Abstract

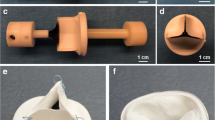

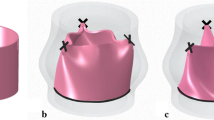

Transcatheter aortic valve implantation (TAVI) has become a popular alternative technique to surgical valve replacement for critical patients. Biological valve tissue has been used in TAVI procedures for over a decade, with over 100,000 implantations to date. However, with only 6 years follow up, little is known about the long-term durability of biological tissue. Moreover, the high cost of tissue harvesting and chemical treatment procedures favor the development of alternative synthetic valve leaflet materials. Textile polyester is one such material which provides outstanding folding and strength properties combined with proven biocompatibility, and could therefore be considered as a candidate to replace the biological valve leaflets in TAVI procedures. For that purpose, in addition to the mechanical properties, the hemodynamic properties of the synthetic material should be comparable to the properties of biological tissue. An ideal replacement heart valve would provide low static and dynamic regurgitation, ensure laminar flow across the valve, and limit the turbidity of flow downstream of the valve. The purpose of the present work is to compare in vitro the mechanical and hemodynamic performances of textile woven polyester valves with biological ones. Testing results indicate that textile valves trade elasticity for superior mechanical strength, relative to biological tissue. Despite this, the dynamic flexibility of textile valve leaflets strongly resembled what was seen with biological leaflets. Regurgitation, as well as slightly modified turbulent patterns, in textile valves was higher than biological valves due to the increased porosity, but, rapid tissue ingrowth post-implantation would likely mitigate this effect. Together these findings provide additional evidence favoring the use of textile polyester as a synthetic heart valve leaflet material.

Similar content being viewed by others

References

Alavi, H., E. Groves, and A. Kheradvar. The effects of transcatheter valve crimping on pericardial leaflets. Ann. Thorac. Surg. 97(4):1260–1266, 2014.

Amoroso, N. J., A. D’Amore, Y. Hong, C. P. Rivera, M. S. Sacks, and W. R. Wagner. Microstructural manipulation of electrospun scaffolds for specific bending stiffness for heart valve tissue engineering. Acta Biomater. 8(12):4268–4277, 2012.

Antiga, L., and D. A. Steinman. Rethinking turbulence in blood. Biorheology. 46:77–81, 2009.

Bark Jr., D. L., W. S. Nesbitt, A. K. T. Wong, and S. P. Jackson. Shear Effects on Platelets and the Vessel Wall in the Pathogenesis of Atherothrombosis, Hemostasis and Thrombosis: Basic Principles and Clinical Practice (6th ed.). Lippincott: Williams & Wilkins, p. 1592, 2013.

Cribier, A., et al. Percutaneous transcatheter implantation of an aortic valve prosthesis for calcific aortic stenosis, first human case description. Circulation 106:3006–3008, 2002.

Davidson, M. J., et al. Percutaneous therapies for valvular heart disease. Cardiovasc. Pathol. 15:123–129, 2006.

Forleo, M., and L. Dasi. Effect of hypertension on the closing dynamics and lagrangian blood damage index measure of the B-datum regurgitant jet in a bileaflet mechanical heart valve. Ann. Biomed. Eng. 42(1):110–122, 2014.

Grigioni, M., C. Daniele, G. D’Avenio, and V. Barbaro. A discussion on the threshold limit for hemolysis related to Reynolds shear stress. J. Biomech. 32:1107–1112, 1999.

Gurvitch, R., A. Cheun, F. Bedogni, and J. G. Webb. Coronary obstruction following transcatheter aortic valve-in-valve implantation for failed surgical bioprostheses. Catheter Cardiovasc. Interv. 77:439–444, 2011.

Haller, N. Noninvasive analysis of synthetic and decellularized scaffolds for heart valve tissue engineering. ASAIO. 59(2):169–177, 2013.

Heim, F., B. Durand, and N. Chakfe. Textile heartvalve prosthesis: Manufacturing process and prototype performances. Text. Res. J. 78:1124–1131, 2008.

Heim, F., B. Durand, and N. Chakfe. Textile heart valve: novel shaping process and material performances. Mater. Manuf. Process. 26:1303–1309, 2011.

Heim, F., and B. S. Gupta. Textile heart valve prosthesis: the effect of fabric construction parameters on long-term durability. Text. Res. J. 79:1001–1013, 2009.

Kameneva, M. V., G. W. Burgreen, K. Kono, B. Repko, J. F. Antaki, and M. Umezu. Effects of turbulent stresses upon mechanical hemolysis: Experimental and computational analysis. ASAIO J. 50:418–423, 2004.

Khoffi, F., and F. Heim. Mechanical degradation of biological heart valve tissue induced by low diameter crimping: an early assessment. JMBBM 2015. doi:10.1016/j.jmbbm.2015.01.005.

Khoffi, F., F. Heim, N. Chakfe, and J. T. Lee. Transcatheter fiber heart valve: effect of crimping on material performances. JBMR-B. 2014. doi:10.1002/jbm.b.33330.

Kiefer, P., et al. Crimping may affect the durability of transcatheter valves: an experimental analysis. Ann Thorac. Surg. 92(1):155–160, 2011.

Kucinska-Lipka, J., I. Gubanska, H. Janik, and M. Sienkiewicz. Fabrication of polyurethane and polyurethane based composite fibres by the electrospinning technique for soft tissue engineering of cardiovascular system. Mater. Sci. Eng. C. 46:166–176, 2015.

Morshed, K. N., D. L. Bark, Jr, M. Forleo, and L. P. Dasi. Theory to predict shear stress on cells in turbulent blood flow. PLoS One 9:e105357, 2014.

Teixeira, N. A., M. M. Platt, and W. J. Hamburger. Mechanics of elastic performance of textile materials: part XII: relation of certain geometric factors to the tear strength of woven fabrics. Text. Res. J. 10:838–861, 1955.

Vaesken, A. and F. Heim. Textile heart valve: fabric construction parameters and in vivo results. The Fiber Society’s Spring Conference 2015, Shanghai, China; 05/2015.

Vaesken, A., F. Heim, and N. Chakfe. Fiber heart valve prosthesis: influence of the fabric construction parameters on the valve fatigue performances. JMBBM. 40:69–74, 2014.

Zegdi, R., et al. Is it reasonable to treat all calcified stenotic aortic valves with a valved stent. J. Am. Coll. Cardiol. 51(5):579–584, 2008.

Acknowledgment

This work was partly supported by the French ANR: ANR-12-EMMA-0001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Associate Editor Ellen Kuhl oversaw the review of this article.

Rights and permissions

About this article

Cite this article

Yousefi, A., Vaesken, A., Amri, A. et al. Heart Valves from Polyester Fibers vs. Biological Tissue: Comparative Study In Vitro . Ann Biomed Eng 45, 476–486 (2017). https://doi.org/10.1007/s10439-016-1632-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10439-016-1632-4