Abstract

CO2 hydrogenation as a route for the chemical energy storage over a commercial Cu/ZnO/Al2O3 catalyst has been studied. To check the optimal conditions for an efficient methanol production the influence of temperature and space velocity on the catalytic performance has been demonstrated. Time-on-stream measurements in the absence and the presence of benzene in the gas feed mixture were performed to investigate the possibility to use alternative carbon sources, which contain traces of aromatics. The catalyst can operate in a stable way without the presence of carbon monoxide in the feed, which means that increased water contents in the product gas cannot destroy the catalyst’s performance completely. The presence of benzene in the feed does not lead to a deactivation of the catalyst. With these findings methanol production starting from exhaust gases from steel mills seems to become an interesting alternative for sustainable methanol production.

Graphical Abstract

Similar content being viewed by others

1 Introduction

Depletion of fossil fuels and climate change are major energy, environmental, and economic issues all over the world. The green-house effect is caused by the release of carbon dioxide into the atmosphere from different power and chemical plants [1]. Conversion of CO2 to methanol by catalytic hydrogenation is recognized as one of the most promising processes to mitigate the atmospheric CO2 level because of a potentially large demand for methanol as both a fuel and a basic chemical [2].

Methanol can be used as a fuel in motor engines because of its efficient combustion and low cost compared to all other fuels. Moreover, using methanol as a fuel allows one to reduce the emissions of undesirable toxic products such as unburned hydrocarbon, CO and NOx [3]. Methanol has a high-octane number in comparison to gasoline that enables efficient engine performance. Another benefit is the possibility to extinguish methanol fire by water. Nevertheless, methanol is corrosive to some materials, which are used in the engines. Therefore, modifications of an engine must be done for utilization of a high-level blend mixture or a pure methanol fuel. Nowadays, low-level blend mixtures can be used without any change of the motor engines [4].

Additionally, the sustainable storage of renewable energies (wind, hydro and solar) is an important issue these days. This can be done by electro-catalytic hydrogen production from water with the following conversion of H2 into methanol [5, 6]. This concept of the methanol economy was studied by Olah [2].

In the conventional continuous process methanol is produced industrially from the syngas—a mixture of CO, CO2, and H2 derived from the reforming of natural gas [7]. However, the exhaust gases from steel mill plants can possibly be also used as a feedstock for methanol synthesis. Three different process stages from coal to steel provide three different gas types: coke oven gas, blast furnace gas, and converter gas, which differ in their composition. The main components of blast furnace and converter gases are carbon dioxide, carbon monoxide and nitrogen. Coke oven gas mostly contains hydrogen and methane [8]. After gas conditioning including purification the exhaust gases can act as a possible feed gas for the methanol synthesis. Nevertheless, due to a lack of a sufficient amount of H2 in the exhaust gases, an additional hydrogen source like sustainable electro-catalytic hydrogen production is mandatory. An alternative could be hydrogen generation via conversion of exhaust CO and water by the water-gas-shift (WGS) reaction to hydrogen and CO2 during feed gas conditioning. In the latter case the hydrogenation of pure CO2 or CO2 enriched synthesis gas mixtures is rendered an interesting reaction. Besides the main components, the steel mill gases additionally contain different impurities such as metals, sulfur-, nitrogen-, and chlorine-containing compounds, polycyclic aromatic hydrocarbons (PAHs), and BTEX-aromatics (benzene, toluene, ethylbenzene and xylenes). With these trace components, an integrated sustainable methanol production will face new challenges. It is well known that sulfur and chlorine will poison the methanol synthesis catalyst [9]. Some metals such as iron and nickel can also affect the catalytic activity and selectivity of the methanol synthesis resulting in the formation of hydrocarbons by the Fischer–Tropsch reaction [10]. However, to the best of our knowledge the effect of aromatic compounds such as BTEX and PAHs on the catalyst’s performance was never tested in the methanol synthesis reaction so far. Nevertheless, for an efficient production of valuable chemicals like methanol from the exhaust gases, it is mandatory to know which components can remain in the gas feed mixture and which components can cause deactivation of the catalyst or selectivity problems and should be removed.

Conventionally, methanol synthesis is performed over the Cu/ZnO/Al2O3 catalyst at 513–533 K and 50–100 bar from the syngas (mixture of CO, CO2 and H2) [11]. There is a debate in the literature about the origin of the carbon source in methanol: carbon monoxide or carbon dioxide. The early work by Klier [12] report that the main source of carbon in a methanol molecule is carbon monoxide. However, later on, Chinchen et al. [13] showed by isotopic labelling of CO2 in syngas that CO2 is the primary methanol source when methanol synthesis is performed over the commercial catalyst. The results obtained by Schlögl and co-workers [14], who also used 13CO2-labeling for the determination of the carbon source, confirm this statement. It is worth to note that carbon monoxide acts as a scavenger of oxygen atoms coming from the water production [11].

