Abstract

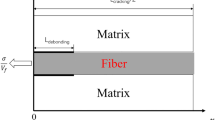

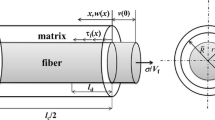

The stress–strain curves of fiber − reinforced ceramic − matrix composites (CMCs) exhibit obvious non-linear behaviour under tensile loading. The occurrence of multiple damage mechanisms, i.e., matrix multicracking, fiber/matrix interface debonding and fibers fracture, is the mainly reason for the non-linear characteristic. The micromechanics approach has been developed to predict the tensile stress–strain curves of unidirectional, cross-ply and woven CMCs. The shear-lag model was used to describe the micro stress field of the damaged composite. The damage models were used to determine the evolution of micro damage parameters, i.e., matrix crack spacing, interface debonded length and broken fibers fraction. By combining the shear-lag model with damage models and considering the effect of transverse multicracking in the 90° plies or transverse yarns in cross-ply or woven CMCs, the tensile stress–strain curves of unidirectional, cross-ply, 2D and 2.5D woven CMCs have been predicted. The results agreed with experimental data.

Similar content being viewed by others

References

Naslain, R.: Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Compos. Sci. Technol. 64, 155–170 (2004). doi:10.1016/S0266-3538(03)00230-6

Schmidt, S., Beyer, S., Knabe, H., Immich, H., Meistring, R., Gessler, A.: Advanced ceramic matrix composite materials for current and future propulsion system applications. Acta Astronaut. 55, 409–420 (2004). doi:10.1016/j.actaastro.2004.05.052

DiCarlo, J.A., Van Roode, M.: Ceramic composite development for gas turbine hot section components. Proc ASME Turbo Expo: Power for Land, Sea and Air 2, 221–231 (2006)

Stephen, T.: General Electric primes CMC for turbine blades. Flight International, 2010. http://www.flightglobal.com/news/articles/general-electric-primes-cmc-for-turbine-blades-349834/

Zhang, L.T., Cheng, L.F., Luan, X.G., Mei, H., Xu, Y.D.: Environmental performance testing system for thermostructure materials applied in aeroengines. Key Eng. Mater. 313, 183–190 (2006). doi:10.4028/www.scientific.net/KEM.313.183

Li, L.B., Song, Y.D., Sun, Y.C.: Modeling the tensile behavior of unidirectional C/SiC ceramic-matrix composites. Mech. Compos. Mater. 49, 659–672 (2014)

Li, L.B., Song, Y.D.: An approach to estimate interface shear stress of ceramic matrix composites from hysteresis loops. Appl. Compos. Mater. 17, 309–328 (2010). doi:10.1007/s10443-009-9122-6

Curtin, W.A.: Stress–strain behavior of brittle matrix composites. Comprehensive composite materials. Elsevier Science Ltd 4, 47–76 (2000). doi:10.1016/B0-08-042993-9/00088-7

Li, L.B.: Effect of fiber Poisson contraction on matrix multicracking evolution of fiber-reinforced ceramic-matrix composites. Appl. Compos. Mater. (2014). doi:10.1007/s10443-014-9426-z

Li, L.B., Song, Y.D., Sun, Y.C.: Modeling loading/unloading hysteresis behavior of unidirectional C/SiC ceramic matrix composites. Appl. Compos. Mater. 20, 655–672 (2013). doi:10.1007/s10443-012-9294-3

Budiansky, B., Hutchinson, J.W., Evans, A.G.: Matrix fracture in fiber-reinforced ceramics. J. Mech. Phys. Solids 34, 167–189 (1986)

Daniel, I.M., Lee, J.W.: The behavior of ceramic matrix fiber composites under longitudinal loading. Compos. Sci. Technol. 46, 105–113 (1993). doi:10.1016/0266-3538(93)90166-E

Aveston, J., Cooper, G.A., Kelly, A.: Single and multiple fracture. Properties of fiber composites: conference on proceedings. England: National Physical Laboratory, IPC. 15–26 (1971)

