Abstract

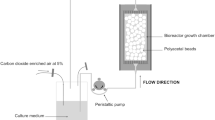

We present in this paper the implementation of an innovative three dimensional (3D) microfabrication technology coupled with numerical simulation to enhance the mass transport in 3D cell culture. The core of this microfabrication technology is a high-resolution projection micro stereolithography (PμSL) using a spatial light modulator as a dynamic mask which enables a parallel fabrication of highly complex 3D microstructures. In this work, a set of poly (ethylene glycol) microfabricated bioreactors are demonstrated with PμSL technology. We observed both experimentally and numerically the regulation of metabolism and the growth of yeast cells by controlling the density of micro-capillaries. Further development of these 3D microfabricated bioreactors is expected to provide artificially constructed tissues for clinical applications.

Similar content being viewed by others

References

R. Dunn, S. Watson, Why climb a ladder when you can take the elevator? Plast Reconstr Surg 107, 283 (2001)

G.I. Taylor, J.H. Palmer, The vascular territories (angiosomes) of the body: experimental study and clinical applications. Br J Plast Surg 40, 113–141 (1987)

Francois Berthiaume and Martin L. Yarmush, Encyclopedia of Physical Science and Technology, 3rd edn. (Academic Press, 2002), 16, p817

Y.K. Ruben, J.S. Henryk, K. Sales, P. Butler, M.S. Alexander, The roles of tissue engineering and vascularisation in the development of micro-vascular networks: a review. Biomaterials 26, 1857–1875 (2005)

R.M. Sutherland et al. Oxygenation and differentiation in multicellular spherioids of human colon carcinoma. Cancer Res. 46, 5320–5329 (1986)

I. Martin et al. Method for quantitative analysis of glycosaminoglycan distribution in cultured natural and engineered cartilage. Ann. Biomed. Eng. 27, 656–662 (1999)

T. Neumann, B.S. Nicholson, J.E. Sanders, Tissue engineering of perfused microvessels. Microvasc Res 66, 59–67 (2003)

L.G. Griffith, B. Wu, M.J. Cima, M.J. Powers, B. Chaignaud, J.P. Vacanti, In virto organogenesis of liver tissue. Ann NY Acad Sci 831, 382–97 (1997)

J.T. Borenstein et al. Microfabrication Technology for Vascularized Tissue Engineering. BMMD 4(3), 167–175 (2002)

S. Levenberg, J. Rouwkema, M. Macdonald, E.S. Garfein, D.S. Kohane, D.C. Darland, R. Marini, C.A. Van Blitterswijk, R.C. Mulligan, P.A.D. Amore, R. Langer, Engineering vascularized skeletal muscle tissue. Nat Biotechnol 23, 879–884 (2005)

C. Sun, N. Fang, D.M. Wu, X. Zhang, Projection micro-stereolithography using digital micro-mirror dynamic mask. Sensors and Actuators A 121, 113–120 (2005)

B.D. Ratner, S.J. Bryant, Biomaterials:Where We Have Been and Where We Are Going. Annu. Rev. Biomed. Eng 6, 41–75 (2004)

Q. Hou, P.A. De Bank, M. Kevin, Shakesheff, Injectable scaffolds for tissue regeneration. J. Mater. Chem. 14, 1915–1923 (2004)

E. Manias, J. Chen, N. Fang, X. Zhang, Polymeric Micromechanical Components with tunable Stiffness. Appl Phys Lett 79(11), 1700–1702 (2001)

N. Fang, C. Sun, X. Zhang, Diffusion-limited photopolymerization in scanning micro-stereolithography. Appl. Phys. A 79, 1839–1842 (2004)

C.G. Xia, C. Sun, D.M. Wu, X. Zhang, N. Fang, 3D Microfabricated Bioreactors. NSTI-Nanotech 2, 140–143 (2006)

L. Michaelis, M. Menten, Die Kinetik der Invertinwirkung. Biochem. Z. 49, 333–369 (1913)

G.E. Briggs, J.B.S. Haldane, A note on the kinetics of enzyme action. Biochem. J. 19, 339 (1925)

K. Otterstedt et al. Switching the mode of metabolism in the yeast Saccharomyces cerevisiae. EMBO reports 5(5), 532–537 (2004)

T.G. Kaufmann, E.F. Leonard, Mechanism of interfacial mass transfer in membrane transport. AIChE J. 14, 421 (1968)

F. Sherman, J. Hicks, Getting started with yeast. Methods in Enzymology 194, 3–21 (1991)

A.A. Vicente, M. Dluhy, E.C. Ferreira, M. Mota, J.A. Teixeira, Mass transfer properties of glucose and O2in Saccharomyces cerevisiae flocs. Biochem Eng J 2, 35–43 (1998)

C. Verduyn, T.P.L. Zomerdijk, J.P. Van Dijken, W.A. Scheffers, Continuous measurement of ethanol production by aerobic yeast suspension with and enzyme electrode. Appl Microbiol Biotechnol 19, 181–185 (1984)

Acknowledgement

This project was supported by the Gauthier Exploratory Research Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, C., Fang, N.X. 3D microfabricated bioreactor with capillaries. Biomed Microdevices 11, 1309–1315 (2009). https://doi.org/10.1007/s10544-009-9350-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10544-009-9350-4