Abstract

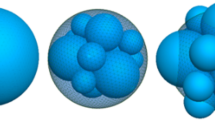

The present paper investigates the influence of microstructural inhomogeneities of brittle grains on grain crushing in cohesionless, frictional granular materials, using the discrete element method. Macrograins are modelled as assemblies of bonded micrograins of different sizes and bond strengths to simulate crushed sandstone. A method is suggested to incorporate fracture mechanical properties in the model through the selection of bond properties. Normal distribution of bond strengths, as well as degraded bonds are assumed to simulate bond defects. Their effects are first examined through single macrograin crushing tests. Then monotonic oedometer compression tests on macrograin ensembles are simulated for a wide range of pressures and different initial void ratios. The paper also explores the applicability of Bauer’s macroscopic compression law to the results of simulations of monotonic, oedometric compression tests. Correlations between the properties of individual macrograins, such as crushing strength and bonding defects, and the properties of the grain ensemble, such as granular hardness and grain size distribution are investigated.

Similar content being viewed by others

References

Nakata, Y., Kato, Y., Hyodo, M., Hyde, A.F.L., Murata, H.: One-dimensional compression behaviour of uniformly graded sand related to single particle crushing strength. Soils Found. 41(2), 39–51 (2001)

Chuhan, F.A., Kjeldstad, A., Bjørlykke, K., Høeg, K.: Porosity loss in sand by grain crushing—experimental evidence and relevance to reservoir quality. Mar. Pet. Geol. 19, 39–53 (2002)

Guimaraes, M.S., Valdes, J.R., Palomino, A.M., Santamarina, J.C.: Aggregate production: fines generation during rock crushing. Int. J. Miner. Process. 81, 237–247 (2007). doi:10.1016/j.minpro.2006.08.004

Silvani, C., Bonelli, T., Désoyer, S.: Fracture of rigid solids: a discrete approach based on damaging interface modelling. Comptes Rendus Mécanique 335(8), 455–460 (2007). doi:10.1016/j.crme.2007.05.023

McDowell, G.R., Bolton, M.D.: On the micromechanics of crushable aggregates. Géotechnique 48(5), 667–679 (1998)

Oldecop, L.A., Alonso, E.E.: Theoretical investigation of the time-dependent behaviour of rockfill. Géotechnique 57(3), 289–301 (2007)

McDowell, G.R., Bolton, M.D., Robertson, D.: The fractal crushing of granular materials. J. Mech. Phys. Solids 44(12), 2079–2102 (1996)

Gundepudi, M.K., Sankar, B.V., Mecholsky, J.J., Clupper, D.C.: Stress analysis of brittle spheres under multiaxial loading. Powder Technol. 94, 153–161 (1997)

Chau, K.T., WeI, X.X., Wong, R.H.C., Yu, T.X.: Fragmentation of brittle spheres under static and dynamic compressions: experiments and analyses. Mech. Mater. 32, 543–554 (2000)

Russell, A.R., Wood, D.M., Kikumoto, M.: Crushing of particles in idealised granular assemblies. J. Mech. Phys. Solids 57, 1293–1313 (2009). doi:10.1016/j.jmps.2009.04.009

Russell, A.R., Wood, D.M.: Point load tests and strength measurements for brittle spheres. Int. J. Rock Mech. Min. Sci. 46, 272–280 (2009). doi:10.1016/j.ijrmms.2008.04.004

McDowell, G.R., Daniell, C.M.: Fractal compression of soil. Géotechniqe 51(2), 173–176 (2001)

Nakata, Y., Hyodo, M., Hyde, A.F.L., Kato, Y., Murata, H.: Microscopic particle crushing of sand subjected to high pressure one-dimensional compression. Soils Found. 41(1), 69–82 (2001)

Lőrincz, J., Imre, E., Gálos, M., Trang, P.Q., Rajkai, K., Fityus, S., Telekes, G.: Grading entropy variation due to soil crushing. Int. J. Geomech. 5(4), 311–319 (2005). doi:10.1061/(ASCE)1532-3641(2005)5:4(311)

Lőrincz, J., Kárpáti, L., Trang, P.Q., Imre, E., Fityus, S.: Some comments on the grading entropy variation and crushing of various sands. In: Anagnostopoulos, A. et al. Proceedings of the 15th European Conference on Soil Mechanics and Geotechnical Engineering: Geotechnics of Hard Soils- Weak Rocks. Amsterdam: IOS Press, 2011, pp. 215–222. doi:10.3233/978-1-60750-801-4-215

Marketos, G., Bolton, M.D.: Compaction bands simulated in discrete element models. J. Struct. Geol. 31, 479–490 (2009). doi:10.1016/j.jsg.2009.03.002

McDowell, G.R., de Bono, J.P.: On the micro mechanics of one-dimensional normal compression. Géotechniqe 63(11), 1–14 (2013)