When methanol is produced only by hydrogenation of pure CO2 (without addition of CO), two important competitive reactions exist: methanol synthesis (Eq. 1) and the reverse water gas shift (RWGS) reaction (Eq. 2).

ΔH = −49.5 kJ/mol

ΔH = 41.2 kJ/mol.

Water formation in both reactions may deactivate the Cu-based catalyst. Liu et al. [15] reported the inhibiting effect of water adsorption during CO2 hydrogenation, which was confirmed by Sahibzada et al. [16] When differential conversions are achieved, CO2 hydrogenation is around 20 times faster than hydrogenation of CO, underlining the role of CO2 as the main carbon source and showing that there is only a negligible inhibition by CO2 itself [16]. But when methanol synthesis is performed at finite, higher conversions, there is an order of magnitude difference between finite and differential conversions in methanol synthesis starting from CO2 [16]. This observation indicates that the product water inhibits the production of methanol. Liu et al. [15] interpreted the inhibiting effect by strong water adsorption and blocking of the active sites for CO2 hydrogenation. The blocking species was further proposed to be carbonate or formate species resulting from the reaction of water with CO2 [16].

Additional reasons for the deactivation of Cu-based catalysts by water mentioned in the literature [17] are blocking of hydrogen adsorption sites, morphology changes of Cu [17, 18], and the oxidation of the active Cu-phase [17]. An irreversible deactivation of Cu catalysts was explained by recrystallization and an enhanced sintering tendency of the Cu particles by water addition [17, 19], whereas no sintering and no Cu oxidation was observed by Omata et al. [17] during their study on the deactivation due to the presence of water.

All of these findings render a deeper understanding of the CO2 hydrogenation and an expansion of the known parameter space of a Cu-based catalyst is important. It is mandatory to investigate, if an economical feasible production of methanol starting from the exhaust gases can be achieved and which purification and feed gas conditioning steps are indispensable.

Parameters such as pressure, temperature and space velocity play important roles in determining the reaction performance.

The aim of this study is to establish a fundament for the usage of the exhaust gases of steel mills as feed gases for methanol synthesis to ascertain a sustainable production for the future. Therefore, the working efficiency of the commercial catalyst at different reaction conditions for the methanol synthesis through hydrogenation of pure CO2 is investigated. Additionally, the production stability of the catalyst in the presence of benzene impurities as a representative of the BTEX aromatics is determined.

2 Experimental

2.1 Catalyst Test

As the catalyst the FHI-standard catalyst (Cu/ZnO/Al2O3) [20] is used for all the investigations in this study.

Catalyst testing in CO2 hydrogenation is performed using stainless steel flow type fixed bed reactor (Fig. 1). The reactor is a 316 stainless steel tube, which is 53.3 cm in length with 19.05 mm o.d. and 13.5 mm i.d. It is larger than often used laboratory-scale reactors (6 mm i.d.) [21]. This allows us to use a higher amount of the catalyst for the measurements up to 1 g. The isothermal zone in the middle of the reactor is 10 cm. Gas flows are controlled and monitored with mass flow controllers (Bronkhorst). The reactor pressure is maintained via a back-pressure regulator. The catalyst bed temperature is measured during the reaction using a type K thermocouple positioned within the reactor itself in the center of the catalyst bed. The reactor temperature is maintained by an external heating furnace. The setup is equipped with the liquid storage vessel, which is cooled to 5 °C to condense and collect the methanol–water mixture. The catalyst bed zone is placed between SiO2 chips (250–355 µm). The ends of the reactor are blocked with glass wool to protect gas lines from SiO2. The catalyst bed contains the Cu/ZnO/Al2O3 catalyst (100–200 µm, 1 g) diluted with SiO2 (1:7 by volume).

The catalyst was activated before catalytic experiments. The fresh catalyst was reduced in-situ at 523 K (1 K/min) for 3 h in a gas mixture with a ratio of H2:N2 = 4:5. Upon reduction a gas mixture of H2/CO2 with a molar ratio of 7:2 was introduced into the reactor. The pressure was increased to 30 bar. All lines were heated to 393 K to avoid methanol and water condensation. The catalyst was stabilized for 18 h at 523 K after the beginning of the reaction.

The catalyst testing is carried out in the temperature range of 473–533 K, at a pressure of 30 bar, and in the space velocity range of 20,000–46,000 h−1. Experiments are performed by establishing T, P, and flow conditions followed by 2 h of equilibration time to achieve the steady state. For the same reaction conditions, products are collected and taken from the vessel twice. The liquid samples are characterized by GC–MS (Agilent) for the quantification of the methanol concentration. Methanol is determined with an Innowax column using the standard calibration method.

