Abstract

Thermotolerant inulin-utilizing yeast strains were successfully isolated in this study. Among the isolated strains, Kluyveromyces marxianus DBKKU Y-102 was found to be the most effective strain for direct ethanol fermentation at high temperature from fresh Jerusalem artichoke (JA) tubers without inulin hydrolysis under consolidated bioprocessing (CBP). The maximum ethanol concentrations produced by this strain under the optimum culture conditions were 104.83 and 97.46 g L−1 at 37 and 40 °C, respectively. Data from this study clearly demonstrated that the use of thermotolerant inulin-utilizing yeast K. marxianus for ethanol production from fresh JA tubers in the CBP process not only provided high levels of ethanol, but also could eliminate the addition of external enzyme for inulin hydrolysis, which might lead to the reduction of operating costs. The expression of genes involved in carbohydrate metabolism in K. marxianus DBKKU Y-102 during ethanol fermentation was investigated by real-time RT-PCR, and the results revealed that expression levels were distinctive depending on the growth phase and growth conditions. However, among the genes tested, adh4 and tdh2 were highly expressed under high temperature conditions in both exponential- and stationary-growth phases, suggesting that these genes might play a crucial role in acquiring thermotolerance ability in this organism under stress conditions.

Similar content being viewed by others

References

Alexandre H, Charpentier C (1998) Biochemical aspects of stuck and sluggish fermentation in grape must. J Ind Microbiol Biotechnol 20:20–27

Anasontzis GE, Zerva A, Stathopoulou PM, Haralampidis K, Diallinas G, Karagouni AD, Hatzinikolaou DG (2011) Homologous over-expression of xylanase in Fusarium oxysporum increases ethanol productivity during consolidated bioprocessing (CBP) of lignocellulosics. J Biotechnol 152:16–23

Auesukaree C, Koedrith P, Saenpayavai P, Asvarak T, Benjaphokee S, Sugiyama M, Kaneko Y, Harashima S, Boonchird C (2012) Characterization and gene expression profiles of thermotolerant Saccharomyces cerevisiae isolates from Thai fruits. J Biosci Bioeng 114(2):144–149

Bai FW, Chen LJ, Zhang Z, Anderson WA, Moo-Young M (2004) Continuous ethanol production and evaluation of yeast cell lysis and viability loss under very high gravity medium conditions. J Biotechnol 110(3):287–293

Banat IM, Nigam P, Marchat R (1992) Isolation of thermotolerant, fermentative yeasts growing at 52°C and producing ethanol at 45 and 50 °C. World J Microbiol Biotechnol 8:259–263

Barthomeuf C, Regerat F, Pourrat H (1991) Production of inulinase by a new mold of Penicillium rugulosum. J Ferment Bioeng 72(6):491–494

Birch RM, Walker GM (2000) Influence of magnesium ions on heat shock and ethanol stress responses of Saccharomyces cerevisiae. Enzyme Microb Technol 26:678–687

Castro RG, Baigorí DM, Siñeriz F (1995) A plate technique for screening of inulin degrading microorganisms. J Microbiol Methods 22:51–56

Chi ZM, Chi Z, Zhang T, Liu GL, Yue LX (2009) Inulinase expressing microorganisms and applications of inulinases. Appl Microbiol Biotechnol 82:211–220

Chubey BB, Dorell DG (1974) Jerusalem artichoke—a potential fructose crop for the prairies. Can Inst Food Sci Technol J 7:98–106

Cooper TG, Britton C, Brand L, Sumrada R (1979) Addition of basic amino acids prevents G-1 arrest of nitrogen-starved cultures of Saccharomyces cerevisiae. J Bacteriol 137:1447–1448

Dorell DG, Chubey BB (1977) Irrigation, fertilizer, harvest dates and storage effects on the reducing sugar and fructose concentration of Jerusalem artichoke tubers. Can J Plant Sci 57:591–596

Dubois M, Gilles KA, Hamilton JR, Robers PA, Smith F (1956) Colourimetric method for determination of sugar and related substances. Anal Chem 28:350–356

Fonseca GG, Heinzle E, Wittmann C, Gombert AK (2008) The yeast Kluyveromyces marxianus and its biotechnological potential. Appl Microbiol Biotechnol 79:339–354

Ge XY, Zhang WG (2005) A shortcut to the production of high ethanol concentration from Jerusalem artichoke tubers. Food Technol Biotechnol 43(3):241–246

Ge XY, Qian H, Zhang WG (2010) Enhancement of l-Lactic acid production in Lactobacilus casei from Jerusalem artichoke tubers by kinetic optimization and citrate metabolism. J Ind Microbiol Biotechnol 20(1):101–109

