Abstract

Photocatalytic degradation is an important method to mediate organic pollution in the environment. This article reports Ag-modified SnO2@TiO2 core–shell composite photocatalysts prepared via a hydrothermal method. The Ag modification and core structure in the composite enhanced the photocatalytic activity and stability of TiO2 in Rhodamine B degradation under visible light irradiation. The composite modified in 0.15 M AgNO3 showed an optimal level of photocatalytic activity, as it degraded 99.14 % Rhodamine B in 60 min while pure TiO2 only degraded 45.7 % during the same time.

Similar content being viewed by others

1 Introduction

Recently, titanium dioxide (TiO2) has attracted great interest in the degradation of pollutants [1–3], such as most organic compounds and inorganic ions [4, 5]. However, the photocatalytic performance of TiO2 is greatly restricted by its wide band gap (3.2 eV) and high electron–hole recombination rate. Proposed solutions to these problems include doping with metallic or nonmetallic ions [6, 7], dye photosensitization on the TiO2 surface [8], deposition of noble metals [9, 10], and semiconductor modification [11].

Modifying TiO2 with semiconductors such as SnO2 has proven to be an effective way to improve the photocatalytic activity, by using the transport and separation of photoproduction carriers between two kinds of semiconductors with different energy gaps. Separately, Ag or other noble metals deposited on the surface of TiO2 form a short-circuit battery with TiO2, which leads to the effective separation of the photo-generated electrons/holes and lower potential in the reduction reaction, thus greatly improving the photocatalytic activity.

In this paper, Ag-modified SnO2@TiO2 core–shell composites were fabricated in two steps: first the synthesis of SnO2@TiO2 composite using a hydrothermal method, and then surface modification of the composite with Ag. The as-prepared samples demonstrated excellent photocatalytic activity and cycle stability under visible light.

2 Experimental

2.1 Preparation of Ag Modified SnO2@TiO2 Core–Shell Composites

2.1.1 Preparation of SnO2

SnCl4·5H2O and polyethylene glycol (PEG) were added into deionized water and magnetically stirred. After SnCl4·5H2O was completely dissolved, excessive ammonia was added dropwise into the solution and stirred well. After filtration, washing, and calcination, the SnO2 powder was obtained.

2.1.2 Preparation of SnO2@TiO2 core–shell composites

Tetrabutyl titanate, acetic acid, and anhydrous alcohol were mixed together, and then alcohol–water solution was slowly added to the mixture and stirred for 30 min. SnO2 was then added, followed by another 30 min of stirring. The obtained solution was transferred to a 100 mL Teflon-lined autoclave and kept in an oven at 150 °C for 4 h. After cooling to room temperature, the precipitation was collected by centrifugation, washed with anhydrous alcohol, dried at 60 °C overnight. The obtained SnO2@TiO2 sample is designated as ST.

2.1.3 Preparation of Ag-Modified SnO2@TiO2 Core–Shell Composites

The ST composite was added to AgNO3 solutions of different concentrations and irradiated under a 500 W mercury lamp. The precipitates were collected by centrifugation and dried at 60 °C overnight to obtain Ag-modified SnO2@TiO2 core–shell composites. The samples are designated as AgST-M, where M is the molar concentration of AgNO3 solution used. For comparison, pure TiO2 and Ag modified TiO2 were synthesized separately, and labeled as PT and AgT.

2.2 Characterization of the Samples

The chemical composition of the samples was analyzed by energy dispersive X-ray spectroscopy (EDX, INCA). Transmission electron microscopy (TEM, JEM-2100, JEOL) was used for morphology characterization. The crystalline structures of the samples were determined by X-ray diffraction (XRD-6000, Japan Shimadzu) using Cu Ka radiation (λ = 0.154 nm) at 40 kV, 250 mA under room temperature. An X-ray photoelectron spectrometer (XPS, Thermo ESCALAB 250, Waltham, MA) was used to analyze the elemental composition and valence states. UV–vis diffuse reflectance spectra (DRS) of the samples was recorded in the range of 200–800 nm using a Shimadzu UV240 spectrophotometer (Kyoto, Japan) equipped with an integrating sphere, and BaSO4 was used as the reference. Thermogravimetry and differential thermal analysis (TG–DTA) were performed by a Pyris Diamond 851e analyzer (PerkinElmer) at a heating rate of 20 °C min−1 under N2 environment with a flow rate = 50 mL min−1.