2.2 Transmission Electron Microscopy (TEM) Measurements

TEM samples of the Cu/ZnO/Al2O3 catalyst after methanol synthesis in the presence of benzene were recorded on a FEI Titan 80-300 equipped with a Cs corrector at the image forming lense. The catalyst was stored in dry methanol. Prior to the measurements, the sample was evacuated and placed without exposure to ambient air in the glove box. Final drying was achieved via the pumping circles during insertion. A lacey carbon coated Au TEM grid was used to image the sample in the microscope. The sample was transferred to the microscope without exposure to ambient air using a TEM vacuum transfer holder.

3 Results and Discussion

The CO2 hydrogenation activity data are presented in terms of CO2 conversion, methanol yield, and methanol selectivity values. The reaction is started at the base line conditions: temperature of 523 K, pressure of 30 bar and space velocity of 37,000 h−1. It is necessary to run the base line experiment from time to time in order to verify that the catalyst retains its steady-state activity. The first set of measurements is carried out in the temperature range of 473–533 K, a pressure of 30 bar, and a space velocity of 37,000 h−1. The upper limit of the temperature is determined by the temperature of brass formation, which can occur at around 573 K [22].

The methanol/water mixture was condensed downstream of the reactor. As it was mentioned in the experimental part, the samples were taken twice after 6 and 18 h of the continuous flows for the same reaction conditions. The long time for the liquid condensation is necessary to obtain reasonable amount of the sample in the storage vessel (Fig. 1). The usage of such kind of setup allows producing a high amount of methanol and get reliable results. Off-line detection of products to obtain high-quality quantitative data is used. Overall time of the measurement without replacing the catalyst was 324 h. The volume of the methanol/water mixture obtained per hour is practically the same for two points (Fig. 2). The difference can be explained by a pressure decrease of 0.2–0.5 bar during opening the vessel to empty it. The lower temperature the lower is the methanol/water amount since the reaction rate decreases. The base line experiments at 523 K show that there is a slight decrease in the produced amount with time that is caused by deactivation of the catalyst. As already mentioned above, deactivation can be caused by the water formation during CO2 hydrogenation, which adsorbs on the active sites of the catalyst. This results in inhibition of the CO2 adsorption. Sahibzada et al. [16] showed that a lower methanol production rate is observed with addition of water to the H2/CO2 feed. Another possible reason of catalyst deactivation is crystallization of Cu and ZnO particles [23]. Water produced during methanol synthesis from CO2-rich feed can accelerate the crystallization of particles leading to deactivation that was observed for the Cu/ZnO/ZrO2/Al2O3 catalyst [19]. The Cu particle size increases from 83 to 135 Å for 500 h of the experiment at 523 K and 50 bar [19].

For the determination of the methanol purity and presence of by-products the methanol/water mixture condensed in the setup vessel is analyzed by GC–MS. It is known that major byproducts obtained during methanol synthesis at typical industrial operating conditions (70–100 bar, 493–553 K, 30,000–40,000 h−1) are higher alcohols, methyl formate, and hydrocarbons [24]. However, the formation of higher alcohols can be suppressed by the presence of CO2 in the feed.

In the current work the determination of the methanol concentration is done by the internal standard calibration method. This method consists of plotting the ratio of the analyte signal to the internal standard signal as a function of the ratio of the concentrations of analyte and internal standard. The internal standard is a compound which is similar to the compound of interest but not exactly the same. In the current work 2-propanol is used as the internal standard. Representative chromatograms (Fig. 3) show the presence of CO2 and methyl formate in trace amount in the condensed methanol/water solutions.

It is known that carbon dioxide has a quite high solubility in water [25]. The temperature of the vessel, where methanol and water are condensed, is 5 °C. At this temperature and atmospheric pressure, the CO2 solubility is 0.3 g in 100 ml of water. Thus, CO2 dissolves in the water. That is confirmed by the chromatogram.

Urakawa and co-workers [26] performed methanol synthesis in the temperature range of 443–553 K, a pressure of 30 bar, and ratio of H2:CO2 = 3.8:1 over a Cu/Al2O3 catalyst. They showed that the formation of methyl formate is observed at low temperatures. The selectivity towards methyl formate decreases from 0.2 to practically 0.0% with a temperature increase from 473 to 503 K [26]. The present work shows the same trend in methyl formate selectivity with the temperature for the ternary Cu/ZnO/Al2O3 catalyst. The methyl formate presence can be observed on the chromatogram presented for the sample, which was produced at 483 K (Fig. 3a). Methyl formate is also observed in the samples obtained in the temperature range of 493–513 K. These chromatograms are not presented in the paper. Hence, increase of the temperature from 473 to 523 K leads to the decrease and total vanishing of methyl formate (Fig. 3b). Above 513 K the formation of methyl formate was suppressed.