Grubb CF, Mawson AJ (1993) Effects of elevated solute concentrations on the fermentation of lactose by Kluyveromyces marxianus Y-113. Biotechnol Lett 15:621–626

Harju S, Fedosyuk H, Peterson KR (2004) Rapid isolation of yeast genomic DNA: Bust n’ Grab. BMC Biotechnol 4:8

Hashem M, Zohri ANA, Ali MMA (2013) Optimization of the fermentation conditions for ethanol production by new thermotolerant yeast strains of Kluyveromyces sp. Afr J Microbiol Res 7(37):4550–4561

Hu N, Yuan B, Sun J, Wang SA, Li FL (2012) Thermotolerant Kluyveromyces marxianus and Saccharomyces cerevisiae strains representing potentials for bioethanol production from Jerusalem artichoke by consolidated bioprocessing. Appl Microbiol Biotechnol 95:1359–1368

Huang J, Cai J, Wang J, Zhu XC, Huang L, Yang ST, Xu ZN (2011) Efficient production of butyric acid from Jerusalem artichoke by immobilized Clostridium tyrobutyricum in a fibrous-bed bioreactor. Bioresour Technol 102(4):3923–3926

Ingledew WM (1999) Alcohol production by Saccharomyces cerevisiae: a yeast primer. In: Jacques KA, Lyons TP, Kelsall DR (eds) The alcohol textbook-a reference for the beverage, fuel and industrial alcohol industries. Nottingham University Press, Nottingham, pp 49–87

Ingram LO, Buttke TM (1984) Effects of alcohols on microorganisms. Adv Microb Physiol 25:253–300

Jin MJ, Balan V, Gunawan C, Dale BE (2011) Consolidated bioprocessing (CBP) performance of Clostridium phytofermentans on AFEX-treated corn stover for ethanol production. Biotechnol Bioeng 108:1290–1297

Kurtzman CP, Fell JW (1998) The yeasts: a taxonomic study, 4th edn. Elsevier, Amsterdam

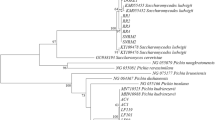

Kurtzman CP, Robnett CJ (1998) Identification and phylogeny of ascomycetous yeasts from analysis of nuclear large subunit ({26S}) ribosomal DNA partial sequences. Anton Leeuw Int J G 73(4):331–371

Kusch H, Engelmann S, Bode R, Albrecht D, Morschhäuser J, Hecker M (2008) A proteomic view of Candida albicans yeast cell metabolism in exponential and stationary growth phases. Int J Med Microbiol 298:291–318

Laopaiboon L, Thanonkeo P, Jaisil P, Laopaiboon P (2007) Ethanol production from sweet sorghum juice in batch and fed-batch fermentations by Saccharomyces cerevisiae. World J Microbiol Biotechnol 23:1497–1501

Lertwattanasakul N, Sootsuwan K, Limtong S, Thanonkeo P, Yamada M (2007) Comparison of the gene expression patterns of alcohol dehydrogenase isozymes in the thermotolerant yeast Kluyveromyces marxianus and their physiological functions. Biosci Biotechnol Biochem 71(5):1170–1182

Lertwattanasakul N, Rodrussamee N, Suprayogi Limtong S, Thanonkeo P, Kosaka T, Yamada M (2011) Utilization capability of sucrose, raffinose and inulin and its less-sensitiveness to glucose repression in thermotolerant yeast Kluyveromyces marxianus DBKU 3-1042. AMB Express 1:20

Lertwattanasakul N, Kosaka T, Hosoyama A, Suzuki Y, Rodrussamee N, Matsutani M, Murata M, Fujimoto N, Suprayogi Tsuchikane K, Limtong S, Fujita N, Yamada M (2015) Genetic basis of the highly efficient yeast Kluyveromyces marxianus: complete genome sequence and transcriptome analyses. Biotechnol Biofuels 8:47

Liang JJ, Zhang MI, Ding M, Mai ZM, Wu SX, Du Y, Feng JX (2014) Alcohol dehydrogenase from Kluyveromyces marxianus: heterologous expression in Escherichia coli and biochemical characterization. BMC Biotechnol 14:45

Lim SH, Ryu JM, Lee H, Jeon JH, Sok DE, Choi ES (2011) Ethanol fermentation from Jerusalem artichoke powder using Saccharomyces cerevisiae KCCM50549 without pretreatment for inulin hydrolysis. Bioresour Technol 102(2):2109–2111

Limtong S, Sringiew C, Yongmanitchai W (2007) Production of fuel ethanol at high temperature from sugar cane juice by newly isolated Kluyveromyces marxianus. Bioresour Technol 98:3367–3374