Lobo-Guerrero, S., Vallejo, L.E., Vesga, L.F.: Visualization of crushing evolution in granular materials under compression using DEM. Int. J. Geomech. 6(3), 195–200 (2006). doi:10.1061/(ASCE)1532-3641(2006)6:3(195)

Lobo-Guerrero, S., Vallejo, L.E.: Discrete element method analysis of railtrack ballast degradation during cyclic loading. Granul. Matter 8, 195–204 (2006). doi:10.1007/s10035-006-0006-2

Whittles, D.N., Kingman, S., Lowndes, I., Jackson, K.: Laboratory and numerical investigation into the characteristics of rock fragmentation. Miner. Eng. 19, 1418–1429 (2006). doi:10.1016/j.mineng.2006.02.004

Refahi, A., Aghazadeh Mohandesi, J., Rezai, B.: Discrete element modeling for predicting breakage behavior and fracture energy of a single particle in a jaw crusher. Int. J. Miner. Process. 94, 83–91 (2010). doi:10.1016/j.minpro.2009.12.002

McDowell, G.R., Harireche, O.: Discrete element modelling of soil particle fracture. Géotechnique 52(2), 131–135 (2002)

McDowell, G.R., Harireche, O.: Discrete element modelling of yielding and normal compression of sand. Géotechnique 52(4), 299–304 (2002)

Cheng, Y.P., Nakata, Y., Bolton, M.D.: Discrete element simulation of crushable soil. Géotechnique 53(7), 633–641 (2003)

Cheng, Y.P., Bolton, M.D., Nakata, Y.: Crushing and plastic deformation of soils simulated using DEM. Géotechnique 54(2), 131–141 (2004)

Liu, H.Y., Kou, S.Q., Lindqvist, P.-A.: Numerical studies on the inter-particle breakage of a confined particle assembly in rock crushing. Mech. Mater. 37, 935–954 (2005). doi:10.1016/j.mechmat.2004.10.002

Kou, S.Q., Liu, H.Y., Lindqvist, P.-A., Tang, C.A., Xu, X.H.: Numerical investigation of particle breakage as applied to mechanical crushing—part II: interparticle breakage. Int. J. Rock Mech. Min. Sci. 38, 1163–1172 (2001)

Bagherzadeh, KhA, Mirghasemi, A.A., Mohammadi, S.: Numerical simulation of particle breakage of angular particles using combined DEM and FEM. Powder Technol. 205, 15–29 (2011). doi:10.1016/j.powtec.2010.07.034

de Bono, J.P., McDowell, G.R.: DEM of triaxial tests on crushable sand. Granul. Matter 16, 551–562 (2014). doi:10.1007/s10035-014-0500-x

Bauer, E.: Calibration of a comprehensive hypoplastic model for granular materials. Soils Found. 36(1), 13–26 (1996)

Itasca: PFC3D—Particle Flow Code in 3 Dimensions User’s Guide. 2003; Minneapolis, Minnesota, USA: Itasca Consulting Group Inc

Nakata, Y., Hyde, A.F.L., Hyodo, M., Murata, H.: A probabilistic approach to sand particle crushing in triaxial tests. Géotechnique 49(5), 567–583 (1999)

McDowell, G.R.: Statistics of soil particle strength. Géotechnique 51(10), 897–900 (2001)

Jaeger, J.C.: Failure of rocks under tensile conditions. Int. J. Rock Mech. Min. Sci. 4, 219–227 (1967)

Weibull, W.: A statistical distribution of wide applicability. J. Appl. Mech. 18, 293–297 (1951)

Duxbury, P.M., Kim, S.G., Leath, P.L.: Size effect and statistics of fracture in random materials. Mater. Sci. Eng. 176, 25–31 (1994)

Kendall, K.: The impossibility of comminuting small particles by compression. Nature 272, 710–711 (1978)

Uygar, E., Doven, A.G.: Monotonic and cyclic oedometer tests on sand at high stress levels. Granul. Matter 8, 19–26 (2006). doi:10.1007/s10035-005-0216-z

von Wolffersdorff, P.A.: A hypoplastic relation for granular materials with a predefined limit state surface. Mech. Cohesive-Frict. Mater. 1, 251–271 (1996)

Niemunis, A., Herle, I.: Hypoplastic model for cohesionless soils with elastic strain range. Mech. Cohesive-Frict. Mater. 2, 279–299 (1997)

Oquendo, W.F., Muñoz, J.D., Lizcano, A.: Oedometric test, Bauer’s law and the micro-macro connection for a dry sand. Comput. Phys. Commun. 180, 616–620 (2009). doi:10.1016/j.cpc.2009.01.002

Gudehus, G.: A comprehensive constitutive equation for granular materials. Soils Found. 36(1), 1–12 (1996)

Acknowledgments

This research was supported by the TÉT 09-1-2010-0018 AT-11/09 project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Laufer, I. Grain crushing and high-pressure oedometer tests simulated with the discrete element method. Granular Matter 17, 389–412 (2015). https://doi.org/10.1007/s10035-015-0559-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-015-0559-z