It has been proposed that formate formation during CO2 hydrogenation can be explained by eventual reduction of carbonate–bicarbonate species, which are formed on the catalyst surface [27]. Methanol can react with the formate species adsorbed on the catalyst’s surface, which are intermediates during methanol synthesis and reverse water gas shift reaction, to produce methyl formate by the reaction given in Eq. 3 [28].

Alternatively, Rosovskii et al. [29] reported that methanol can decompose over a Cu-based catalyst in the temperature range of 423–523 K to methyl formate, CO, and H2 (Eqs. 4, 5).

Methanol decomposition was studied [28] by injections of methanol at 473 and 573 K over the Cu/ZnO/Al2O3 catalyst. According to the obtained results the methyl formate amount decreases and the CO amount increases with time. This is an illustration of the case of an intermediate and a final product for consecutive reactions. It should be noted that at temperatures higher than 473 K the selectivity of methanol dehydrogenation to methyl formate is low. These results also confirm our data that at higher temperature methyl formate disappears.

Hence, the commercial catalyst designed for methanol synthesis using CO-containing syngas is also efficient for CO2 hydrogenation without producing high amount of the by-products under the investigated conditions. However, one should keep in mind that the trace amount of methyl formate can still cause a problem for the downstream use of methanol produced. The trace amount of CO2 and methyl formate was not taken into account for the calculation of the catalytic productivity.

The dependence of the CO2 conversion on the temperature and the space velocity as well as equilibrium conversion predicted from thermodynamics is shown in Fig. 4. The thermodynamic equilibrium for the conversion is calculated using the software HSC 5.1 assuming that the only products are CH3OH, H2O and CO. The increase of CO2 conversion at high temperatures (>540 K) is caused by a contribution of the RWGS reaction.

The experimental CO2 conversion increases monotonously with the reaction temperature approaching thermodynamic equilibrium and lies in the range of 2–16.5% at the pressure of 30 bar and space velocity of 37,000 h−1 (Fig. 4). Methanol formation is thermodynamically favored at low temperatures, while carbon monoxide is produced in the higher extent at high temperatures due to the reverse water gas shift reaction. As already explained before, the activity of the catalyst can be suppressed with pure CO2/H2 feed because of the presence of water. Water can be adsorbed on the active sites of the catalyst. This results in inhibition of the adsorption of CO2 on the active site for the further catalytic performance. When carbon monoxide is present, it can act as a scavenger and reacts with water to form carbon dioxide and hydrogen by the water gas shift reaction to regenerate active sites on copper [30].

The second suite of the experiments was performed to observe the effect of the space velocity on the CO2 conversion. As expected, the conversion increases with longer contact time (decreasing space velocity) of the gas mixture with the catalyst surface during reaction. With a space velocity of 30,000 h−1 the CO2 conversion reaches 18% at 533 K. However, there is still a gap between measured conversion and the maximum conversion calculated from thermodynamics.

When the measurement takes place under ideal differential conditions without heat or mass transport limitations with infinitesimal small conversions, the production rate of a reaction should keep constant independent of the space velocity. That is why at higher space velocities a lower conversion is expected as more reactants are introduced into the reactor and the same amount reacts rendering the fraction of reacted molecules smaller. As the productivity in methanol synthesis is changing with the space velocity as illustrated later on in Table 1, it is clear that measurements are not performed under perfect differential conditions. The given productivities are integral reaction rates over the catalyst bed. At higher conversions, lower partial pressures of CO2 and H2 are expected at the outlet of the reactor because a significant amount did already react. Therefore, a lower reaction rate is expected. Additionally, when investigating reversible reactions, the back reaction becomes faster as partial pressures of methanol and water becomes higher. The measured integral productivity is then an average of all reaction rates at different axial positions over the catalyst bed. At lower space velocities, a higher conversion is measured. The productivity becomes smaller as lower partial pressures of reactants hydrogen and CO2 are present at the end of the reactor.

Figure 5 shows the influence of the reaction temperature and space velocity on the CH3OH yield and CH3OH selectivity. The methanol yield was calculated as the ratio of produced methanol to the total amount of CO2 passed through the reactor. The methanol yield increases with temperature (Fig. 5a). This indicates that high temperature promotes formation of methanol in spite of a decrease in methanol selectivity. That is, the rates of both reactions increase, however, the contribution of the reverse water gas shift reaction is higher with higher temperature. The influence of the space velocity on the methanol yield is also considered in this investigation. The methanol yield increases with decrease of space velocity due to longer contact time of reactants with the catalyst surface.