Livak KJ, Schmittgen TD (2001) Analysis of relative gene expression data using real-time quantitative PCR and the \( {2}^{\Delta \Delta {\text {C}}_{\rm T}}\) method. Methods 25:402–408

Lynd LR, van Zyl WH, McBride JE, Laser M (2005) Consolidated bioprocessing of cellulosic biomass: an update. Curr Opin Biotechnol 16:577–583

McCracken LD, Gong CS (1982) Fermentation of cellulose and hemicellulose carbohydrates by thermotolerant yeasts. Biotechnol Bioeng 12:91

Mustofa A, Suranto (2009) Activity of Zymomonas mobilis on ethanol products made of cashew nut apple (Anacardium occidentale) with different sources of nitrogen. Nusant Biosci 1:105–109

Narendranath NV, Power R (2005) Relationship between pH and medium dissolved solids in terms of growth and metabolism of Lactobacilli and Saccharomyces cerevisiae during ethanol production. Appl Environ Microbiol 71(5):2239–2243

Negro MJ, Ballesteros I, Manzanares P, Oliva JM, Saez F, Ballesteros M (2006) Inulin-containing biomass for ethanol production. Appl Biochem Biotechnol 132(1):922–932

Nonklang S, Abdel-Banat BM, Cha-aim K, Moonjai N, Hoshida H, Limtong S, Yamada M, Akada R (2008) High-temperature ethanol fermentation and transformation with linear DNA in the thermotolerant yeast Kluyveromyces marxianus DMKU3-1042. Appl Environ Microbiol 74:7514–7521

Nuanpeng S, Laopaiboon L, Srinophakun P, Klanrit P, Jaisil P, Laopaiboon P (2011) Ethanol production from sweet sorghum juice under very high gravity conditions: Batch, repeated-batch and scale up fermentation. Electron J Biotechnol 14(1). http://www.ejbiotechnology.info/index.php/ejbiotechnology/article/view/v14n1-2/1259

O’Donnell K (1993) Fusarium and its near relatives. In: Reynolds DR, Taylor JW (eds) The fungal holomorph: mitotic, meiotic and pleomorphic speciation in fungal systematics. CAB International, Wallingford, pp 225–233

Okamoto K, Nitta Y, Maekawa N, Yanase H (2011) Direct ethanol production from starch, wheat bran and rice straw by the white rot fungus Trametes hirsuta. Enzyme Microb Technol 48:273–277

Olsson L, Hahn-Hägerdal B (1996) Fermentation of lignocellulosic hydrolysates for ethanol production. Enzyme Microb Technol 18:312–331

Ozmihci S, Kargi F (2007) Comparison of yeast strains for batch ethanol fermentation of cheese-whey powder (CWP) solution. Lett Appl Microbiol 44:602–606

Pereira FB, Guimarães PMR, Teixeira JA, Domingues L (2010) Optimization of low-cost medium for very high gravity ethanol fermentations by Saccharomyces cerevisiae using statistical experimental designs. Bioresour Technol 101:7856–7863

Pratt-Marshall PL, Bryce JH, Stewart GG (2003) The effects of osmotic pressure and ethanol on yeast viability and morphology. J Inst Brew 109:218–228

Razmovski RN, Sciban MB, Vucurovic VM (2011) Bioethanol production from Jerusalem artichoke by acid hydrolysis. Rom Biotechnol Lett 16(5):6497–6503

Russell I (2003) Understanding yeast fundamentals. In: Jacques KA, Lyons TP, Kelsall DR (eds) The alcohol textbook-a reference for the beverage, fuel and industrial alcohol industries. Nottingham University Press, Nottingham, pp 85–119

Saitou N, Nei M (1987) The neighbor-joining method. A new method for reconstructing phylogenetic trees. Mol Biol Evol 4:406–425

Silalertruksa T, Gheewala SH (2010) Security of feedstocks supply for future bioethanol production in Thailand. Energy Policy 38(11):7476–7486

Sootsuwan K, Irie A, Murata M, Lertwattanasakul N, Thanonkeo P, Yamada M (2007) Thermotolerant Zymomonas mobilis: comparison of ethanol fermentation capability with that of an efficient type strain. Open Biotechnol J 1:52–58

Sree NK, Sridhan M, Suresh K, Banat IM, Rao LV (2000) Isolation of thermotolerant, osmotolerant, flocculating, Saccharomyces cerevisiae for ethanol production. Bioresour Technol 72:43–46

Sumrada R, Cooper TG (1978) Basic amino acid inhibition of cell division and macromolecular synthesis of Saccharomyces cerevisiae. J Gen Microbiol 108:45–56

Swanton CJ, Cavers PB, Clements DR, Moore MJ (1992) The biology of Canadian weeds: 101 Helianthus tuberosus L. Can J Plant Sci 72:1367–1382

