Abstract

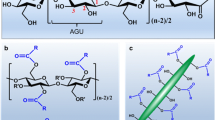

Chemical surface modification of nanofibrillated cellulose (NFC) was performed using a long aliphatic isocyanate chain. Different molar ratios of the coupling agents were tested, i.e., 1, 10, 30 equivalents with respect to hydroxyl groups of the NFC surface. FE-SEM analyses revealed that there were no changes in their morphology thus keeping nanofibril-like structure with about 30 nm of diameter. All these samples were characterized by different techniques (e.g., FTIR) to check the efficiency of the grafting. Hydrophobic NFC were achieved whatever the grafting agent ratio. The Degree of Substitution was determined by Elemental Analyses and the Degree of Substitution of the Surface was calculated thanks to X-ray Photoelectron Spectroscopy data. Combining these two techniques, the Internal Degree of Substitution was proposed for the first time. It indicates if the modification occurs also within NFC internal layers. Surface (contact angle), rheological (water suspension viscosity) and thermal properties (ThermoGravimetric Analysis) of grafted NFC do not follow the expected linear evolution of properties with the increase of molar ratio. X-Ray Diffraction analyses showed that the grafted aliphatic chains display crystalline waxy domains at some ratios. A model for aliphatic chain organization at the surface is proposed and clearly explained for the first time why a compromise in molar ratio is necessary to achieve best properties.

Similar content being viewed by others

References

Ahmed A, Adnot A, Grandmaison JL, Kaliaguine S, Doucet J (1987) ESCA analysis of cellulosic materials. Cellulose Chem Technol 21(5):483–492

Andresen M, Johansson LS, Tanem B, Stenius P (2006) Properties and characterization of hydrophobized microfibrillated cellulose. Cellulose 13:665–677

Belgacem MN, Gandini A (2009) Natural fibre-surface modification and characterisation. Natural fibre reinforced polymer composites: from macro to nanoscale chapter 2. In: Sabu T, Pothan L (eds) Cellulose fibre reinforced polymer composites. Old City Publishing, Philadelphie, pp 14–46

Berglund LA, Peijs T (2010) Cellulose biocomposites—from bulk moldings to nanostructured systems. MRS Bull 35(03):201–207

Berlioz S, Molina-Boisseau S, Nishiyama Y, Heux L (2009) Gas-phase surface esterification of cellulose microfibrils and whiskers. Biomacromolecules 10(8):2144–2151

Buschle-Diller G, Zeronian SH (1992) Enhancing the reactivity and strength of cotton fibers. J Appl Polym Sci 45(6):967–979

Carlmark A, Malmstrom E (2003) ATRP grafting from cellulose fibers to create block-copolymer grafts. Biomacromolecules 4(6):1740–1745

Çetin NS, Tingaut P, Özmen N, Henry N, Harper D, Dadmun M, Sèbe G (2009) Acetylation of cellulose nanowhiskers with vinyl acetate under moderate conditions. Macromol Biosci 9(10):997–1003

Chinga-Carrasco G, Syverud K (2010) Computer-assisted quantification of the multi-scale structure of films made of nanofibrillated cellulose. J Nanopart Res 12(3):841–851

Coskun M, Temüz MM (2005) Grafting studies onto cellulose by atom-transfer radical polymerization. Polym Int 54(2):342–347

Dorris GM, Gray D (1978a) The surface analysis of paper and wood fibres by ESCA (electron spectroscopy for chemical analysis). I. Application to cellulose and lignin. Cellulose Chem Technol 12:9–23

Dorris GM, Gray D (1978b) The surface analysis of paper and wood fibres by ESCA. II. Surface composition of mechanical pulps. Cellulose Chem Technol 12:721–734

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito AN, Mangalam A, Simonsen J, Benight AS, Bismarck A, Berglund LA, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

Eyholzer C, Bordeanu N, Lopez-Suevos F, Rentsch D, Zimmermann T, Oksman K (2010) Preparation and characterization of water-redispersible nanofibrillated cellulose in powder form. Cellulose 17:19–30