Figure 5b compares the selectivity to methanol obtained at different temperatures and space velocities over the commercial catalyst. As expected from thermodynamics, the higher amount of CO is produced during the experiment at higher temperature, and the selectivity towards methanol production decreases. This behavior can be caused by the competitive reverse water gas shift reaction, which is thermodynamically more preferable at higher temperatures. This may hint on a very fast side reaction, which reaches the thermodynamic equilibrium. At least, the CO formation is accelerated faster with the temperature increase than that of CH3OH, thus, favoring the CO selectivity at higher temperatures. This goes well in line with a higher energy of activation as it is mentioned later. The methanol selectivity monotonously decreases with the temperature and lies in the ranges of 33–66% at 37,000 h−1.

The reaction was also performed at a lower space velocity of 30,000 h−1. The same dependence of the methanol selectivity on the temperature is observed. However, there is no clear trend in influence of the space velocity on selectivity. Sun et al. [31] showed that the methanol selectivity decreases with lower space velocity. It can be explained by additional formation of CO from the secondary reaction of methanol decomposition (CH3OH = CO + 2H2) under the chosen reaction conditions. When the contact time of reactant gases with the catalyst surface is long this reaction is not a negligible process anymore. On the other hand, the lower space velocity results in the higher selectivity in case of the high water formation, which promotes a shift of the equilibrium of the reverse water gas shift reaction to the side of reactants: CO2 and H2. Hence, a lower CO amount will be formed. With these effects compensating each other, a more or less constant selectivity can be explained.

In our work for the temperatures of 473, 523 and 533 K the selectivity values are practically the same for different values of the space velocity. Therefore, the effect of the gas hourly space velocity, which is a parameter that reflects the reactor efficiency, is also tested at the temperature of 523 K and a pressure of 30 bar (Fig. 6).

The space velocities in the range of 20,000–46,000 h−1 are used for studying the catalytic behavior. More CO2 and H2 are introduced into the reactor with the higher space velocity; the contact time of the reactants with the catalyst surface is shorter. As a result, CO2 conversion decreases. As it was mentioned before, the methanol yield increases with decrease of space velocity because of a longer contact time of the reactants with the catalyst surface. However, as can be seen, the selectivity to methanol practically does not depend on the space velocity, which is in line with expectations for the reaction in the kinetic region not disturbed by mass and heat transport processes [32].

The methanol production rates are presented in Table 1 for different reaction conditions. They are calculated from the concentrations of methanol determined by GC–MS and the volume of the methanol–water mixture condensed. The methanol production rate increases with an increase of temperature. It was possible to achieve production rates as high as 0.96 gMeOH/(gcat*h), which renders the hydrogenation of pure CO2 over the commercial Cu/ZnO/Al2O3 catalyst an interesting alternative for the production of methanol.

The measured production rate could possibly be even further increased by increasing the space velocity until differential reaction conditions would be reached.

According to the linear relationship between the natural logarithm of the production rate and the reciprocal of the temperature that exists in the controlling region of kinetics, the values of apparent activation energy were calculated for the methanol and CO production. The obtained CO amount was calculated from the stoichiometry of the two reactions:

The total volume of the mixture solution is known. The methanol concentration is quantified by GC–MS measurement. Using the stoichiometry of the reaction the water and carbon monoxide amount produced during methanol synthesis was calculated. The resulting apparent activation energies are listed in Table 2. The activation energies for the methanol production are 43–44 kJ/mol. It can be concluded that space velocity does not influence the activation barriers.

The activation energies published in this work are lower than that for the Cu(110) plane (67 kJ/mol) [33] and polycrystalline Cu (77 kJ/mol) [34]. The values of the activation energy are lower over the promoted Cu-based catalysts than that over crystalline copper. It can be assumed that promoters participate in the reaction favoring a decreasing activation barriers [35]. The apparent activation energies are 33 and 45 kJ/mol for methanol formation by CO2 hydrogenation over the Cu/ZnO/ZrO2 catalysts promoted by a variety of metals prepared by citric and carbonate methods, respectively [32]. Similar values of 37–41 kJ/mol for methanol formation in CO2 hydrogenation at ambient pressure were obtained by Schumann et al. [21] for the Cu/ZnO catalysts doped with Al or Ga prepared by the impregnation method. The activation energies for methanol synthesis published in the present work are well in line with that activation energies.

In the case of the reverse water-gas-shift reaction, the activation energies for CO formation are 82–83 kJ/mol. The main consequence of this result is that the rate of methanol formation decreases slower than that of CO formation, when the temperature is decreased, thus, favoring the methanol selectivity at lower temperatures.

For an economic feasibility, the methanol catalyst should reveal a stable productivity for long time-on-stream measurements. There is a lack of data for long term stability tests over the commercial Cu/ZnO/Al2O3 catalyst in CO2 hydrogenation with a molar ratio of H2:CO2 = 7:2. That is why a stability test was carried out at temperatures of 523 and 503 K for 210 and 325 h, respectively (Fig. 7).

