Abstract

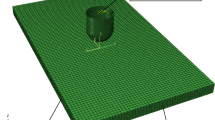

High velocity impact on composite aircraft structures leads to the formation of flexural waves that can cause severe damage to the structure. Damage and failure can occur within the plies and/or in the resin rich interface layers between adjacent plies. In the present paper a modelling methodology is documented that captures intra- and inter-laminar damage and their interrelations by use of shell element layers representing sub-laminates that are connected with cohesive interface layers to simulate delamination. This approach allows the simulation of large structures while still capturing the governing damage mechanisms and their interactions. The paper describes numerical algorithms for the implementation of a Ladevèze continuum damage model for the ply and methods to derive input parameters for the cohesive zone model. By comparison with experimental results from gas gun impact tests the potential and limitations of the modelling approach are discussed.

Similar content being viewed by others

References

MAAXIMUS More Affordable Aircraft through EXtended, Integrated and Mature NUmerical Sizing, EU Aeronautics Research Project, FP7-213371, 2008-2013.

Olsson R.: Mass criterion for wave controlled impact response of composite plates. Compos. A: Appl. Sci. Manuf. 31(8), 879–887 (2000)

Ladevèze P., LeDantec E.: Damage modelling of the elementary ply for laminated composites. Compos. Sci. Technol. 43(3), 257–267 (1992)

Allix O., Ladeveze P.: Interlaminar interface modelling for the prediction of delamination. Compos. Struct. 22(4), 235–242 (1992)

Johnson A.F., Pickett A.K., Rozycki P.: Computational methods for predicting impact damage in composite structures. Compos. Sci. Technol. 61(15), 2183–2192 (2001)

Pickett A.K., Fouinneteau M.R.C., Middendorf P.: Test and modelling of impact on pre-loaded composite panels. Appl. Compos. Mater. 16(4), 225–244 (2009)

Heimbs S., Bergmann T., Schueler D., Toso-Pentecôte N.: High velocity impact on preloaded composite plates. Compos. Struct. 111, 158–168 (2014)

Turon A., Davila C.G., Camanho P.P., Costa J.: An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models. Eng. Fract. Mech. 74(10), 1665–1682 (2007)

Chadwick A., Evans R., Findlay D., Rickett B., Spriggs J.: Airport Runway Debris Detection Study Report no: 72/01/R/146/U. Technical report, Roke Manor Research Limited (2001)

Wu D., Salerno A., Malter U., Aoki R., Kochendörfer R., Kächele P.K., et al.: Inspection of aircraft structural components using lockin-thermography. Quantitative Infrared Thermography, QIRT. 96, 251–256 (1996)

Imielińska K., Castaings M., Wojtyra R., Haras J., Le Clezio E., Hosten B.: Air-coupled ultrasonic C-scan technique in impact response testing of carbon fibre and hybrid: glass, carbon and Kevlar/epoxy composites. J. Mater. Process. Technol. 157, 513–522 (2004)

Liu D.: Impact-induced delamination—a view of bending stiffness mismatching. J. Compos. Mater. 22(7), 674–692 (1988)

Guynn, E. G., and O’Brien, T. K. (1985). The influence of lay-up and thickness on composite impact damage and compression strength. In Proc 26th AIAA/ASME/ASCE/AHS/ASC Structures, Structural dynamics and Materials Conf, Orlando, FL (pp. 15–17).

Kachanov, L. (2013). Introduction to continuum damage mechanics (Vol. 10). Springer Science & Business Media.

