Abstract

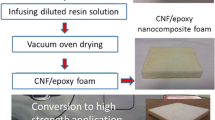

In this study, biodegradable foams were produced using cellulose nanofibrils (CNFs) and starch (S). The availability of high volumes of CNFs at lower costs is rapidly progressing with advances in pilot-scale and commercial facilities. The foams were produced using a freeze-drying process with CNF/S water suspensions ranging from 1 to 7.5 wt% solids content. Microscopic evaluation showed that the foams have a microcellular structure and that the foam walls are covered with CNF’s. The CNF’s had diameters ranging from 30 to 100 nm. Pore sizes within the foam walls ranged from 20 to 100 nm. The materials’ densities ranging from 0.012 to 0.082 g/cm3 with corresponding porosities between 93.46 and 99.10 %. Thermal conductivity ranged from 0.041 to 0.054 W/m-K. The mechanical performance of the foams produced from the starch control was extremely low and the material was very friable. The addition of CNF’s to starch was required to produce foams, which exhibited structural integrity. The mechanical properties of materials were positively correlated with solids content and CNF/S ratios. The mechanical and thermal properties for the foams produced in this study appear promising for applications such as insulation and packaging.

Similar content being viewed by others

References

Ali ZM, Gibson LJ (2013) The structure and mechanics of nanofibrillar cellulose foams. Soft Matter 9:1580–1588

Chen L, Gordon SH, Imam SH (2004) Starch graft poly(methyl acrylate) loose-fill foam: preparation, properties and degradation. Biomacromolecules 5:238–244

Dufresne A, Vignon MR (1998) Improvement of starch film performances using cellulose microfibrils. Macromolecules 31:2696–2963

Gibson LJ, Ashby MF (1997) Cellular Solids; Structure and Properties. Cambridge University Press, Cambridge, United Kingdom

Glenn GM, Irving DW (1995a) Starch-based microcellular foams. Carbohydrates 72(2):155–161

Glenn GM, Irving DW (1995b) Starch-based microcellular foams. Cereal Chem 72(2):155–161

Glenn GM, Klamcynski A, Holtman KM, Chiou B-S, Orts WJ, Wood D (2007) Cellulose fiber reinforced starch-based foam composites. J Biobased Mater Bioenerg 1:360–366

Glenn GM, Imam SH, Orts WJ (2011) Starch-based foam composite materials: processing and bioproducts. MRS Bull 36:696–702

Gypsum Assosiation (2010) Gypsum board typical mechanical and physical properties (GA-235-10) www.gypsum.org

Hong CQ, Han JC, Zhang XH, Du JC (2013) Novel nanoporous silica aerogel impregnated highly porous ceramics with low thermal conductivity and enhanced mechanical properties. Scripta Mater 68:599–602

Hsu CL, Heldman DR (2004) Prediction models for the thermal conductivity of aqueous. Int J Food Sci Technol 39:737–743

Mahlia TMI, Taufiq Ismail BN, Masjuki HH (2007) Correlation between thermal conductivity and the thickness of selected insulation materials for building wall. Energy Build 39:182–187

Martins IMG, Magina SP, Oliveira L, Freire CSR, Silvestre AJD, Neto CP, Gandini A (2009) New biocomposites based on thermoplastic starch and bacterial cellulose. Compos Sci Technol 69:2163–2168

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2010) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3944

Moran JI, Alvarez VA, Cyras VP, Vazquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15:149–159

Nabar Y, Raquez JM, Dubois P, Narayan R (2005) Production of starch foams by twin-screw extrusion: effect of maleated poly(butylene adipate-co-terephthalate) as a compatibilizer. Biomacromolecules 6:807–817

Ptersson L, Kvien I, Oksman K (2007) Structure and thermal properties of poly(lactic acid)/cellulose whiskers nanocomposite materials. Compos Sci Technol 67:2535–2544

Reuss A (1929) Calculation of the flow limits of mixed crystals on the basis of the plasticity of mono-crystals. Z Angew Math Mech 9:49–58

Sehaqui H, Zhou Q, Berglund LA (2011) High-porosity aerogels of high specific surface area prepared from nanofibrillated cellulose (NFC). Compos Sci Technol 71:1593–1599

Shey J, Imam SH, Glenn GM, Orts WJ (2006) Properties of baked starch foam with natural rubber latex. Ind Crops Prod 24:34–40

Siro I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Svagan AJ, Azizi Samir MAS, Berglund LA (2008) Biomimetic foams of high mecahanical performance based on nanostructured cell walls reinforced by native cellulose nanofibrils. Adv Mater 20:1263–1269

Svagan AJ, Berglund LA, Jensen P (2011) Cellulose Nanocomposite Biopolymer Foam-Hierarchical Structure Effects on Energy Adsorption. Appl Mater Interfaces 3:1411–1417

Tatarka PD, Cunningham RL (1996) Properties of protective loose-fill foams. J Appl Polym Sci 67:1157–1176

Wang X, Zhong J, Wang Y, Yu M (2006) A study of the properties of carbon foam reinforced by clay. Carbon 44:1560–1564

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Acknowledgments

The authors thank University of Maine Process Development Center for supplying cellulose nanofibrils in this study and thank Melanie Blumentritt’s contribution of conducting the SEM images. This work partly supported by the USDA/NIFA under the Wood Utilization Research Program (Project 2010-34158-21182).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yildirim, N., Shaler, S.M., Gardner, D.J. et al. Cellulose nanofibril (CNF) reinforced starch insulating foams. Cellulose 21, 4337–4347 (2014). https://doi.org/10.1007/s10570-014-0450-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0450-9