Abstract

We investigated the changes in cellulose crystallinity in the cell walls of moso bamboo (Phyllostachys pubescens Mazel) during the growth process. Changes in crystallinity in bamboo cell walls were traced along the longitudinal and radial directions using flat-sawn specimens obtained from each internode using X-ray diffraction measurements. Cellulose crystallinity in cell walls in the same culm was higher around the base of the bamboo culms in less than 10 days after the emergence of bamboo shoots, while the upper internodes remained lower in crystallinity. Thereafter, crystallinity in the upper internodes of bamboo culms became higher. This suggests that cellulose crystallinity within bamboo cell walls has gradually increased from the base to the top with the elongation of the internode during the growth process of bamboo shoots. In addition, cellulose crystallinity in cell walls increased particularly in the outer part of the bamboo culms in all internodes. Moreover, increases of crystallinity occurred after elongation growth of internodes. It is considered that increases in crystallinity in the outer portion of each internode are one of the countermeasures of bamboo culms against increased bending moment due to the elongation growth.

Similar content being viewed by others

Introduction

Bamboos are monocotyledonous plants of the family Gramineae found in tropical, subtropical, and temperate regions around the world [1]. Bamboo is a perennial plant of which the culms (main stem) are lignified during elongation growth, without secondary growth in thickness [2, 3]. Bamboo has been used for various daily necessities, although many artificial materials become widely used today. For example, it is used as a structural material in the field of architecture, e.g., laminated bamboo lumber [4, 5].

The structural features of bamboo are different from wood. Bamboo culms consist of parenchyma and rigid bundle sheaths. The rigid bundle sheath, which aligns nearly parallel to the longitudinal axis of the culm, is found more in the outer section of the culm than in the inner side [2, 6, 7]. This optimized spatial construction gives bamboo culms better physical and mechanical properties [8–11]. Bamboo is also one of the fastest-growing plants, and can reach 15–30 m in height within 2–4 months [6]. Nomura [2] reported that moso bamboo (Phyllostachys pubescens) and madake bamboo (Phyllostachys bambusoides) can grow more than a meter in a day. This rapid growth rate is due to the sum of the growth amount at each internode.

Some researchers have reported the time-dependent variation in the macroscopic morphology of bamboo during the growth process [2, 12–14]. In addition, a few studies have focused on the changes in crystalline properties of cellulose in bamboo cell walls during the growth process. Taniguchi [15] analyzed the chemical components of bamboo, and revealed that the cellulose content in bamboo shoot rapidly increased after stripping off the leaf during the growth process. Nomura and Yamada [16] performed X-ray diffraction (XRD) measurements at ages of 2, 4, and 5 weeks, and obtained similar results as Taniguchi [15]. In addition, they demonstrated that the crystallinity near the base of bamboo shoots (internodal growth) was higher than at the top. Wang et al. [17] measured the radial distribution of crystallinity, crystal size, and microfibril angle in 0.5- to 10.5-year-old bamboo culms using X-ray scattering techniques; however, there have been no detailed studies on the crystalline properties of bamboo shoots during the process of internodal growth at the intervals of several days.

In the present study, we investigated the changes in cellulose crystallinity in the cell walls of moso bamboo during the growth process; thus, we collected detailed information on the growth of bamboo using XRD techniques, and assessed how the bamboo culm forms mechanically optimized conformations during the growth process.

Methods

Bamboo shoots

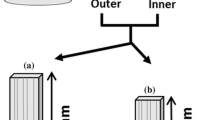

The studied specimens were prepared from culms of moso bamboo (Phyllostachys pubescens Mazel), which are grown in the forests of Matsue (35.26°N, 133.50°E), Japan. Dozens of bamboo shoots, which emerged a few centimeters off the ground, were selected on April 23, 2012, and were sequentially cut down at intervals of several days until early December. We dug up the ground about 20 cm around the each bamboo culm to cut off the bamboo base from the rhizome. All of the specimens were covered with plastic wrap after cutting, and were immediately taken to the laboratory without drying. All of the internodes, except the bamboo base, were numbered from the base to the top as shown in Fig. 1. To avoid decaying and dimensional changes due to drying, specimens were temporarily stored in 50 % (v/v) aqueous ethanol solution. Table 1 shows the characteristics of the tested bamboos.