2.3 Photocatalytic Activity

The photocatalytic activities of the samples were evaluated by the degradation of Rhodamine B in a 500 mL jacketed beaker, and a 500 W mercury lamp was selected as the visible light source. In a typical experiment, 0.05 g of the as-prepared sample was dispersed in the Rhodamine B solution (40 mL, 5 mg L−1). The solution was then maintained in the dark for 30 min prior to irradiation, in order to reach the adsorption–desorption balance. During irradiation, 4 mL of the sample solution was taken out every 10 min and analyzed by UV–vis spectroscopy. The degradation rate of Rhodamine B can be calculated via the formula: \(\eta = ( 1- A/A_{0} ) \times 100 \% ,\) where A0 and A are the absorbance values of the original Rhodamine B solution and irradiated solution.

3 Results and Discussion

3.1 Phase Structure and Morphology Characterization

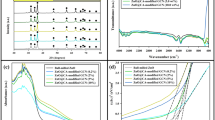

The XRD spectra of Ag-modified SnO2@TiO2 and comparison samples are shown in Fig. 1. Figure (ST) and (AgST) displayed the anatase phase of TiO2 in 2θ = 25.3°, but it could not prove that the samples containing anatase phase of TiO2, because there was only one peak. Mostly because of the low amount of TiO2, X-ray diffraction (XRD) could not detect its presence. And no Ag peaks were detected in Figure (AgT) and (AgST), mostly due to the low amount of Ag [12–14].

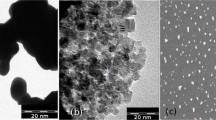

Figure 2 shows the typical TEM images of AgST-0.15, showing that the as-prepared sample consists of many uniform and decentralized nanoparticles with diameters of 30–50 nm. The core–shell nanostructures can be observed in Fig. 2c, as the surface of SnO2 nanoparticles is coated with a layer of TiO2.

Figure 3a shows the TEM images of SnO2 nanoparticles and Fig. 3b shows the TEM images of TiO2 nanoparticles, it is showed the diameters of SnO2 are 20–30 nm and the diameters of TiO2 nano hybrids are about 400 nm, but these TiO2 nano hybrids can disperse and cover SnO2 nanoparticles. The diameters of Ag nanoparticles are also litter, so the diameters of AgST-0.15 are 30–50 nm.

3.2 Thermal Analysis-TG

TG–DTA curves of the Ag-modified SnO2@TiO2 core–shell nanoparticles are exhibited in Fig. 4. The results show that the nanoparticles undergo a multistep decomposition process in the temperature range of 25–800 °C. The endothermic peak in the temperature range of 25–90 °C is related to the desorption of physically adsorbed free water and residual ethanol, with about 8 % weight loss. The sharp exothermic peak in the temperature range of 200–300 °C is due to the combustion of organics on the surface of the sample. During this stage the weight loss percentage is about 5 %. In the temperature range of 300–400 °C there is another exothermic peak owing to further carbonization of organics and removal of constitution water. These results indicate that the as-prepared Ag-modified SnO2@TiO2 core–shell composite exhibits high thermal stability.

3.3 Qualitative Elementary Analysis

AgST-0.15 was further analyzed by XPS to determine the main elements and their chemicals states on the TiO2 surface. The survey spectrum is shown in Fig. 5a. The binding energies obtained in the analysis were corrected for specimen charging by referencing C ls to 284.8 eV [15]. The results indicate the presence of five elements C, Ti, O, Sn, and Ag. Figure 5b shows the Sn 3d XPS spectrum. The two peaks centered at 495.2 and 486.9 eV correspond to the Sn 3d3/2 and Sn 3d5/2 peaks, respectively. The binding energy of Sn 3d5/2 (486.9 eV) matches the typical values for SnO2 [16, 17], indicating that the Sn4+ dopant was incorporated into TiO2 to form SnO2. Figure 5c shows the XPS spectrum of Ag 3d. The binding energies of 368.2 and 374.2 eV were, respectively attributed to Ag 3d5/2 and Ag 3d3/2. The 6.0 eV slitting of the 3d doublet of Ag indicates the formation of metallic Ag on the surface of TiO2 [18, 19]. The Ag content of AgST-0.3 estimated from XPS was 3.76 %. The atomic ratio of O/Ti determined from XPS is 2.82:1, which suggests the existence of oxygen vacancies on the surface of TiO2.