Gaiolas C, Belgacem MN, Silva L, Thielemans W, Costa AP, Nunes M, Silva MJS (2009) Green chemicals and process to graft cellulose fibers. J Colloid Interface Sci 330(2):298–302

Gandini A, Belgacem MN (2011) Physical & chemical methods of fiber surface modification. In: Zafeiropoulos E (ed) Interface engineering in natural fibre composites for maximum performance. Woodhead Publishing, Cambridge, UK, pp 3–42

Goussé C, Chanzy H, Excoffier G, Soubeyrand L, Fleury E (2002) Stable suspensions of partially silylated cellulose whiskers dispersed in organic solvents. Polymer 43(9):2645–2651

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110(6):3479–3500

Herrick FW, Casebier RL, Hamilton JK, Sandberg KR (1983) Microfibrillated cellulose: morphology and accessibility. J Appl Polym Sci 28(1):797–813

Hon DN-S, Shiraishi N (2001) Wood and cellulosic chemistry, vol chapter 3: structure of cellulose. Marcel Dekker, New York, USA

Huang B, Ge JJ, Li Y, Hou H (2007) Aliphatic acid esters of (2-hydroxypropyl) cellulose—effect of side chain length on properties of cholesteric liquid crystals. Polymer 48(1):264–269

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3(1):71

Johansson L, Campbell J, Koljonen K, Kleen M, Buchert J (2004) On surface distributions in natural cellulosic fibres. Surf Interface Anal 36(8):706–710

Johansson L, Campbell J, Fardim P, Hultén A, Boisvert J, Ernstsson M (2005) An XPS round robin investigation on analysis of wood pulp fibres and filter paper. Surf Sci 584(1):126–132

Johansson L, Tammelin T, Campbell J, Setälä H, Österberg M (2011) Experimental evidence on medium driven cellulose surface adaptation demonstrated using nanofibrillated cellulose. Soft Matter 22(7):10917–10924

Jonoobi M, Harun J, Mathew A, Hussein M, Oksman K (2010) Preparation of cellulose nanofibers with hydrophobic surface characteristics. Cellulose 17(2):299–307

Katz S, Gray DG (1980) Solvent extraction for the ESCA analysis of paper. Svensk Papperstidning 8:226–228

Krouit M, Bras J, Belgacem MN (2008) Cellulose surface grafting with polycaprolactone by heterogeneous click-chemistry. Eur Polymer J 44(12):4074–4081

Labet M, Thielemans W, Dufresne A (2007) Polymer grafting onto starch nanocrystals. Biomacromolecules 8(9):2916–2927

Lee JL, Pearce EM, Kwei TK (1997a) Morphological development in alkyl-substituted semiflexible polymers. Macromolecules 30(26):8233–8244

Lee JL, Pearce EM, Kwei TK (1997b) Side-chain crystallization in alkyl-substituted semiflexible polymers. Macromolecules 30(22):6877–6883

Lin N, Huang J, Dufresne A (2012) Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials: a review. Nanoscale 11(4):3274–3294

Liu A, Walther A, Ikkala O, Belova L, Berglund LA (2011) Clay nanopaper with tough cellulose nanofiber matrix for fire retardancy and gas barrier functions. Biomacromolecules 12(3):633–641

Lonnberg H, Zhou Q, Brumer H, Teeri TT, Malmstrom E, Hult A (2006) Grafting of cellulose fibers with poly(ε-caprolactone) and poly(l-lactic acid) via ring-opening polymerization. Biomacromolecules 7(7):2178–2185

Lonnberg H, Larsson K, Lindström T, Hult A, Malmström E (2011) Synthesis of polycaprolactone-grafted microfibrillated cellulose for use in novel bionanocomposites—influence of the graft length on the mechanical properties. ACS Appl Mater Interfaces 3(5):1426–1433

Lu J, Askel P, Drzal LT (2008) Surface modification of microfibrillated cellulose for epoxy composite applications. Polymer 49(5):1285–1296

Ly B, Bras J, Sadocco P, Belgacem MN, Dufresne A, Thielemans W (2010) Surface functionalization of cellulose by grafting oligoether chains. Mater Chem Phys 120(2–3):438–445