Specimen preparation

Flat-sawn specimens of dimensions 1 × 10 × 10 mm (thickness × length × width) were made from each internode using a saw, chisel, and cutter knife. All of the specimens were prepared under wet conditions to prevent shrinkage of cell walls. Figure 1 shows the process of specimen preparation. First, both the upper and lower parts of each bamboo node were removed from each internode. The rest of the tubular internode was divided longitudinally, and then it was vertically segmented into three blocks (upper, middle, lower). After removing a few millimeters from both surfaces which included the epidermal tissues, the outer and inner sides of specimens in each block were obtained. The middle specimens were prepared from the central region of each remaining block. Then all of the specimens were freeze-dried using a vacuum freeze dryer (VD-400, Taiyo Kagaku Co., Ltd., Japan) to retain the intact condition of the cell wall structure.

XRD measurements

XRD measurements were performed to assess the crystalline properties of air-dried bamboo cell walls using an X-ray diffractometer (XD-D1w, Shimadzu Co., Japan). All XRD measurements were made with the reflection technique. The incident X-ray radiation was the characteristic Cu Kα X-ray passing through a nickel filter with a power of 30 kV and 30 mA. Both the air-scattering prevention slit and the divergence slit were 1°. The width of the detection slit was 0.1 mm, and scanning speed and integration time in the measurements of crystallinity were 2.0°/min and 2.0 s, respectively. Scanning ranges of 2θ angle was 5.0°–40.0°. Flat-sawn specimens obtained from each internode were vertically fixed on the specimen holder of the XRD device to irradiate the tangential section.

The crystallinity of the crystalline cellulose in the cell wall of bamboo was calculated using the following Segal method [18, 19]:

where C s is the crystallinity (%), I 200 is the reflection intensity of (200) plane diffraction, and I Am is the intensity at the minimum near 18.5° of 2θ angle. The Segal method is simple to apply and does not require peak separation between (110) and (\( 1\overline{1} 0 \)) reflections.

In the present study, the cellulose microfibril angle of the bamboo cell walls was also measured in some specimens to confirm its effect on the crystallinity. Cave’s method [20] was adopted to calculate the cellulose microfibril angle in the S2 layer (MFA) by using an X-ray diffractometer (XD-D1w, Shimadzu Co., Japan) with a symmetrical transmission mode. A point-focused X-ray beam (Cu-Kα X-ray, beam diameter 2 mm) was applied to the flat-sawn specimens. Each specimen was rotated around its normal axis with a rotation angle from 180° to 330° at a rotation speed of 6° per minute in a position of 2θ = 22.4°: the diffraction angle of the (200) plane of cellulose I β. The scattered X-rays were detected by a Na-I scintillation counter behind a receiving slit of 0.6 mm width. Estimation of the mean MFA was based on following formula:

where T was “angle T” which was calculated from the diffraction pattern of the (200) plane [20].

Results and discussion

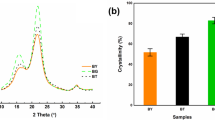

Figures 2 and 3 show the relationship between the crystallinity of the bamboo cell walls and the internode number for each growing period. Both figures focused on the differences in spatial position of each internode, as shown in Fig. 1. That is, Fig. 2 shows the changes in crystallinity in the longitudinal direction, whereas Fig. 3 shows it in the radial direction. These two figures suggest that the crystallinity near the base of the bamboo culms is higher than in the upper internodes of the same culm in less than 10 days after the emergence of bamboo shoots (Figs. 2a, b, 3a, b). On the other hand, the crystallinity in the upper internode of bamboo culm was relatively lower even after 29 days of growth (Figs. 2f, 3f), although the bamboo culm became higher than 12 m. This suggests that cellulose crystallinity in cell walls in bamboo shoots gradually increased from the base to the top during the elongation process. In addition, development of the bamboo cell wall was more matured around the base of the bamboo culm than in the upper internodes during the growth process. Figure 4 shows the typical changes in XRD pattern in the 23 days growth specimen that corresponding to Figs. 2e and 3e. Lower internodes showed sharp (200) diffraction peaks (Fig. 4a). The outer part also showed sharp (200) diffraction peaks (Fig. 4b).