The bandgap of composite SnO2@TiO2 became smaller compared with TiO2 is because of the atomic orbital of Ti is 3d2,4s2, and the atomic orbital of Sn is 5s2,5p2, the four electrons of outer orbital of Ti will migrate to the outer orbital of Sn after they are all lost four electrons to form composite SnO2@TiO2, it can achieve the lowest energy for composite SnO2@TiO2. The deposition of Ag particles greatly increased the activity, the main reason is that the binding energies of Ag is lower than Sn and Ti(368.2 and 374.2 eV were, respectively attributed to Ag 3d5/2 and Ag 3d3/2), of course the activity depends on the loading amount of Ag, the energy is lower, the electronic migration is easier, the catalytic performance is better.

3.4 Photoelectrochemical Performances

3.4.1 UV–vis DRS Analysis

The activity of a photocatalyst mainly depends on the width of its band gap and the recombining rate of electron–hole pairs. From the UV–vis DRS results in Fig. 6, the band gaps for PT, AgT, ST, and AgST-0.3 are estimated to be 3.17, 3.06, 3.02, and 2.85 eV, respectively. Compared to PT, both AT and ST exhibited enhanced absorption extending towards the visible region. AgST-0.3 exhibited significant absorption of both ultraviolet and visible regions, revealing the synergistic effect of SnO2 addition and Ag modification in narrowing the band gap of TiO2. It can be ascribed to the following reasons: (1) the charge-transfer transitions between SnO2 electrons and the TiO2 conduction band [20, 21], (2) the incorporated metallic Ag serving as a delocalization energy level in the energy gap, which would extend the absorbance of TiO2-based photocatalyst to the visible region [22].

3.4.2 Photocatalytic Activity in Rhodamine B Degradation

The photocatalytic activities of the samples were evaluated by the degradation of Rhodamine B under visible light irradiation, and the results are shown in Fig. 7. Compared with PT, all modified TiO2 samples show improved photocatalytic performance, especially the Ag-modified SnO2@TiO2 core–shell composites, which remarkably accelerated the photodegradation. Importantly, the photocatalytic efficiency initially increased with the concentration of AgNO3 used for treatment, from 0 to 0.1 and then 0.15 M. Afterwards, the efficiency decreased with AgNO3 concentration up to 0.3 M. The AgST-0.15 sample exhibited the best catalytic efficiency, which degraded 99.14 % of the Rhodamine B in 60 min, while PT degraded only 45.7 % during the same time.

3.5 Photochemical Stability of the Catalysts

Figure 8 compares the cycle stability of AgST-0.15 (the most effective Ag-modified catalyst) and unmodified PT. The activity of PT was approximately halved, from 45.7 to 23.63 %, after four catalytic cycles of 60 min each. In contrast, AgST-0.15 maintained a high level of catalytic activity after the same number of cycles.

4 Conclusion

Ag-modified SnO2@TiO2 core–shell composites were successfully prepared by a hydrothermal method. Compared with pure TiO2, the composite sample had significantly improved photocatalytic activity in visible light, due to the synergistic effect of Ag modification and SnO2 addition. Surprisingly, there is an optimal Ag content for improving the photocatalytic efficiency, beyond which the efficiency decreases. The sample modified with 0.15 M AgNO3 possessed the best photocatalytic performance, as well as cycle stability.

References

Fujishima A, Rao TN, Tyrk DA (2000) Titanium dioxide photocatalysis. J. Photochem Photobiol C Photochem Rev 1:1–21

Carp O, Huisman CL, Reller A (2004) Photoinduced reactivity of titanium dioxide. Prog Solid State Chem 32:33–177

Zhao J, Yang XD (2003) Photocatalytic oxidation for indoor air purification. Build Environ 38:645–654

Ohko Y, Saitoh S, Tatsuma T, Fujishima A (2001) Photoelectrochemical anticorrosion and self-cleaning effects of a TiO2 coating for type 304 stainless steel. J Electrochem Soc 148:B24–B28

