Abstract

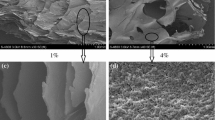

Ultralight and highly porous cellulose was fabricated via cellulose/sodium hydroxide/urea aqueous solution followed by gelation, coagulation and freeze-drying in the current work. The water content and freeze rate of cellulose coagulated sample are two crucial factors controlling the morphology, density and porosity of porous cellulose, which led to an interesting morphological transition from three dimensional nanofibrillar network to sheet network in porous cellulose. It was proposed that the aggregation and assembly of cellulose-rich phase and crystallization of water-rich phase were closely related to this transition. Based on this concept, a series of cellulose materials with densities varied from 0.129 to 0.330 g cm−3 and corresponding porosities ranged from 91.4 to 78.0 %, were obtained. The porous celluloses showed a good ductility (strain to fracture is more than 30 %) and high modulus, which also could be tuned by porous morphology. The new understanding on the morphological transition in porous cellulose could be beneficial for the development of “green” porous materials.

Similar content being viewed by others

References

Aaltonen O, Jauhiainen O (2009) The preparation of lignocellulosic aerogels from ionic liquid solutions. Carbohydr Polym 75:125–129

Cai J, Zhang L (2005) Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions. Macromol Biosci 5:539–548

Cai J, Liu Y, Zhang L (2006) Dilute solution properties of cellulose in LiOH/urea aqueous system. J Polym Sci Part B: Polym Phys 44:3093–3101

Cai J, Zhang L, Chang C, Cheng G, Chen X, Chu B (2007) Hydrogen-bond-induced inclusion complex in aqueous cellulose/LiOH/urea solution at low temperature. Chem Phys Chem 8:1572–1579

Cai J, Zhang L, Liu S, Liu Y, Xu X, Chen X, Chu B, Guo X, Xu J, Cheng H (2008) Dynamic self-assembly induced rapid dissolution of cellulose at low temperatures. Macromolecules 41:9345–9351

Chang CY, Zhang LN (2011) Cellulose-based hydrogels: present status and application prospects. Carbohydr Polym 84:40–53

Chang CY, Zhang LN, Zhou JP, Zhang LN, Kennedy JF (2010) Structure and properties of hydrogels prepared from cellulose in NaOH/urea aqueous solutions. Carbohydr Polym 82:122–127

Dash R, Li Y, Ragauskas AJ (2012) Cellulose nanowhisker foams by freeze casting. Carbohydr Polym 88:789–792

Deng M, Zhou Q, Du A, van Kasteren JV, Wang Y (2009) Preparation of nanoporous cellulose foams from cellulose-ionic liquid solutions. Mater Lett 63:1851–1854

Desbrieres J, Hirrien M, Ross-Murphy S (2000) Thermogelation of methylcellulose: rheological considerations. Polymer 41:2451–2461

Duchemin BJ, Staiger MP, Tucker N, Newman RH (2010) Aerocellulose based on all-cellulose composites. J Appl Polym Sci 115:216–221

Gavillon R, Budtova T (2008) Aero cellulose: new highly porous cellulose prepared from cellulose-NaOH aqueous solutions. Biomacromolecules 9:269–277

Gesser HD, Goswami PC (1989) Aerogels and related porous materials. Chem Rev 89:765–788

Han J, Zhou C, Wu Y, Liu F, Wu Q (2013) Self-assembling behavior of cellulose nanoparticles during freeze drying: effect of suspension concentration, particle size, crystal structure, and surface charge. Biomacromolecules 14:1529–1540

Heymann E (1935) Studies on sol-gel transformations. I. The inverse sol-gel transformation of methylcellulose in water. Trans Faraday Soc 31:846–864

Hoepfner S, Ratke L, Milow B (2008) Synthesis and characterisation of nano fibrillar cellulose aerogels. Cellulose 15:121–129

Huang SJ (1995) Polymer waste management–biodegradation, incineration, and recycling. J Macromol Sci Part A Pure Appl Chem 32:593–597

Hüsing N, Schubert U (1998) Aerogels-airy materials: chemistry, structure, and properties. Angew Chem Int Ed 37:22–45

Innerlohinger J, Weber HK, Kraft G (2006) Aerocellulose: aerogels and aerogel-like materials made from cellulose. Macromol Symp 244:126–135

Ishikawa A, Okano T, Sugiyama J (1997) Fine structure and tensile properties of ramie fibres in the crystalline form of cellulose I, II, III and IV. Polymer 38:463–468

Jin H, Nishiyama Y, Wada M, Kuga S (2004) Nanofibrillar cellulose aerogels. Colloids Surf A 240:63–67

Kistler SS (1931) Coherent expanded aerogels and jellies. Nature 127:741

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393

Kolpak FJ, Blackwell J (1976) Determination of the structure of cellulose II. Macromolecules 9:273–278

Lee J, Deng Y (2011) The morphology and mechanical properties of layer structured cellulose microfibril foams from ice-templating methods. Soft Matter 7:6034–6040