Cellulose crystallinity in the vertical position in bamboo cell walls in each growth period. Black, gray, and white circles indicate the results in the specimens prepared from upper, middle, and lower positions in each internode, respectively. Specimens in a, b, and d were not divided into three sections due to the shortness of the longitudinal direction. Each plot with an error bar represents an averaged value of three specimens

Cellulose crystallinity in the radial position in bamboo cell walls in each growth period. Black, gray, and white circles indicate the results in specimens prepared from outer, middle, and inner positions in each internode, respectively. Each plot with an error bar represents an averaged value of three specimens

Typical changes in XRD pattern in 23 days growth bamboo specimen. a Differences induced by vertical position of internodes. Five XRD patterns in this figure correspond to the outer part of specimens in each internode number. The numbers on the right side of each XRD patterns show internode number. On the other hand, b differences in XRD pattern induced by radial position. Three XRD patterns in this figure correspond to the radial position in number 1 for internode number. The lower and outer parts of bamboo specimens had sharp (200) diffraction peak

Figure 2 focuses on changes in crystallinity related to the vertical positions within each internode. There was no significant variation in crystallinity in the longitudinal direction within each internode, even after 225 days of growth (Fig. 2k) (i.e., the crystallinity of each block showed similar values without regularity, regardless of growing period). Nomura and Yamada [16] performed XRD measurements using the 30th internode of a bamboo culm, the height of which was 865 cm after 5 weeks of growth, and showed that crystallinity was higher in the upper part of the internode. Additional investigations are necessary to clarify the reason for the different results regarding the crystallinity of bamboo cell walls in the longitudinal direction within the internode, such as the relationship between bamboo growth and lignification, and analysis of chemical composition during the growth process of bamboo shoot.

Figure 3 focuses on the changes in crystallinity related to the radial position in each internode. The crystallinity showed clear differences in the radial direction within each internode, that is, crystallinity gradually became higher in the outer side as growth progressed. This broad distinction of crystallinity was never observed in young bamboo culms (Fig. 3a–d), whose growing period was within 20 days. Differences in crystallinity in the radial direction began to appear near the base of the bamboo culm in early stages of growth, while the bamboo top still showed low values (Fig. 3e, f); the differences gradually progressed to the upper internodes (Fig. 3g–j). The crystallinity profiles of bamboo culms that grew more than 50 days (Fig. 3i, j) were almost identical to those that grew 225 days (Fig. 3k). Therefore, it is considered that the cellulose crystallinity in bamboo cell walls became constant in approximately 50 days, although it is considered that the completion of bamboo maturation, such as distribution of bundle sheath, fiber length and so forth, are much later [2]. These results suggest that increases in crystallinity in the outer portion of each internode are one of the countermeasures of bamboo culms against increased bending moment due to the elongation growth, for example, in the case when the bamboo culm bows by crosswind.

Figure 5 shows how the (a) internode length and (b) crystallinity varied with internode position. The seven data plot, which are indicated by circled black letters, are for samples with growth periods of 2 (A), 15 (B), 18 (C), 23 (D), 29 (E), 36 (F) and 43 (G) days. Gaussian curves were fitted to these data plots, and the maxima are indicated by the open circles. Internode lengths were measured by image processing software (QuickGrain Strandard, Inotech Co., Japan). Images of the vertical section in each internode were used for internode length analysis, and our results for internode length coincide with previous studies [2, 16]. Thus, the maximum internode length was 457 mm for node 28 for the sample that grew for 36 days. Likewise, the maximum crystallinity was 61 % for node 23 for the sample that grew 43 days. The internode numbers for each maximum are indicated by the circled gray letters. As the growth periods increased, the maximum internode length and maximum crystallinity were found at higher-numbered internodes. This indicates that increasing crystallinity in bamboo cell walls occurs after elongation growth of the internode from the base to the top.

Comparisons of changes in a internode lengths and b crystallinity at each internode number for samples with different growth periods. The samples with different growth periods of 2 (A), 15 (B), 18 (C), 23 (D), 29 (E), 36 (F) and 43 (G) days are indicated with circled black letters; the maxima for Gaussian curves fitted to each growth period data set are indicated by open circles. The circled gray letters indicate the positions of the open circles along the internode number axis for the respective samples

The structure of a bamboo cell wall is different from a wood cell wall. The model of a bamboo cell wall consists of 7–9 layers [21, 22]. In this model, the MFA of cellulose in each layer is nearly parallel or perpendicular to the fiber direction. Similar to the cell walls of wood, the layers with small MFAs are dominant in the bamboo cell wall. In the present study, the MFA of some specimens were measured to confirm its effect on the differences in crystallinity in the radial direction. Figure 6 shows the relationship between internode number and the MFA. MFA showed no significant change in the radial direction in each specimen. In particular, the specimens that showed clear differences in crystallinity (Fig. 3i, k) had almost identical MFA values, except in the base. Therefore, MFA had little influence on crystallinity in our study, although we also found that the MFA was larger in 23-day-old specimens compared to others (Fig. 6b). Wang et al. [17] reported large variation in the MFA in the radial direction using moso bamboo that grew more than half a year. The degree of maturation of bamboo cell walls may affect the variation in MFA; however, further investigations of the formation of the cell wall structure of bamboo shoots are necessary for a complete understanding of bamboo growth.

