcrop.2012.03.018

Kajanto I, Kosonen M (2012) The potential Use of micro- and nano fibrillated Cellulose as a reinforcing Element in Paper and Board based Packaging. TAPPI International Conference on Nanotechnology for Renewable Materials 2012:393–408

Katz S, Beatson RP (1984) The determination of strong and weak acidic groups in sulfite pulps. Sven Papperstidning 87:48–53

Lavoine N, Bras J, Desloges I (2014) Mechanical and barrier properties of cardboard and 3D packaging coated with microfibrillated cellulose. J Appl Polym Sci. doi:10.1002/app.40106

Lavoine N, Desloges I, Manship B, Bras J (2015) Antibacterial paperboard packaging using microfibrillated cellulose. J Food Sci Technol. doi:10.1007/s13197-014-1675-1

Liimatainen H, Visanko M, Sirviö JA et al (2012) Enhancement of the nanofibrillation of wood cellulose through sequential periodate–chlorite oxidation. Biomacromolecules 13:1592–1597. doi:10.1021/bm300319m

Missoum K, Martoïa F, Belgacem MN, Bras J (2013) Effect of chemically modified nanofibrillated cellulose addition on the properties of fiber-based materials. Ind Crops Prod 48:98–105. doi:10.1016/j.indcrop.2013.04.013

Moon RJ, Martini A, Nairn J et al (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994. doi:10.1039/C0CS00108B

Nakagaito AN, Yano H (2004) The effect of morphological changes from pulp fiber towards nano-scale fibrillated cellulose on the mechanical properties of high-strength plant fiber based composites. Appl Phys Mater Sci Process 78:547–552. doi:10.1007/s00339-003-2453-5

Oksman K, Mathew AP, Sain M (2009) Novel bionanocomposites: processing, properties and potential applications. Plast, Rubber Compos 38:396–404

Pääkkö M, Ankerfors M, Kosonen H et al (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941. doi:10.1021/bm061215p

Rattaz A, Mishra SP, Chabot B, Daneault C (2011) Cellulose nanofibres by sonocatalysed-TEMPO-oxidation. Cellulose 18:585–593. doi:10.1007/s10570-011-9529-8

Rebouillat S (2013) State of the art manufacturing and engineering of nanocellulose: a review of available data and industrial applications. J Biomater Nanobiotechnol 04:165–188. doi:10.4236/jbnb.2013.42022

Saito T, Nishiyama Y, Putaux J-L et al (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687–1691. doi:10.1021/bm060154s

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491. doi:10.1021/bm0703970

Sehaqui (2013) Nanofibrillated cellulose for enhancement of strength in high-density paper structures. Nord Pulp Pap Res J 28:182–189. doi:10.3183/NPPRJ-2013-28-02-p182-189

Sehaqui H, Ezekiel Mushi N, Morimune S et al (2012) Cellulose nanofiber orientation in nanopaper and nanocomposites by cold drawing. ACS Appl Mater Interfaces 4:1043–1049. doi:10.1021/am2016766

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494. doi:10.1007/s10570-010-9405-y

Sood YV, Tyagi R, Tyagi S et al (2010) Surface charge of different paper making raw materials and its influence on paper properties. J Sci Ind Res 69:300–304

Svagan AJ, Azizi Samir MAS, Berglund LA (2007) Biomimetic polysaccharide nanocomposites of high cellulose content and high toughness. Biomacromolecules 8:2556–2563. doi:10.1021/bm0703160

Taipale T, Österberg M, Nykänen A et al (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020. doi:10.1007/s10570-010-9431-9

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natural fibres. Polym Int 47:291–294. doi:10.1002/(SICI)1097-0126(199811)47:3<291:AID-PI11>3.0.CO;2-1

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci: Appl Polym Symp 37:815–823

Zimmermann T, Pöhler E, Geiger T (2004) Cellulose Fibrils for Polymer Reinforcement. Adv Eng Mater 6:754–761. doi:10.1002/adem.200400097

Acknowledgments

The authors would like to thank Mondo Minerals B.V., Finland for providing the talc sample used in the handsheet preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hietala, M., Ämmälä, A., Silvennoinen, J. et al. Fluting medium strengthened by periodate–chlorite oxidized nanofibrillated celluloses. Cellulose 23, 427–437 (2016). https://doi.org/10.1007/s10570-015-0801-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0801-1