Majoinen J, Walther A, McKee JR, Kontturi E, Aseyev V, Malho JM, Ruokolainen J, Ikkala O (2011) Polyelectrolyte brushes grafted from cellulose nanocrystals using Cu-mediated surface-initiated controlled radical polymerization. Biomacromolecules 12(8):2997–3006

Menezes AJd, Siqueira G, Curvelo AAS, Dufresne A (2009) Extrusion and characterization of functionalized cellulose whiskers reinforced polyethylene nanocomposites. Polymer 50(19):4552–4563

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8(6):1934–1941. doi:10.1021/bm061215p

Paquet O, Krouit M, Bras J, Thielemans W, Belgacem MN (2010) Surface modification of cellulose by PCL grafts. Acta Mater 58(3):792–801

Roy D, Guthrie JT, Perrier S (2005) Graft polymerization: grafting poly(styrene) from cellulose via reversible addition-fragmentation chain transfer (RAFT) polymerization. Macromolecules 38(25):10363–10372

Saito T, Isogai A (2004) TEMPO-mediated oxidation of native cellulose. The effect of oxidation conditions on chemical and crystal structures of the water-insoluble fractions. Biomacromolecules 5(5):1983–1989. doi:10.1021/bm0497769

Saito T, Nishiyama Y, Putaux J-L, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7(6):1687–1691

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8(8):2485–2491

Scofield JH (1976) Hartree-Slater subshell photoionization cross-sections at 1254 and 1487 eV. J Electron Spectrosc Relat Phenom 8(2):129–137

Siqueira G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 10(2):425–432

Siqueira G, Bras J, Dufresne A (2010a) Cellulosic bionanocomposites: a review of preparation, properties and applications. Polymers 2(4):728–765

Siqueira G, Bras J, Dufresne A (2010b) New process of chemical grafting of cellulose nanoparticles with a long chain isocyanate. Langmuir 26(1):402–411

Siqueira G, Tapin-Lingua S, Bras J, Perez DdS, Dufresne A (2010c) Mechanical properties of natural rubber nanocomposites reinforced with cellulosic nanoparticles obtained from combined mechanical shearing, and enzymatic and acid hydrolysis of sisal fibers. Cellulose 18(1):57–65

Siqueira G, Tapin-Lingua S, Bras J, Perez DdS, Dufresne A (2010d) Morphological investigation of nanoparticles obtained from combined mechanical shearing, and enzymatic and acid hydrolysis of sisal fibers. Cellulose 17(6):1147–1158

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494

Stenstad P, Andresen M, Tanem B, Stenius P (2008) Chemical surface modifications of microfibrillated cellulose. Cellulose 15(1):35–45

Syverud K, Chinga-Carrasco G, Toledo J, Toledo PG (2011) A comparative study of eucalyptus and Pinus radiata pulp fibres as raw materials for production of cellulose nanofibrils. Carbohydr Polym 84(3):1033–1038

Tingaut P, Zimmermann T, Lopez-Suevos F (2010) Synthesis and characterization of bionanocomposites with tunable properties from poly(lactic acid) and acetylated microfibrillated cellulose. Biomacromolecules 11:454–464

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci 28(1):815–827

Walther A, Timonen JVI, Díez I, Laukkanen A, Ikkala O (2011) Multifunctional high-performance biofibers based on wet-extrusion of renewable native cellulose nanofibrils. Adv Mater 23(26):2924–2928

Zimmermann T, Bordeanu N, Strub E (2010) Properties of nanofibrillated cellulose from different raw materials and its reinforcement potential. Carbohydr Polym 79(4):1086–1093

Acknowledgments

This research was supported by the “Scale-Up of Nanoparticles in modern PAPermaking” (SUNPAP) project of the seven framework program of European research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Missoum, K., Bras, J. & Belgacem, M.N. Organization of aliphatic chains grafted on nanofibrillated cellulose and influence on final properties. Cellulose 19, 1957–1973 (2012). https://doi.org/10.1007/s10570-012-9780-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9780-7