Zok, F.W., Spearing, S.M.: Matrix crack spacing in brittle matrix composites. Acta Metall. Mater. 40, 2033–2043 (1992). doi:10.1016/0956-7151(92)90189-L

Zhu, H., Weitsman, Y.: The progression of failure mechanisms in unidirectional reinforced ceramic composites. J. Mech. Phys. Solids 42, 1601–1632 (1994). doi:10.1016/0022-5096(94)90089-2

Solti, J.P., Mall, S., Robertson, D.D.: Modeling damage in unidirectional ceramic-matrix composites. Compos. Sci. Technol. 54, 55–66 (1995). doi:10.1016/0266-3538(95)00041-0

Curtin, W.A.: Multiple matrix cracking in brittle matrix composites. Acta Metall. Mater. 41, 1369–77 (1993). doi:10.1016/0956-7151(93)90246-O

Hsueh, C.H.: Crack-wake interface debonding criterion for fiber-reinforced ceramic composites. Acta Mater. 44, 2211–2216 (1996). doi:10.1016/1359-6454(95)00369-X

Gao, Y.C., Mai, Y., Cotterell, B.: Fracture of fiber-reinforced materials. J. Appl. Math. Phys. 39, 550–572 (1988). doi:10.1007/BF00948962

Sun, Y.J., Singh, R.N.: The generation of multiple matrix cracking and fiber-matrix interfacial debonding in a glass composite. Acta Mater. 46, 1657–1667 (1998). doi:10.1016/S1359-6454(97)00347-9

Thouless, M.D., Evans, A.G.: Effects of pull-out on the mechanical properties of ceramic matrix composites. Acta Metall. Mater. 36, 517–522 (1988). doi:10.1016/0001-6160(88)90083-1

Cao, H.C., Thouless, M.D.: Tensile tests of ceramic-matrix composites: theory and experiment. J. Am. Ceram. Soc. 73, 2091–2094 (1990). doi:10.1111/j.1151-2916.1990.tb05273.x

Sutcu, M.: Weibull statistics applied to fiber failure in ceramic composites and work of fracture. Acta Metall. Mater. 37, 651–661 (1989). doi:10.1016/0001-6160(89)90249-6

Schwietert, H.R., Steif, P.S.: A theory for the ultimate strength of a brittle-matrix composite. J. Mech. Phys. Solids. 38, 325–343 (1990). doi:10.1016/0022-5096(90)90002-L

Curtin, W.A.: Theory of mechanical properties of ceramic-matrix composites. J. Am. Ceram. Soc. 74, 2837–2845 (1991). doi:10.1111/j.1151-2916.1991.tb06852.x

Weitsman, Y., Zhu, H.: Multiple-fracture of ceramic composites. J. Mech. Phys. Solids. 41, 351–388 (1993). doi:10.1016/0022-5096(93)90012-5

Hild, F., Domergue, J.M., Leckie, F.A., Evans, A.G.: Tensile and flexural ultimate strength of fiber-reinforced ceramic-matrix composites. Int. J. Solids. Strut. 31, 1035–1045 (1994). doi:10.1016/0020-7683(94)90010-8

Curtin, W.A., Ahn, B.K., Takeda, N.: Modeling brittle and tough stress–strain behavior in unidirectional ceramic matrix composites. Acta Mater. 46, 3409–3420 (1998). doi:10.1016/S1359-6454(98)00041-X

Paar, R., Valles, J.-L., Danzer, R.: Influence of fiber properties on the mechanical behavior of unidirectionally-reinforced ceramic matrix composites. Mater. Sci. Eng. A 250, 209–216 (1998). doi:10.1016/S0921-5093(98)00593-0

Liao, K., Reifsnider, K.L.: A tensile strength model for unidirectional fiber-reinforced brittle matrix composite. Int. J. Fracture. 106, 95–115 (2000). doi:10.1023/A:1007645817753

Zhou, S.J., Curtin, W.A.: Failure of fiber composites: a lattice green function model. Acta Metall. Mater. 43, 3093–3104 (1995). doi:10.1016/0956-7151(95)00003-E

