Abstract

Objectives

To optimize conversion of rutin to isoquercetin by commercial α-l-rhamnosidase using high hydrostatic pressure (HHP).

Results

The de-rhamnosylation activity of α-l-rhamnosidase for isoquercetin production was maximal at pH 6.0 and 50 °C using HHP (150 MPa). The enzyme showed high specificity for rutin. The specific activity for rutin at HHP was 1.5-fold higher than that at atmospheric pressure. The enzyme completely hydrolysed 20 mM rutin in tartary buckwheat extract after 2 h at HHP, with a productivity of 10 mM h−1. The productivity and conversion were 2.2- and 1.5-fold higher at HHP than at atmospheric pressure, respectively.

Conclusions

This is the first report concerning the enzymatic hydrolysis of isoquercetin in tartary buckwheat at HHP.

Similar content being viewed by others

References

Amado NG, Cerqueira DM, Menezes FS, Mendes da Silva JF, Vivaldo MN, Abreu JG (2009) Isoquercitrin isolated from hyptis fasciculata reduces glioblastoma cell proliferation and changes beta-catenin cellular localization. Anticancer Drugs 20:543–552

Dirix C, Duvetter T, Loey AV, Hendrickx M, Heremans K (2005) The in situ observation of the temperature and pressure stability of recombinant Aspergillus aculeatus pectin methylesterase with Fourier transform IR spectroscopy reveals an unusual pressure stability of beta-helices. Biochem J 392:565–571

Eisenmenger MJ, Reyes-De-Corcuera JI (2009a) High pressure enhancement of enzymes: a review. Enz Microb Technol 45:331–347

Eisenmenger MJ, Reyes-De-Corcuera JI (2009b) High hydrostatic pressure increased stability and activity of immobilized lipase in hexane. Enz Microb Technol 45:118–125

Kim YS, Yeom SJ, Oh DK (2011) Reduction of galactose inhibition via the mutation of β-galactosidase from Caldicellulosiruptor saccharolyticus for lactose hydrolysis. Biotechnol Lett 33:353–358

Kuntić V, Pejić N, Ivković B, Vujić Z, Ilić K, Mićić S, Vukojević V (2007) Isocratic RP-HPLC method for rutin determination in solid oral dosage forms. J Pharm Biomed Anal 43:718–721

Lee HS, Park CH, Park BJ, Kwon SM, Chang KJ, Kim SL (2006) Rutin, catechin, derivatives, and chemical components of tartary buckwheat (Fagopyrum tataricum Gaertn.) sprouts. Korean J Crop Sci 51:277–282

Lu Z, Wang J, Lin S, Zhang Y (2012) Degradation of rutin into isoquercitrin by Bacillus litoralis strain C44. IOSR J Eng 2:1154–1161

Makino T, Shimizu R, Kanemaru M, Suzuki Y, Moriwaki M, Mizukami H (2009) Enzymatically modified isoquercitrin, α-oligoglucosyl quercetin 3-O-glucoside, is absorbed more easily than other quercetin glycosides or aglycone after oral administration in rats. Biol Pharm Bull 32:2034–2040

Mateo C, Monti R, Pessela BC, Fuentes M, Torres R, Guisán JM, Fernández-Lafuente R (2004) Immobilization of lactase from Kluyveromyces lactis greatly reduces the inhibition promoted by glucose. full hydrolysis of lactose in milk. Biotechnol Prog 20:1259–1262

Palaniyandi SA, Damodharan K, Lee KW, Yang SH, Suh JW (2015) Enrichment of ginsenoside Rd in Panax ginseng extract with combination of enzyme treatment and high hydrostatic pressure. Biotechnol Bioprocess Eng 20:608–613

Park SY, Kim JH, Kim DH (2005) Purification and characterization of quercitrin-hydrolyzing α-l-rhamnosidase from Fusobacterium K-60, a human intestinal bacterium. J Microbiol Biotechnol 15:519–524

Pedro HAL, Alfaia AJ, Marques J, Vila-Real HJ, Calado A, Ribeiro MHL (2007) Design of an immobilized enzyme system for naringin hydrolysis at high-pressure. Enzyme Microb Technol 40:442–446

Real HJV, Alfaia AJ, Calado ART, Ribeiro MHL (2007) High pressure–temperature effects on enzymatic activity: naringin bioconversion. Food Chem 102:565–570

Yadav V, Yadav PK, Yadav S, Yadav KDS (2010) α-l-Rhamnosidase: a review. Proc Biochem 45:1226–1235

You HJ, Ahn HJ, Ji GE (2010) Transformation of rutin to antiproliferative quercetin-3-glucoside by Aspercillus niger. J Agric Food Chem 58:10886–10892

Zhang R, Yao Y, Wang Y, Ren G (2011) Antidiabetic activity of isoquercetin in diabetic KK-Ay mice. Nutr Metab (Lond) 8:85

Zhang R, Zhang BL, Xie T, Li GC, Tuo Y, Xiang YT (2015) Biotransformation of rutin to isoquercirtin using recombinant α-l-rhamnosidase from Bifidobacterium breve. Biotechnol Lett 37:1257–1264

Acknowledgments

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (grant number 2015R1D1A1A01059570).

Supplementary Information

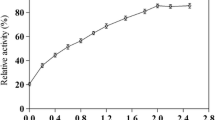

Supplementary Fig. 1—Effect of enzyme concentration on isoquercetin production by commercial α-l-rhamnosidase. The reactions were performed in 50 mM McIlvaine buffer (pH 6.0) containing 0.5–4 U enzyme ml −1 and 20 mM rutin with 5 % DMSO at 50 °C for 3 h. Error bars indicate the standard deviations of triplicate samples.

Supplementary Fig. 2—Effect of substrate (rutin) concentration on isoquercetin production by commercial α-l-rhamnosidase. The reactions were performed in 50 mM McIlvaine buffer (pH 6.0) containing 3 U enzyme ml −1 and 1–20 mM rutin with 5 % DMSO at 50 °C for 3 h. Error bars indicate the standard deviations of triplicate samples.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kim, DY., Yeom, SJ., Park, CS. et al. Effect of high hydrostatic pressure treatment on isoquercetin production from rutin by commercial α-l-rhamnosidase. Biotechnol Lett 38, 1775–1780 (2016). https://doi.org/10.1007/s10529-016-2157-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-016-2157-5