Abstract

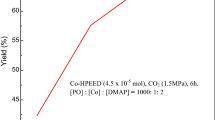

Synthesis of various cyclic carbonates with yield up to 100% and turn over frequency (TOF) of 351 h−1 using CO2 and epoxides and a cobalt (III) complex of tetraamidomacrocyclic ligand is described. The catalyst was characterized by single crystal X-ray crystallography. A study of reaction conditions indicates that 2 MPa pressure of CO2 without any co-solvent is sufficient to achieve the desired product.

Graphic Abstract

Similar content being viewed by others

References

Darensbourg DJ, Holtcamp MW (1996) Coord Chem Rev 153:155

Xiao XD, Moulijn JA (1996) Energy Fuels 10:305

Shi M, Shen Y-M (2003) Curr Org Chem 7:737

Sakakura T, Choi J-C, Yasuda H (2007) Chem Rev 107:2365

Gibson DH (1999) Coord Chem Rev 335:185

Omae I (2006) Catal Today 115:33

Coates GW, Moore DR (2004) Angew Chem Int Ed Engl 43:6618

Shaikh A, Sivaram S (1996) Chem Rev 96:951

Sakakura T, Kohno K (2009) Chem Commun 1312

Wakihara M, Yamamoto O (1998) Lithium ion batteries: fundamentals and performance. Kodansha Ltd, Tokyo

Clements JH (2003) Ind Eng Chem Res 42:663

Weissermel K, Arpe H (1997) Industrial organic chemistry, 3rd edn. Wiley-VCH Weinheim, NY

Ream BC (1989) US Patent 4,877,886

McMullen CH, Nelson JR, Ream BC and Sims JA Jr (1982) US Patent 4,314,945

Peppel WJ (1958) J Ind Eng Chem 50:767

Kossev K, Koseva N, Troev K (2003) J Mol Catal A Chem 194:29

Kihara N, Hara N, Endo T (1993) J Org Chem 58:6198

Matsuda H, Ninagawa A, Nomura R, Tsuchida T (1979) Chem Lett 8:1261

Kim HS, Kim JJ, Lee BG, Jung OS, Jang HG, Kang SO (2000) Angew Chem Int Ed 39:4096

Aresta M, Quaranta E, Ciccarese A (1987) J Mol Catal 41:355

Li F, Xia C, Xu L, Sun W, Chen G (2003) Chem Commun 2042

Sun J, Fujita S-I, Zhao F, Arai M (2004) Green Chem 6:613

Takeda N, Inoue S (1978) Bull Chem Soc Jpn 51:3564

Aida T, Inoue S (1983) J Am Chem Soc 105:1304

Paddock RL, Hiyama Y, McKay JM, Nguyen ST (2004) Tetrahedron Lett 45:2023

Lu XB, Pan YZ, Ji DF, He R (2000) Chin Chem Lett 11:589

Ji D, Lu X, He R (2000) Appl Catal A Gen 203:329

Darensbourg DJ, Mackiewicz RM, Phelps AL, Billodeaux DR (2004) Acc Chem Res 37:836

Lu X-B, He R, Bai C-X (2002) J Mol Catal A Chem 186:1

Meléndez J, North M, Pasquale R (2007) Eur J Inorg Chem 2007:3323

Meléndez J, North M, Villuendas P (2009) Chem Commun 2577

Lu X-B, Liang B, Zhang Y-J, Tian Y-Z, Wang Y-M, Bai C-X, Wang H, Zhang R (2004) J Am Chem Soc 126:3732

Paddock RL and Nguyen ST (2004) Chem Commun 1622

Darensbourg DJ, Bottarelli P, Andreatta JR (2007) Macromolecules 40:7727

North M, Pasquale R (2009) Angew Chemie Int Ed Engl 48:2946

Baleiza C, Garcia H (2006) Chem Rev 106:3987

Srivastava R, Srinivas D, Ratnasamy P (2003) Catal Lett 89:81

Collins TJ, Richmond TG, Santarsiero BD, Treco BGRT (1986) J Am Chem Soc 108:2088

Collins TJ, Uffelman ES (1989) Angew Chem Int Ed Engl 101:1552

Patterson RE, Gordon-Wylie SW, Woomer CG, Norman RE, Weintraub ST, Horwitz CP, Collins TJ (1998) Inorg Chem 37:4748

Horwitz CP, Ghosh A (2006) US Patent 7060818

Li F, Xiao L, Xia C, Hu B (2004) Tetrahedron Lett 45:8307

Acknowledgments

AG likes to thank UALR faculty start up grant and Department of Energy (Grant number DE-FG36-06GO86072) for financial assistance to complete the work. AG and SLC also like to thank Arkansas State Technology Authority for a summer scholarship (09-EPSCoR-0072) grant for financial support.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Synthesis of the catalyst, X-ray crystallographic information, GC and IR spectrum of propylene carbonate are described in the supporting information.

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ghosh, A., Ramidi, P., Pulla, S. et al. Cycloaddition of CO2 to Epoxides Using a Highly Active Co(III) Complex of Tetraamidomacrocyclic Ligand. Catal Lett 137, 1–7 (2010). https://doi.org/10.1007/s10562-010-0325-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-010-0325-0