Abstract

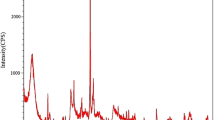

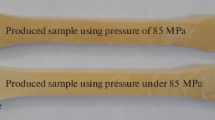

In this paper, acrylonitrile-butadiene-styrene (ABS) nanocomposite foams are produced using carbon dioxide through the solid-state batch process. Microcellular closed-cell foams are produced with the relative density ranging from 0.38 to 0.97. The effects of the processing conditions on the density, morphology, and flexural properties of ABS and its nanocomposite foams are studied. It is found that nano-clay particles, as nucleating sites, play an important role in reducing the size of cells and increasing their number in the unit volume of foamed polymer, as well as increasing the flexural modulus of foam through reinforcing its matrix.

Similar content being viewed by others

References

Martini, J. E. The Production and Analysis of Microcellular Foam, Ph. D. dissertation, MIT (1981)

Kumar, V. and Suh, N. P. A process for making microcellular thermoplastic parts. Polymer Engineering and Science, 30, 1323–1329 (1990)

Murray, R. E., Weller, J. E., and Kumar, V. Solid-state microcellular acrylonitrile-butadynestyrene foams. Cellular Polymers, 19, 413–426 (2000)

Kumar, V. and Weller, J. E. Production of microcellular polycarbonate using carbon dioxide for bubble nucleation. ASME Journal of Engineering for Industry, 116, 413–420 (1994)

Aubert, J. H. and Clough, R. H. Low-density, microcellular polystyrene foams. Polymer, 26, 2047–2054 (1985)

Nadella, K. and Kumar, V. Extrusion of microcellular PVC. 63rd Society of Plastics Engineers, Knovel, New York (2005)

Martinache, J. D., Royer, J. R., Siripurapu, S., Hénon F. E., Genzer, J., Khan, S. A., and Carbonell, R. G. Processing of polyamide 11 with supercritical carbon dioxide. Industrial and Engineering Chemistry Research, 40, 5570–5577 (2001)

Miller, D. and Kumar, V. Fabrication of microcellular HDPE foams in a sub-critical CO2 process. Cellular Polymers, 28, 25–40 (2009)

Goel, S. K. and Beckman, E. J. Generation of microcellular polymeric foams using supercritical carbon dioxide I: effect of pressure and temperature on nucleation. Polymer Engineering and Science, 34, 1137–1147 (1994)

Kumar, V., Nadella, K., Branch, G., and Flinn, B. Extrusion of microcellular foams using presaturated pellets and solid-state nucleation. Cellular Polymers, 23, 369–385 (2004)

Li, W., Nadella, K., and Kumar, V. Manufacturing of micro-scale open-cell polymeric foams using the solid-state foaming process. Transactions of NAMRI/SME, 31, 371–378 (2003)

Kumar, V., VanderWel, M., Weller, J. E., and Seeler, K. A. Experimental characterization of tensile behavior of microcellular polycarbonate foams. ASME Journal of Engineering Materials and Technology, 116, 439–445 (1994)

Lin, C. K., Chen, S. H., Liou, H. Y., and Tian, C. C. Study on mechanical properties of ABS parts in microcellular injection molding process. 63rd Society of Plastics Engineers, Knovel, New York (2005)

Fu, J., Jo, C., and Naguib, H. The effect of the processing parameters on the mechanical properties of PMMA microcellular foams. ANTEC, 2616–2621 (2005)

Bureau, M. and Kumar, V. Fracture toughness of high density polycarbonate microcellular foams. Journal of Cellular Plastics, 42, 229–240 (2006)

Juntunen, R. P., Kumar, V., Weller, J. E., and Bezubic, W. R. Impact strength of high density microcellular PVC foams. Journal of Vinyl and Additive Technology, 6, 93–99 (2000)

Kumar, V., Juntunen, R. P., and Barlow, C. Impact strength of high relative density solid state carbon dioxide blown crystallizable poly (ethylene terephthalate) microcellular foams. Cellular Polymers, 19, 25–37 (2000)

Seeler, K. A. and Kumar, V. Tension-tension fatigue of microcellular polycarbonate: initial results. Journal of Reinforced Plastics and Composites, 12, 359–376 (1993)

Arun, P., Wing, G., Kumar, V., and Tuttle, M. The effect of CO2 on the creep response of polycarbonate. Polymer Engineering and Science, 45, 1639–1644 (2005)

Lee, L. J., Zeng, C., Cao, X., Han, X., Shen, J., and Xu, G. Polymer nanocomposite foams. Composites Science and Technology, 65, 2344–2363 (2005)

Jo, C. and Naguib, H. E. Effect of nanoclay and foaming conditions on the mechanical properties of HDPE-clay nanocomposite foams. Journal of Cellular Plastics, 43, 111–121 (2007)

Nam, P. H., Maiti, P., Okamoto, M., Kotaka, T., Nakayama, T., Takada, M., Ohshima, M., Usuki, A., Hasegawa, N., and Okamoto, H. Foam processing and cellular structure of polypropylene/clay nanocomposites. Polymer Engineering and Science, 42, 1907–1918 (2002)

Alian, A. M. and Abu-Zahra, N. H. Mechanical properties of rigid foam PVC-clay nanocomposites. Polymer-Plastics Technology and Engineering, 48, 1014–1019 (2009)

Ito, Y., Yamashita, M., and Okamoto, M. Foam processing and cellular structure of polycarbonatebased nanocomposites. Macromolecular Materials and Engineering, 291, 773–783 (2006)

Zhu, B., Zha, W., Yang, J., Zhang, C., and Lee, L. J. Layered-silicate based polystyrene nanocomposite microcellular foam using supercritical carbon dioxide as blowing agent. Polymer, 51, 2177–2184 (2010)

Yeh, J. M., Chang, K. C., Peng, C. W., Lai, M. C., Hung, C. B., Hsu, S. C., Hwang, S. S., and Lin, H. R. Effect of dispersion capability of organoclay on cellular structure and physical properties of PMMA/clay nanocomposite foams. Materials Chemistry and Physics, 115, 744–750 (2009)

Yuan, M. and Turng, L. S. Microstructure and mechanical properties of microcellular injection molded polyamide-6 nanocomposites. Polymer, 46, 7273–7292 (2005)

Ema, Y., Ikeya, M., and Okamoto, M. Foam processing and cellular structure of polylactide-based nanocomposites. Polymer, 47, 5350–5359 (2006)

Hwang, S. S., Liu, S. P., Hsu, P. P., Yeh, J. M., Chang, K. C., and Lai, Y. Z. Effect of organoclay on the mechanical/thermal properties of microcellular injection molded PBT-clay nanocomposites. International Communications in Heat and Mass Transfer, 37, 1036–1043 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohyeddin, A., Fereidoon, A. & Taraghi, I. Study of microstructure and flexural properties of microcellular acrylonitrile-butadiene-styrene nanocomposite foams: experimental results. Appl. Math. Mech.-Engl. Ed. 36, 487–498 (2015). https://doi.org/10.1007/s10483-015-1925-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10483-015-1925-9