The experiment performed at 523 K shows the decrease in the methanol space time yield (STY) by 9.8% in the first 42 h. After that STY monotonously decreases to 0.75 g/(gcat*h). For the temperature of 503 K the measurements were done for a longer time of 325 h. A decrease in the catalytic productivity by 8.1% in the first 72 h is observed. After that the catalyst works stable for another 250 h and shows only a slight deactivation afterwards.

It is supposed that the Cu sintering is the primary cause of deactivation in the Cu/ZnO-based methanol synthesis catalysts [9]. As mentioned above, the crystallization of Cu and ZnO particles in the catalyst could be accelerated by water produced along with methanol using CO2-rich feed [19]. This leads to the reduction of surface area and copper surface area, and as a result to the catalyst deactivation. Hence, the initial rapid deactivation of the Cu/ZnO/Al2O3 can be caused by a loss of copper surface area when some of the very finely dispersed Cu crystallites agglomerate [10]. The growth of ZnO particles weakens the Cu–ZnO interfacial contact during methanol synthesis through pure CO2 hydrogenation, leading to the agglomeration of Cu particles [36]. When CO is present in the feed, the deactivation of the catalyst occurs in the same manner [37]. It was shown that the methanol productivity drops by 17% for 500 h of the experiment during methanol synthesis over Cu/ZnO/Al2O3 catalyst at 50 bar and 498 K. Hence, the similar stabilities are achieved in the presence of only CO2. The results of the stability tests show that the catalyst can operate in a stable way without the presence of carbon monoxide in the feed meaning that substantial water contents in the product stream seem not to destroy the catalyst.

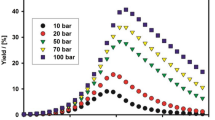

It is known that higher pressures are preferable for a high methanol yield. Due to the steady loss in activity, a reasonable performance of the methanol synthesis reaction is increasing the pressure with time to keep the catalytic productivity constant. Bart et al. [11] published the results obtained by Boelens. He showed that it is possible to maintain 86% of the initial methanol yield after 1850 h of the experiment by increase of the pressure from 69 to 88 bar at 513 K and 35,000 h−1. A rise of the temperature is not an option to maintain the catalytic productivity on the same level since this would lead to sintering of the catalyst and formation of brass.

There is a lack of information dedicated to investigation of pressure effect on the methanol synthesis. Nevertheless, if methanol will be produced from exhaust gases as feedstock together with hydrogen from renewable energies, intermittent production conditions have to be taken into account due to the special occurrence of the feed. The possibility of unexpected shutdown of one of the ovens during steel production cannot be excluded. So far, Bansode et al. [26] carried out an experiment on the Cu/Al2O3 catalyst at different temperatures (443–553 K °C) and pressures (4–360 bar). They showed that the maximum value of the CO2 conversion is 29.6% at 360 bar and 553 K. However, for every new pressure conditions the new catalyst was placed in the reactor. Such kind of experiment cannot show the influence of the pressure on the catalyst deactivation.

Therefore, the investigation of the dynamics of the pressure change was done in the present work. The time on stream measurements are performed with switches of the pressure between 30 and 50 bar for 500 h (Fig. 8). After 200 h of the experiment the switch is repeated every day for 12 days. It can be seen that a long time of the experiment is needed for achievement of the steady-state performance of the catalyst.

At 30 bar the loss in productivity [from 0.93 to 0.80 g/(gcat*h)] is 13.7% for the first 180 h. For the next 270 h the decrease in the methanol production rate is only 4.5%. The results are in agreement with the measurements presented in Fig. 7. As it was mentioned before, the fast deactivation at the beginning of the experiment can be caused by the sintering Cu particles. After that the methanol production rate approaches a steady state. The measurements performed at 50 bar showed the smaller drop in catalytic activity for the whole time range, it is only 13% versus 18% at 30 bar. However, the observed decrease is continuous, and it does not approach to the steady-state level even after 500 h of the experiment. The longer time to reach steady state may be needed for the measurements which are done at 50 bar.

It was reported [18] that the continuous deactivation of the Cu/ZnO/ZrO2/Al2O3 catalyst occurs during methanol synthesis in CO2-rich gas feed (CO2:CO:H2 = 22:3:75) at 50 bar and 523 K. The stable catalytic performance was not reached in 500 h. It is assumed that water produced along with methanol accelerates crystallization of Cu and ZnO during methanol synthesis. This is in agreement with our results. Nevertheless, this deactivation at 50 bar does not affect the activity at 30 bar, which renders an irreversible crystallization of Cu and ZnO unlikely. By comparison of the production rates at 30 bar and 523 K shown in Figs. 6 and 7 it is proven that dynamical pressure changes to 50 bar do not influence the catalyst performance at 523 K and 30 bar.