Liebner F, Potthast A, Rosenau T, Haimer E, Wendland M (2008) Cellulose aerogels: highly porous, ultra-lightweight materials. Holzforschung 62:129–135

Liebner F, Haimer E, Wendland M, Neouze MA, Schlufter K, Miethe P, Heinze T, Potthast A, Rosenau T (2010) Aerogels from unaltered bacterial cellulose: application of sc CO2 drying for the preparation of shaped, ultra-lightweight cellulosic aerogels. Macromol Biosci 10:349–352

Maeda H, Nakajima M, Hagiwara T, Sawaguchi T, Yano S (2006) Bacterial cellulose/silica hybrid fabricated by mimicking biocomposites. J Mater Sci 41:5646–5656

Müller FA, Müller L, Hofmann I, Greil P, Wenzel MM, Staudenmaier R (2006) Cellulose-based scaffold materials for cartilage tissue engineering. Biomaterials 27:3955–3963

O’Brien FJ, Harley BA, Yannas IV, Gibson LJ (2005) The effect of pore size on cell adhesion in collagen-GAG scaffolds. Biomaterials 26:433–441

Pääkkö M, Vapaavuori J, Silvennoinen R, Kosonen H, Ankerfors M, Lindström T, Berglund LA, Ikkala O (2008) Long and entangled native cellulose I nanofibers allow flexible aerogels and hierarchically porous templates for functionalities. Soft Matter 4:2492–2499

Pierre AC, Pajonk GM (2002) Chemistry of aerogels and their applications. Chem Rev-Columbus 102:4243–4266

Qi H, Chang C, Zhang L (2008) Effects of temperature and molecular weight on dissolution of cellulose in NaOH/urea aqueous solution. Cellulose 15:779–787

Raymond S, Kvick A, Chanzy H (1995) The structure of cellulose-II: a revisit. Macromolecules 28:8422–8425

Roy C, Budtova T, Navard P (2003) Rheological properties and gelation of aqueous cellulose-NaOH solutions. Biomacromolecules 4:259–264

Sehaqui H, Salajková M, Zhou Q, Berglund LA (2010) Mechanical performance tailoring of tough ultra-high porosity foams prepared from cellulose I nanofiber suspensions. Soft Matter 6:1824–1832

Sehaqui H, Zhou Q, Ikkala O, Berglund LA (2011) Strong and tough cellulose nanopaper with high specific surface area and porosity. Biomacromolecules 12:3638–3644

Sescousse R, Budtova T (2009) Influence of processing parameters on regeneration kinetics and morphology of porous cellulose from cellulose-NaOH-water solutions. Cellulose 16:417–426

Sescousse R, Gavillon R, Budtova T (2011) Aero cellulose from cellulose-ionic liquid solutions: Preparation, properties and comparison with cellulose-NaOH and cellulose-NMMO routes. Carbohydr Polym 83:1766–1774

Svagan AJ, Jensen P, Dvinskikh SV, Furó I, Berglund LA (2010) Towards tailored hierarchical structures in cellulose nanocomposite biofoams prepared by freezing/freeze-drying. J Mater Chem 20:6646–6654

Tan C, Fung BN, Newman JK, Vu C (2001) Organic aerogels with very high impact strength. Adv Mater 13:644–646

Tsioptsias C, Stefopoulos A, Kokkinomalis I, Papadopoulou L, Panayiotou C (2008) Development of micro-and nano-porous composite materials by processing cellulose with ionic liquids and supercritical CO2. Green Chem 10:965–971

Westman L, Lindström T (1981) Swelling and mechanical properties of cellulose hydrogels. i. preparation, characterization, and swelling behavior. J Appl Polym Sci 26:2519–2532

Yan L, Gao Z (2008) Dissolving of cellulose in PEG/NaOH aqueous solution. Cellulose 15:789–796

Zhang H, Wu J, Zhang J, He J (2005) 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Zhang W, Zhang Y, Lu CH, Deng YL (2012) Aerogels from crosslinked cellulose nano/micro-fibrils and their fast shape recovery property in water. J Mater Chem 22:11642–11650

Zhou JP, Zhang LN, Cai J (2004) Behavior of cellulose in NaOH/urea aqueous solution characterized by light scattering and viscometry. J Polym Sci Part B Polym Phys 42:347–353

Zhou JP, Chang CY, Zhang RP, Zhang LN (2007) Hydrogels prepared from unsubstituted cellulose in NaOH/urea aqueous solution. Macromol Biosci 7:804–809

Acknowledgments

The authors gratefully acknowledge the National Natural Science Foundation of China (Grants No. 51121001, 51203104, and 50925311), and New Teachers Fund for Doctor Stations, Ministry of Education (No. 20120181120101) for financial support. We also would like to express sincere thanks to the Shanghai Synchrotron Radiation Facility (SSRF, Shanghai, China), for the kind help on WAXD measurements.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, CY., Zhong, GJ., Huang, HD. et al. Phase assembly-induced transition of three dimensional nanofibril- to sheet-networks in porous cellulose with tunable properties. Cellulose 21, 383–394 (2014). https://doi.org/10.1007/s10570-013-0096-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-0096-z