References

Fujii T (2008) Basic science and advanced technologies for industrial applications of bamboo (in Japanese). CMC, Tokyo

Nomura T (1980) Growth of bamboo (in Japanese). Wood Res Tech Notes 15:6–33

Li XB, Shupe TF, Peter GF, Hse CY, Eberharrdt TL (2007) Chemical changes with maturation of the bamboo species phyllostachys pubescens. J Trop For Sci 19:6–12

Mahdavi M, Clouston PL, Arwade SR (2011) Development of laminated bamboo lumber: review of processing, performance, and economical considerations. J Mater Civ Eng 23:1036–1042

Xiao Y, Yang RZ, Shan B (2013) Production, environmental impact and mechanical properties of glubam. Constr Build Mater 44:765–773

Liese W (1987) Research on bamboo. Wood Sci Technol 21:189–209

Iguchi Y, Fishitani M, Kubo T, Sato K (2002) Effect of volume fraction of bundle sheath and water extractives on bending creep behavior of bamboo under changing moisture conditions (in Japanese). Mokuzai Gakkaishi 48:413–424

Urakami H (1996) Relationships between dynamic viscoelasticity of mosochiku (Phyllostachys pubescens) and internode number, age, and specific gravity (in Japanese). Mokuzai Gakkaishi 42:832–838

Obataya E, Kitin P, Yamauchi H (2007) Bending characteristics of bamboo (Phyllostachys pubescens) with respect to its fiber-foam composite structure. Wood Sci Technol 41:385–400

Tsubaki T, Nakano T (2010) Creep behavior of bamboo under various desorption conditions. Holzforschung 64:489–493

Wang X, Ren H, Zhang B, Fei B, Burgert I (2012) Cell wall structure and formation of maturing fibres of moso bamboo (Phyllostachys pubescens) increase buckling resistance. J R Soc Interface 9:988–996

Nomura T, Yamada T (1974) X-ray analysis of tyrosine in growing stage of bamboo (Phyllostachs eduis A. & C. Riviere). Wood Res 56:21–27

Nomura T, Yamada T (1991) Growth of moso bamboo (Phyllostachys heterocycla) I. Internodeal growth (in Japanese). Mokuzai Gakkashi 37:1115–1122

Liese W, Weiner G (1996) Aging of bamboo culms. A review. Wood Sci Technol 30:77–89

Taniguchi E (1956) Chemical studies on the crystalline region of cellulose materials. XIV. Variation of fine structure in Akamatsu (Pinus densiflora Sieb. et Zucc.) and Mosochiku (Phyllostachys edulis Riv.) through growth (in Japanese). Mokuzai Gakkaishi 2:152–157

Nomura T, Yamada T (1974) Crystallinity change in the growing stage of bamboo (Phyllostachys mitis). Wood Res 57:23–30

Wang Y, Leppänen K, Andersson S, Serimaa R, Ren H, Fei B (2012) Studies on the nanostructure of the cell wall of bamboo using X-ray scattering. Wood Sci Technol 46:317–332

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Toba K, Yamamoto H, Yoshida M (2013) Crystallization of cellulose microfibrils in wood cell wall by repeated dry-and-wet treatment, using X-ray diffraction technique. Cellulose 20:633–643

Cave ID (1966) Theory of X-ray measurement of microfibril angle. For Prod J 16:37–42

Tono T, Ono K (1962) Researches on the morphological structure and the physical properties of bamboo fiber for paper making. II. The layered structure and its morphological transformation by acid treatment (in Japanese). Mokuzai Gakkaishi 8:245–249

Parameswaran N, Liese W (1976) On the fine structure of bamboo fibers. Wood Sci Technol 10:231–246

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Toba, K., Nakai, T., Shirai, T. et al. Changes in the cellulose crystallinity of moso bamboo cell walls during the growth process by X-ray diffraction techniques. J Wood Sci 61, 517–524 (2015). https://doi.org/10.1007/s10086-015-1490-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-015-1490-y