Subasri R, Shinohara T (2004) Application of the photoeffect in TiO2 for cathodic protection of copper. Electrochemistry 72:880–884

Yuan JN, Tsujikawa S (1995) Characterization of sol-gel-derived TiO2 coatings and their photoeffects on copper substrates. J Electrochem Soc 142:3444–3450

Song LZ, Zhao J, Wang XL (2005) Modification and anticorrosion property of carbon steel with TiO2 film. J Iron Steel Res Int 12:37–41

Xie K, Sun L, Wang C, Lai Y, Wang M, Chen H, Lin C (2010) Photo electrocatalytic properties of Ag nanoparticles loaded TiO2 nanotube arrays prepared by pulse current deposition. Electrochimica Acta 55:7211–7218

Li SN, Fu JJ (2013) Improvement in corrosion protection properties of TiO2 coatings by chromium doping. Corros Sci 68:101–110

Lei CX, Liu Y, Zhou H, Feng ZD, Du RG (2013) Photogenerated cathodic protection of stainless steel by liquid-phase-deposited sodium polyacrylate/TiO2 hybrid films. Corros Sci 68:214–222

Doslu ST, Mert BD, Yazici B (2013) Polyindole top coat on TiO2 sol-gel films for corrosion protection of steel. Corros Sci 66:51–58

Lai YK, Zhuang HF, Xie KP, Gong DG, Tang YX, Sun L, Lin CJ, Chen Z (2010) Fabrication of uniform Ag/TiO2 nanotube array structures with enhanced photoelectron-chemical performance. New J Chem 34:1335–1340

Liu Y, Hu J, Li J (2011) Synthesis and photoactivity of the highly efficient Ag species/TiO2 nanoflakes photocatalysts. J Alloys Compd 509:5152–5158

Li X, Xiong R, Wei G (2009) Preparation and photocatalytic activity of nanoglued Sn-doped TiO2. J Hazard Mater 164:587–591

Gao S, Li Z, Jiang K, Zeng H, Li L, Fang X, Jia X, Chen Y (2011) Biomolecule-assisted in situ route toward 3D superhydrophilic Ag/CuO micro/nanostructures with excellent artificial sunlight self-cleaning performance. J Mater Chem 21:7281–7288

Jia F, Sun W, Zhang J, Li Y, Yang B (2012) A facile approach to fabricate three-dimensional ordered macroporous rutile titania at low calcination temperature. J Mater Chem 22:2435–2441

Cao Y, Yang W, Zhang W, Liu G, Yue P (2004) Improved photocatalytic activity of Sn 4 + doped TiO2 nanoparticulate films prepared by plasma-enhanced chemical vapor deposition. New J Chem 28:218–222

Liu Y, Wang X, Yang F, Yang X (2008) Excellent antimicrobial properties of mesoporous anatase TiO2 and Ag/TiO2 composite films. Microporous Mesoporous Mater 114:431–439

Wu M, Yang B, Lv Y, Fu Z, Xu J, Guo T, Zhao Y (2010) Efficient one-pot synthesis of Ag nanoparticles loaded on N-doped multiphase TiO2 hollow nanorod arrays with enhanced photocatalytic activity. Appl Surf Sci 256:7125–7130

Zhao G, Cui X, Liu M, Li P, Zhang Y, Cao T, Li H, Lei Y, Liu L, Li D (2009) Electrochemical degradation of refractory pollutant using a novel microstructured TiO2 nanotubes/Sb-doped SnO2 electrode. Environ Sci Technol 43:1480–1486

Cao Y, Zhang X, Yang W, Du H, Bai Y, Li T, Yao J (2000) A bicomponent TiO2/SnO2 particulate film for photocatalysis. Chem Mater 12:3445–3448

Zhang F, Zheng Y, Zhan Y, Lin X, Zhang H, Zheng Q (2009) Studies on Ag-TiO2/KIT-6 composite nanosized photocatalyst. Spectrosc Spect Anal 29:2166–2170

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Sheng, J., Tong, H., Xu, H. et al. Preparation and Photocatalytic Activity of SnO2@TiO2 Core–Shell Composites Modified by Ag. Catal Surv Asia 20, 167–172 (2016). https://doi.org/10.1007/s10563-016-9217-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10563-016-9217-7