Szambelan K, Nowak K, Chrapkowska KJ (2004) Comparison of bacterial and yeast ethanol fermentation yield from Jerusalem artichoke (Helianthus tuberosus L.) tubers pulp and juices. Acta Sci Pol Technol Aliment 3(1):45–53

Szambelan K, Nowak J, Jelen H (2005) The composition of Jerusalem artichoke (Helianthus tuberosus L.) spirits obtained from fermentation with bacteria and yeasts. Eng Life Sci 5:68–71

Tamura K, Peterson D, Peterson N, Stecher G, Nei M, Kumar S (2011) Mega 5: molecular evolutionary genetics analysis using maximum likelihood evolutionary distance, and maximum parsimony methods. Mol Biol Evol 28:2731–2739

Thanonkeo P, Sootsuwan K, Laopaiboon P, Yamada M (2007) Magnesium ions improve growth and ethanol production of Zymomonas mobilis under heat or ethanol stress. Biotechnol 6(1):112–119

Thanonkeo P, Monkeang R, Saksirirat W, Thanonkeo S, Akiyama K (2010) Cloning and molecular characterization of glyceraldehydes-3-phosphate dehydrogenase gene from thermotolerant mushroom, Lentinus polychrous. Afr J Biotechnol 9(22):3242–3251

Thanonkeo P, Thanonkeo S, Charoensuk K, Yamada M (2011) Ethanol production from Jerusalem artichoke (Helianthus tuberosus L.) by Zymomonas mobilis TISTR548. Afr J Biotechnol 10(52):10691–10697

Thomas KC, Ingledew WM (1990) Fuel alcohol production: effects of free amino nitrogen on fermentation of very-high-gravity wheat mashes. Appl Environ Microbiol 56:2046–2050

Walker GM (1994) The roles of magnesium in biotechnology. Crit Rev Biotechnol 14:311–354

Walter S, Buchner J (2002) Molecular chaperones-cellular machines for protein folding. Angew Chem Int Ed Engl 41(7):1098–1113

Yee KL, Rodriquez MJ, Thompson OA, Fu C, Wang ZY, Davison BH, Mielenz JR (2014) Consolidated bioprocessing of transgenic switchgrass by an engineered and evolved Clostridium thermocellum strain. Biotechnol Biofuels 7:75

Ying Z, Ma R, Zhao Z, Zhou Z, Lu W, Chen M (2010) ire, an exogenous gene from Deinococcus radiodurans, improves the growth and ethanol production by a Zymomonas mobilis strain under ethanol and acid stresses. J Microbiol Biotechnol 20:1156–1162

Yuan WJ, Zhao XQ, Ge XM, Bai FW (2008) Ethanol fermentation with Kluyveromyces marxianus from Jerusalem artichoke grown in salina and irrigated with a mixture of seawater and freshwater. J Appl Microbiol 105:2076–2083

Yuan WY, Yuan WJ, Chang BL, Chen LJ, Bai FW (2010) Ethanol production from Jerusalem artichoke by SSF fermentation using Kluyveromyces cicerispora. J Biotechnol 150S:367–368

Yuan WJ, Chang BL, Ren JG, Liu JP, Bai FW, Li YY (2011) Consolidated bioprocessing strategy for ethanol production from Jerusalem artichoke tubers by Kluyveromyces marxianus under high gravity conditions. J Appl Microbiol 112:38–44

Zhang T, Chi Z, Zhao CH, Chi ZM, Gong F (2010) Bioethanol production from hydrolysates of inulin and the tuber meal of Jerusalem artichoke by Saccharomyces sp. W0. Bioresour Technol 101(21):8166–8170

Zhao CH, Zhang T, Li M, Chi CM (2010) Single cell oil production from hydrolysates of inulin and extract of tubers of Jerusalem artichoke by Rhodotorula mucilaginosa TJY15a. Process Biochem 45:1121–1126

Zoecklein BW, Fugelsang KC, Gump BH, Nury FS (1995) Wine analysis and production. Chapman & Hall, New York

Acknowledgments

This research was supported by the program of Strategic Scholarships for Frontier Research Network for the Ph.D. Program Thai Doctoral degree from the Office of the Higher Education Commission, Thailand. Apart of this works was also supported by the National Research University (NRU) Project of Khon Kaen University for P. Thanonkeo under the Project Number NRU543048.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Charoensopharat, K., Thanonkeo, P., Thanonkeo, S. et al. Ethanol production from Jerusalem artichoke tubers at high temperature by newly isolated thermotolerant inulin-utilizing yeast Kluyveromyces marxianus using consolidated bioprocessing. Antonie van Leeuwenhoek 108, 173–190 (2015). https://doi.org/10.1007/s10482-015-0476-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10482-015-0476-5