As it was mentioned in the introduction, the steel mill gases contain different impurities such as BTEX-aromatics and PAHs. Its presence may poison the catalyst during long-term methanol synthesis and results in decreasing CO2 conversion and methanol yield. However, the influence of aromatics in the gas feed for methanol synthesis has never been reported. The first step to understand the effect of aromatics on catalyst performance is done by adding benzene to the feed gas mixture.

The experiments in the presence of benzene impurities are performed in the gas mixture of H2/CO2/(500 ppm C6H6 in N2) with a ratio of 37:10:4. The long-term stability test is done at 523 K, 15 bar, and 37,000 h−1. Changes in the methanol production rate with time-on-stream are presented in Fig. 9. For comparison, a measurement under a pure H2/CO2/N2 gas mixture was performed at the beginning of the long-term stability test.

The benzene concentration, which was detected in crude gases from different coke ovens, varies in the range of 28–35 g/m3 depending on the coal used [38]. After cleaning the gas contains less than 5 g/m3 of benzene. In our work the benzene concentration of approximately 1.6 g/m3 is used. During the experiment 1.3 g of benzene passed through the catalyst bed.

The methanol production rate stays in the same order of magnitude [ca. 0.3 g/(gcat*h)] compared to benzene-free feed gas, which is represented in the first data point. The methanol production rate is much lower than that [ca. 0.8 g/(gcat*h)] for methanol synthesis performed at 30 bar. As we showed before, the pressure has a high impact on catalyst performance. The pressure limit for the experiment in the presence of benzene impurities is determined by total pressure of the gas cylinder used. The catalyst shows a high stability with time-on-stream for 240 h at the present reaction conditions in the presence of benzene impurities in the gas feed mixture. Benzene is condensed in the storage vessel along with methanol and water. However, the concentration is too low to be determined quantitatively by GC–MS.

It is worth to note that there are two drops in methanol yield after 50 and 165 h of the experiment. It can be caused by decrease of the setup pressure during sample taking and its equilibration afterwards. The value of the pressure drops and the time for stabilization of the pressure depends on the time period how long the vessel was opened.

TEM samples of the Cu/ZnO/Al2O3 catalyst after methanol synthesis in the presence of benzene impurities were recorded. Figure 10 shows a TEM image of the sample after methanol synthesis in the presence of benzene. After reaction wurtzite ZnO nanoislands have formed on top of the Cu nanoparticles, which was also observed on the same catalyst in the initial stages of reaction [23]. Corrugation at the surfaces may indicate a remaining ZnO overlayer as it has been described for this type of catalyst after reductive activation [39].

A further purification step of the steel mill gases from BTEX aromatics does not seem to be necessary as the impurities do not affect the catalyst’s stability and activity. The measurement performed in the presence of benzene is the first step to a usage of the exhaust gases from steel mills for methanol synthesis and investigation of catalyst performance.

4 Conclusion

The aim of the present work was to find optimal conditions to obtain a high efficiency of methanol production and low concentrations of side products. High selectivity of methanol is preferable as it is the main desired product of methanol synthesis and less concentration of CO produced during the reaction because of its toxicity.

We showed that methanol produced by CO2 hydrogenation using a commercial catalyst contains trace amount of methyl formate which depends on the temperature used. Methyl formate can still cause the problem in downstream use of methanol. The temperature of the reaction is determined by brass formation and thermodynamic equilibrium. An increase of temperature results in a decrease of methanol selectivity because of a higher contribution of the reverse water gas shift reaction. However, an increase of the methanol yield is observed, when the system is operated under kinetic control.

The catalyst can operate in a stable way without CO in the feed gas meaning that water contents in the product stream seem not to destroy the catalyst. Additionally, it was possible to operate the catalyst under intermittent production conditions simulated by dynamic pressure changes from 30 to 50 bar. No restraining influence on the performance at 30 bar was observed by the temporal changes to 50 bar. Additionally, it was found that the never tested interaction of the Cu/ZnO/Al2O3 catalyst with benzene impurities do not affect the catalyst stability. That is an important hint towards the possibility of using the steel mill gases for methanol production without a further purification step from BTEX-aromatics. In summary, this study showed that the commercial Cu-based catalyst developed for the conventional methanol synthesis process starting from CO/CO2/H2 feed gas mixtures is a promising candidate for the usage during sustainable methanol synthesis from exhaust gases under dynamic operation conditions possibly together with hydrogen produced from renewable energies. This will help to do the next step in developing sustainable and environmental friendly production routes for basic chemicals like methanol.

