Abstract

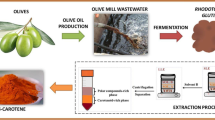

A biotechnological process concept for generation and in situ separation of natural β-ionone from β-carotene is presented. The process employs carotenoid cleavage dioxygenases (CCDs), a plant-derived iron-containing nonheme enzyme family requiring only dissolved oxygen as cosubstrate and no additional cofactors. Organophilic pervaporation was found to be very well suited for continuous in situ separation of β-ionone. Its application led to a highly pure product despite the complexity of the reaction solution containing cell homogenates. Among three different pervaporation membrane types tested, a polyoctylmethylsiloxane active layer on a porous polyetherimide support led to the best results. A laboratory-scale demonstration plant was set up, and a highly pure aqueous–ethanolic solution of β-ionone was produced from β-carotene. The described process permits generation of high-value flavor and fragrance compounds bearing the desired label “natural” according to US and European food and safety regulations and demonstrates the potential of CCD enzymes for selective oxidative cleavage of carotenoids.

Similar content being viewed by others

References

Auldridge ME, McCarty DR, Klee HJ (2006) Plant carotenoid cleavage oxygenases and their apocarotenoid products. Curr Opin Plant Biol 9:315–321

Berger R (2009) Biotechnology of flavours—the next generation. Biotechnol Lett 31:1651–1659

Bluemke W, Schrader J (2001) Integrated bioprocess for enhanced production of natural flavors and fragrances by Ceratocystis moniliformis. Biomol Eng 17:137–142

Bowen TC, Noble RD, Falconer JL (2004) Fundamentals and applications of pervaporation through zeolite membranes. J Membr Sci 245:1–33

Etschmann MM, Sell D, Schrader J (2005) Production of 2-phenylethanol and 2-phenylethylacetate from l-phenylalanine by coupling whole-cell biocatalysis with organophilic pervaporation. Biotechnol Bioeng 92:624–634

Floss DS, Walter MH (2009) Role of carotenoid cleavage dioxygenase 1 (CCD1) in apocarotenoid biogenesis revisited. Plant Signal Behav 4:172–175

Hausmanns S (1999) Organophile Pervaporation wäßriger Mehrkomponentensysteme. VDI Verlag, Dusseldorf

Hoshino K, Sakurai K (2002) Perfume composition for laundry detergent. Patent no.: 9/866,606

Huang RYM, Feng X (1992) Pervaporation of water/ethanol mixtures by an aromatic polyetherimide membrane. Sep Sci Technol 27:1583–1597

Lipnizki F, Hausmanns S, Laufenberg G, Field R, Kunz B (2000) Use of pervaporation-bioreactor hybrid processes in biotechnology. Chem Eng Technol 23:569–577

Michael DW (1990) Powdered abrasive cleansers with encapsulated parfume. Patent no.: 436274

Nacke C, Schrader J (2011) Liposome based solubilisation of carotenoid substrates for enzymatic conversion in aqueous media. J Mol Catal B Enzym 71:133–138

Nacke C, Schrader J (2012) Micelle based delivery of carotenoid substrates for enzymatic conversion in aqueous media. J Mol Catal B Enzym 77:67–73

Ohmiya A (2009) Carotenoid cleavage dioxygenases and their apocarotenoid products in plants. Plant Biotechnol 26:351–358

Pereira CC, Ribeiro CP, Nobrega R, Borges CP (2006) Pervaporative recovery of volatile aroma compounds from fruit juices. J Membr Sci 274:1–23

Schäfer T, Heintz A, Crespo JG (2005) Sorption of aroma compounds in poly(octylmethylsiloxane) (POMS). J Membr Sci 254:259–265

Schilling M, Patett F, Schwab W, Schrader J (2007) Influence of solubility-enhancing fusion proteins and organic solvents on the in vitro biocatalytic performance of the carotenoid cleavage dioxygenase AtCCD1 in a micellar reaction system. Appl Microbiol Biotechnol 75:829–836

Schilling M (2008) Gewinnung von Aromastoffen durch enzymatische Spaltung von Carotinoiden mit der rekombinanten Dioxygenase AtCCD1. Technical University of Munich, Munich

Schmidt H, Kurtzer R, Eisenreich W, Schwab W (2006) The carotenase AtCCD1 from Arabidopsis thaliana is a dioxygenase. J Biol Chem 281:9845–9851

Schwartz SH, Qin X, Zeevaart JA (2001) Characterization of a novel carotenoid cleavage dioxygenase from plants. J Biol Chem 276:25208–25211

Verhoef A, Figoli A, Leen B, Bettens B, Drioli E, Van der Bruggen B (2008) Performance of a nanofiltration membrane for removal of ethanol from aqueous solutions by pervaporation. Sep Purif Technol 60:54–63

Winterhalter P, Rouseff R (2002) Carotenoid-derived aroma compounds: an introduction In: Winterhalter P, Rouseff R (eds) ACS Symposium Series American Chemical Society. Washington, USA, pp 1–17

Wu Z, Robinson DS (1999) Co-oxidation of beta-carotene catalyzed by soybean and recombinant pea lipoxygenase. J Agric Food Chem 47:4899–4906

Zorn H, Langhoff S, Schreibner M, Nimtz M, Berger RG (2003) A peroxidase from Lepista irina cleaves b-carotene to flavor compounds. Biol Chem 384:1049–1056

Acknowledgments

We are indebted to Wild Flavours GmbH, Berlin, Germany for providing carotenoid samples. This research was financially supported by the German Federal Ministry of Economics and Technology via the AiF ZUTECH program (project no. 243 ZN).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nacke, C., Hüttmann, S., Etschmann, M.M.W. et al. Enzymatic production and in situ separation of natural β-ionone from β-carotene. J Ind Microbiol Biotechnol 39, 1771–1778 (2012). https://doi.org/10.1007/s10295-012-1182-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-012-1182-1