Dutton, R.E., Pagano, N.J., Kim, R.Y.: Modeling the ultimate tensile strength of unidirectional glass-matrix composites. J. Am. Ceram. Soc. 83, 166–174 (2000). doi:10.1111/j.1151-2916.2000.tb01166.x

Xia, Z., Curtin, W.A.: Toughness-to-brittle transitions in ceramic-matrix composites with increasing interfacial shear stress. Acta Mater. 48, 4879–4892 (2000). doi:10.1016/S1359-6454(00)00291-3

Laws, N., Dvorak, G.J.: Progressive transverse cracking in composite laminates. J. Compos. Mater. 22, 900–916 (1988). doi:10.1177/002199839002401108

Pryce, A.W., Smith, P.A.: Matrix cracking in unidirectional ceramic matrix composites under quasi-static and cyclic loading. Acta Metall. Mater. 41, 1269–1281 (1993). doi:10.1016/0956-7151(93)90178-U

Beyerle, D.S., Spearing, S.M., Zok, F.W., Evans, A.G.: Damage and failure in unidirectional ceramic matrix composites. J. Am. Ceram. Soc. 75, 2719–25 (1992). doi:10.1111/j.1151-2916.1992.tb05495.x

Sørensen, B.F., Holmes, J.W.: Effect of loading rate on the monotonic tensile behavior of a continuous-fiber-reinforced glass-ceramic matrix composite. J. Am. Ceram. Soc. 79, 313–320 (1996). doi:10.1111/j.1151-2916.1996.tb08122.x

Beyerle, D.S., Spearing, S.M., Evans, A.G.: Damage mechanisms and mechanical properties of a laminated 0/90 ceramic/matrix composite. J. Am. Ceram. Soc. 75, 3321–3330 (1992). doi:10.1111/j.1151-2916.1992.tb04428.x

Wang, S.W., Parvizi-Majidi, A.: Experimental characterization of the tensile behavior of Nicalon fiber-reinforced calcium aluminosilicate composites. J. Mater. Sci. 27, 5483–5496 (1992)

Zawada, L.P., Butkus, L.M., Hartman, G.A.: Tensile and fatigue behavior of silicon carbide fiber-reinforced aluminosilicate glass. J. Am. Ceram. Soc. 74, 2851–2858 (1991). doi:10.1111/j.1151-2916.1991.tb06854.x

Mei, H., Cheng, L.F., Zhang, L.T.: Damage evolution and microstructural characterization of a cross-woven C/SiC composite under tensile loading. J Chin. Ceramic Soc. 35, 137–143 (2007)

Wang, Y.Q., Zhang, L.T., Cheng, L.F.: Tensile performance and damage evolution of a 2.5D C/SiC composite characterized by acoustic emission. Appl. Compos. Mater. 15, 183–188 (2008). doi:10.1007/s10443-008-9066-2

Wang, Y.Q., Zhang, L.T., Cheng, L.F., et al.: Characterization of tensile behavior of a two-dimensional woven carbon/silicon carbide composite fabricated by chemical vapor infiltration. Mater. Sci. Eng. A 497, 295–300 (2008). doi:10.1016/j.msea.2008.07.050

Mei, H.: Measurement and calculation of thermal residual stress in fiber reinforced ceramic matrix composites. Compos. Sci. Technol. 68, 3285–92 (2008). doi:10.1016/j.compscitech.2008.08.015

Morscher, G.N., Singh, M., Kiser, J.D., Freedman, M., Bhatt, R.: Modeling stress-dependent matrix cracking and stress–strain behavior in 2D woven SiC fiber reinforced CVI SiC matrix. Compos. Sci. Technol. 67, 1009–17 (2007). doi:10.1016/j.compscitech.2006.06.007

Acknowledgments

The work reported here is supported by the Natural Science Foundation of Jiangsu Province (Grant No. BK20140813).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Longbiao, L. Micromechanical Modeling for Tensile Behaviour of Carbon Fiber − Reinforced Ceramic − Matrix Composites. Appl Compos Mater 22, 773–790 (2015). https://doi.org/10.1007/s10443-014-9435-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-014-9435-y