Nezhad H.Y., Merwick F., Frizzell R.M., McCarthy C.T.: Numerical analysis of low-velocity rigid-body impact response of composite panels. International Journal of Crashworthiness. 20(1), 27–43 (2015)

McCarthy M.A., Xiao J.R., Petrinic N., Kamoulakos A., Melito V.: Modelling bird impacts on an aircraft wing–part 1: material modelling of the fibre metal laminate leading edge material with continuum damage mechanics. International Journal of Crashworthiness. 10(1), 41–49 (2005)

Mishnaevsky L., Dong M., Hoenle S., Schmauder S.: Computational mesomechanics of particle-reinforced composites. Comput. Mater. Sci. 16(1), 133–143 (1999)

Belytschko T., Liu W.K., Moran B.: Nonlinear Finite Elements for Continua and Structures, 1 edn. Wiley, Chichester (2000)

Mi Y., Crisfield M.A., Davies G.A.O., Hellweg H.B.: Progressive delamination using interface elements. J. Compos. Mater. 32(14), 1246–1272 (1998)

Cui W., Wisnom M.R.: A combined stress-based and fracture-mechanics-based model for predicting delamination in composites. Composites. 24(6), 467–474 (1993)

Turon A., Camanho P.P., Costa J., Dávila C.G.: An interface damage model for the simulation of delamination under variable-mode ratio in composite materials. NASA/Technical Memorandum. 213277, (2004)

Reeder J.R.: An evaluation of mixed-mode delamination failure criteria. NASA/Technical Memorandum. 104210, (1992)

Wu, E. M., and Reuter Jr, R. C. (1965). Crack extension in fiberglass reinforced plastics (vol. 275). Illinois Univ. Dept. of Theoretical and Applied Mechanics.

Allix O., Lévêque D., Perret L.: Identification and forecast of delamination in composite laminates by an interlaminar interface model. Compos. Sci. Technol. 58(5), 671–678 (1998)

Choi H.Y., Chang F.-K.: A model for predicting damage in graphite/epoxy laminated composites resulting from low-velocity point impact. J. Compos. Mater. 26(14), 2134–2169 (1992)

Geubelle P.H., Baylor J.S.: Impact-induced delamination of composites: a 2D simulation. Compos. Part B. 29(5), 589–602 (1998)

Ladevèze P., Lubineau G.: An enhanced mesomodel for laminates based on micromechanics. Compos. Sci. Technol. 62(4), 533–541 (2002)

Zou Z., Reid S.R., Li S., Soden P.D.: Modelling interlaminar and intralaminar damage in filament-wound pipes under quasi-static indentation. J. Compos. Mater. 36(4), 477–499 (2002)

Camanho P.P., Davila C.G., De Moura M.F.: Numerical simulation of mixed-mode progressive delamination in composite materials. J. Compos. Mater. 37(16), 1415–1438 (2003)

Hallett, S. R. and Harper, P. W. (2015). Modelling delamination with cohesive interface elements. In Numerical modelling of failure in advanced composite materials (pp. 55–72). Elsevier.

Borg R., Nilsson L., Simonsson K.: Simulation of delamination in fiber composites with a discrete cohesive failure model. Compos. Sci. Technol. 61(5), 667–677 (2001)

Heimbs S., Heller S., Middendorf P., Hähnel F., Weiße J.: Low velocity impact on CFRP plates with compressive preload: test and modelling. International Journal of Impact Engineering. 36(10), 1182–1193 (2009)

Abaqus: Abaqus Analysis User’s Manual. Dassault Systèmes Simulia Corp, Providence (2010)

Chowdhury M.A., Nuruzzaman D.M., Roy B.K.: Experimental investigation of friction coefficient and wear rate of stainless steel 304 sliding against smooth and rough mild steel Counterfaces. Gazi University Journal of Science. 26(4), 597–609 (2013)

Schön J.: Coefficient of friction of composite delamination surfaces. Wear. 237(1), 77–89 (2000)

Williams K.V., Vaziri R., Poursartip A.: A physically based continuum damage mechanics model for thin laminated composite structures. Int. J. Solids Struct. 40(9), 2267–2300 (2003)

Acknowledgments

Part of the research leading to these results has received funding from the European Community’s Seventh Framework Programme FP7/2007-2013 under grant agreement n°213371.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schueler, D., Toso-Pentecôte, N. & Voggenreiter, H. Simulation of High Velocity Impact on Composite Structures - Model Implementation and Validation. Appl Compos Mater 23, 857–878 (2016). https://doi.org/10.1007/s10443-016-9489-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-016-9489-0