References

Chunshan S (2006) Catal Today 115: 2

Olah GA (2005) Angew Chem Int Ed 44:2636

Kunkes E, Behrens M (2013) Methanol chemistry. Chemical energy storage. De Gryter, Berlin, p 413

Methanol: the clear alternative for transportation, 2011. http://www.methanol.org

Kauw M, Benders RMJ, Visser C (2015) Energy 90:208

Friebel D, Louie MW, Bajdich M, Sanwald KE, Cai Y, Wise AM, Cheng MJ, Sokaras D, Weng TC, Alonso-Mori R, Davis RC, Bargar JR, Nørskov JK, Nilsson A, Bell AT (2015) J Am Chem Soc 137: 1305

Cañete B, Gigola CE, Brignole NB (2014) Ind Eng Chem Res 53:7103

Bermúdez M, Ferrera-Lorenzo N, Luque S, Arenillas A, Menéndez JA (2013) Fuel Process Technol 115: 215

Twigg MV, Spencer MS (2003) Top Catal 22:191

Kung HH (1992) Catal Today 11:443

Bart JCJ, Sneeden RPA (1987) Catal Today 2:1

Klier K (1982) Adv Catal 31:243

Chinchen GC, Denny PJ, Parker DG, Spencer MS, Whan DA (1987) Appl Catal 30:333

Studt F, Behrens M, Kunkes EL, Thomas N, Zander S, Tarasov A, Schumann J, Frei E, Varley JB, Abid-Pedersen F, Nørskov JK, Schlögl R (2015) ChemCatChem 7:1105

Liu G, Willcox D, Garland M, Kung HH (1985) J Catal 96:261

Sahibzada M, Metcalfe IS, Chadwik D (1998) J Catal 174:111

Omata K, Hashimoto M, Watanabe Y, Umegaki T, Wagatsuma S, Ishiguro G, Yamada M (2004) Appl Catal A 262:207

Clausen BS, Schiøtz J, Gråbæk L, Ovesen CV, Jacobsen KW, Nørsko JK, Topsøe H (1994) Top Catal 1:1367

Wu J, Saito M, Takeuchi M, Watanabe T (2001) Appl Catal A 218:235

Schumann J, Lunkenbein T, Tarasov A, Thomas N, Schlögl R, Behrens M (2014) ChemCatChem 6:2889

Schumann J, Eichelbaum M, Lunkenbein T, Thomas N, Álvarez Galván MC, Schlögl R, Behrens M (2015) ACS Catal 5:3260

Spencer MS (1999) Top Catal 8:259

Lunkenbein T, Girgsdies F, Kandemir T, Thomas N, Behrens M, Schlögl R, Frei E (2016) Angew Chem Int Ed 55:12708

Hansen JB, Nielsen PEH (2008) Methanol synthesis. Handbook of heterogeneous catalysis. Wiley-VCH, Weinheim

Kaye GWC, Laby TH (1986) Tables of physical and chemical constants. Longman, New York, p 219

Bansode A, Tidona B, von Rohr PR, Urakawa A (2013) Catal Sci Technol 3:767

Ramarson A, Kieffer R, Kiennemann A (1982) Appl Catal 4:281

Yu KMK, Yeung CMY, Tsang SC (2007) J Am Chem Soc 129:6360

Rozovskii AY, Lin GI (2003) Top Catal 22:137

Joo OS, Jung KD, Moon I, Rozovskii AY, Lin GI, Han SH, Uhm SJ (1999) Ind Eng Chem Res 38:1808

Sun Q, Zhang YL, Chen HY, Deng JF, Wu D, Chen SY (1997) J Catal 167:92

Słoczyński J, Grabowski R, Olszewski P, Kozłowska A, Stoch J, Lachowska M, Skrzypek J (2006) Appl Catal A 310:127

Yoshihara J, Campbell CT (1996) J Catal 161:776

Yoshihara J, Parker SC, Schafer A, Campbell CT (1995) Catal Lett 31:313

Karelovic A, Bargibant A, Fernàndez C, Ruiz P (2012) Catal Today 197:109

Natesakhawat S, Ohodnicki PR Jr, Howard BH, Lekse JW, Baltrus JP, Matranga C (2013) Top Catal 56:1752

Ding W, Liu Y, Wang F, Zhou S, Chen A, Yang Y, Fang W (2014) RSC Adv 4:30677

Hein M, Kaiser M (2012) Air pollution—a comprehensive perspective. Environmental Sciences, InTech, p 240

Lunkenbein T, Schumann J, Behrens M, Schlögl R, Willinger MG (2015) Angew Chem Int Ed 54:4544

Acknowledgements

Open access funding provided by Max Planck Society.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bukhtiyarova, M., Lunkenbein, T., Kähler, K. et al. Methanol Synthesis from Industrial CO2 Sources: A Contribution to Chemical Energy Conversion. Catal Lett 147, 416–427 (2017). https://doi.org/10.1007/s10562-016-1960-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-016-1960-x