Abstract

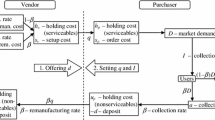

We study an extended joint economic lot size problem which incorporates the return flow of remanufacturable used products. The supply chain under consideration consists of a single supplier and a single buyer. The buyer orders a single product from the supplier, uses it for her own needs, and collects the remanufacturable items after use. The ordered items are shipped from the supplier to the buyer in the lot-for-lot fashion by a vehicle which also returns the collected used items from the buyer to the supplier for remanufacturing and subsequent service of the buyer’s demand in the next order cycle. For satisfying the total demand, the supplier manufactures new items or remanufactures used ones received from the buyer. For given demand, productivity, collection rate, disposal cost, setup cost, order cost, holding cost for serviceable and nonserviceable products at the supplier as well as the buyer the lot size (order size) for the supplier (buyer) has to be found which minimizes the total cost. Furthermore, we address a decentralised decision making of the parties under a two-part tariff and determine their equilibrium strategies within the Nash framework.

Similar content being viewed by others

References

Akçalı E, Çetinkaya S (2011) Quantitative models for inventory and production planning in closed-loop supply chains. Int J Prod Res 49(8):2373–2407

Atasu A, Guide VDR, Van Wassenhove LN (2008) Product reuse economics in closed-loop supply chain research. Prod Oper Manag 17(5):483–496

Banerjee A (1986) A joint economic-lot-size model for purchaser and vendor. Decis Sci 17(3):292–311

Bhattacharya S, Guide VDR, Van Wassenhove LN (2006) Optimal order quantities with remanufacturing across new product generations. Prod Oper Manag 15(3):421–431

Brandenburger AM, Nalebuff BJ (1996) Co-opetition. Currency Doubleday, New York

Cachon GP (2003) Supply chain coordination with contracts. In: de Kok AG, Graves SC (eds) Supply chain management: design, coordination and operation, handbooks in operations research and management science, chapter 6, vol 11. Elsevier, Amsterdam, pp 229–339

Corbett CJ, Savaskan RC (2002) Contracting and coordination in closed-loop supply chains. In: Guide VDR, Van Wassenhove LN (eds) Closed-loop supply chains: a business perspective. Carnegie Bosch Institute, Pittsburgh, pp 93–113

Dobos I, Richter K (2000) The integer EOQ repair and waste disposal model—further analysis. Cent Eur J Oper Res 8(2):173–194

Dobos I, Richter K (2003) A production/recycling model with stationary demand and return rates. Cent Eur J Oper Res 11(1):35–46

Dobos I, Gobsch B, Pakhomova N, Pishchulov G, Richter K (2011a) A vendor-purchaser economic lot size problem with remanufacturing and deposit. Discussion Paper 304, Faculty of Economics and Business Administration, European University Viadrina, Frankfurt (Oder), Germany

Dobos I, Gobsch B, Pakhomova N, Richter K (2011b) Remanufacturing of used products in a closed-loop supply chain. In: Csutora M, Kerekes S (eds) Accounting for climate change—-What and how to measure. Proceedings of the EMAN-EU 2011 Conference, 24–25 January 2011. Budapest, Hungary, pp 130–146

Dolan RJ (1987) Quantity discounts: managerial issues and research opportunities. Mark Sci 6(1):1–22

Fleischmann M, Bloemhof-Ruwaard JM, Dekker R, van der Laan E, van Nunen JAEE, Van Wassenhove LN (1997) Quantitative models for reverse logistics: a review. Eur J Oper Res 103(1):1–17

Goyal SK (1976) An integrated inventory model for a single supplier single customer problem. Int J Prod Res 15(1):107–111

Guide VDR, Van Wassenhove LN (2009) The evolution of closed-loop supply chain research. Oper Res 57(1):10–18

Jaber MY, El Saadany AM (2011) An economic production and remanufacturing model with learning effects. Int J Prod Econ 131(1):115–127

Kohli R, Park H (1989) A cooperative game theory model of quantity discounts. Manag Sci 35(6):693–707

Li Y, Zhang J, Chen J, Cai X (2010) Optimal solution structure for multi-period production planning with returned products remanufacturing. Asia-Pac J Oper Res 27(5):629–648

Luo Y (2005) Toward coopetition within a multinational enterprise: a perspective from foreign subsidiaries. J World Bus 40(1):71–90

Osborne MJ, Rubinstein A (1994) A course in game theory. MIT Press, Cambridge

Pishchulov G, Dobos I, Gobsch B, Pakhomova N, Richter K (2012) Remanufacturing of used products in a closed-loop supply chain with quantity discount. In: Klatte D, Lüthi HJ, Schmedders K (eds) Operations Research Proceedings 2011: Selected Papers of the International Conference on Operations Research (OR 2011), August 30–September 2, 2011. Springer, Zurich, Switzerland, pp 457–462

Pishchulov G, Dobos I, Gobsch B, Pakhomova N, Richter K (2013) A vendor-purchaser economic lot size problem with remanufacturing. J Bus Econ (under revision)

Reyniers DJ (2001) The effect of vertical integration on consumer price in the presence of inventory costs. Eur J Oper Res 130(1):83–89

Richter K (1994) An EOQ repair and waste disposal model. In: Proceedings of the Eighth International Working Seminar on Production Economics, 21–25 February 1994. Igls/Innsbruck, Austria, vol. 3, pp. 83–91

Richter K (1997) Pure and mixed strategies for the EOQ repair and waste disposal problem. OR Spectrum 19(2):123–129

Savaskan RC, Van Wassenhove LN (2006) Reverse channel design: the case of competing retailers. Manag Sci 52(1):1–14

Savaskan RC, Bhattacharya S, Van Wassenhove LN (2004) Closed-loop supply chain models with product remanufacturing. Manag Sci 50(2):239–252

Sucky E (2006) A bargaining model with asymmetric information for a single supplier–single buyer problem. Eur J Oper Res 171(2):516–535

Toktay LB, Wein LM, Zenios SA (2000) Inventory management of remanufacturable products. Manag Sci 46(11):1412–1426

Author information

Authors and Affiliations

Corresponding author

Additional information

Imre Dobos gratefully acknowledges the financial supports by the OTKA-105888 research program and the Deutscher Akademischer Austauschdienst (DAAD)

Rights and permissions

About this article

Cite this article

Dobos, I., Gobsch, B., Pakhomova, N. et al. Design of contract parameters in a closed-loop supply chain. Cent Eur J Oper Res 21, 713–727 (2013). https://doi.org/10.1007/s10100-013-0308-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10100-013-0308-5